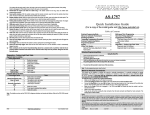

Download User manual

Transcript