Download Note

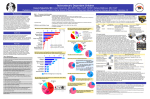

Transcript