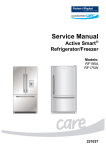

Download Service Manual

Transcript