Download SR785 Service Manual - Stanford Research Systems

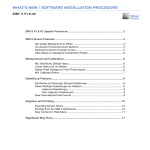

Transcript