Download Service Manual

Transcript

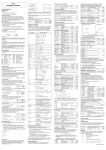

Service Manual pH communication functions SM12B06J03-04E-E 1st Edition 2 Contents Introduction3 1 Communication functions 1.1General 3 3 2Connection 2.1Connector pin allocation 3 3 3 Setting of communication condition 3.1Communication parameters 3 3 4 MODBUS communication protocol 4.1General 4.2Composition of message 4.3Address mapping 4.3.1 Memory contents 4.3.2 Read-out data 4.3.4. Description 4 4 4 4 4 4 4 5 Adress map and data format 5.1Data format 5.2Address map 5.3Supplement to address map 5.3.1 Impedance (IR11-13) 5.3.3 Model code (HR38-45) 5.3.4 Serial number (HR48-50) 5.3.5 Yokogawa Time Stamp (HR51-52) 5.3.6 FIR filter setting (HR56) 5.3.7 RUN register (HR58) 5.3.8 Sensor type for display (HR60) 5.3.9 TAG information reservation (HR1051-1100) 5 5 5 8 8 8 8 9 9 9 9 9 SM 12B06J03-04E-E 3 Introduction This manual describes the communication function of SENCOM pH sensors, in particular with regard to the sensors specific data and how to access this data. The sensor is protected in order to prevent erroneous writing of data resulting in a dysfunctional sensor. Please read this manual and reference documents carefully before using a Human Machine Interface to access data in the sensor. Reference documents IM 12B6J3-04E-EInstruction IM 12B6J8-01E-EInstruction IM 12B6J1-41E-EInstruction IM 12B6W2-03E-EInstruction Manual Manual Manual Manual FU20F pH/ORP SENCOM sensor FU24F pH/ORP SENCOM sensor SC25F pH SENCOM sensor WU11 Interconnection extension cable for SENCOM sensor Notices • This manual is meant for software developers and engineers who want to access the SENCOM sensors memory outside the normal scope of operation. • Yokogawa Process Analyzers Europe B.V. (hereinafter referred to as YPA Europe) does not warrant that the functions will suit a particular purpose of the user. • No part of this document may be reproduced in any form without YPA Europe’s written permission. • The contents of this manual are subject to change without prior notice. • If any question arises or errors are found, or if any information is missing in this manual, please inform the nearest Yokogawa sales office. 1 Communication functions 3 Setting of communication condition 1.1 General Bi-directional digital communication (RS 485) with limited MODBUS support. SENCOM sensor is regarded as slave, the Human Machine Interface (HMI) is regarded as master. Data storage/transfer is done via Input registers (read only) and Hold registers (read/write). Each register is 2 bytes. The communication parameters of the HMI have to be set correctly to work with the SENCOM sensors. In a multiple sensor loop, each connected sensor must have a unique MODBUS address (Slave ID). 2 Connection Table 2: Connection should be performed using the WU11 interconnection cable for SENCOM sensors. 2.1 Connector pin allocation The definition of connector pin to WU11 cable and signal description is given in Table 1. Table 1: Pin # 1 2 3 4 5 Signal description Wire color Data - Yellow Data + Green Supply + Brown Shield Black Supply Gnd White 3 5 Wire number 83 84 87 82 86 1 2 2 1 4 Figure 1: (front view) Sensor connector, male 3.1 Communication parameters The parameters to be set are shown in Table 2. Item Transmission speed *1 Data length Stop bit Parity setting Slave ID *2 Factory default Setting range 9600bps fixed 8 bits fixed 1 bit fixed Even fixed 1 1-247 Note: *1 Transmission speed: The transmission speed (baud rate) is configurable but part of protected settings to guarantee proper working with the FLXA21 analyzer. The default baud rate is set at 9600bps. *2 Slave ID: All sensors are set to Slave ID 1 by factory setting. This Slave address can only be changed by using the SENCOM MODBUS Slave Configuration Tool R2.02. 5 3 4 Figure 2: (front view) Cable connector, female SM 12B06J03-04E-E 4 4 MODBUS communication protocol 4.1 General In MODBUS protocol the communication is always started by the master station (e.g. HMI), where a slave station (e.g. SENCOM sensor) responds to the received message. 4.3 Address mapping Transmission procedures are: 1)The master station sends a command message to a slave station with specified address. 2)The slave station checks whether the address in the received message matches with the own Slave ID or not. 3)If matched, the slave station executes the command and sends back the response message. 4)If mismatched, the slave sensor ignores the request and waits for the next command message. 4.3.2 Read-out data The read-out data is the specific data belonging to a parameter (see Section 5.2) For some parameter, the data contains a factor*, value and unit. The master station can individually communicate with any one of the slave stations connected on the same line upon setting the Slave ID. in the command message. 4.2 Composition of message Command message and response message consists of 4 fields which are send in the following order: 1 Slave ID (1 byte) 2 Function code (1 byte) 3 Data (2 to 100 bytes) (limited to 50 addresses) 4 Error check code (CRC-16) (2 bytes) Slave ID (1 byte) Slave ID is the number specifying a slave station. The slave station that corresponds to “Slave ID” number will execute a command. Function code (1 byte) Function code tells the slave which table to access and whether to read from or write to the table. The following function codes can be used for SENCOM sensors: Table 3: Function 04 (04 hex) 03 (03 hex) 06 (06 hex) 16 (10 hex) Action Read Read Write single Write multiple Table Name Analoge Input Registers Analoge Output Holding Registers Analoge Output Holding Register Analoge Output Holding Registers Data Data contains a start address (register number), quantity of addresses and the specific content of the addresses. The register number transmitted on message is expressed as its relative address. The relative address is calculated by the following expression. For example, when the register number designated by a function code is 40003, relative address 0002 (=(lower 4 digits of 40003) - 1) is used on the message. First address is ‘0’ ~ 40001 Error check code This is the code to detect message errors (change in bit) in the signal transmission. With the MODBUS protocol (RTU mode), CRC-16 (Cyclic Redundancy Check) is applicable. SM 12B06J03-04E-E 4.3.1 Memory contents The memory contents describe the parameter. Note: * To maximize the information in the address, some information in the address is written with a factor x. The x followed by a number is the multiplying factor of the address content (e.g. x10; the content in this address needs to be divided by ten for corrected value). 4.3.3 Display The display data is defined using one of the following methods with the remark that for the Hexadecimal method and Binary method the most significant bit (msb or MSB, also called the high-order bit) is the bit position in a binary number having the greatest value. In a 2 address string the first (left) byte is defined as most significant resulting in the second byte as least significant. Singed/unsigned 16 bit signed numbers range from -32766 to +32767. 16 bit unsigned numbers range from 0 to +65535. Hexadecimal Long strings of ones and zeroes are difficult to read, so the bits are combined and shown in hexadecimal code. Each block of 4 bits is represented by one of the sixteen characters from 0 to F. 0000 0001 0010 0011 = = = = 0 1 2 3 0100 0101 0110 0111 = = = = 4 5 6 7 1000 1001 1010 1011 = = = = 8 9 A B 1100 1101 1110 1111 = = = = C D E F Each block of 8 bits (called a byte) is represented by one of the 256 character pairs from 00 to FF. Binary A binary code represents text using the binary number system’s two binary digits, 0 and 1. A binary code assigns a bit string to each symbol or instruction. For example, a binary string of eight binary digits (bits) can represent any of 256 possible values and can therefore correspond to a variety of different symbols, letters or instructions. Long To accommodate values that can reach beyond the 16-bit limitation. A 32-bit register represented in 32-bit Integer format is passed via communications as two 16-bit registers: High-Order Register =value/65536 Low-Order Register = value modulus 65536 (value = register high x 65536 + register low) 4.3.4. Description Description contains the explanation how the read-out data should be interpreted. In case the explanation covers calculations or more details, the description in written in a supplement of the address map (see Section 5.3). 5 5 Adress map and data format 5.1 Data format The MODBUS protocol used RTU (Remote Terminal Unit) mode which means that transmitted data is “numeric value” and not ASCII code”. 5.2 Address map Table 4a: Input registers 3xxxx Relative Register Memory contents addressnumber 0000 30001 pH1-ref voltage Read-out data Display Description ×20: -15000…+15000mV SignedmV value pH1-Ref; (limits -20000...+20000mV) 0001 30002 pH2-Ref voltage ×10: -15000…+15000mV SignedmV value pH2-Ref; (limits -20000...+20000mV) 0002 30003 Ref-LE voltage ×10: -15000…+15000mV SignedmV value Ref-LE; (limits -20000...+20000mV) 0003 30004 pH1-LE ×10: -15000…+15000mV SignedmV value pH1-LE; (limits -25000...+25000mV) 0004 30005 pH2-LE ×10: -15000…+15000mV SignedmV value pH2-LE; (limits -25000...+25000mV) 0005 30006Reserved Signed 0006 30007 pH value ×1000: -2000…+16000pH SignedpH value; (limits -32000…+32000pH) 0007 30008 Temperature used ×100: -3500…+15500°C Signed Temperature in °C; in calculations (limits -4000…+16000ºC) 0008 30009 ORP value ×10: -15000…+15000mV Signed (limits -20000…+20000mV) 0009 30010 rH value ×100: 0...10000 Signed (limits -1000…+11000) 0010 30011 Glass Impedance pH 1 x 1: 10...10000kOhm Signedvalue x or code -1, -2, -3, -4, -5, see 5.3.1 0011 30012 Glass Impedance pH 2 x 1: 10...10000kOhm Signedvalue x or code -1, -2, -3, -4, -5, see 5.3.1 0012 30013 Reference Impedance x 2: 5...2000kOhm Signedvalue x or code -1, -2, -3, -4, -5, see 5.3.1 0013 30014 Board status :AD error BinaryReflection of different status of sensor, error configuration etc. 0014 30015 Temperature measured ×100 : -3500…+15500°C Signed Temperature in °C; value Pt1000 (Limits -5000…+17490°C) 0015 30016 Checksum value -32768…+32768 Signed Calculated checksum value in case of calculated by Sensor checksum error of specific region Table 4b: Input registers 3xxxx Relative Register Memory contents Read-out data Display Description addressnumber 0100 30101 Total time of operation 0...3600 seconds UnsignedCounter in seconds of operating mode 1. since last connection netto Counter resets every 3600 sec’s for the purpose of hour counter (HR1019) 0101 30102 Temperature Electronics x1: -150…+150°C Signed Temperature value PCB; Only updated uncompensated in °C during impedance measurement 0102 30103 Temperature electronics x1: -150…+150°C Signed Temperature value PCB; IR 30102 compensated in °C compensated for TOFS (HR 40057) 0103 30104 Total time of operation 0…65536 seconds UnsignedCounter in seconds regardless of operating since last connection mode. Counter reset after 65536 sec’s 0104 30105 Major software version -32768…+32768 Unsignedsee 5.3.2 0105 30106 Minor software version -32768…+32768 Unsignedsee 5.3.2 SM 12B06J03-04E-E 6 Table 5a: Hold registers 4xxxx Relative Register Memory contents Read-out data Display Description addressnumber 0000 40001 Communication speed 1:4800, 2:19200, other:9600 UnsignedDefault 9600bps 0001 40002 Module ID PH: 0x04, SC: 0x08, Unsigned ISC: 0x0C, DO: 0x10 0002 40003 Indentification number PCB UnsignedUnique ID number PCB electronics 0003 40004 LE control level 0: disabled , UnsignedEnable LE control other value = enabled 0004 40005 Prod. ordernumber High 1-999 UnsignedProduction order number PCB 0005 40006 Prod. ordernumber Low 1-999 UnsignedProduction order number PCB 0006 40007 Prod. ordernumber 1-999 UnsignedSerial number of panel in the production serial number batch 0007 40008 Production panel position 1-20 UnsignedPosition number of the sensor in a panel 000840009 : : Reserved 002740028 0028 40029 Design impedance value @25°C (imp) 0-50000 MOhm Unsigned 0029 40030 Delay factos (vf) 1-1000 (0=1) Unsigned 0030 40031 Impedance config input 1 0: low 1: high Unsigned 0031 40032 Impedance config input 2 0: low 1: high Unsigned 0032 40033 Impedance config input 3 0: low 1: high Unsigned 0033 40034 Impedance settling time Seconds UnsignedStable time parameter for impedance measurement 0034 40035 Set impedance interval Seconds Unsigned 0035 40036 Sensor connection types 1, 2, 3, 4, 5, 6, 7, 8, 9 UnsignedHardware configuration setting of analogue sensor to PCB. 0036 40037 Modbuss address number 1...247 UnsignedAll other address 1 0037 40038 : : Model code See 5.3.3 Hex 16 bytes (alpha numeric) 8 address string 0046 40047 0045 40046 Unit rev. x100 (two decimals) UnsignedTest software ATE factory 0046 40047 Assy rev. x100 (two decimals) UnsignedHardware revision PCB 004740048 : : Serial No. See 5.3.4 Hex 6 bytes, 3 address string 2 bytes 0049 40050 for production location 005040051 : : Date YOKOGAWA See 5.3.5 UnsignedProduction date in seconds from: 0051 40052 TIME STAMP 2000-01-01-00:00:00 0052 40053 Available sensor type bit Bit 0:PH, bit 1:ORP, bit 2 Binary The bit of this parameter is set by specific PH+ORP, other bit are 0. sensor type. This parameter is used by FLXA and PC. 0: possible , 1:impossible “PH8”: PH only, bit 1 and 2 are set to 1 “OR8”: ORP only, bit 0 and 2 are set to 1 “FU20”, “FU24”, “SC25”: all bits set to 0 0053 40054 Reserved Reserved, prepared for FD YHQ 0054 40055 Temp. element 148 Signed Type code of temperature element for display setting FLXA/PC 0055 40056 FIR settings for input reg 8 See 5.3.6 Signed Filter setting for Temperature value (temp for measurements) of IR 30008 0056 40057 TOFS PCB temperature x1: -150…+150°C Signed Offset used for temp PCB measurement in degree Celsius 0057 40058 Run Measurement & data update 0 : stop, 1 : run 2: run UnsignedMeasurement & data update. See: 5.3.7 0058 40059 JCSS(Japan Calibration 0 : Normal Service System) mode 1 : Japanese Unsigned 158 : PH Sensor type; setting for calculation used for 0059 40060 Sensor type (of display) 159 : ORP UnsignedpH, ORP and RH. Also function for display 160 : PH+ORP Setting FLXA/PC See: 5.3.8 0060 40061 TOFS ×100: -10...+10°C Signed (Limits: -1000...+1000ºC) 0061 40062 Temperature measuring 0: manual, 1: automatic Unsigned manual or automatic (using sensor value) 0062 40063 Set manual temp value ×100 : -3500..+15500°C Signed 0063 40064 ITP × 1000: 0..14000 pH Signed 0064 40065 PHZERO1 x 10 : -5000…+5000mV Signed SM 12B06J03-04E-E 7 Table 5a: Hold registers 4xxxx (contineud) 0065 40066 PHSLOPE1 x 100 : 7000…11000% Signed 0066 40067 pH 3 points CAL flag 0 : none, 1: ITP, 2 : 3point Unsigned 0067 40068 pH 3 points CAL direction Signed 0068 40069 pH 3 points CAL cross ×100 mV Signed points mV 0069 40070Reserved 0070 40071 pH 3 points CAL PHZERO2x 10: -5000…+5000mV Signed 0071 40072Reserved 0072 40073 pH 3 points CAL SLOPE2 x 100: 7000...11000% Signed 0073 40074Reserved 0074 40075Reserved 0075 40076 ORP slope x 100: 7000…11000% Signed 0076 40077Reserved 0077 40078 ORP zero most significant x 100: -50000…+50000mV Long 0078 40079 ORP zero least significant 0079 40080 Auto correct mode 0:Disable, 1:Enable Signed 0080 40081 Auto correct zero x 10: -5000…+5000mV Signed 0081 40082 Auto correct slope x 100: 7000…11000% Signed 0082 40083 pH calibration date 1st byte = Year, 2nd byte = Month Hex 0083 40084 1st byte = Day, 2nd byte = Hours Hex 0084 40085 1st byte = Minutes, 2nd byte = Seconds Hex 0085 40086 ORP calibration date 1st byte = Year, 2nd byte = Month Hex 0086 40087 1st byte = Day, 2nd byte = Hours Hex 0087 40088 1st byte = Minutes, 2nd byte = Seconds Hex 008840089 : : Reserved for calibration 0089 40090 data 0090 40091 Not used. These area are not included in : : Reserved CRC target or back-up mechanism. 0099 40100 If these area are used, these parameter will not be saved to back up area. Table 5b: Hold registers 4xxxx Relative Register Memory contents Read-out data Display Description addressnumber 1000 41001 Set temperature high ×100 : -3500…+15500mV Signed Used for internal loggings 1001 41002 Set pH low ×1000 : -2000…+16000mV Signed Used for internal loggings 1002 41003 Set pH high ×1000 : -2000…+16000mV Signed Used for internal loggings 1003 41004 Set logging interval hours UnsignedUsed for internal loggings 1004 41005 Yokogawa time stamp Seconds from 2000-01-01-00:00:00 UnsignedActual time updated by FLEXA 1005 41006 Yokogawa time stamp Unsigned 1006 41007 Yokogawa time stamp Use first logging time (after 3600 seconds up to 24 hr) UnsignedTime of first customer use. 1007 41008 Yokogawa time stamp Seconds from 2000-01-01-00:00:00Unsigned 1008 41009Reserved 1009 41010Reserved 1010 41011 Maximum temperature ×100: -2000…+15000°C Signed Value is updated if maximum is valid for exposed more than 1 minute 1011 41012 Minimum temperature ×100: -2000…+15000°C Signed Value is updated if minimum is valid for exposed more than 1 minut 1012 41013 HRS pH low 0…65536 Signed Total hrs of pH below set point 1013 41014 # pH low 0…65536 UnsignedNumber of time that pH value is lower than set point for at least 1 minute Value need to be reached for more >1 min. 1014 41015 HRS pH high 0…65536 Signed Total hrs of pH above set point 1015 41016 # pH high 0…65536 UnsignedNumber of time that pH value is higher than set point for at least 1 minute Value need to be reached for more >1 min. 1016 41017 Lowest pH reached ×1000 : -2000…+16000mV Signed Value need to be reached for more >5 min. SM 12B06J03-04E-E 8 Table 5b: Hold registers 4xxxx (contineud) Relative Register Memory contents Read-out data Display Description addressnumber 1017 41018 Highest pH reached ×1000 : -2000…+16000mV Signed Value is updated is maximum is valid for more than 5 minutes 1018 41019 Total time of operations 0…65536 UnsignedDays 1019 41020 Total time of operations 0…65536 UnsignedHours 1020 41021 HRS temp high 0…65536 UnsignedTotal hrs of temp above set point 1021 41022 # Temp high 0…65536 Signed Number of time that temp is higher than set point for at least 1 minute Value need to be reached for more >1 min. Table 5c: Hold registers 4xxxx Relative Register Memory contents addressnumber 1050 41051 Reserved for tool : : 1099 41100 TAG information Read-out data Display Description t.b.d. t.b.d. See 5.3.9 5.3 Supplement to address map 5.3.1 Impedance (IR30011-30013) The impedance value measured by the sensor is measured automatically or on request (see Section 5.3.7) and the result in written in IR30011 to IR30013. Dependent on the sensor type, the impedance value is valid or not valid. A non-valid impedance value is identified with an error code, see Table 6 and Table 7. 5.3.2 Software revision (IR30105-30106) Input registers IR105-106 contains the software revision. The software revision is divided in a major revision number which is stored in IR105 and a minor revision number which is stored in IR106. Combined the addresses show the complete revision number as XX.XX The glass impedance is measured on pH1 and/or pH2 input. The reference is measured on pHref input. The electronics of these inputs are optimized for the high ohmic pH glass electrode or the low ohmic reference electrode. The inputs are pre-defined in Hold registers 40031, 40032 and 40033. If a pH glass electrode is used as measurement element, the impedance is High and the setting of the Hold register is 1. In case of a reference electrode, the impedance is Low and the setting of the Hold register is 0. The Hold register settings 40031-40033 are corresponding with 30011-30013. 5.3.3 Model code (HR40038-40047) Hold registers HR38 – 47 contain the modelcode. The format of the modelcode is a string of maximum 16 ASCII codes, each ASCII code is 1 byte. Each Hold register address has two (2) bytes which means that two (2) ASCII codes can be stored. The hexadecimal representations of both ASCII codes are added and converted to a decimal number that is stored in the Hold register address. Table 6: Glass impedance 10…10000 kOhm = value for Glass impedance < 100 kOhm = Glass breakage > 100 kOhm = a correct glass impedance 0= no measurement value available -1= almost 0, maybe shorted or glass breakage -2= < 10 kOhm, glass breakage -3= above lineair range. > 10 MOhm -4= above lineair range. > 200 MOhm -5= No good calculation. Airbubble/dry measurement etc. Table 7: Reference impedance 5…2000 kOhm = value for Reference impedance 0= no measurement value available. -1= almost 0, maybe shorted, function of reference good -2= low, below linear range, function of reference good -3= above linear range. Out of spec. -4= too high, probably open/dry. Out of spec. -5= No good calculation. Airbubble/ dry measurement etc. SM 12B06J03-04E-E Example: Modelcode FU20F-NPT: F= 70 (ASCII code) U= 85 (ASCII code) = 46 = 55 (hex) (hex) Added: Converted: = 4655 (hex) = 18005 (dec) The result is stored in Hold register HR40038 2 = 50 (ASCII code) = 32 (hex) 0 = 48 (ASCII code) = 30 (hex) Added: Converted: = 3230 (hex) = 12848 (dec) The result is stored in Hold register HR40039 Etc. 5.3.4 Serial number (HR40048-40050) Hold registers HR48 - 50 contain the Serialnumber. The format of the Serial number is a string of four (4) ASCII codes representing characters (N3YM) and five (5) ASCII codes representing a decimal number (xxxxx). The translation method of the ASCII codes representing the characters is the same as for the Modelcode (see Section 5.3.3). The results are stored in HR48 and HR49. The ASCII codes representing the numbers is stored as unsigned integer in HR50. 9 5.3.5 Yokogawa Time Stamp (HR40051-40052) The Yokogawa Time Stamp is the number of seconds elapsed since 01/01/2000 00:00:00. This unsigned integer is stored in 2 Hold register addresses (4 bytes). The seconds are converted to hexadecimal format. The first 4 ‘digits’ are stored in HR40051 as (hexa)decimal, the second 4 ‘digits’ are stored in HR40052 as (hexa)decimal. Example: Date: 25/11/2014 10:23:52 => Yokogawa Time Stamp = 470226232 seconds Converted: => 1C071538 (hex) The result 1C07 (hex) or 7175 (dec) is stored in Hold register HR40051, the result 1538 (hex) or 5432 (dec) is stored in Hold register HR40052. 5.3.6 FIR filter setting (HR40056) The FIR register is a filter on the last three measurements. Each measurement can be set with an individual weight factor, but the total factor has to be lower than 256. In general the weight factor of the last measurement and the second last measurement are set, and the weight factor of the first measurement is calculated (all three weight factors added will give 255). In the FIR register we can describe the last and the second last weight factor of measurement using one address. This address is 16 bits where the least significant 8 bits are describing the weight factor of the last measurement and most significant 8 bits are describing the weight factor of the second last measurement. Example: first 2nd last last Moving average: 111 Total number Weight factor: 858585 255 |||| Hexadecimal notation: 55 55 5555 Decimal notation: 85 85 21845 5.3.7 RUN register (HR40058) The sensor has different operating modes, all regulated by the Run register. Run register value: 0 = no measurements 1 = pH-, temperature-, ORP-, impedance measurements on set interval time (defined in HR40035) 2 = same as run1 but starts routine with impedance measurement. By factory default the sensor is set to run mode 1 (hold register 40058). This means that when the sensor is powered, the pH measurement will start immediately and the impedance measurement will be performed after 120 seconds as set in the interval register (default value). So for the first two minutes the input registers corresponding the impedance values are 0 (see Section 5.3.1) If an impedance measurement is preferred directly from start on, the sensors run register (40058) should be set to value 2. Be aware that a change of the run register to 1 or 2 should always be proceded by a run=0 setting with an interval of 500ms in between each setting or a power off/on sensor. 5.3.8 Sensor type for display (HR40060) The setting of the sensor type for display defines the calculation methot for ORP. Setting 158: Only pH is calculated and values for ORP and rH are fixed to 0 in the input registers. Setting 159: The ORP is calculated using pH as reference glass which gives a pH compensated ORP value stored in input register 30009. Setting 160: pH, normal ORP and rH are calculated. 5.3.9 TAG information reservation (HR41051-41100) These addresses are reserved for third parties to enter TAG information. The content of these registers are not part of any CRC check or back-up mechanism. SM 12B06J03-04E-E 10 SM 12B06J03-04E-E 11 SM 12B06J03-04E-E YOKOGAWA HEADQUARTERS 9-32, Nakacho 2-chome, Musashinoshi Tokyo 180 Japan Tel. (81)-422-52-5535 Fax (81)-422-55-1202 www.yokogawa.com YOKOGAWA CORPORATION OF AMERICA 2 Dart Road Newnan GA 30265 United States Tel. (1)-770-253-7000 Fax (1)-770-251-2088 www.yokogawa.com/us YOKOGAWA EUROPE B.V. Euroweg 2 3825 HD AMERSFOORT The Netherlands Tel. +31-88-4641 000 Fax +31-88-4641 111 www.yokogawa.com/eu YOKOGAWA ELECTRIC ASIA Pte. Ltd. 5 Bedok South Road Singapore 469270 Singapore Tel. (65)-241-9933 Fax (65)-241-2606 www.yokogawa.com/sg SM12B06J03-04E-E Subject to change without notice- Copyright© Yokogawa has an extensive sales and distribution network. Please refer to the European website (www.yokogawa.com/eu) to contact your nearest representative. Printed in The Netherlands, 01-1503 (G) I