Download Friedrich MC24Y3F User's Manual

Transcript

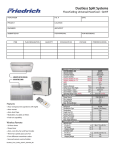

SPLIT TYPE AIR CONDITIONER CASSETTE type (60Hz) Models Indoor unit Outdoor unit MC24Y3F MR24UY3F CONT E NT S SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . 1 DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2 REFRIGERANT SYSTEM DIAGRAM . . . . . . . 4 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . 5 INDOOR PCB CIRCUIT DIAGRAM . . . . . . . . 7 OUTDOOR PCB CIRCUIT DIAGRAM . . . . . . 8 ERROR CONTENTS . . . . . . . . . . . . . . . . . . . . 11 DISASSEMBLY ILLUSTRATION . . . . . . . . . . 13 PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . 21 STANDARD ACCESSORIES . . . . . . . . . . . . . 23 SP EC I FI CA TI O N S NOISE LEVEL COOLING & HEATING TYPE MC24Y3F INDOOR UNIT INDOOR UNIT MR24UY3F OUTDOOR UNIT 22,200 / 22,200 BTU/h COOLING CAPACITY OUTDOOR UNIT 24,200 / 24,200 BTU/h HEATING CAPACITY ELECTRICAL DATA RUNNING CURRENT INPUT WATTS E.E.R. 230 / 208 V 60Hz COOLING 9.2 / 10.1 A HEATING 10.4 / 11.4 A COOLING 2.10 / 2.10 kW HEATING LOW-SPEED 38.0 dB COOL 53.0 dB HEAT 55.0 dB 50 m MAX PIPE HEIGHT 30 m FULL CHARGE AMOUNT 49 ft. (15 m) 4 lb 3 oz (1,900 g) 66 ft. (20 m) 4 lb 10 oz (2,100 g) 98 ft. (30 m) 5 lb 8 oz (2,500 g) 6 lb 6 oz (2,900 g) COOLING 3.10 / 3.10 kW/kW HEATING 3.00 / 3.00 kW/kW 164 ft. (50 m) 7 lb 5 oz (3,300 g) ADDITIONAL REFRIGERANT 0.424 oz / ft. (40 g / m) MOISTURE REMOVAL 3.0 l/hr 1,050 m3/hr AIRCIRCULATION -High COMPRESSOR Total enclosed type, 4 poles, Inverter, Twin Rotary TYPE TNB220FPBM9 DISCRIMINATION R410A 4 lb 3 oz, 1,900 g FAN MOTOR DISCRIMINATION MFA-24RPT HIGH-SPEED 490 r.p.m. / 440 r.p.m. MED-SPEED 430 r.p.m. / 380 r.p.m. LOW-SPEED 360 r.p.m. / 330 r.p.m. S-LOW-SPEED OUTDOOR UNIT DISCRIMINATION ( Cool / Heat ) HIGH-SPEED - / 250 r.p.m. MFE-45ROM 850 r.p.m. / 900 r.p.m. DIMENSIONS INDOOR UNIT HxWxD 9-3/4" x 32-3/4" x 32-3/4" inch ( 246 x 830 x 830 mm ) OUTDOOR UNIT HxWxD 32-3/4" x 35-1/2" x 13" inch ( 830 x 900 x 330 mm ) INDOOR UNIT Gross / Net 44 kg / 34 kg OUTDOOR UNIT Gross / Net 70 kg / 64 kg WEIGHT 2006.05.25 43.0 dB 131 ft. (40 m) 9.5 A INDOOR UNIT ( Cool / Heat ) MED-SPEED MAX PIPE LENGTH Pipe Length 2.37 / 2.37 kW STARTING CURRENT REFRIGERANT 45.0 dB REFRIGERANT CHARGE (R410A) 1 POWER SOURCE HIGH-SPEED 1 D I M E NS IO N S 32-3/4" (830) 37" (940) 29-17/32" (750) 9-3/4" (246) 1-3/16" (30) INDOOR UNIT unit : inch (mm) 29-17/32" (750) 37" (940) 32-3/4" (830) 2006.05.18 9-25/32" (248.5) 2 11-3/4" (298.5) 12" (305.5) 9-25/32" (248.5) 3-15/16" (100) 12" (305.5) 2-3/8" (60) 11-3/4" (298.5) 2-3/4" (70) 9-1/4" (235) 2-3/8" (60) outside Dia. ø1-1/2" (ø37) 2-3/4" (70) Dia. ø1-1/4" (ø32) 7-7/8" (200) inside 3-15/16" (100) Drain OUTDOOR UNIT unit : inch (mm) 3"(77) 13" (330) 1/2" (12) 3/8" (9) 7/8" (21) 17-3/8" (440) 32-3/4" (830) 35-1/2" (900) 1-1/4" (31) 15-3/4" (400) 25-5/8" (650) 5-3/4" (147) 6-3/4" (170) 2006.05.18 3 7-3/4" (196) 3-7/8" (99) 14-5/8" (370) Air Flow R E FR I G E R A N T SYSTEM D I AGRAM OUTDOOR UNIT INDOOR UNIT Pressure Check Valve Refrigerant Pipe 15.88mm (5/8") Muffler High Pressure Switch Charging Valve 4-way Valve Condenser Evaporator Accumulator Compressor Expansion Valve Strainer Refrigerant Pipe 9.52mm (3/8") Strainer Charging Valve : COOL : HEAT 2006.05.18 4 C I RC U I T D I A G R A M INDOOR UNIT PIPE TEMPERATURE THERMISTOR BLACK WHITE 2 (N) CN10 BLACK 1 1 2 2 BLACK 1 1 2 2 3 3 RED 1 2 3 5 6 BLACK BLACK TO OUTDOOR UNIT 5 1 2 3 4 5 1 1 2 2 3 3 1 1 2 2 1 2 3 4 5 BROWN RED ORANGE YELLOW M STEP MOTOR WHITE BLACK FLOAT SWITCH BLACK YELLOW YELLOW DRAIN PUMP MOTOR M WHITE BLACK FAN MOTOR 1 2 3 5 6 BLACK WHITE RED FM 1 1 2 2 WHITE GREEN / YELLOW PURPLE BLUE 3 TERMINAL 2006.05.18 WHITE 1 1 2 2 3 3 CN4 1 RED WHITE G BLACK GREEN RED 1 1 2 2 3 3 YELLOW CN15 L N BROWN RED ORANGE CN6 POWER SUPPLY PCB ASSY 1 2 3 4 5 CN16 Use T3.15A-250V Fuse on F101 BLACK 1 1 2 2 3 3 1 2 3 4 5 CN5 RED WHITE BLACK CN8 1 2 BLACK CN7 CONTROLLER PCB ASSY 1 2 1 2 CN17 3 TERMINAL 1 2 1 2 CN1 TO REMOTE CONTROL UNIT GRAY GRAY ROOM TEMPERATURE THERMISTOR WHITE FAN MOTOR CAPACITOR OUTDOOR UNIT BLACK PIPE TEMPERATURE THERMISTOR BROWN BLACK EMI FILTER CONNECTOR 1T 1 RED CN37 2 RED U RED U WHITE W304 W BLACK BLACK FUSE F4 T 5A-250V 1 BLACK CN30 2 3 BLACK W303 ACTIVE FILTER MODULE BROWN 1 2 RED 3 ORANGE BLACK BLACK CHOKE COIL WHITE BROWN L1 L2 + 1 2 CONTROLLER 3 CN407 4 5 4 5 6 YELLOW TERMINAL YELLOW P N - HIGH PRESSURE SWITCH V WHITE V W HEAT SINK TEMPERATURE THERMISTOR 1 2 1 2 1 2 1 2 1 2 CN21 CN22 CN23 CN26 CN25 W305 COMPRESSOR COMPRESSOR TEMPERATURE THERMISTOR BROWN DISCHARG TEMPERATURE THERMISTOR RED OUTDOOR TEMPERATURE THERMISTOR BLUE BLUE PCB ASSY 1 2 3 CN802 4 5 6 W12 W13 EMI FILTER 2T FUSE F2 T 3.15A-250V BLACK W16 W17 W10 CN1 1 2 3 4 TM102 BLACK TM101 BLACK WHITE YELLOW BLUE RED BROWN BLUE ORANGE YELLOW WHITE FM FAN MOTOR EV EXPANSION VALVE COIL CN34 W200 1 2 3 WHITE BLACK BROWN RED W11 WHITE 1 2 3 CN27 4 5 6 RED 1 2 3 CN1 BLACK RED 4WV SOLENOID COIL W9 W8 W3 W6 W7 W4 W5 GREEN BLACK WHITE BLACK WHITE POWER SUPPLY PCB ASSY RED 1 G EARTH 2006.05.18 6 2 (N) 3 L N G EARTH I N D O O R PC B C I R C UIT DIAGRAM Model : MC24Y3F 2006.05.25 CONTROLLER PCB ASSEMBLY K01AL-050LHSE-C1 7 OUTD O O R PC B C I R C U I T DIAGRAM Model : MR24UY3F INVERTER ASSEMBLY EZ-005FHUE POWER SUPPLY PCB ASSY K04BA-0500HUE-P0 CONTROLLER PCB ASSY K04AW-0502HUE-C1 2006.05.25 8 Model : MR24UY3F CONTROLLER PCB ASSEMBLY K04AW-0502HUE-C1 600/450V x 4 2006.05.25 9 Model : MR24UY3F POWER SUPPLY PCB ASSEMBLY K04BA-0500HUE-P0 TM100 BLACK W4 B POWER SOURCE 230V 60Hz WHITE W5 VA101 470V <TNR> VA102 470V <TNR> C101 3.3 <LE> W6 TO INDOOR UNIT W7 EARTH AC VOLT OUT C60 + 220/16V <PJ> B R60 1.0K <1/10W> (1%) B WHITE 2006.05.25 TM102 10 CN1 B3B-XASK-1-A 5V D60 5V DAN217U B BLACK W9 C111 3.3 <LE> CT1 CT-1B B GREEN W8 C107 3.3 <LE> TM101 C112 0.015 <YE> C113 0.015 <YE> B WHITE W3 L4 RCH4730-021PF07 C106 3.3 <LE> B SA100 RA-302M BLACK L2 N200500K1D7C L1 RCH4730-021PF07 C104 0.033 <YE> C105 0.033 <YE> VR1 B2K R61 3.74K <1/10W> (1%) C65 0.1 R68 22K <F> <1/10W> C64 0.1 <F> WHITE 1 2 3 CT OUT ER RO R C O NTEN TS (indoor unit) Error code (1) Stop the air conditioner operation. (2) Press the master control button and the fan control button simultaneously for 2 seconds or more to start the test run. 13 14 15 16 17 18 19 1A 1b 1c 1d 1E 1F Test run display (3) Press the start/stop button to stop the test run. [SELF-DIAGNOSIS] When the error indication "E:EE" is displayed, follow the following items to perform the self-diagnosis. "E:EE" indicates an error has occurred. 1. REMOTE CONTROLLER DISPLAY (1) Stop the air conditioner operation. simultaneously for 5 sec(2) Press the set temperature buttons onds or more to start the self-diagnosis. Refer to the following tables for the description of each error code. Unit number (usually 0) Error code Error contents Outdoor signal abnormal Excessive outdoor pressure (permanent stop) Compressor temperature sensor Pressure switch error IPM error CT error Active filter module (AFM) error Compressor does not operate Outdoor unit fan error Communication error (inverter multicontroller) 2 way valve sensor error Expansion valve error Connection indoor unit error SU MO TU WE TH FR SA Ex. Self-diagnosis 2. CHECKING DRAINAGE (3) Press the set temperature buttons onds or more to stop the self-diagnosis. Error code 00 01 02 03 04 05 06 08 09 0A 0c 11 12 2006.05.25 simultaneously for 5 sec- To check the drain, remove the water cover and fill with 2 to 3 of water as shown in figure. The drain pump operates when operating in the cooling mode. Error contents Communication error (indoor unit remote controller) Drain pipe Communication error (indoor unit outdoor unit) Room temperature sensor open Water cover Room temperature sensor short-circuited Indoor heat exchanger temperature sensor open Indoor heat exchanger temperature sensor shortcircuited Outdoor heat exchanger temperature sensor Watering pot Power source connection error Float switch operated Outdoor temperature sensor Discharge pipe temperature sensor Model abnormal Indoor fan abnormal 11 E RR O R CO N TEN TS ( out door uni t) 1. Make a TEST RUN in accordance with the installation instruction sheet for the indoor unit. 2. When the product is operating: 1 Press the PUMP DOWN switch on the outdoor unit. The LED on the outdoor unit circuit board lights, and operation stops. At this point, recovery has not been completed, so do not close the two- and three-way valves. 2 The pump down operation (cooling operation) begins after three minutes. Close the three-way valve (liquid) after operation starts. 3 After 2 - 3 minutes, operation stops. Close the threeway valve (gas) within one minute after operations stops. 4 The LED will go out three minutes after it stops. Disconnect the power supply after confirming that the LED has gone out. 2. OUTDOOR UNIT LEDS When a malfunction occurs in the outdoor unit, the LED on the circuit board lights to indicate the error. Refer to the following table for the description of each error according to the LED. LED Error contents 1 flash Communication error (Indoor unit - Outdoor unit) 2 flash Discharg pipe temperature sensor 3 flash Outdoor heat exchanger temperature sensor 4 flash Outdoor temperature sensor 7 flash Compressor temperature sensor 8 flash Heat sink temperature sensor 9 flash Pressure switch abnormal 12 flash IPM error 13 flash Compressor rotor position cannot detect 14 flash Compressor cannot operate 15 flash Outdoor fan abnormal (upper fan) 16 flash Outdoor fan abnormal (lower fan) lighting No error *When the pump down operation is repeated, temporarily disconnect the power supply after opening the closed valves (both liquid and gas). Reconnect the power supply after 2 - 3 minutes and perform the pump down operation. *When the start of the operation after pump down operation has been completed, temporarily disconnect the power supply after opening the closed valves (both liquid and gas). Reconnect the power supply after 2-3 minutes and be sure to perform a test operation for cooling. 3-way valve (Liquid) SPECIAL INSTALLATION SETTING PUMP DOWN (Refrigerant collecting operation) 3-way valve (Gas) Perform the following procedures to collect the refrigerant when moving the indoor unit or the outdoor unit. 1. When the product is stopped: PUMP DOWN SW (SW2) 1 Press the PUMP DOWN switch on the outdoor unit. (The LED on the outdoor unit circuit board lights.) 2 The pump down operation (cooling operation) begins right away. After oparation starts, close the three-way valve (liquid). 3 After 2 - 3 minutes, operation stops. Close the threeway valve (gas) within one minute after operations stops. 4 The LED will go out three minutes after it stops.Disconnect the power supply after confirming that the LED has gone out. DANGER This part (Choke coil) generates high voltages. Never touch this part. 2006.05.18 12 DIS AS S E MBLY IL L US T RATION 122 122 122 847 338 692 692 847 INDOOR UNIT 847 847 226 690 522 876-2 122 692 692 690 690 543 543 692 692 122 847 847 544 544 543 847 543 542 834-2 544 705 705 544 545 93 240 481 481 71 472-2 472-1 472-4 777-2 253-A 858 71 481 481-1 487 858 472-3 777-1 469 468 472-5 472-5 472-5 472-5 710 61 2006.05.25 13 INDOOR UNIT 462 479 187 460-1 460-2 484 835 803 484 467 127 835 482 464 484 798 465 244 814 563 541 334 815-1 541-1 168 484 164 474 476-2 146-2 565 337-2 477 146-1 197 197 337-1 337-1 160 834-1 457 223 514 457 2006.05.18 488 14 INDOOR UNIT 212 875 236 815-2 380 320-1 32 320-1 380 381-4 34 380 625 195 234 381-4 731-2 2006.05.18 15 INDOOR UNIT 187 138 184-1 235 735 896 2006.05.18 16 OUTDOOR UNIT 1 6 4 3 2 2006.05.25 5 17 OUTDOOR UNIT 10 13 9 11 17 18 15 8 2006.05.25 18 14 OUTDOOR UNIT 26 24 25 31 27 22 23 19 29 28 12 12 30 20 2006.05.24 19 OUTDOOR UNIT 38 37 36 35 33 34 2006.05.18 20 PARTS LIST INDOOR UNIT Ref. No 32 34 61 71 93 122 127 138 146-1 146-2 160 164 168 184-1 187 195 197 212 223 226 234 235 236 Control Box Assy Capacitor (Fan Motor) Decoration Plate Holder (Hook) Filter Holder(LouverSupporter) Drain Hose Separate wall Evaporator-A Assy Evaporator-B Assy Kit (Drain Pan Sub Assy) Motor, Induction Cabinet-E Thermistor Spring-A Clamp No. 1219 Binder-C Wind Guide Board Clamp NK-4N Control Box Motor Gear Room Temp. Thermistor Pipe Temp. Thermistor Controller PCB Assy 240 244 253-A 320-1 334 337-1 337-2 338 380 381-4 457 460-1 460-2 462 464 465 467 468 469 472-1 472-2 Remote Control Unit Pipe CoverAssy Wire Assy Wire Clamp Metal Wire Cover RFM (Eva. )-A RFM (Eva. )-B Motor Holder Locking Spacer Spacer RFM (Drain Pan) Pump Cover-A Pump Cover-B Panel(Top)Assy Cabinet-A Assy Cabinet-B Assy Drain Port M10 Nut-A (Large) M10 Nut-B (Small) RFM (Grille)-A RFM (Grille)-B Description Part No. MC24Y3F 67200589 67220259 67200591 67200557 67200555 67200569 67200548 67200600 67200601 67200602 67200603 67220260 67220210 67206400 67220226 67220227 67220261 67200453 67200590 67200572 67203505 67203506 67203713 (K01AL-05L1HSE-C1) 2006.06.13 67200604 67200605 67200606 67200607 67200608 67200609 67200610 67200573 67207455 67207464 67200503 67200611 67200612 67200592 67220206 67220207 67200551 67207462 67207463 67200560 67200561 Ord. Q'ty Ref. No 472-3 472-4 472-5 474 476-2 479 481 481-1 482 484 487 488 514 522 541 541-1 542 543 544 545 563 565 625 690 692 705 710 731-2 735 777-1 777-2 798 803 814 815-1 815-2 834-1 834-2 835 847 858 875 876-2 896 21 Description RFM (Grille)-C RFM (Grille)-D RFM (Grille)-E Turbo Fan Assy Washer(Turbo Fan) Float Switch Insulation (Grille)-A Insulation (Grille)-B Pump Unit Hook Hinge Wire (Grille) Drain Pan Plug ControlBox Cover Joint Gear TerminalBase TerminalCover PanelBase Holder (Panel Frame) Holder (Panel Base) Panel Frame InnerBox EvaporatorHolderAssy Cord Bushing Joint-A Joint Shaft LouverAssy Intake Grille Holder Distributor Assy Hook (Grille)-A Hook (Grille)-B Drain Pump Holder Cabinet-D Cabinet-C Terminal-3P Terminal-3P Cover(Wire)-A Cover(Wire)-B Cushion (Pump) LouverSupporter Spring (Grille) Power Supply PCB Assy Motor,Step Coupling Pipe Assy Part No. MC24Y3F 67200562 67200563 67200564 67200587 67207465 67200614 67200615 67200616 67200617 67200618 67200619 67200550 67200542 67200567 67201709 67201708 67200575 67500576 67500574 67200577 67200620 67200552 67230030 67200621 67200622 67200593 67200623 67200566 67200595 67200558 67200559 67200594 67220209 67220208 67200585 67200584 67200596 67200597 67200545 67200570 67200565 67200598 67200599 67200613 Ord. Q'ty OUTDOOR UNIT 2006.05.25 Ref. No 1 2 3 4 5 6 8 9 Top Panel Sub Assy Front Panel Fan Guard Grip Side Service Panel Sub Assy Right Panel Propeller Fan Assy Motor, Induction Part No. MR24UY3F 67201640 67201601 67201602 67201603 67201688 67201605 67201607 67201608 10 11 12 13 14 15 17 18 Condenser-A Assy CoilChoke Strainer Assy Separate Wall Assy Cap Foot Base Assy 3-Way Valve Assy (3/8) 3-Way Valve Assy (5/8) 67201609 67201633 67201611 67201647 67201650 67201648 67201614 67201615 19 20 22 23 24 25 26 27 Check Joint Assy CompressorAssy 4-Way Valve Solenoid Pressure Switch Inlet Pipe Cond A Assy Inlet Pipe Cond B Assy Outlet Pipe Cond A Assy 67201616 67201689 67201619 67201681 67201621 67201622 67201690 67201691 28 29 30 31 33 34 35 36 Expansion Valve Assy Coil (Expansion Valve) Distributor Discharge Pipe A Assy Terminal2P Terminal5P ACTPM Holder Thermo 67201692 67201422 67201693 67201694 67220181 67201632 67201627 67201628 37 38 ------------------- Inverter PCB Assy Power PCB Assy Fuse 3.15A-250V Thermistor (Outdoor Temp.) Heat Exchanger Thermistor Thermistor (Discharge) Compressor Thermistor Thermistor 67201695 67201696 67201697 67201686 67201698 67201635 67201637 67201430 ------------------------- Heatsink Thermistor Transformer Varistor Arrester Relay Relay Switch Push Switch Slide 67201685 67201699 67201700 67201701 67201702 67201703 67201704 67201705 ------- Drain Pipe Assy Drain Cap 67201706 67201707 Description 22 Ord. Q'ty STA N D A RD A C C ESSORIE S INDOOR UNIT ACCESSORIES Name and Shape Q’ty Coupler heat insulation 2 Tapping Screw (flush heads) 2 Special nut A (large flange) 4 Special nut B (small flange) 4 Application For indoor side pipe joint For installing the remote controller For installing indoor unit For installing indoor unit For ceiling hole cutting Template 1 Binder (small) 1 For fixing the remote controller cord For discharged air Blower cover insulation 2 For installing intake grille Hook wire 2 Remote controller 1 For connecting the remote controller Remote controller cord 1 OUTDOOR UNIT ACCESSORIES Name and Shape Q'ty Drain pipe 1 Drain cap 5 2006.05.25 23 Application For outdoor unit drain piping work (May not be supplied, depending on the model.) 0605G3089