Download OPERATORS MANUAL

Transcript

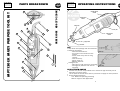

EC DECLARATION We (Incorporating EC Directive EC EC HD Directive 400.1; HD hereby regarding EN that Model the DC regarding Directive 400.2; certify Charger KOBE 24238) VDE Drill with 0700 Teil 207; KENNEDY Works, ISO 9001 the ABH provisions EEC, equipment EN as EN of the amended; 73/23 89/336 50082-1; KOBE 24VET relevant compatibility Manufactured Wigston Model all 89/392 low-voltage electromagnetic DIN CONFORMITY Cordless comply machinery regarding 60335-1; OF 55014; EEC, EN INDUSTRIAL as 60555-2; EN 60555-3 MUL TI PURPOSE Position: QUALITY KOBE INDUSTRIAL KOBE MODEL England. INDUSTRIAL the KOBE the quality TOOLS POWER highest and they be INDUSTRIAL found to be (fair Please The 2002 Cooke Kennedy TOOLS are they tear & will & 9001 as 130W l Flexible l Telescopic Tool l 118 Accessory Multi Purpose Drive Piece Shaft Steady manufacturers & The by fully be all sectors guaranteed repaired Bench Clamp Kit warranty. of industry. against or replaced free of charge excepted). proof of purchase. For: Leicester, England. COMPANY YOUR Kennedy with manufactured DISTRIBUTOR OPERATORS © Tool TOOLS REGISTERED FROM l specifications misuse invoice Works, KBE-279-2200K workmanship Manufactured ISO CODE WARRANTY designed either KENNEDY Wigston & are and/or supplier Ltd. years required TOOLS materials and retain AVAILABLE Group one standards POWER defective, wear carry performance faulty Should Febuary Martin MPT130EK COMPANY GUARANTEE POWER to Assuring Director, KIT TOOLS Signed: Name: TOOL for Leicester, REGISTERED 1st TOOLS amended. ORDER Date: POWER EEC; Group Ltd. 02/04 MANUAL KOBE shock precautions: and operate In at case the all use tools of times. your common when you electrical switch Watch or off are what sense. tool and Do intended not malfunction, l Never l Do disconnect l use original Kobe accessories safely if the tool is used at the which rate. apply not your plug. Only and are tired. mechanical the you try hand. Never force. to stop Wait press the the for it shaft accessory to rotating with the is stop. lock while tool can obtained Ensure the that shaft from the size Compare the accessory your collet of the Kobe size that of KOBE grinding wheels over rpm of l each tool. Do not use drill bits Power over 1 / 8” Speed 280-1607T -4121S -4120S -4119S -4117S -4118S -4116S -4115S -4113S CONTROL (3.2mm) MPT130EK 230v~ 50 Voltage Consumption Load -4114S 4” diameter. Number Nominal -4112S -4111S -4109S -4110S -4108S -4107S -4105S -4106S -4104S -4103S 1 / 1 TOOLS Model No use SPECIFICATIONS I N D U S T R I A L POWER not (32mm) diameter. allowed the Do with accessory. maximum with l dealer. corresponds No. l be SPEED alert VARIABLE efficiently Stay running. l a COLLET SPANNER of more 21 done 22 be force job RING will not the 20 job do do SHELL SET The job, to 19 the PIN for LOCK tool. tool attachments with supervision. SHAFT heavy or familiar SPRING correct tools not without 18 the small are them 17 Use who handle BUTTON l lit. people LOCK well repaired technician. let tools SHAFT is be not power 16 should Do not in use. immediately l area part authorised l are Disconnect the tool from the power source when doing l work an parts COVER Ensure by all WIRE l damaged serviced that liquids 15 l A ensure flammable WIRE l and tool near GRIP BLOCK functional. the tools ELECTRIC using power WIRE necessary. Before use 14 l not gases. 13 or NAIL Do if SCREW mask 12 dust SET a SWITCH and ON-OFF glasses C F). (122 l safety o 50 o parts tool. wear where exceed 11 moving locations or SET from in reach 626-2Z away machine may BEARING cord the CIRCUIT BOARD the store temperature 9 the keep Always not the 10 of Do SET l from children. Always damp BRUSH injury. away or CARBON invites place, rain conditions. 8 clutter to not ARMATURE - secure tools are basic 7 clean dry, power these NAIL a follow COIL (STATOR) area in expose work FIELD tool not you SCREW l work Store Do injury, help procedures 6 l Keep l SAFETY personnel to safety Description l GENERAL and designed correct 5 electric if 698-2Z fire, specifically dangerous years. BEARING of been procedures many 4 risk be for REST the have can last is life. FINGER reduce tools maintenance will that service 3 To TOOLS Power and tool product long -4102S POWER EFFICIENTLY. this and -4101S INDUSTRIAL and industrial COLLET NUT KIT KOBE quality safety observed SAFELY observed. use, a performance CHANGE correct are high COLLET NUT If for QUICK purchased BREAKDOWN TOOLS 2 have designed l POWER 1 You PARTS I N D U S T R I A L TOOLS Code POWER INSTRUCTIONS KBE-298 SAFETY I N D U S T R I A L Order KOBE Hz 130W Speed 8,000-30,000rpm Noise 82db(A) Weight 640gms Complies to EN 50144-1 2 & EN 68 1977. 7 KOBE PARTS I N D U S T R I A L KOBE BREAKDOWN 19 16 Speed Control Carbon Brush Holder Shaft Lock Holder CODE 14 On/Off Carbon 6 Brush Holder ORDER 20 8 9 15 11 12 10 13 18 17 KIT Variable Finger Collet Rest Nut 7 21 USE • • Keep the air Mounting vent openings clean and uncovered. accessories: Hand Push - Turn - Loosen 22 - and hold collet nut shaft until Grip lock. shaft locks into position. collet nut by hand or using 4 5 spanner. • - Insert - Tighten - Release Holding accessory. collet nut. shaft the tool - Hand grip - Pencil for lock. rough work such as grinding. Pencil 3 grip for precision work such Grip as 2 engraving. 1 MUL TI INSTRUCTIONS TOOLS KBE-279-2200K POWER TOOL PURPOSE OPERATING I N D U S T R I A L TOOLS MPT130EK POWER APPLICATION • Practice on determine • • Let the the speed - ADVICE piece of the - scrap High tool for for material first to choose the right accessory and to speed. speeds Medium Medium of correct Recommended Low 6 a do the work for you are: polishing other & cleaning applications 3 and do not apply too much pressure. KOBE KOBE MAINTENANCE I N D U S T R I A L POWER ACCESSORIES I N D U S T R I A L POWER TOOLS TOOLS Type I nspect power cables regularly. Keep handles and switches dry, clean and free from oil Description Order Code Type Description Order Code and 19mm Ø Bristle brush x 1.2mm thickness KBE-280 grease. It is ventilation important holes are to kept keep clean, the motor blow out ventilated dust and during dirt operation, therefore ensure the 1.6mm 1 / ( 32”) KBE-280 Collet -1601T -1632T regularly. 3.2mm Shank 3.2mm Ø KBE-280 KBE-280 Excessive sparking could indicate worn-out carbon brushes. Replace broken or worn carbon 2.4mm 1/ 16”) ( Collet Bristle brush -1633T -1602T 3.2mm brushes (less than 5mm) immediately with genuine Kobe brushes. Always replace brushes in Shank 19mm Ø 1.2mm thickness KBE-280 KBE-280 pairs. If any part of the tool is damaged contact a qualified technician. 3.2mm 1 / ( 8”) Collet Carbon steel 3.2mm Shank circular brush -1631T -1603T 16mm Ø x 10mm length 13mm Ø KBE-280 KBE-280 Pink KOBE POWER aluminium oxide Wire brush -1629T -1644T SERVICE I N D U S T R I A L & REPAIR TOOLS 3.2mm 10mm Shank Mounted tapered x Point 6.5mm 3.2mm Shank 13mm length Ø KBE-280 KBE-280 Pink aluminium Brass oxide wire brush -1630T -1649T 3.2mm Shank 6.35mm Ø x Mounted 10.5mm Point length 3.2mm Shank 3.2mm Ø, KBE-280 KBE-280 Pink aluminium oxide Cylindrical diamond coated burr -1616T -1646T 3.2mm Shank 9.8mm Ø Ball Mounted Point 3mm end Shank 2.4mm Ø Ball end KBE-280 KBE-280 Pink aluminium oxide Diamond coated burr -1617T -1645T 3.2mm Shank 6.35mm Ø x Mounted 14mm Point 3mm length Shank 12.5mm Ø KBE-280 KBE-280 Pink aluminium oxide Sanding band holder -1623T -1648T 2.4mm A comprehensive repair and 10mm Shank Ø x Mounted 3.2mm Point 3.2mm thickness Shank 10mm Ø KBE-280 KBE-280 Pink service facility is available through aluminium oxide Sanding band holder -1622T -1650T 3.2mm your local agent. Shank 6.35mm Ø x Mounted 13.5mm Point 3.2mm length Shank 10mm Ø x 12.5mm width KBE-280 KBE-280 Pointed pink aluminium oxide 60 Grit sanding band -1618T -1647T 3.2mm 20mm Shank Ø x Mounted 3.2mm Point Aluminium 10mm thickness Ø x oxide 12.5mm width KBE-280 KBE-280 Pink aluminium 120 oxide Grit sanding band -1619T -1627T Grinding Aluminium wheel 10.5mm Ø 12.5mm Ø oxide x 12.5mm width KBE-280 KBE-280 Green/blue silicon carbide 60 Grit sanding band -1620T -1637T 3.2mm 13mm Shank Mounted Point Aluminium Ø 12.5mm Ø oxide x 12.5mm width KBE-280 KBE-280 Green/blue 2.4mm TOOL I N D U S T R I A L POWER silicon carbide 120 KIT CONTENTS 20mm Shank Ø x Mounted 3.2mm Green/blue Aluminium Threaded silicon Brown x 19.8mm aluminium rubber drive 3.2mm shaft for use 16mm where KBE-280 3.2mm Shank -1615T length Screw Shank Ø x head mandrel KBE-280 oxide -1635T Shaft mandrel wheel Ø KBE-280 Flexible band oxide carbide -1626T Grinding Drive sanding -1621T Point thickness KBE-280 TOOLS 10mm Flexible Grit -1636T KOBE Mounted 10mm 2.4mm shank 3.2mm HSS -1614T Point length KBE-280 KBE-280 Brown aluminium oxide drill bit -1651T -1634T maximun access flexibility in confined is required, to improve 3.2mm 16mm spaces. Shank Ø x Mounted 10mm Point length KBE-280 KBE-280 Grey silicon carbide 10mm 3.2mm 19mm Shank Ø x Mounted 3.6mm silicon and Tool 12mm Steady -1611T 25mm fix the tool multi steady tool in to a place work bench when Ø using or table the to Ball Mounted Felt Flexible Drive silicon Shaft. 6.5mm thickness -1613T 12.5mm Ø x 6mm thickness 1.5mm thickness 6mm x Mounted 13mm Felt wheel -1612T Point length 32mm Ø x KBE-280 KBE-280 silicon carbide Fibreglass reinforced -1604T -1642T 3.2mm 10mm Shank Mounted Point Cut silicon wheel 24mm Non -1640T Shank 8mm x Ø Mounted 13mm x 0.8mm reinforced cut thickness off wheel 32mm Ø x 1.6mm thickness Mounted Non Sharpening stone Green/blue silicon reinforced cut off wheel Various collets, Kit cutters, drills, 20mm 19.5mm abrasives, 19mm Ø burrs, wheels, discs of 10mm Ø x x KBE-280 carbide 60 Grit sanding disc -1624T 10mm 3.4mm Aluminium thickness 19mm oxide Ø KBE-280 KBE-280 White brushes, x aluminium oxide 120 Grit sanding disc -1625T -1628T mandrels. Grinding 20mm KBE-280-4820K Ø wheel x 3mm Aluminium 20mm Ø KBE-280 impregnated 800 -1638T Cleaning 4 oxide thickness KBE-280 Emery -1606T Point -1608T Accessory KBE-280 carbide Shank KBE-280 Piece -1605T length -1641T 118 KBE-280 Point KBE-280 silicon 3.2mm Ø carbide 3.2mm Grey off Ø KBE-280 Grey KBE-280 carbide Shank Grey KBE-280-4810K KBE-280 end 3.2mm Ø x wheel Point -1643T hold Ø carbide Shank KBE-280 Grey To cone length -1609T 3.2mm Clamp Felt Point KBE-280 Grey Bench Ø -1639T KBE-280-4800K & Polishing wheel 5 Grit wet & dry disc -1610T