Download PFC.DLL User Guide - Flight Simulator Center

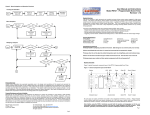

Transcript