Transcript

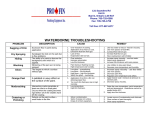

Troubleshooting processing problems Problem Proposal for solution / diagnosis Edging strip can easily be removed by hand. X Insufficient glue application quantity Hot melt remains on the chipboard. X Edging strip material too cold Grid structure of the glue applicator roll can X Hot melt temperature too low be seen. X Feed rate too slow X Room temperature too low X Insufficient contact pressure of glue applicator roll or counter roll X Panel material temperature too high Edging strip can easily be removed by hand. X Panel too cold Hot melt remains on the chipboard. X Edging strip too cold Hot melt surface is smooth. X Wrong hot meld X Incorrect bonding agent application X Insufficient contact pressure X Edging strip too cold X Missing edging strip pretension X Wrong hot meld X Hot meld does not set quickly enough X Feed rate too high Edging strips are only glued in the boundary X Insufficient contact pressure areas. X Excessive edging strip pretension X Joint cut at panel part is hollow Insufficient gluing at panel front edge of the X Insufficient glue application glued edging strip or splintering edging strip. X Incorrect glue applicator roll position Milling has wavy lines. X Feed rate too high X Milling cutter speed to low X Milling not counter direction Edge protection tape changes colour during X Scraper blade is too thick (max. 0.1 mm) milling (stress whitening). X Heat milling area with hot air Edging strip can be removed by hand. Hot melt remains on edging strip to a great extent. Glue joint is not closed.