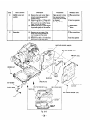

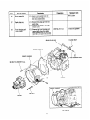

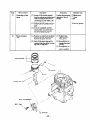

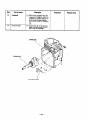

Download R650 GENERATOR SERVICE MANUAL

Transcript