Download Parts book for Singer 211W151 - Superior Sewing Machine and

Transcript

litiin

3173W

())1)

SERVICE MANUAL

FOR

SINGER*

211W151

machine

SINGLE NEEDLE

LOCK STITCH

/

2_—

This book contains complete information covering operation

and adjustment of machine and a list of parts, accessories and

special fittings. Illustrations and descriptions of parts in rear

of book should be consulted when ordering any part of machine

requiring renewal.

THE SINGER MANUFACTURING COMPANY

© 1962 try The Singer Monrrfonturrng Con,pony

Copyright Under Irrternotionr,I Copyright Union

All RrhU Rr ,rrvrd r,rrdrr I,rtrr-Anreriron Copyright Unjon

copyright

°A Trodenrgrk of THE SINGER MANUFACTURING COMPANY

Printed in U.

S. A.

2

DESCRIPT iON

Macbin v 21 1 W 151 produces high speed,

precision stitching on coats, suits, over—

ails, rainwear, sports oute rwear, work

do the s and si m liar itt’ m s of medium to

heavy weight fabrics.

Single needle, lock stitch. l’tdtral

Stitch Type 301.

Beit driven rotary sewing hook on ver

tical axis makes two revolutions for each

stitch.

Safety clutch, adjustable to suit sewing

conditions, prote cts hook from damage

resulting from accidental strain. Should

any foreign matter clog the hook, this

new type safety clutch will disengage it

self and will re-engage only after area

has been cleared.

Compound feed, combination of drop

feed and needle feed.

Maximum length of stitch, 5 to inch.

Presser bar lift, 1/4 inch.

Hinged presser foot.

Needle bar stroke, 1-5/16 inches.

Needle thread lubricated by felt pad

automatically supplied with oil from res

ervoir in face plate.

Bed, 20-3/8 inches long, 7 inches wide.

Space at right of needle, 10-1/2 inches.

hole in drip pan and attach oil jar D,

as shown.

Fig. 2. Knee Lifter, Drip Pan ond Oil Jar In Position

HOOK LUBRICATION

Hook saddle contains oil pumped to

bobbin case raceway in hook during op

eration. To control amount of oil flow,

tip machine back and loosen control valve

set screw A, Fig. 3.

SPEED

Maximum speed, 4000 R. P. M., depend

ing on material being stitched. It is ad

visable to run a new machine slower than

maximum speed for first few minutes to

allow time for oil to reach moving parts.

Machine pulley turns over toward operator.

SETTING

UP

Fasten drip pan to table with its left end

evenwith left end of cut-out. Fasten knee

lifter bracket in location shown in Fig. 2.

Assemble it so that lifter rod A does not

strike drip pan. Screw slots in bracket

provide necessary adjustment. Set stop

stud B to stop action of knee lifter as soon

as presser foot is raised enough to trip

hand lever. Screw drain pipe C into drain

Fig. 3. Sewing Hook Oil

Control Valve Set Screw

Fig. 4. Sewing Hook

Oil Control Valve Screw

Return machine to upright position.

Turn control valve K to right for more oil;

to left for less oil.

After desired adjust

ment is attained, re-tighten control valve

set screw A. See complete lubricating

instructions next.

3

LU KRICATJON

CLEANING

Use SI NGER OIL, ‘‘I’YI-i A’’ or

‘‘TYPI C’’. Use ‘‘TYPE C’’ OIL when

an oi[ is desired which will produce

minimum stain on fabrics even after

long period of storage.

CLean out all lint and other waste from

around sewing hook and between feed

rows on underside of throat plate.

FILl. THREAD LUBRICATOR

RESERVOIR WITH

HIGH MARK

FILL RESERVOIR

SI NGER*

THREAD LUBRICANT

“TYPE E”

ON

WHEN MACHINE

IS RUNNING—

—

(CHECK TWICE DAILY)

T L_-

OFF

WHEN MACHINE

IS IDLE

FOR

MORE

THREAD

LUBRICANT

-

Fig. 6. Reservoir in Arm

LUBRICATING PAD

Fig. 5. LubricatIng Nachine Head

FILL RESERVOIR

TO HIGH MARK

CHECK TWICE DAILY

/

HIGH MARK

C-.’

SATURATE WICK

OIL TWICE DAILY

Fig. 7. Reservoir in Bed

NEEDLES

Use SINGER* Needles

Catalog 1901 (135x7)

when machine is set with 1/4” clear

ance under presser foot

or

Catalog 3355 (135x17)

when machine is set with 3/8” clear

ance under presser foot

Needle sizes determined by size of

thread and type of material being sewn.

MOVE TO

HIGHEST POINT

LONG

TO

LEFT

LOOSEN SCREW

INSERT NEEDLE UP

AS FAR AS POSSIBLE

AND TIGHTEN SCREW

jg. 8. Setting the Needle

4

THREADING

NEEDLE

Fig. 10. Threading Tension Assembly

OIL PAD

Fig. 9. Upper Threading Complete

Fig.

BOBBIN

REMOVAL

RAISE LATCH

BOBBIN

7

Fig.

12.

11. Threading Needle

5

TI-IF BOBBIN

WINDING

TENSION CONTROL

1. PLACE BOBBIN ON

SPINDLE AS FAR

AS IT WILL GO

OIL

LOOSEN TO

ADJUST FOR

EVEN WINDING

3. PRESS DOWN

TO PUSH PULLE

AGAINST BELT,

2. WIND THREAD

AROUND BOBBIN

N0TETIGHTEN FOR MORE THREAD ON BOBBIN:

Regulate to stop winder when bobbin is wound

1/16 inch short of bobbin rim

THEN START

MACHINE

Fig.

BOBBIN

13.

REPLACEMENT

PLACE BOBBIN ON CENTER STUD

2

CLOSE LATCH

I,

DIRECTION OF THREAD

AROUND BOBBIN

Fig.

THREADING

14.

BOBBIN CASE

DRAW THREAD TO

BACK OF PROJECTION

DRAW THREAD UP

TWO INCHES

Fig. 15.

Fig.

16.

6

THREAD

TENSIONS

Turn machine pulley until tension

screw is accessible.

Regulate needle thread tension only

when presser foot is down.

MORE

TENSION

MORE TENSION

LESS TENSION

<-..

Fig. 17. Hobbin Thread Tension

Tension on threads should be as light

as possible while still sufficient to set

Fig. 18.

stitch in material.

STITCH LENGTH REGULATION

1. Stop machine 2. Depress button shown in Fig. 19

3. Turn machine pulley toward you

slowly— until button drops (clicks).

4. Turn machine pulley until desired

stitch length is opposite mark on

arm (see Fig. 20 ).

5. Release button.

Needle Thread Tension

Fig. 20. Stitch Length

Indicator

Never depress the button while the

machine is running.

Make certain that plunger is disengaged

before starting machine.

BUTTON

Fig. 19. Stitch Length Button Regulator

PRESSER FOOT

PRESSURE

TURN TO

ADJUST

The pressure on the material should be

as light as possible, while still suffi

cient to insure correct feeding.

Fig. 21. Adjusting Pressure

7

THREAD

CONTROLLER

The function of the thread controller

spring is to hold back the slack of the

needle thread until point of needle reach

es the goods in its descent, as without

this controlling action of the spring, the

slack thread (especially silk) will some

times be penetrated by point of needle as

needle is descending.

TO SET A NEEDLE BAR WHICH HAS NO

MARK

Regulate the stitch length as instructed

on page 6, so that there is no feeding mo

tion, then set needle bar so that when it

rises 3/32 inch from its lowest position

and point of sewing hook is at center of

needle, eye of needle will be about 1/16

inch below point of hook.

RELATIVE POSITIONS OF NEEDLE BAR

AND PRESSER BAR

The distance between the needle bar and

presser bar (after regulating stitch length

so that there is no feed movement) should

be 17/32 inch as shown below.

Fig. 22. Adjustment of Thread Controller

To change the thread controller stop

for more controller action on the thread,

loosen set screw Z, and turn thread con

troller spring stop T, Fig. 22 to the

right; for less action, turn thread con

troller spring stop T to the left, after

which securely tighten set screw Z.

It may be found advisable to increase

tension of spring for coarse thread, or

to lessen it for fine thread.

To increase tension of thread controller

on thread, loosen tension stud set screw

Y, located nearly under tension stud, and

turn tension stud AZ slightly to the left.

To decrease tension turn it to the right.

Re-tighten stud set screw Y.

TO SET NEEDLE BAR

See that needle is up in the holder as

far as it will go. There are two lines

across the needle bar about two inches

above the lower end. When needle bar

is at its lowest position, the upper mark

should be just visible at end of needle

bar frame.

In case needle bar is not correctly set,

loosen needle bar connecting stud pinch

screw M, Fig. 23 and place needle bar

in correct position as directed above,

then re-tighten screw M.

Fig. 23. Relative Positions of Needle

Bar and Presser Bar

If the distance between needle bar and

presser bar is more or less than 17/32

inch, loosen needle bar frame shaft clamp

screw NZ, Fig. 24. While this screw is

loose, needle bar frame can be moved for

ward or backward, as may be required,

N2

Fig. 24. To Adjust Needle Rook Frame

S

until the distance between the needle bar

and presser bar is 17/32 inch. A piece

ol. sheet metal 17/32 inch wide may be

llse(1 to det. rnine the correct distance.

When the adj ustinent has been made,

securely tighten screw NZ.

TO ADJUST HEIGHT OF

SEWING HOOK

When lower timing mark A, Fig. 26 on

needle bar is just visible at end of needle

bar frame on upward stroke of needle bar,

the hook point should be about 1/16 inch

above eye of neecUc, as shown in Fig. 26.

To adjust height of hook, fasten throat

plate to bed of machine with bobbin case

stop finger K, Fig. 26, in sewing position.

Use 032 inch shim. Shim should slide

between bobbin case stop finger K and

throat plate. If the shim is too loose,

turn machine pulley so that socket screws

hook so that a hole in bobbin case is in

line with hook height adjusting screw J2,

Fig. 25. To raise hook, turn down screw

J2. if there is insufficient space for the

shim to pass between bobbin case stop

finger K and throat plate, turn up screw JZ

and press down hook. Check timing and

tighten socket screws HZ, then turn screw

JZ just enough to leave a light tension.

TO SET SEWING HOOK TO

OR FROM NEEDLE

N

.

J2

Fig. 27. Adjustments Underneath the Nachine

Fig. 25. Height Adjustment of Sawing Hook

HZ, Fig. 25 are accessible with a socket

wrench. Loosen both screws and remove

cloth washer from bobbin case, then turn

To prevent point of hook from dividing

strands of thread, it should pass as close

as possible to the needle (within the clear

ance above needle eye).

Turn machine pulley over toward you

until point of sewing hook is at center of

needle. Loosen screws N and T, Fig. 27,

underneath bed of machine and move hook

saddle to the right or left, as may be re

quired, until point of hook is as close to

needle as possible without striking it, then

securely tighten screws N and T.

CAUTION: Make sure hook driving gears

U, are set correctly with relation to face

of hook saddle. Use 008 shim.

The function of hook washer (needle

guard) GZ, Fig. 25, which is attached to

bottom of sewing hook, is to prevent point

of hook from striking needle if, when pass

ing through material, needle is deflected

toward hook.

The needle guard can be bent with a small

pair of pliers until it prevents hook point

from striking needle, but it should not be

bent outward enough to deflect needle from

its normal path.

.

Fig. 26. Height Adjustment of Sewing Hook

9

‘10 l’IM1 SEW[NG HOOK

on

Regulate tin stitch length, as instructed

JiLg 6,

so that there i s no feeding mo

TO REMOVE BOBBIN CASE

FROM SEWING I-lOOK

(see Fig. Z9)

—

tiun

Remove throat plate and turn machi tie

pulley over toward you until lower mark

across needle bar is just visible at end

of needle bar frame on upward stroke of

needle bar, as shown in Fig. 26. If

needle bar and sewing hook are correctly

timed, the point of hook will be at center

of needle (about 1/16 inch above the eye)

as shown in Fig. 26.

Remove the two hook gib screws W,

from sewing hook, lift oil hook gib F2,

and remove bobbin case X.

x

Fi(;. 29. To Remove Bobbin Case from

Sewin; Hook

TO REMOVE SEWING HOOK

FROM MACHINE

Remove presser foot, throat plate and

feed dog, then loosen two socket screws

in hub of hook HZ, Fig. 30 and lift hook

off end of shaft. To remove hook shaft,

first remove screws in ball bearing re

J2

Fj. 28. Timin Sew1n Hook

In case sewing hook is not correctly

timed, turn machine pulley over toward

you until needle bar has descended to

its lowest point and has risen to the po

sition

where

lower timing mark

across needle bar is just visible at end

of needle bar frame, as shown at A,

Fig. 26. Loosen two socket screws in

hub of hook shaft gear L2, Fig. 28 and

turn hook until point of hook is at center

of needle. Then securely tighten two

socket screws in hook shaft gear L2.

Fig. 30. To Remove Sewinc hook from Machine

taming cap directly under hook. Next,

tip machine back and loosen set screws

L2, Fig. 28 in hook shaft gear and lift

hook shaft by top end. If shaft does not

lift out easily, loosen screws in cover

plate of hook saddle sufficiently to per

mit oil to drain out, then remove cover,

being careful not to damage the gasket

MZ, Fig. 32, page 10, then tap end of

hook shaft.

10

CAUTION: The hook is equipped with a

screw in the hub for adjusting the vertical

position of the hook relative to the throat

plate seat. This position is set to a gauge

at the factory. When replacing or install

ing a new hook, care must be taken to see

that the bobbin case stop finger K, Fig. 31

fits correctly in the throat plate. If it is

too high, it will interfere with the free

passage of thread. If it is too low, it may

slip out and cause damage to hook and

bobbin case when machine is in operation.

To make the adjustment, remove cloth

washer in bottom of bobbin case, loosen

socket screws HZ, Fig. 30, page 9 in hook

hub, then turn hook until adjusting screw

appears beneath one of the holes in the

bottom of bobbin case. Hold hook down

against its seat and turn adjusting screw

with screwdriver until the proper up and

down position is attained. Tighten socket

screws HZ, Fig. 30 in hub of hook.

To remove ball bearing from hook shaft,

rest bearing with shaft-end up on two pieces

of sheet metal placed across the open jaws

of a vise. Tap shaft until bearing is re

moved.

Y

E2

D2

C2

Fig. 31. Adjusting Bobbin Case Opener

TO ADJUST BOBBIN CASE OPENER

(see Fig. 31)

The bobbin case opener Y should be

set so that it touches the bobbin case as

lightly as possible, yet turns the bobbin

case enough to make a sufficient open

ing for the free passage of the thread be

tween throat plate and bobbin case.

TO TIME BOBBIN CASE OPENER

(see Figs. 31 and 3Z)

Turn machine pulley over toward you

until lower timing mark on needle bar is

even with end of needle bar frame on up

ward stroke of needle. In this position,

the mark DZ, on flange of opener driving

shaft, should line up with reference mark

CZ on hook saddle. If opener shaft is out

of time, tip machine back and loosen

Fig. 32. Timing Bobbin Case Opener

socket screws KZ in opener driving gear

then return machine to upright position

and turn shaft with screwdriver in screw EZ

at top end of shaft, then tighten socket

screws KZ in gear.

11

TO RAISR OR LOWVR THE FEED DOG

(see Fig. 33)

THE FEED ECCENTRIC

(see Fig. 34)

Usually when feed dog is at its highest

position, it should show a full tooth above

throat plate.

To adjust, remove throat plate; clean

the lint and dust from between feed points

and replace throat plate; tip machine back

and turn machine pulley toward you until

feed dog is at its highest position; loosen

screw V in feed lifting cam fork and raise

or lower feed dog, as may be required.

Then re-tighten screw V.

Feed eccentric is provided with a gib P2

which can be adjusted to take up any wear

or loose motion between feed eccentric and

eccentric body. To adjust gib, loosen two

locking screws 02 nearest gib and turn in

the two adjusting screws 02 against gib

until all play is eliminated and eccentric fits

snugly in slot in eccentric body. Securely

tighten two locking screws QZ.

B3

Fig. 33. Feed Adjustments

When raising or lowering feed dog, be

careful that its underside does not drop

low enough to strike sewing hook.

Feed dog should be set so that when

needle is down it will be slightly in front

of center of needle hole in feed dog. In

case needle is not correctly located in

needle hole, loosen pinch screws B3

and adjust feed dog as required. Then

securely tighten pinch screws B3 and

check relative position of the needle

bar and presser bar as instructed on

page 7.

Fig. 34. Feed Eccentric

Spring R2 presses against feed eccen

tric cam to prevent it from moving out

of position while machine is operating.

Collar S2 may be moved to right or left

to change spring pressure. It should

ordinarily be set flush with end of hub

of eccentric body.

12

TO RLMOV1 NEEDLE BAR ROCK FRAME

Open the fact plate. Remove take— up

hinge stud L, Fig. 23, page 7, and Lake—tip.

Remove cover plate on front upright por

tion oi arm and loosen needle bar rock

frame rock shaft connection pinch screw

N2, Fig. 35. Pull needle bar rock frame

with its shaft from machine.

TO REPLACE ARM SHAFT

CONNECTION BELT

(see Fig. 37)

Remove needle to avoid damage while ma

chine is out of time. Slide belt off lower

pulley XZ. Loosen two screws in machine

pulley and remove machine pulley and ball

bearing which comes out with the pulley.

Lift belt up and draw it around arm shaft

through space at M2, Fig. 36, normally

occupied by ball bearing.

\

Fig. 33. To Remove Needle Bar Rock Frame

Fig. 37. To Replace Arm Shaft Connection Belt

TO REMOVE TAKE-UP LEVER

Remove arm cover on top of

Loosen set screw U2, Fig. 36,

move take-up lever hinge stud

page 7. Lift take-up lever out

slot VZ in top of arm.

V2 U2

Fig. 36. To Remove Take-up Lever

machine.

and re

L, Fig. 23,

through

T2

Replace belt through ball bearing hole at

MZ, Fig. 36, After placing belt over upper

pulley TZ, Fig. 36 replace machine pulley

with ball bearing. To remove all end play

from shaft, lightly tighten set screws in ma

chine pulley and (holding needle bar crank

in place) tap machine pulley into position

with palm of hand. Tighten machine pulley

set screws firmly.

Turn machine pulley over toward you un

til thread take-up lever is at its highest

point. Then turn hook driving shaft until the

“B’ setting mark at Z2 on safety clutch in

pulley X2 is in line with mark Y2 cut into ma

chine bed. Now, without disturbing either

arm shaft or hook driving shaft, slip belt

over lower pulley. The feed will then be

correctly timed with needle.

NOTE: Safety clutch in lower belt pulley

XZ has been set at factory for correct torque

and must not be disturbed.

13

PARTS LIST

FOR

SINGER

211w151

MACHINE

Parts marked with a diamond (+) are furnished only when repairs are

made at the factory; these (+) parts are named at bottom of descriptive

list opposite illustration.

14

ARM SI-LAF’T, NEEDLE BAR AND TAKE-UP ASSEMBLY

R I.

No.

1

2

3

1

5

6

7

8

9

10

11

12

13

1 L1

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

31*

35

36

37

38

39

Part

No.

Zi01 39

267239

235706

200383 C

Description

Likc”-iip Lever

hinge Stud with 235706

Oil Packing (wick)

Hinge Stud Set Screw

202552

Connecting Link

Driving Stud with 2i071

202399

LO7 1

1

2L

Oil Packing (wick)

26i7 1

Connecting Stud with 200072C and 202330

Pinch Screw

20007 ZC

202330

Oil Packing (wick)

267160

Oil Pad (felt) (upper)

267236

Oil Reservoir Oil Wick

267247

Arm Shaft +267158 with 200333C, 200347AL, 200378C,

200388C, 267221 and +267Z22

267221

Connecting Link Stud with 267466

267466

Oil Packing (wick)

20037AL Set Screw

200388C

Set Screw

200333C

Position Screw

200378C

Position Screw Check Screw

267221

Friction Washer

L7L+7

1

2L

Arm ShMt Bushing

2 0i 329

Oil Pad (felt) (lower)

2003LlC

Set Screw

267162

Belt Pulley with 200363AL, 350492C and two 202253

202253

Spring Flange

350’+92C

Position Screw

200363AL

Set Screw

267161

Connection Belt (reinforced neoprene)

2L722

Machine Pulley 2L72l with 27211*2

2L721

Machine Pulley (aluminum alloy ca;ting) for “V” belt

(outside diam. of belt groove 2.9 in.) (rim diam.

+

1

in.) (inside belt groove) with l1*1566C and l’il567C

l1*1566C

Position Screw

l1*l567C

Set Screw

27211*2

Bearing (back) (double shielded bearing)

21*0020

Needle Bar with ZOO125ALX, 200l75D and 21*0039

ZOO1Z5ALX Set Screw

200l75D

Needle Bar Thread Guide Screw

21*0039

Needle Bar Thread Guide

21*1*726

Take-up Lever Guard

20l31*lC

+267158

+267222

Guard Screw (3)

Arm Shaft

Needle Bar Crank

15

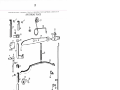

ARM SHAFT, NEEDLE BAR AND TAKEU ASSEMBLY

4

1

r

6

38

n

7

12

16

14

}13

29

31

26

30

33

24

21

27

34

—

— —

35%

37—

36

ll

16

LUBRICATION DEVICE, BED SLIDES, COVERS AND MISCELLANEOUS PARTS

Ref.

No.

I

2

Part

No.

3

15

16

17

18

19

20

21

22

271017

Z0l525E

267272

267395

i705

1

2i

20007D

268197

267220

201313F

267388

0003

1

2L

2OOO

223811

223812

2OLZ35

20O90&E

202005

267152

350563E

26700

23

267396

25

26

27

28

237D

267397

200l33E

267398

267399

1_I

5

6

7

8

9

10

11

12

1 3

2lr751

Z000Li7X

+244701

+244702

Description

Arm Cover (top) with 267272

Screw (6)

Thread Guide (top of Arm)

Lock Nut

Oil Level Indicator

Gasket (vellumoid)

Face Plate

Face Plate Screw (2)

Needle Bar Connecting Link Oil Guard Lock Plate

Oil Guard

Screw (2)

Tension Release Lever Rod Tube

Bed Slide (back)

Bed Slide (front)

Stop

Spring

Arm Position Pin (2)

Arm Screw (4:)

Washer ()

Arm Cover (side)

Screw

Dynamic Head End Lubrication Device complete, Nos. 267396

267397, 267398, 267399 and five 237D

Oil Vibrating Pump Block

Oil Vibrating Pump Screw(S)

Oil Vibrating Pump Bracket

Oil Vibrating Pump Bracket Screw (Z)

Oil Vibrating Pump Weight

Oil Vibrating Pump Weight Spring

Arm with 267388

Bed

17

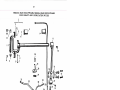

LUBRICATION DEVICE, BED SLIDES, COVERS AND MISCELLANEOUS PARTS

_r__1

()

/

3

1°

1

5

2

0

jO

01

o

21

/)

12

I

_j

1o

20

19

22

23

24

26

24

__,/

27

24

14

F:

—

0

13

I,

18

PRESSER BAR, PRESSER FOOT, PRESSER FOOT LIFTING ASSEMBLY

ANT) Ti-IROAT PLATE

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Part

No.

Description

208566

Presser Bar with 200074F

20007’+F

Screw

207072

Presser Bar Bushing (2)

ZOO35ZALX Set Screw.(3)

210949

Spring Bracket with Z00086ALX

Z00086ALX Pinch Screw

267238

Releasing Lever Bracket

202671

Presser Bar Lifter

200653C

Hinge Screw

206608

Releasing Lever Bracket Spring

202401

Take-up Lever Oiling Felt

200132E

Oiling Felt Screw

202338

Guide Lever with Z00086ALX

Z00086ALX Pinch Screw

202337

Position Guide

200738X

Spring Stop Screw

35046+X

Lever Hinge Screw

267289

Lifting Lever Spring

240068

Lifting Lever

240067

Connection Lever

200262X

Hinge Screw

267251

Spring (flat)

350581C

Spring Regulating Screw

200948F

Spring Support Screw

20097SF

Lever Bracket Guide Screw

267265

Lever Rod

240564

Lifting Rod

227227

Lifting Rod Stop Collar with 200 113F

200113F

Set Screw

275050

Presser Foot (hinged) complete, Nos.202090, 203013

and 275049

275049

Shank with 200355X and 201537X

203013

Plate

202090

Hinge Pin

200355X

Plate Stop Screw

201537X

Stop Screw Lock Nut

240025

Throat Plate

691F

Throat Plate Screw (2)

19

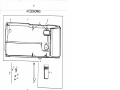

PRESSER BAR,

PRISS1R FOOT, PRESSER FOOT LIFTING ASSEMBLY

A N I) TiIROAT PLATE

IS

,15

14

ir

cD

2O

13

‘Ji

12-0

23

9

.J

4

27

I

1

28

36

30

33

34

32

29

20

TENSION COMPLETE, THREAD GUIDES AND THREAD LUBRICATOR

Ref.

Part

No.

1

No.

21+ L1 727

2

21+0023

3

201Z21+X

1+

5

236060

223703

6

200309E

Z23706

350588X

223701+

Z1+1+0’*8

201+271

2231*38

Z01572X

267368

ZO1199F

201+925

21+1+729

200l59F

267315

267316

Z00582X

Z00337C

21+1*71+5

7

8

9

10

11

12

13

11+

15

16

17

18

19

20

21

ZZ

23

21*

25

26

21+1+735

Z011+02X

21+1+731*

27

28

29

30

31

32

33

31*

35

36

37

38

39

1*0

L+1

1*2

1*3

1*1*

21+1*71+1*

200582X

21*17 65

263551*

ZOO1L+3X

21+1*737

21*1+738

1623X

21*1*71*3

201738X

21+1*71+6

201750X

21*1*739

21*1+71*2

21*1*71*0

267323

21+1*71*1

21*1+736

Des c ription

Tension Bracket complete, Nos.201199F, 201+271,Z231+38,

223703, 223701+, 223706, 21+0023, 267315, 267368, 350588X,

two each 200309E, 201572X and 21*1+01+8

Tension Bracket with 20122

-+X and 236060

1

Tension Stud

Tension Disc Position Pin

Tension Release Lever

Release Lever Screw

Thread Controller Disc

Controller Disc Screw

Tension Release Plunger

Tension Disc

Tension Release Washer

Tension Spring

Thumb Nut

Thread Controller Spring

Thread Controller Stud with 201+925

Thread Controller Stud Washer

Thread Retainer

Tension Bracket Screw

Thread Controller Spring Stop

Thread Guide

Guide Screw

Thread Controller Stud Set Screw

Thread Lubricator complete, Nos. l623X, Z0l738X, 20l750X,

21+1+731* to 21*1+71+3, 267323,two Z1+1+7L6 and six ZOl1*OZX

Thread Lubricator Oil Reservoir Cover

Cover Screw

Thread Lubricator Oil Pad Holder complete, Nos, 21*1765,

21+1*71+1*, 263551+ and two 200l1*3X

Thread Lubricator Plate

Plate Screw (2)

Thread Lubricator Oil Pad (felt)

Oil Pad Holder

Pad Holder Screw

Thread Lubricator Oil Socket

Socket Lock Nut Washer

Socket Lock Nut

Oil Tube

Tube Nut

Socket Oil Seal

Plunger Adjusting Nut

Socket Plunger

Plunger Spring

Plunger Oil Seal (rubber)

Plunger Release Lever Pin

Plunger Release Lever

Reservoir Cover Gasket

21

TENSION COMPLETE, THREAD

GUiDES AN1) THREAD LUBRICATOR

10

12

17

61:jf

‘%

16

20

21

23

24

32

35

34

2

-‘j:

.37

38

40

°‘°

30

41

43

36

LOWER FEED ASSEMBLY WITH FEED DOG

R(.c.

No.

1

Part

No.

Z11i709

2

21+0221+

Description

Feed l)riving Rock Shaft 21+1+7 08 with Z01518E, 21+0221+,

21+1+707 and 350393C

Feed Bar 21+0223 with 225837, 267273 and 350197E

3

1+

5

6

7

8

9

10

11

12

13

21+1+708

350393C

Z0l5l8E

2-i0223

21+1+707

350l97E

225837

267273

223655

200173D

21+0259

200106E

21+1+730

200036E

202625

200383C

2’+1+71o

200029E

200051+C

200398C

267031+

267032

268063

267031

270653

20Z251+

2+371+1+

350366X

Rock Shaft

Hinge Screw (driving)

Nut

Feed Bar

Feed Driving Rock Frame with two 200036E

Fork Screw

Washer

Eccentric Fork with 200l73D and 223655

Oiling Felt

Screw

Feed Dog, 1+0 needle hole,for needle size 20 and 22

Screw (Z)

Bushing (left and right)

Rock Frame Pinch Screw

Stop Collar with two 200383C (2)

Set Screw

+C and 200398C

1

Crank with 200029E, 20005

Pinch Screw

Pinch Screw

Set Screw

Hinge Stud

Connection Z67031 with 268063 and 270653

Needle Bearing

Connection

Needle Bearing

Oil Wick (2)

Gasket (2)

Oil Stop Screw (2)

11+

15

16

17

18

19

20

21

22

23

21+

25

26

27

28

29

30

23

LOWER FEED ASSEMBLY WITH FEED DOG

14

13

‘—1

12

-

f

i

2

4

22

28

19

29

3o—

5____ 30

24

HOOK DRIVING AND FEED 1)RIVING ECCENTRIC ASSEMBLY

WITH HOOK SADDLE BEARINGS

Ref.

N0

1

2

Part

No.

Z02Z5-i

2672L+5

3

270026

1

OZL5

1

ZL

5

6

7

8

9

350i0X

27l2

263093

Z7l5

267182

10

11

12

13

1

1L

15

16

17

18

19

20

267188

ZOO38ZALX

2O1Z2OALX

2&718

7

1

2238L

267033

200582X

26806L

267623

35058C

267180

21

22

23

ZL&l763

35077C

350L&67C

268065

268066

268067

2Lj1+711&

267190

713

1

21*L

267063

200580X

244760

202253

140 197AL

244761

244762

1Z58AL

1266AL

244763

244764

244759

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Description

Wick (2)

Feed Regulating Stud

Spring

Retaining Spring

Bed Oil Screw

Driving Shaft

Driving Shaft Bearing Packing (wick)

Driving Shaft Bearing (left)

Feed Lifting Eccentric with 201220ALX

Gear (spiral) with ZOO382ALX and 2O1ZZOALX

Set Screw

Screw

Saddle Bearing (right)

Saddle Bearing Oil Packing Wick

Friction Washer

Screw (3)

Feed Driving Eccentric

Friction Plate

Screw

1

2

67C,35077C,

763,350

Flange with 267623,two each 1

and 3505&8C

Set Screw Packing (brass)

Set Screw

Set Screw

Adjusting Disc

Spring

Collar with two 200382ALX

Collar 267190 with 2&k713

Collar with 200382ALX and 2O1ZZOALX

Ball Bearing

Retaining Washer

Screw (3)

Safety Clutch and Belt Pulley with 202253

Spring Flange

Safety Clutch Overload Pulley Set Screw

Safety Clutch Overload Pulley with two 140197AL and three 1Z58AL

Safety Clutch Driving Ball Spring

Safety Clutch Overload Pulley Adjusting Screw

Safety Clutch Overload Pulley Adjusting Screw Lock Screw

Safety Clutch Retaining Ring

Safety Clutch Driving Ball

Safety Clutch and Belt Pulley, Complete

1 &°

9C

L Cf

cQ

6E

CC

/

OC

[C

9;

c;

6?

[[

\

[[

U

L7

BE

‘

/1)

Ii

Pt

6

Cl.

c[

Il.

L

i)

-

9

P

—

SDNI’dV iaav TOOH HLIM

A[{WgSV DIIJMDD OMIAIHa UT GNV DNIAI’thJ NOOH

c?

1-TOOK AND BOBBIN CASE WITH BOBBIN

Ref.

No.

Part

No.

1

2

1

2

+

711

i

235100

3

1+

5

6

7

8

9

10

11

12

13

20361+8

2031+73

2031+71+

203216

203211+

20098L+C

200591+E

21+1671+

21+1675

3501+05C

267356

j14

15

16

17

18

19

20

21

22

Description

Flook and Bobbin Case complete, Nos 235100 and 267356

Bobbin Case complete,Nos.Z0059LiE,20098L1C,*202056,

20321k, 203216, 203173, Z03i7Li, 2036’iS, +235099,

05C

1

2+1671i, 2-iJ675 and two 350L

Bobbin Case Latch

Latch Plunger

Latch Spring

Washer (cloth)

Tension Spring

Tension Spring Regulating Screw

Tension Spring Screw

Oiling Felt

Retainer

Screw

Hook +267355 with 267358 to 267360, 35057

+F, two each

1

200591X, 201253F and 2011+09F

Hook Height Adjusting Screw

350571+F

11+0L+31+ALX Set Screw

267360

Thread Guard

200591X

Screw

Needle Guard

267359

2011+09 F

Screw

Hook Gib

267358

201253F

Screw

21+1+750

Bobbin

+202056

+235099

+267355

Bobbin Case Latch Pin

Bobbin Case (chromium plated)

Hook (sewing) with two 11+01+31+ALX

Cr4

k)

0

‘o__

cJ1

‘0

‘C.)

JS)

‘-4

0

H

CID

C

z

0

0

0

28

HOOK SADDLE COMPLETE

Ref.

No.

1

2

3

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

31

35

36

37

38

39

Part

No.

2*720

Description

Hook Saddle complete, Nos.200110D, ZOO37LiALX,200378C,

200388C, 2Li08, 2i70Li, 21I*711, 267053, 267166, 267167,

8,

1

, 267198, 267200,267212, 267215, 2672L

1

L

9

267172, 2671

267351,267365,267366,35056L&E,two eachZ00089X,

Z00135C, 267361 and eight Z00061ALX

2iLi711

Hook and Bobbin Case complete

Hook Ball Bearing

267053

Retainer

267361

Screw

200089X

Oil Wick Holder

276061

Oil Wick

270880

Hook Shaft with 270880 and 276061

267215

Link

267172

Cap Screw

200135C

2L70

Cam Shaft

Pinion (spiral) with two 350595XC

267366

Set Screw

350595XC

Oil Regulating Screw

E

1

35056

Hinge Stud

267167

Opener Crank

267166

Bobbin Case Opener

267351

Screw

200110D

Pinion Thrust Bearing

Z6728

Hook Shaft Bushing

267367

L

9

267l

Hook Saddle with 200 185D, 267367, 267370 and 267371

Cam Shaft Bushing (upper)

267371

Cam Shaft Gear (spiral) with two 350595XC

267365

Cam Shaft Bushing (lower)

267370

Oil Regulating Screw Check Screw

200378C

Check Screw Packing (fibre)

Oil Stop Screw

200185D

20037L&ALX Hinge Stud Set Screw

200388C

Check Screw

Z67198

Oil Gauge Sleeve with 267277

Oil Strainer

267277

Gasket

267212

Oil Reservoir

267200

20006 1ALX Sc rew

Pinch Sleeve (upper)

2671i0

Pinch Sleeve (lower)

267139

Screw

200001E

Washer

225585

Hook Saddle Screw

200006E

C)

C.)

C.)

I

7

‘)

c)

•

0

C.)

0’

1

—

o

0

—

t::j

t:tl

H

C

t:1

C)

Cr1

C

C

0

30

NEEI)LE BAR ROCK FRAME, NEEDLE BAR ROCK FRAME

ROCK SHAFT AND LUBRICATING WICKS

Ref.

No.

1

Part

No.

267286

2

3

L

0

1

025

267287

200587D

267231

267233

267232

200176E

267362

200398C

267229

200029G

267230

350566C

202277

201517E

2LjLf725

267 25L+

267276

*C

1

20003

267293

267257

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

267263

267321

267322

21+Liz7l6

27l7

ZLkLI7O6

267Z61

2-&*719

267262

267256

•267281

+267285

Description

0025

1

Needle Bar Rock Frame Rock Shaft •267285 with L

and •26728+

Position Pin

Wear Plate

Screw

Oiling Felt

Retainer (lower)

Retainer (upper)

Screw (i-i)

Rock Shaft Bushing (2)

Set Screw

Connection with 200029C

Pinch Screw

Link

Hinge Screw with 202277 (2)

Packing (wick)

Nut (2)

Rock Shaft Crank with 200029C and 200398C

Bed Oil Tube Clamp

Clamp Oiling Felt

Screw

Feed Driving Eccentric Connection Oil Tube Support

Feed Driving Rock Shaft Bushing (right) Oil Tube with

267263

Wick

Bed Oil Supply Tube with 267322

Oil Wick

Hook Driving Shaft Ball Bearing Oil Tube with 2L717

Wick

Feed Driving Eccentric Connection Oil Tube with 267261

Wick

Hook Saddle Bearing (right) Oil Tube with 267262

Wick

Feed Driving Rock Shaft Bushing (left) Oil Tube with

267262

Needle Bar Rock Frame with two 267Z87 and four Z00587D

Needle Bar Rock Frame Rock Shaft

31

NEEDLE BAR ROCK FRAME, NEEDLE BAR ROCK FRAME

ROCK SHAFT AND LUBRICATING WICKS

3

9

j

9

2

8

7

11

5

12

8

6

20

fl\

13

21

w

15

19

17

22

24

30

31

29

10

32

ACCESSORI ES

Ref.

Part

No.

1

No.

228886

2

3

228885

228883

350708

267197

12361

22+13

5

6

7

8

9

10

11

12

13

1-i

15

16

17

18

19

20

200113F

22&12

22+11

200270X

1203Lj2

1203L+3

Z25&98

228+76

L1I+0o

22555k

Z00157X

2750

Z672’2

135 x7 Y

Description

Drip Pan (Plastic) complete, Nos. 228883, 228885 and

five 350708

Drip Pan

Drip Pan Drain Jar

Drip Pan (Plastic) Screw Nail

Hook Saddle Oil Gauge

Machine Hinge Connection (2)

Knee Lifter Connection Lever Lifting Rod Roller Bracket

complete, Nos. 200270X, Z2Lii+ll and 224412

Set Screw

Rod Roller Bracket with 200113F

Rod Roller

Hinge Screw

Oiler (copper plated) with l203i3

Spout

Screw Driver

Screw Driver (Bobbin Case)

Machine Rest Pin (wood)

Wrench

Attachment Screw

Bobbin

Wrench (3/32 in. Hex.)

Needles, six, size 21 with Supplementary Shoulders

33

ACCSSORI ES

12

/14

13

15

18

‘F

16

1f

SING

1!

Li

1’

17

34

ACCESSORIES

BOBBIN WINDER (SWINGING AUTOMATIC, RIGHT HAND)

FOR “V” BELT DRIVE

Ref.

No.

Part

No.

1

259462

2

225462

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

201572X

13710

2102

225461

201499X

200082D

228026

259662

225456

225455

259930

457AL

200113F

259429

259428

200299X

202478

225458

225459

225444

200056E

225381

259660

225454

244071

225453

Description

Universal Bobbin Winder complete,Nos.200056E,200082D,

200113F, 200299X, 202478, 225381, 225444, 225453 to

225456, 225458, 225162, 228026, 259428, 259129, 259662,

Z59930,two each 225459 and wood screws 3/4 in.,

No. 12,RH.B.

Bobbin Winder Tension Bracket complete,Nos. 13710,

201572X, 225461 and two 2102

TensionStudThumbNut

Tension Spring

Tension Disc

Tension Bracket with 201499X

Tension Stud

Tension Bracket Screw

Washer

Bobbin Winder and Tension Bracket Base

Frame Spring Plunger

Frame Spring

Pulley with Li57AL

Set Screw

Brake Clamp Screw

Brake Clamp

Brake (leather)

Trip Lever Hinge Screw

Stop Latch Trip Lever

Stop Latch Thumb Lever

Stud

Stop Latch

Screw

Spindle

Oil Well Washer

Frame Hinge Pin

Oil Packing (wick)

Frame with 244071 and 259660

35

ACCESSORIES

BOBBIN WINDER (SWINGING AUTOMATIC, RIGHT HAND)

FOR “V’ BEL’r DRIVE

6

0

2{j

7

8

9

10

0

j/fl

12

26

13

24

14

15

16

21

17

18

19

36

ACCESSORI ES

KNEE LIFTER

Ref.

No.

Part

No.

1

ZZ890L

2

228751

3

228707

5

6

7

8

9

10

1].

12

13

14

15

228363

2003

f

1

7AL

228155

228367

228386

228752

228365

200530C

267 371i

350231C

228318

228364

Description

Knee Lifter Rock Lever 1

comp1ete,Nos.228318,22836

,

228365, Z28751 and Z67374

Bracket 228707 with 228363, 228367, 228386, 228L55 and

228752

Bracket with 200347AL and three wood screws 7/8 in.,

No. 12

Hinge Pin

Stop Stud Set Screw

Position Spring

Stop Stud

Spring

Rock Lever with two 350231C

Rod

Set Screw

Extension with 200530C

Set Screw

Knee Plate Arm

Knee Plate with 350231C

37

ACCESSORI ES

KNEE LIFTER

2

r

9

4

8

5

13

(‘12)

Cl

13

15

38

NUMERICAL

Page

No.

Part

No.

Z37D.

457AL.

691F...

1258AL

1266AL

1623X.

2102

•

.

16

34

18

24

24

20

34

32

12361

13710

.34

.30

40025

32

41400

120342

.32

120343

.32

.24

140 197AL

140434ALX. .26

14

141 566G.

.14

141567G.

Z00001E.

.28

200004E

16

28

200006E

30

200029C

22

200029E

200034C

30

Z00036E

22

Z00047D

16

200047X

16

Z00054C

22

200056E

34

Z00061ALX.. .28

200072G

14

Z00074F

18

200082D

34

200086ALX.. .18

28

200089X

200106E

22

ZOO11OD

28

ZOO113F... 18,32, 34

ZOO125ALX. ..14

200132E

18

200133E

16

200135G

28

200143X

ZO

200157X

32

20

Z00159F

Z00173D

22

200175D

14

200176E

30

-

•

.

Part

No.

LIST

Page

No.

OF

Part

No.

Z8

+202056

200262X

18

202090

200270X

32

202253

Z02254

200Z99X

34

202277

20

200309E

202330

200333C

14

202337

200337C

20

202338

200341C

14

200347ALX. .36

202399

202401

ZOO35ZALX. .18

Z0Z478

200355X

18

20255

2

200363ALX. .14

200374ALX...14,28 202625

200378C

14, 28 202671

203013

200382ALX. .24

200383G

14, ZZ 203214

200388G

14,28 203216

200398C

22, 30 203473

203474

200530C

36

203648

200580X

24

200582X

20, 24 204235

204271

Z00587D

30

204329

26

200591X

204925

26

200594E

206608

200653C

18

207072

Z00738X

18

208566

200948F

18

210949

200975F

18

223438

26

200984C

223655

20

201199F

223703

ZO1ZZOALX.. .24

223704

20

201224X

Z2370

6

26

201253F

223811

201254C

24

223812

201313F

16

223847

Z01341C

14

224411

20

20140ZX

201409F

224412

26

224413

34

201499X

Z01517E

30

225381

201518E

22

225444

201525E

225453

16

201537X

18

225454

201572X

20,34 225455

225456

201738X

20

201750X

20

225458

202005

ZZ5459

16

ZOO1SBD

PARTS

Page

No.

26

Part.

No.

Z25461

225462

18

14, 24 225498

22, 24 225554

30

225585

14

225837

227227

18

228026

18

228318

14

228363

18

34

228364

14

228365

228367

22

22838

18

6

228455

18

228476

26

228707

26

228751

26

228752

26

228883

26

228885

16

228886

20

228904

14

20

+235099

235100

18

18

235706

18

236060

18

240003

20

240004

22

240020

20

240023

20

240025

20

240039

240067

16

240068

16

24

240139

240223

32

240224

32

3Z

240245

240259

34

240564

34

241674

34

241675

34

241763

34

241765

34

34

243744

34

244048

Page

No.

34

34

32

32

28

22

18

34

36

36

36

36

36

36

36

32

36

36

36

32

32

32

36

Z6

26

14

20

16

16

14

20

18

14

18

18

14

22

22

Z4

22

18

26

26

24

20

22

20

39

NUMERICAL

Part

No.

244071

244084

+244701

+244702

244704

244705

244706

244707

Z44708

Z44709

244710

244711

244712

244713

244714

244715

244716

244717

244718

244719

244720

244721

244722

244725

244726

244727

244729

244730

244734

244735

244736

244737

244738

244739

244740

244741

244742

244743

244744

244745

244746

244747

244750

244751

244759

244760

Page

No.

Part

No.

14, 34 244761

28

244762

16

244763

244764

16

28

259428

16

259429

30

259462

ZZ

259660

22

259662

22

259990

22

263093

26

263554

24

264714

24

267031

24

267032

24

267033

30

267034

30

267053

24

Z67063

30

267139

28

267140

14

267152

14

+267158

30

267160

14

267161

20

267162

20

267166

22

267167

267172

20

20

267180

20

267182

20

267188

20

267190

20

267194

20

267197

20

267198

20

267200

20

267212

20

267215

20

267220

20

267221

14

+267222

18,32 267224

16

267229

24

267230

24

267231

Page

No.

24

24

24

24

34

34

34

34

34

34

24

28

14

22

22

24

22

28

24

28

28

16

14

14

14

14

28

28

28

24

24

24

24

28

32

28

28

28

28

16

14

14

14

30

30

30

LIST

OF

Part

No.

26723Z

267233

267236

267238

267239

267242

267245

267Z47

267248

267251

267254

267256

267257

267261

267262

267263

267265

267272

267273

267276

267277

+267284

+267285

267286

267287

267289

267293

267315

267316

267321

267322

267323

267351

+267355

267356

267358

267359

267360

267361

267362

267365

267366

267367

267368

267370

267371

PARTS

Page

N o.

30

30

14

18

14

32

24

14

28

18

30

30

30

30

30

30

18

16

22

30

28

30

30

30

30

18

30

20

20

30

30

20

18

26

26

26

26

28

28

30

28

28

28

20

28

28

Part

No.

267374

267388

267395

267396

267397

267398

267399

267400

267466

267623

268063

268064

268065

268066

268067

268197

270026

270653

270880

271017

272142

275049

275050

276061

350197E

350231C

350366X

350393C

350405C

350440X

350464X

350467C

350477C

350492C

350548C

350563E

350564E

350566C

350574F

350581C

350588X

350595XC

350708

Page

No.

.

.

.

36

16

16

16

16

16

16

16

14

24

ZZ

24

24

24

26

16

24

22

28

16

14

18

18

Z8

22

36

22

22

26

24

18

24

24

14

24

16

28

30

26

18

20

.28

3Z