Download Eaton Power-Sure 700

Transcript

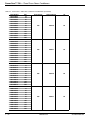

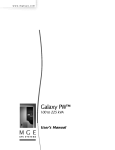

w w w. m g e o p s . c o m Power-Sure™ Three Phase Power Conditioners Installation and User Manual Power-Sure™ 700 — Three Phase Power Conditioners IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS – This manual contains important instructions for Power-Sure™ 700 that must be followed during operation of the equipment. WARNING Opening enclosures expose hazardous voltages. Always refer service to qualified personnel only. ATTENTION L'ouverture des cabinets expose des tensions dangereuses. Assurez-vous toujours que le service ne soit fait que par des personnes qualifiees. WARNUNG! Das öffnen der Gehäuse legen gefährliche Spannungen bloss. Service sollte immer nur von qualifizierten Personal durchgeführt werden. WARNING As standards, specifications, and designs are subject to change, please ask for confirmation of the information given in this publication. ATTENTION Comme les normes, spécifications et produits peuvent changer, veuillez demander confirmation des informations contenues dans cette publication. WARNUNG! Normen, Spezifizierungen und Pläne unterliegen Anderungen. Bitte verlangen Sie eine Bestätigung über alle Informationen, die in dieser Ausgabe gemacht wurden. NOTE This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at user's own expense. Certification Standards ◗ ANSI/IEEE C57.12.91 Standards ◗ IEEE C62.41 cat.A3 ◗ NFPA 70 – National Electrical Code ◗ FCC rules and regulations of Part 15, Subpart J, Class A ◗ UL listed under 1012, Power Supplies - General Purpose ◗ NEMA PE 1 (National Electrical Manufacturers Association) ◗ NEMA 250 (National Electrical Manufacturers Association) – Enclosures for Electrical Equipment (1000 Volts Maximum) ii ◗ ISO 9001 ◗ Occupational Safety & Health Administration (OSHA) Important Safety information 86-108814-00 B01 Installation and User Manual WARNING To reduce the risk of fire or electric shock, install in a temperature and humidity controlled indoor area free of conductive contaminants. This equipment is intended only for installations in a RESTRICTED ACCESS LOCATION. ATTENTION Pour réduire le riske d'inccendie ou d'électrocution, installer dans une enciente intérieure contrôlée en température et humidité et sans contaminants conducteurs. Ce matériel est destiné seulement pour des installations dans un EMPLACEMENT RESTREINT d'cAccès. WARNUNG! Um die Gefahr von Feuer und elektrischem Schock zu reduzieren, muss das Gerät in einem temperatur – und feuchtigkeitskontrollierten Raum, frei von leitungsfähigen Verunreinigungen, installiert werden. Dieses Gerät ist nur für die Installation an einem Ort mit eingeschränkter Zugangserlaubnis vorgesehen. Diese Ausrüstung ist nur für Anlagen in einem EINGESCHRäNKTEN ZUGRIFF STANDORT bestimmti. WARNING HIGH LEAKAGE CURRENT. Earth connection essential before connecting supply. ATTENTION COURANT DE FUITE ELEVE. Raccordement a la terre indispensable avant le raccordement au reseau. WARNUNG! Hoher Ableitstrom Vor Inbetriebnahme Schutzleiterverbindung herstellen. How to use this manual and Symbol Usage This manual is designed for ease of use and easy location of information. Locate specific topics in the Table of Contents. Typographical conventions use single quote marks in procedures to denote a prompt for user action: For example: 1. After the selections are complete, click on the “Save” button. This manual uses four icon symbols with text to convey important information and tips. 86-108814-00 B01 WARNING indicates information provided to protect the user and service personnel against safety hazards and/or possible equipment damage. CAUTION indicates information provided to protect the user and service personnel against possible equipment damage. IMPORTANT indicates information provided as an operating instruction, or as an operating tip. NOTE indicates information provided as an operating tip or an equipment feature. How To Use This Manual iii Power-Sure™ 700 — Three Phase Power Conditioners CAUTION: Record All Serial Numbers! RECORD ALL SERIAL NUMBERS FOR THE POWER-SURE™ 700 AND COMPONENTS. THESE SERIAL NUMBERS WILL BE REQUIRED IF YOUR SYSTEM NEEDS SERVICE. KEEP THIS MANUAL IN A PLACE WHERE YOU CAN REFERENCE THE SERIAL NUMBERS IF SERVICE IS REQUIRED! POWER-SURE™ 700 SERIAL NUMBER: _______________________________________________ ADDITIONAL SERIAL NUMBERS: iv ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ ____________________________ ______________________________ CAUTION: Record All Serial Numbers 86-108814-00 B01 Installation and User Manual Power-Sure™ 700 Three Phase Power Conditioners Installation and User Manual Revision History Power-Sure™ 700 Three Phase Power Conditioners Installation and User Manual Revision: A00 Initial Release 09/2003 A01 ECN#: 003787 02/2004 B00 ECN#: 004681 08/2006 B01 ECN#: 005088 12/2006 86-108814-00 Copyright © 2007 MGE Office Protection Systems All rights reserved. Printed in U.S.A. MGE Office Protection Systems 13 Whatney, Suite #101 Irvine, CA 92618 (949) 268-2800 For Technical Support, Customer Care Center, or Customer FAQ, please visit our website: www.mgeops.com or call (800) 279-7776 86-108814-00 B01 v Power-Sure™ 700 — Three Phase Power Conditioners (This page left blank intentionally) vi 86-108814-00 B01 Installation and User Manual Contents section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .ii Certification Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii How to Use This Manual and Symbol Usage . . . . . . . . . . . . . . . . . . .iii CAUTION: Record All Serial Numbers! . . . . . . . . . . . . . . . . . . . . . . . .iv Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v Section 1 Introduction section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1.0 1.1 1.2 1.3 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1 Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1 Section Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1 Receiving and Inspection Notes . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2 Location and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2 Electrical and Performance Specifications . . . . . . . . . . . . . . . . . 1 — 3 Main Transformer Specification . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 3 Input Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4 Monitoring the Power-Sure™ 700 . . . . . . . . . . . . . . . . . . . . . . . .1 — 4 Protection for the Power-Sure™ 700 . . . . . . . . . . . . . . . . . . . . . .1 — 4 1.3.1 1.4 1.4.1 1.4.2 1.4.3 1.5 1.6 Section 2 Installation and Operation section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2.0 2.1 2.2 2.3 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1 Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1 MGE Office Protection Systems Power-Sure™ 700 . . . . . . . . . .2 — 1 Power-Sure™ 700 Installation Drawings and Cabinet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2 General Operation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 5 Power-Sure™ 700 Cable Connections . . . . . . . . . . . . . . . . . . . .2 — 6 Input Wire Size, Grounding and Output Wiring . . . . . . . . . . . . . .2 — 6 Start-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8 2.4 2.5 2.5.1 2.6 86-108814-00 B01 Contents ci Power-Sure™ 700 — Three Phase Power Conditioners Section 3 Maintenance section 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11 3.12 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1 Power-Sure™ 700 Performance Checklist . . . . . . . . . . . . . . . . . .3 — 2 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 — 4 Troubleshooting Power Line and Electrical Connections . . . . . . .3 — 5 3.3.1 Step 1. Disassembling the Power Conditioners . . . . . . . . . . . . . .3 — 5 3.3.2 Step 2. Electrical Connections, Fuses . . . . . . . . . . . . . . . . . . . . .3 — 5 Checking the Power Modules (SCR) . . . . . . . . . . . . . . . . . . . . . .3 — 5 Check SCR Snubber Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6 3.5.1 Check Control Card and Filter Card . . . . . . . . . . . . . . . . . . . . . . .3 — 7 Final Testing and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 8 Unit Component Location Diagrams . . . . . . . . . . . . . . . . . . . . . .3 — 9 SCR Heat Sink Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 12 Field Adjustments of Circuit Cards . . . . . . . . . . . . . . . . . . . . . . .3 — 15 3.9.1 Power-Sure™ 700 Control Card #49120/407415 . . . . . . . . . . .3 — 15 3.9.2 Control Card Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . .3 — 16 3.9.3 Over/Under Voltage Detection Board #35867 . . . . . . . . . . . . . .3 — 17 3.9.3.1 Undervoltage Adjustment . . . . . . . . . . . . . . . . . . . . . . .3 — 17 3.9.3.2 Overvoltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . .3 — 17 3.9.3.3 Delay Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 18 Manual Bypass Switch Option . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 18 3.10.1 Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 18 3.10.2 Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 18 3.10.3 Remote Emergency Power OFF (REPO) (Optional) . . . . . . . . .3 — 18 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 19 Parts Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 19 Appendices Appendix A A-1: A-2: A-3: 10-50kVA Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 1 75-150kVA Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 2 125-300kVA Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 3 Technical Support and Field Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 3 MGE Office Protection Systems Service and Repair Who to Contact Scheduling Field Service Engineer Support Return for Repair (RMA) c ii Contents 86-108814-00 B01 Installation and User Manual Figures figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-1: 2-2: 2-3: 2-4: Power-Sure™ Power-Sure™ Power-Sure™ Power-Sure™ 700 700 700 700 — — — — 10-15kVA Mechanical Cabinet Measurements . . .2 — 2 25-30kVA Mechanical Cabinet Measurements . . .2 — 3 45-150kVA Mechanical Cabinet Measurements . .2 — 4 225-300kVA Mechanical Cabinet Measurements .2 — 5 3-1: 3-2: 3-3: 3-4: 3-5: 3-6: Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5 Test Wire Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6 Power-Sure™ 700 — 10-15kVA Major Components . . . . . . . . . . . . . . . .3 — 9 Power-Sure™ 700 — 25-30kVA Major Components (Rear View) . . . . . .3 — 9 Power-Sure™ 700 — 45-150kVA Major Components (Rear View) . . . .3 — 10 Power-Sure™ 700 — 225-300kVA Cable Connections, Input Output Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 11 3-7: Power-Sure™ 700 — 10-30kVA SCR Heatsink Assembly . . . . . . . . . .3 — 12 3-8: Power-Sure™ 700 — 45-50kVA SCR Heatsink Assembly . . . . . . . . . .3 — 13 3-9: Power-Sure™ 700 — 75-150kVA SCR Heatsink Assembly . . . . . . . . .3 — 14 3-10: Power-Sure™ 700 — 225-300kVA SCR Heatsink Assembly . . . . . . . .3 — 15 3-11: Power-Sure™ 700 Controller Card (Top View) . . . . . . . . . . . . . . . . . . .3 — 16 Tables table description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 86-108814-00 B01 2-1: 2-2: 480 VAC Input and 208 VAC Output Wire Size Chart . . . . . . . . . . . . . . .2 — 7 208 VAC Input and 208 VAC Output Wire Size Chart . . . . . . . . . . . . . . .2 — 7 3-1: Power-Sure™ 700 Power Conditioners Part Numbers . . . . . . . . . . . . .3 — 19 Contents c iii Power-Sure™ 700 — Three Phase Power Conditioners (This page left blank intentionally) c iv 86-108814-00 B01 Installation and User Manual Introduction 1.0 Scope This section is a general description of the Power-Sure™ 700 Three Phase Power Conditioners. Includes receiving, location and storage, electrical, mechanical specifications, monitoring, and internal protection for components. 1.1 Reference Manuals N/A 1.2 Section Descriptions This manual is divided into three sections: Section 1: Introduction This section is a general description of the Power-Sure™ 700 Three Phase Power Conditioners. It includes receiving, location and storage, electrical and mechanical specifications, monitoring and internal protection for components. Section 2: Installation and Operation This section describes installation requirements, system dimensions, cable connections, and start-up procedures for the Power-Sure™ 700 Three Phase Power Conditioners. Section 3: Maintenance This section contains preventive maintenance for the Power-Sure™ 700, electrical connection troubleshooting, checking power modules (SCR), voltage adjustments, and PCB card troubleshooting to assist the user with communication and configuration connections. 86-108814-00 B01 Introduction 1—1 Power-Sure™ 700 — Three Phase Power Conditioners 1.3 Receiving and Inspection Notes Before accepting the shipment from the freight carrier, inspect the exterior surfaces of all shipping containers or packaging used, and the equipment, for damage that may have occurred during transit. If the shipping containers or equipment shows evidence of damage, note the damage on the receiving document (bill of lading) prior to signing for receipt of equipment. ALL CLAIMS FOR SHIPPING DAMAGE MUST BE FILED DIRECTLY WITH THE CARRIER. Replacements for damaged components should be ordered through MGE Office Protection Systems. Check by thorough inspection if any electrical connections have become loose because of vibration during shipment. Remove top and side panels (Not applicable on 225kVA and larger). Check the nameplate to be sure that the voltage and frequency match the available power supply. Under no circumstance should the unit be connected to a power source which does not conform to the nameplate rating. 1.3.1 Location and Storage The unit has been completely inspected and extensively tested under various load conditions prior to shipment. Care to install it at a proper location will assure long trouble free operation. The unit is forced air cooled with the air intake at the bottom, front or sides and exhausts out at the top or rear. Therefore, it should be installed in a clean, dry place with enough clearance to allow a free flow of air. Allow at least 4 inches of space between the unit and the wall or other equipment for portable units. Allow enough space for maintenance as indicated on the cabinet outlines. See Section 2.0, Figures 2-1 thru 2-4. If the equipment is to be stored prior to installation, it should be stored in a cool, dry, well-ventilated location that is protected from rain, splashing water, chemical agents, etc. The equipment should be covered with a tarpaulin or plastic wrapper to protect it against dust, dirt, paint, or other foreign materials. 1.4 General Description The Power-Sure™ 700 is a continuous duty power conditioner designed to supply reliable, clean regulated power to critical loads. An efficient design with state of the art micro-processor controlled solid state devices provide immunity to all line disturbances. The cabinet is a heavy gauge industrial steel throughout. Metal is anti-corrosive phosphate treated prior to paint. Paint is a baked finish. The basic design consists of a three phase triple shielded isolation transformer with seven separate voltage taps per phase. Output regulation is achieved by monitoring the input and automatically switching taps anytime the input line sags or surges. The use of a triple shielded isolation transformer provides superior common mode and transverse mode noise attenuation. Automatic switching occurs during current zero allowing noise free switches for both leading and lagging power factor loads that are connected to the Power-Sure™ 700. The Power-Sure™ 700 Power Conditioner is operated by simply turning on the main AC input circuit breaker. As an option, units may have a bypass switch. This is a no load switch and MUST only be operated when the unit is OFF. The bypass switch should be in the “NORMAL” position unless a problem occurs with the system. If a problem occurs, turn OFF the main AC circuit breaker and turn the bypass switch to the “BYPASS” position. Re-energize the system by turning on the AC circuit breaker and contact the Customer Care Center for repairs. Any ‘ALERT” condition requires the main AC input breaker to be turned off in order to reset the “ALERT” light. 1—2 Introduction - Description 86-108814-00 B01 Installation and User Manual 1.4.1 Electrical and Performance Specifications *Output Maintained to within ± 3% of nominal. *Input +10% to -20% of the nominal rated input. *Frequency 60 Hertz ± 3 Hertz. Efficiency 95% Minimum. Line Regulation Output is ± 3% of nominal for input variations of +10% to -20% of nominal. Load Regulation Output maintained within 3% from no load to full load. Response Time 1/2 Cycle. Correction Time Output will correct in one step to within ±3% of nominal in 1.5 cycles or less. Harmonic Distortion Adds less than 1.0% THD. Transverse-Mode Noise Attenuation 3 dB down at 1000 Hertz, 40 dB decade to below 50 dB with resistive load. Common-Mode Noise Attenuation 120 dB or greater. Audible Noise 45 dB to 55 dB, depending on kVA rating. Turn On Characteristics When energized voltage overshoot will be less than 5% of nominal for 1 cycle or less. Overload Rating 1000% for 1 cycle and 200% for 10 seconds. Ambient Rating -10 to +40 degrees Celsius. *Optional extended input regulation range provided on some units. If provided, reference description next to the units specification tag. 50 Hz models available. Listed to UL1012, Standard for “power units other than Class 2”. 1.4.2 Main Transformer Specification Windings All copper. Magnetics Grain orientated, M6 grade, stress relieved transformer steel is utilized for minimum losses and maximum efficiency. Insulation Class (N) 200 all sizes. Shielding Multiple triple copper shield to minimize interwinding capacitance, transient, and noise coupling between primary and secondary windings. Cooling Convection, operating temp is 130 degrees Celsius maximum rise above ambient. Isolation Output is fully isolated from input. 86-108814-00 B01 Introduction - Specifications 1—3 Power-Sure™ 700 — Three Phase Power Conditioners 1.4.3 Input Breaker Main input molded case circuit breaker, rated at 125% of full load input current. 1.5 Monitoring the Power-Sure™ 700 Monitoring of the Power-Sure™ 700 is simple, clean, and effective. Three green light indicators are utilized to display “POWER ON” (output line to neutral for each phase) and one red light indicator to display “ALERT”. The “POWER ON” display is connected directly to the output that indicates the Power-Sure™ 700 is operating properly with just a quick glance. The “ALERT” display represents an overtemp problem or output voltage loss (optional) when illuminated, and will shut down the output, but cooling fans remain on. Overtemp thermal sensors are strategically located at critical points on the regulator assemblies and transformer. The main AC input circuit breaker must be turned off in order to reset the “ALERT” light. 1.6 Protection for the Power-Sure™ 700 Protection is accomplished very effectively to minimize failures and the cost of repairs by the four major methods listed below: 1. The input is protected with a integrally mounted AC circuit breaker for abnormal current overloads and provides a convenient means of disconnecting utility power. As an option, the input breaker may be equipped with a shunt trip device that is interfaced with a REMOTE EMERGENCY POWER OFF PUSH BUTTON. By pressing this button, the input breaker will trip and disable the Power-Sure™ 700 completely. The input breaker must be physically reset before unit will turn on again. 1—4 2. The electronic regulating devices are protected with fast acting semi-conductor fuses. These fuses are designed to clear before damage occurs to the more expensive SCR regulating devices. The main transformer is protected by fuse links connecting the SCR regulators together, and are designed to clear in the event that two or more SCRs should fail. This will prevent a transformer tap short and the possibility of transformer failure. 3. When provided with the optional Under/Over Voltage Shutdown Card (UOV2020), the output of the Power-Sure™ 700 is constantly monitored for extreme over and under voltage conditions. This card monitors each output phase and will electronically disable the Power-Sure™ 700 when any phase exceeds +10% or -10% of nominal output voltage. 4. Overtemp sensing devices are mounted at critical points on the SCR regulating assembly and the main transformer. When an overtemp condition exists the “ALERT” light will illuminate and hold until the overtemp is corrected. There are no automatic shutoff circuits for the “ALERT” condition. The main AC input breaker must be turned off in order to reset the “ALERT” light. Introduction - Protection 86-108814-00 B01 Installation and User Manual Installation and Operation 2.0 Scope This section describes installation requirements, system dimensions, cable connections, and start-up procedures for the Power-Sure™ 700 Three Phase Power Conditioners. WARNING: 2.1 HIGH VOLTAGE, ONLY QUALIFIED ELECTRICIANS SHOULD INSTALL OR PERFORM MAINTENANCE. Installation Notes ◗ The Power-Sure™ 700 requires ventilation. Reference Section 1.3.1 for cabinet placement for each model. ◗ After installation is complete, verify the output voltage is within its rated specifications. ◗ Provide overcurrent protection per article NFPA 70 latest revision article 450-3(b). ◗ Optional output cables must be specified in lengths of 10 feet, cables may have receptacles on the terminating end. ◗ For installation of conduit, reference NEC Article 348 and 350 and any applicable local electrical codes. Refer to the following installation diagrams for electrical hookup. 2.2 MGE Office Protection Systems Power-Sure™ 700 An efficient installation depends on careful planning and site preparation. Installation of the equipment must be handled by skilled technicians and electricians familiar with the special requirements of high-voltage electrical equipment. The installation must comply with the requirements of the National Electrical Code (ANSI/NFPA 70, latest issue) and local codes as applicable, and safety standard, UL1012 listed; UL1449 compliant; meets FCC Cat. A. We strongly recommend contacting MGE Office Protection Systems for system start-up. Do not allow unqualified personnel to handle, install, or operate the Power-Sure™ 700. A good way to insure that the Power-Sure™ 700 is sized properly is to use the following guide lines: ◗ List each piece of equipment, include Model, Voltage, Current and kVA. ◗ Calculate kVA of load plus a safety margin. ◗ When this is not possible, gather the data by reading the specification plate of the equipment you plan on backing up. ◗ One method is to ask the vendor of the computer equipment to supply you with the information you need. ◗ Be sure to verify the input supply voltage and the output requirements of the Power-Sure™ 700. 86-108814-00 B01 Installation and Operation 2—1 Power-Sure™ 700 — Three Phase Power Conditioners 2.3 Power-Sure™ 700 Installation Drawings and Cabinet Dimensions When sizing the Power-Sure™ 700, be sure to take into consideration all loads and circuits the Power-Sure™ 700 is to supply. Figure 2-1: Power-Sure™ 700 — 10-15kVA Mechanical Cabinet Measurements. 12" (304.80m) FOR INSTALLATION PURPOSES ONLY TO REMOVE TOP: REMOVE RETAINING SCREW IN REAR OF TOP, LIFT REAR AND SLIDE FORWARD TO REMOVE SIDE: REMOVE RETAINING SCREW IN TOP OF PANEL, LIFT PANEL STRAIGHT UP 12" (304.80m) FOR INSTALLATION PURPOSES ONLY 24" (609.60m) CLEARANCE FOR SERVICEABILITY ENVIRONMENTAL CLEARNESS TOP VIEW INPUT BREAKER 29" (736.60m) 21.5" (546.10m) INPUT TERMINALS ALLEN BRADLEY #1492-CE2 #12-I/O WIRE “ON” LIGHTS OUTPUT ALERT A B C CONDITIONED POWER INPUT GROUND TERMINAL ILSCO #TA-2 #2-#14 WIRE “ALERT” LIGHTS COOLING FANS HOLE PROVIDED FOR 1 INPUT CONDUIT 30" (762m) G N L3 L2 L1 H1 H2 H3 OUTPUT DISTRIBUTION (OPTIONAL) OPTIONAL BYPASS FRONT VIEW 2—2 RIGHT SIDE VIEW Installation and Operation HOLE PROVIDED 1 OUTPUT CONDUIT REAR VIEW OUTPUT TERMINALS CONSISTS OF PK9 GROUNDING BAR WIRE: 14 ga. - 4 ga. & ta 2/0 lug WIRE: 14 ga - 2/0 86-108814-00 B01 Installation and User Manual Figure 2-2: Power-Sure™ 700 — 25-30kVA Mechanical Cabinet Measurements. 12" (304.8m) FOR INSTALLATION PURPOSES ONLY TO REMOVE TOP: REMOVE RETAINING SCREW IN REAR OF TOP, LIFT REAR AND SLIDE FORWARD 12" (304.8m) FOR INSTALLATION PURPOSES ONLY 24" (609.6m) CLEARANCE FOR SERVICEABILITY ENVIRONMENTAL CLEARNESS TO REMOVE SIDE: REMOVE RETAINING SCREW IN TOP OF PANEL, LIFT PANEL STRAIGHT UP TOP VIEW 21.5" (546.1m) POWER ON 29" (736.6m) INPUT CIRCUIT BREAKER ALERT BYPASS SWITCH (OPTIONAL) INPUT TERMINALS ALLEN BRADLEY 31492 -CE2 #12-I/O WIRE COOLING FANS INPUT GROUND TERMINAL ILSCD #TA-2 #2-#14 WIRE 44" (1117.6m) HOLE PROVIDED FOR 1 INPUT CONDUIT OUTPUT DISTRIBUTION (OPTIONAL) HOLE PROVIDED 1 OUTPUT CONDUIT OUTPUT TERMINALS ILSCOTA2/0 WIRE RANGE: #14 AWG-2/0 PK9 WIRE RANGE: 14GA. -#4AWG FRONT VIEW 86-108814-00 B01 RIGHT SIDE VIEW Installation and Operation REAR VIEW 2—3 Power-Sure™ 700 — Three Phase Power Conditioners Figure 2-3: Power-Sure™ 700 — 45-150kVA Mechanical Cabinet Measurements. 12.000 FOR INSTALLATION PURPOSES ONLY 24.000 CLEARANCE FOR SERVICEABILITY 12.000 FOR INSTALLATION PURPOSES ONLY ENVIRONMENTAL CLEARNESS TOP VIEW FRONT 45.000 29.000 "ON" LIGHTS OUTPUT "ALERT" LIGHT ALERT A B C CONDITIONED POWER PREFERED INPUT CONDUIT LOCATION PREFERED OUTPUT CONDUIT LOCATION 44.000 5.500 12.000 RIGHT SIDE VIEW FRONT VIEW *NOTE: RIGHT SIDE PANEL MAY USED FOR OPTIONAL INPUT & OUTPUT CONDUIT LOCATIONS. INPUT CIRCUIT BREAKER BY-PASS SWITCH (OPTIONAL) COOLING FANS 1.500 1.000 .750 .500 ÿ 0.312 ÿ 0.312 1.000 1.000 .25" COPPER BAR .25" COPPER BAR INPUT TERMINATION OUTPUT TERMINATION H1 H2 H3 G L1 L2 L3 N G 3.500 RECOMMENDED INPUT CONDUIT LOCATION (SEE NOTE) 2—4 27.000 9.000 FIELD WIRING TERMINALS ACCESS COVER REAR VIEW RECOMMENDED OUTPUT CONDUIT LOCATION (SEE NOTE) Installation and Operation 86-108814-00 B01 Installation and User Manual Figure 2-4: Power-Sure™ 700 — 225-300kVA Mechanical Cabinet Measurements. 6" CLEARANCE REQUIRED (THIS SIDE) OUTPUT TERMINALS LIFT-OFF ACCESS PANEL OUTPUT ACCESS PLATE LIFT-OFF ACCESS PANEL 1.75" (44.45m) CABINET COOLING FAN EDGE FRAMING FOR SCREENING (18 GAGE .047 THICK STEEL) 1.73" (43.94m) 5" CLEARANCE REQUIRED (THIS SIDE) OUTPUT CONDUIT LOCATION 36" CLEARANCE REQUIRED (THIS SIDE) INPUT CONDUIT LOCATION METAL – LAYER 1 (1.47D X 1.47W , 120 THICK) 1" (25.4m) 4.625" (117.47m) 2" (50.8m) 1" (25.4m) 8" (203.2m) METAL (GALVANIZED STEEL – LAYER 2 (1.25D X 1.25W , 120 THICK) 5.25" (133.35m) 8" (203.2m) LIFT-OFF ACCESS PANEL 45" (1143m) Clearance OUTPUT TERMINAL DETAIL .25 X 4 COPPER BUSS 9" (228.6m) TOP VIEW EDGE FRAMING FOR SCREENING (18 GAGE .047 THICK STEEL) 5.5" (139.7m) LAYER 2 32" (1812.8m) LAYER 1 3.25" (82.55m) POWER ON 32" (1812.8m) ALERT 4.625" (117.47m) INPUT CIRCUIT BREAKER (TERMINATE INPUT CABLES AT CIRCUIT BREAKER) 77.207" (159.9m) 2.75" (69.85m) G N L3 L2 L1 OPTIONAL BYPASS SWITCH (OPEN DOOR FOR ACCESS) 35" (889m) 2.75" (69.85m) 41.5" (1054.1m) LEFT SIDE VIEW 2.4 OUTPUT TERMINALS CUSTOMER SIDE 50.5" (1282.7m) 56" (1422.4m) FRONT VIEW CLEARANCE HOLE FOR 1/2" MOUNTING BOLT RIGHT SIDE VIEW REAR VIEW General Operation Notes The Power-Sure™ 700 Power Conditioners provides the triple function of isolation, noise attenuation and voltage regulation. The first two functions are provided by the power transformer, where as the third function of voltage regulation is achieved through solid state thyristors (SCRs) connected to taps on the power transformer. A micro-processor monitors and controls the overall function of regulating the system. The power transformer is manufactured with a unique method of shielding which produces very low capacitive coupling between the primary and secondary. This low coupling provides excellent attenuation of the common-mode noise. In addition, special care is taken in the design of the transformer to attenuate transverse-mode noise above 1000 Hz. The power transformer has taps to which solid state switches (SCRs) are connected. The voltage regulator incorporated in the Power-Sure™ 700 Power Conditioners is microprocessor controlled to achieve optimum correction time of input voltage sags and surges. The response time is typically one (1/2) cycle for 100% correction, therefore, a very smooth switch takes place undetected by computer equipment. 86-108814-00 B01 Installation and Operation 2—5 Power-Sure™ 700 — Three Phase Power Conditioners As the input voltage (building power) varies, the voltage available at each tap of the transformer will also change. The amount of variation is dependent upon the input sag or surge, turns ratio and transformer losses. By selecting a particular tap voltage, the output can be kept within a tight range. The way in which this is accomplished is that an electronic control card using a micro-processor continually monitors the input voltage. When a voltage fluctuation occurs, which exceeds the limit of rated regulation (typically ± 3%), the output is switched to another tap, that is within the required range. This switch will be made at the next current zero crossing to allow for both leading and lagging power loads to be connected to the conditioner. 2.5 Power-Sure™ 700 Cable Connections 2.5.1 Input Wire Size, Grounding, and Output Wiring ◗ Conduit should be used for both input and output wiring. ◗ Minimum ground wire size is based on 1990 Nation Electric Code Table 250-95. ◗ Input wire size is based on 1990 NEC Table 310-16 specifying not more than 3 conductors in a raceway based on ambient of 30 degrees Celsius, and wire rated at 75 degrees Celsius. ◗ Output neutral to ground is already bonded during manufacturing of Power Conditioner. ◗ Output requires 4 (5 including ground wire) conductors in a raceway assuming neutral as a current carrying conductor. This requires conductors to be derated by using a multiplier of .8, reference 1990 NEC Article 310 Section 8A. Example: 1. Assume #10 wire max current = 25 Amps. 2. Multiply 25 x .8 = 20. 3. 20 Amps is max current for #10 wire in a raceway with 4 conductors. NOTE: 2—6 Installation is subject to local codes – verify with a local electrical inspector. Installation and Operation 86-108814-00 B01 Installation and User Manual Table 2-1: 480 VAC Input and 208 VAC Output Wire Size Chart. Unit Size in kVA 10 Input Breaker Size 15 Amp Input Wire Size #10 Minimum Ground Wire Size #10 Maximum Output Current 28 15 25 Amp #10 #8 42 25 50 Amp #8 #4 70 30 50 Amp #8 #4 83 45 80 Amp #6 #2 125 50 80 Amp #6 #2 139 75 125 Amp #1 #6 208 100 150 Amp 1/0 4/0 278 125 200 Amp 1/0 2 pcs 1/0 347 150 225 Amp 1/0 2 pcs 2/0 417 225 350 Amp 4/0 2 pcs 250 625 300 500 Amp 2 pcs 2/0 3 pcs 250 833 Table based on 480 VAC input and 208 VAC output. Table 2-2: 208 VAC Input and 208 VAC Output Wire Size Chart. Unit Size in kVA 10 Input Breaker Size 40 Amp Input Wire Size #8 Minimum Ground Wire Size #10 Maximum Output Current 28 15 60 Amp #8 #8 42 25 110 Amp #4 #4 70 30 110 Amp #4 #4 83 45 175 Amp #1 #2 125 50 175 Amp #1 #2 139 75 300 Amp 2/0 2/0 208 100 350 Amp 4/0 4/0 278 125 450 Amp 2 pcs 1/0 2 pcs 1/0 347 150 600 Amp 2 pcs 3/0 2 pcs 3/0 417 225 800 Amp 2 pcs 250 2 pcs 250 625 300 1200 Amp 3 pcs 250 3 pcs 250 833 Table based on 208 VAC input and 208 VAC output. NOTE: 86-108814-00 B01 Refer to NEC for output wire size based on output breaker size and Article 310 Section 8A. Installation and Operation 2—7 Power-Sure™ 700 — Three Phase Power Conditioners 2.6 Start-Up Sequence WARNING: THERE ARE DANGEROUSLY HIGH VOLTAGES PRESENT WITHIN THE ENCLOSURE OF THE POWER SUPPLY SYSTEM. CAUTION MUST BE TAKEN WHEN WORKING WITH THE ENCLOSURE. IT IS RECOMMENDED THAT ALL WORK BE PERFORMED BY QUALIFIED ELECTRICAL PERSONNEL ONLY. NOTE: INITIAL START-UP SHOULD BE PERFORMED WITH NO-LOAD ON THE SYSTEM. 2—8 1. Re-install all panels that may have been removed during installation. 2. Make sure the input circuit breaker is in the off position. 3. Energize the primary building power. 4. Turn on the main AC input breaker. 5. Verify that the output voltage is within the specified range. 6. Verify output phase rotation is correct. 7. Turn the system off. 8. Connect the loads one at a time and repeat Step 5. Installation and Operation 86-108814-00 B01 Installation and User Manual Maintenance 3.0 Scope This section contains preventive maintenance for the Power-Sure™ 700, electrical connection troubleshooting, checking power modules (SCR), voltage adjustments, and PCB card troubleshooting to assist the user with communication and configuration connections. WARNING: 3.1 HIGH VOLTAGE DANGER OF ELECTRICAL SHOCK, TURN OFF ALL POWER SUPPLING THIS EQUIPMENT PRIOR TO MAINTENANCE. ONLY QUALIFIED ELECTRICIANS SHOULD PERFORM MAINTENANCE OR TROUBLE SHOOTING. Preventive Maintenance To ensure longer component life and trouble free operation, minor preventive maintenance procedures should be performed at regular intervals, recommended once every year. More frequent inspection intervals would be needed for more severe operation conditions and and larger number of hours of continuous operation. At each service inspection, remove any dust, dirt or foreign particles. Thoroughly inspect and tighten any loose electrical connections. A slight tug should be used to test if there are any loose electrical connections. Make sure all cooling fans are running. A. At each service inspection, remove top and side panels and carefully remove any accumulated dust, dirt, or foreign particles. Special care should be exercised in cleaning the thyristors, heat sinks, and the control assembly. B. Inverse Parallel Silicon Rectifiers (SCRs) or Thyristors. The silicon controlled rectifiers (SCRs) usually fail in the shorted mode. When this happens, normally the fusible link within the SCR will be blown open to clear the short and prevent damage to the transformers. The individual SCR can be checked with an ohmmeter. Refer to Section 3.4 for resistance checking procedures. C. A simple performance checklist has been developed for use in maintenance, on pages 3-2 and 3-3. Check off items 1-8. D. After items 1-8 have been checked on the performance checklist, the next step is to check the operation of the system. E. Replace top and side panels. Turn unit on with no load. Check item 9 on the performance checklist. F. Turn on loads and check items 10-13 of the performance checklist. NOTE: 86-108814-00 B01 Preventive Maintenance plans are available. Please contact the Customer Care Center for information. Maintenance 3 —1 Power-Sure™ 700 — Three Phase Power Conditioners Power-Sure™ 700 Performance Checklist Company: ____________________________________________________________________________________ Model #:_________________________________________Serial #: ______________________________________ 1. Customer Comments or Problems: ______________________________________________________________________________________________ 2. Power Conditioner Environment (clean and dust free): Yes__________ No__________ 3. Phase Rotation Correct (ABC): Yes__________ No__________ 4. Electrically wired properly (ie., conductor sizing, breakers, grounding): ____________________________ 5. Verify Input Voltage (see spec. tag): ______________________________________________________________________________________________ 6. Check Tightness of Electrical Connections: Input Connections__________ Output Connections__________ Heatsink Connections (SCRs) __________ Circuit Board Connections__________ By-Pass Switch__________ Fuse Connections__________________ Fan Connections__________ Transformer Connections__________ 7. Exercise all Circuit Breakers: Input Breaker____________________________ Output Breakers __________________________________ 8. Resistance Check of all Semiconductors Power Modules (SCRs): NOTE: 3 —2 Phase A Phase B Phase C _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ _______ Must remove Semiconductor Fuses from circuit prior to resistance checking SCRs. Maintenance 86-108814-00 B01 Installation and User Manual Power-Sure™ 700 Performance Checklist 9. 10. 11. (Continued) Input/Output Voltage Checks (Adjust as needed): No Load Input No Load Output A-B____________VAC AN____________VAC A-B____________VAC B-C____________VAC BN____________VAC B-C____________VAC A-C____________VAC CN____________VAC A-C____________VAC Available Load Input Available Load Output A-B____________VAC AN____________VAC A-B____________VAC B-C____________VAC BN____________VAC B-C____________VAC A-C____________VAC CN____________VAC A-C____________VAC Input/Output Current Checks (Balance as needed): Input Output A____________Amps A____________Amps B____________Amps B____________Amps C____________Amps C____________Amps N____________Amps G____________Amps 12. Fans Operational: _________________________________________________________________________________________ 13. Testing Shutdown Circuitry ie...REPO, Over/Under Voltage: _________________________________________________________________________________________ 14. Comments: _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ _________________________________________________________________________________________ 86-108814-00 B01 Maintenance 3 —3 Power-Sure™ 700 — Three Phase Power Conditioners 3.2 Troubleshooting Guide SYMPTOM PROBABLE CAUSES 1. No Output on One or More Phases. A. B. C. D. E. Blown Fuse. Defective SCR or Power Module Defective Control Card. Defective Sense Card. No Input. 2. Output is to High or to Low. A. B. C. D. E. Control Card Adjustment. Defective Control Card. Defective Sense Card. Defective SCR or Power Module Input Out of Range. 3. Input Breaker Tripping Off. A. Defective Breaker. B. System Overloaded. C. Over/Under Voltage Detection is Shutting Down System (See Symptom #2). D. Defective Over/Under Detection Card. E. Shorted Taps. 4. Blowing Semi-Conductor Fuses. A. Shorted SCRs or Power Modules B. Output Loads Shorted. 5. No Output Voltage. A. Defective Over/Under Output Detection PCB. WARNING: 3.3 THERE ARE DANGEROUSLY HIGH VOLTAGES PRESENT WITHIN THE ENCLOSURE OF THE POWER SUPPLY SYSTEM. UNDER NO CIRCUMSTANCES SHOULD ANY PERSON REACH WITHIN THE ENCLOSURE OF THIS EQUIPMENT. ALL SERVICE TO THIS PIECE OF EQUIPMENT SHOULD BE PERFORMED BY QUALIFIED PERSONNEL ONLY. Troubleshooting Power Line and Electrical Connections NOTE: Circuit diagrams in this manual are for reference only. Always refer to the actual circuit diagrams received with the system. This procedure is written in a specific order and must be used from start to finish when troubleshooting. Any steps skipped over may cause serious damage to the system. Required equipment for troubleshooting the Power-Sure™ 700 is a True RMS Digital multimeter, SCR tester, common hand tools, and a spare parts kit. 3 —4 Maintenance 86-108814-00 B01 Installation and User Manual 3.3.1 Step 1. Disassembling the Power Conditioners 1. Turn off the power to the conditioner at its source. 2. Turn off the input circuit breaker on the unit and the output circuit breakers to all loads. (Remove all loads from unit). 3. Remove the top and side covers to the conditioner. 3.3.2 Step 2. Electrical Connections, Fuses Refer to Sections 3.7 and 3.8 for component locations. 1. Inspect the unit for proper tightness of all electrical connections, burnt, frayed, broken or loose connections, and components in these areas. 2. Input and output connections, SCR assembly, SCR snubber, output filter assembly, MOVs (metal oxide varistors), circuit boards, bypass switch, and transformer connections need to be checked. 3. Correct and tighten any loose connections. Replace any physically burned or broken components. 4. Check all fuses in system (see NOTE). Also check time delay fuses, semi-conductor fuses, fan fuses, circuit board fuses, and SCR fusible link wire. NOTE: 3.4 Remove fuses from circuit when checking to avoid false readings. Checking the Power Modules (SCR) Refer to Section 3.8 Figures for specific 10-30kVA SCR, 45-50kVA SCR, 75-150kVA SCR, and 225-300kVA for SCR assemblies. 1. Unplug the connections to the control cards Part #49120/407415 labeled TB1, TB2, and TB3. 2. Disconnect any cooling fans in the unit so your SCR resistance checks are not interfered with by fan motor coils. Also remove main semi-conductor fuse located on all 3 SCR assemblies and any wires attached to the fuse. Each power module contains 2 inverse parallel SCRs. Figure 3-1: Power Module. TRANSFORMER G1 SHUNT G2 POWER MODULE 3. Measure the following resistance on each power module. There are 7 per phase or 21 for all three phases. Refer to the circuit diagrams received with your unit. 86-108814-00 B01 Maintenance 3 —5 Power-Sure™ 700 — Three Phase Power Conditioners NOTE: When checking the power module assembly, if more than one defective power module is present it will appear as if all the power modules are defective. The individual power module must be isolated from the power transformer: ◗ K1-1 to K2-1 thru K1-7 to K2-7 = High resistance, 1 Meg Ohm. ◗ K1-1 to G1-1 thru K1-7 to G1-7 = 10 to 90 Ohms. ◗ K1-1 to G2-1 thru K1-7 to G2-7 = 1 Meg Ohm. ◗ K2-1 to G2-2 thru K2-7 to G2-7 = 10 to 90 Ohms. ◗ K2-1 to G1-1 thru K2-7 to G1-7 = 1 Meg Ohm. ◗ G1-1 to G2-1 thru G1-7 to G2-7 = 1 Meg Ohm. 4. Replace any defective power modules. This may require removing the shunt and loosening the K1 bus from all the power modules to get the defective power module out. Use only equivalent hardware and heat sink grease when replacing power modules. 5. If a resistance measure is questionable, a more thorough test will assure an SCR is good or bad. Test procedure: ◗ Completely isolate SCR under test by removing all connections to the device. ◗ Hook up the following test circuit to each individual SCR. ◗ Plug in SCR tester. With Switch #1, open light bulb should be off. If not, replace SCR. ◗ Close Switch #1. Light bulb should illuminate to about 3/4 brilliance. If not, replace SCR. Figure 3-2: Test Wire Diagram. 1K 6. 1 WATT Switch #1 Reassemble the power module assembly, making sure all connections are tight. DO NOT CONNECT THE SEMI-CONDUCTOR FUSE, WIRES OR FAN WIRES AT THIS POINT. 3.5 Check SCR Snubber Card Three components make up the SCR snubber: Resistors, MOVs and Capacitors. 3 —6 ◗ Check for open resistors. ◗ Check MOVs for shorts, they should read high resistance when ohm meter is placed across them. ◗ Resistance check each capacitor. The DC resistance across the snubber capacitor should look capacitive, that is high resistance after the meter charges the capacitor. ◗ If it measures open or shorted, replace the snubber card. Maintenance 86-108814-00 B01 Installation and User Manual RE-CONNECT SEMI-CONDUCTOR FUSE, AND ALL WIRES AND FANS. DOUBLE CHECK THAT ALL CONNECTIONS ARE SECURE. NOTE: Control board #49120 is for 10kVA to 50kVA units. Control board #407415 is for 75kVA and larger. DO NOT CONNECT TB1, TB2, and TB3 CONNECTORS FROM THE CONTROL CARDS #49120/407415 YET! 3.5.1 Check Control Card and Filter Card 1. Verify input to the conditioner matches the units specification. Also verify correct control board #49120 / 407415 jumper setup. See Figure 3-11, Page 3-16. 2. Disable the over/under voltage shutdown card #35867 (optional card) by removing connectors K1 and K2 on the card. 3. Turn on AC input breaker to unit. IMPORTANT: 4. Extreme caution must be taken when measuring voltages on Molex connectors. Do not press meter leads into connectors or bend connectors back. Measure the following voltages on wires feeding the TB1 Molex connector to the control card on all 3 phases. Pins 1 & 3 = 4-6 VAC. Pins 7 & 8 = 120 VAC NOTE: When the connector is plugged in, this voltage is around 3 VAC. If this voltage is incorrect or not present, then check the fuses associated with the filter card or replace filter card and re-check voltages. 5. Turn main AC circuit breaker off. Plug in connectors TB1 and TB3 ONLY on the control card #49120/407415 on all 3 phases. 6. Turn main AC on. With DC voltmeter on the millivolt scale check between TP1 and TP GND of the control card and adjust pot P2 so meter reads “0” millivolts or close as possible. NOTE: This step does not apply to Control Board #407415. 7. Use the following formula to calculate the next adjustments. You must calculate each input phase for each control card or a total of 3 calculations. ◗ For phase 1, control card measures AC input at Line 1 to Line 2. ◗ For phase 2, control card measures AC input at Line 2 to Line 3. ◗ For phase 3, control card measures AC input at Line 1 to Line 3. 86-108814-00 B01 Maintenance 3 —7 Power-Sure™ 700 — Three Phase Power Conditioners FORMULA AC Input x 2.47 = Volts DC at TP2 480 (Nominal) Example: 475 Volts AC Input x 2.47 = 2.44 Volts DC at TP2 480 (Nominal) 8. After calculations are complete, place DC voltmeter on the 20 volt scale and check between TP2 and TP GND on control card. Adjust pot P1 so meter reads DC level calculated in Step 7 of Section 3.5.1 for all three phases. NOTE: If adjustments in Steps 6 and 7 are not possible, replace control card #49120/407415 and repeat Steps 6 and 8. Be sure to turn power off when replacing circuit boards. Be sure AC input is stable when making this adjustment. If the input changes, you must re-calculate. Output voltage correction is a “stepped correction”. Adjusting P1 will not cause a smooth change in output voltage as it is adjusted. 9. 10. Turn the unit off. Plug in TB2 Molex connectors to all the control cards #49120/407415. Replace connectors K1 and K2 on over/under detect #35867. NOTE: 3.6 Final Testing and Adjustments 1. Connect AC voltmeter to output of system with proper meter scale selected. NOTE: On 3 phase systems, connect your AC voltmeter across the output phase to neutral. 2. Disconnect customers loads. 3. Energize system. 4. Verify the output is within specifications. If not, adjust P1 on control board, for the appropriate phase. See Section 3.9.2, Control Card Adjustment Procedure, page 3-16. NOTE: 3 —8 P1 pot turned clockwise = decrease in output voltage and counter-clockwise = increase in output voltage. By changing this adjustment on phase1 you may see the output voltage change from line to neutral on two phases. It is best to use procedures in Steps 1 – 9 of Section 3.6. On 3 phase systems, be sure and check all 3 phases. If the main AC breaker trips or there is no output voltage, disable the over/under detect circuit #35867 by disconnecting K1 and K2 connectors and then calibrate the control boards if the output voltage is out of spec. Maintenance 86-108814-00 B01 Installation and User Manual 3.7 5. Turn the input circuit breaker off. 6. Connect customers equipment. 7. Energize system. 8. Repeat Step #4 and adjust as needed. 9. Be sure over/under detect is connected and if input breaker trips or there is no output voltage, re-calibrate the detect board or replace board if defective. Unit Component Location Diagrams Figure 3-3: Power-Sure™ 700 — 10-15kVA Major Components. SENSE CARD CONTROL CARD SEMI-CONDUCTOR FUSES SCR POWER MODULE INPUT CIRCUIT BREAKER HEATSINK SNUBBER CARD OUTPUT FILTERING OUTPUT TERMINAL PADS INPUT TERMINAL BLOCK MULTI-SHIELDED ISOLATION TRANSFORMER Figure 3-4: Power-Sure™ 700 — 25-30kVA Major Components (Rear View). SENSE CARD INPUT CIRCUIT BREAKER CONTROL CARD MULTI-SHIELDED ISOLATION TRANSFORMER SEMI-CONDUCTOR FUSES HEATSINK OUTPUT FILTERING OUTPUT TERMINAL PADS INPUT TERMINAL BLOCK 86-108814-00 B01 SCR POWER MODULE SNUBBER CARD Maintenance 3 —9 Power-Sure™ 700 — Three Phase Power Conditioners Figure 3-5: Power-Sure™ 700 — 45-150kVA Major Components (Rear View). MULTI-SHIELDED ISOLATION TRANSFORMER SENSE CARD OUTPUT FILTERING CONTROL CARD HEATSINK INPUT TERMINAL PADS SNUBBER CARD OUTPUT TERMINAL PADS SCR POWER MODULE REGULATOR ASSEMBLY COOLING FAN 3 —10 SEMI-CONDUCTOR FUSES Maintenance 86-108814-00 B01 Installation and User Manual Figure 3-6: Power-Sure™ 700 — 225-300kVA Cable Connections, Input Output Locations. 6" CLEARANCE REQUIRED (THIS SIDE) OUTPUT TERMINALS OUTPUT ACCESS PLATE LIFT-OFF ACCESS PANEL LIFT-OFF ACCESS PANEL CABINET COOLING FAN EDGE FRAMING FOR SCREENING (18 GAGE .047 THICK STEEL) 5" CLEARANCE REQUIRED (THIS SIDE) OUTPUT CONDUIT LOCATION 36" CLEARANCE REQUIRED (THIS SIDE) 1.75" (44.45m) INPUT CONDUIT LOCATION METAL – LAYER 1 (1.47D X 1.47W , 120 THICK 1.73" (43.94m) 8" (203.2m) METAL (GALVANIZED STEEL – LAYER 2 (1.25D X 1.25W , 120 THICK 1" (25.4m) 4.625" (117.47m) 8" (203.2m) LIFT-OFF ACCESS PANEL 9" (228.6m) 45" (1143m) Clearance 2" (50.8m) 1" (25.4m) 5.25" (133.35m) TOP VIEW OUTPUT TERMINAL DETAIL .25 X 4 COPPER BUSS EDGE FRAMING FOR SCREENING (18 GAGE .047 THICK STEEL) LAYER 2 32" (1812.80m) LAYER 1 POWER ON ALERT HEATSINK ASSEMBLY W/SNUBBER CARD INPUT CIRCUIT BREAKER (TERMINATE INPUT CABLES AT CIRCUIT BREAKER) HEARSINK ASSEMBLY COOLING FAN 77.207" (159.9m) OPTIONAL BYPASS SWITCH (OPEN DOOR FOR ACCESS) CONTROL CARD SENSE CARD 35" (889m) 2.75" (69.85m) 50.5" (1282.7m) 2.75" (69.85m) CLEARANCE HOLE FOR 1/2" MOUNTING BOLT 56" (1422.4m) 41.5" (1054.1m) LEFT SIDE VIEW FRONT VIEW 5.5" (139.70m) 3.25" (82.55m) OUTPUT TERMINALS CUSTOMER SIDE 32" (1812.8m) 4.625" (117.47m) G N L3 L2 L1 OUTPUT FILTERING INPUT SEMI CONDUCTOR FUSES MULTI-SHIELDED ISOLATION TRANSFORMER RIGHT SIDE VIEW 86-108814-00 B01 REAR VIEW Maintenance 3 —11 Power-Sure™ 700 — Three Phase Power Conditioners 3.8 SCR Heat Sink Assemblies Figure 3-7: Power-Sure™ 700 — 10-30kVA SCR Heatsink Assembly. SEMI-CONDUCTOR FUSE CABLE TO TRANSFORMER SHUNT TAP WIRES FROM POWER TRANSFORMER (K2-1 THROUGH K2-7 CONNECTIONS, TYPICAL) GATE CONNECTIONS G1 - 1 THROUGH G1 - 7, G2 - 1 THROUGH G2 - 7 (TYPICAL) THERMAL SENSOR FUSIBLE LINK POWER MODULE 3 —12 Maintenance 86-108814-00 B01 Installation and User Manual Figure 3-8: Power-Sure™ 700 — 45-50kVA SCR Heatsink Assembly. SEMI-CONDUCTOR FUSE CABLE TO TRANSFORMER SHUNT TAP WIRES FROM POWER TRANSFORMER (K2-1 THROUGH K2-7 CONNECTIONS, TYPICAL) GATE CONNECTIONS G1 - 1 THROUGH G1 - 7, G2 - 1 THROUGH G2 - 7 (TYPICAL) THERMAL SENSOR FUSIBLE LINK POWER MODULE 86-108814-00 B01 Maintenance 3 —13 Power-Sure™ 700 — Three Phase Power Conditioners Figure 3-9: Power-Sure™ 700 — 75-150kVA SCR Heatsink Assembly. POWER MODULE GATE CONNECTIONS G1 - 1 THROUGH G1 - 7, G2 - 1 THROUGH G2 - 7 (TYPICAL) TAP WIRES FROM POWER TRANSFORMER (K2-1 THROUGH K2-7 CONNECTIONS, TYPICAL) HEATSINK THERMAL SENSOR FUSIBLE LINK (CONTINUOUS THROUGH EACH POWER MODULE) INPUT CABLE DIODE 3 —14 Maintenance 86-108814-00 B01 Installation and User Manual Figure 3-10: Power-Sure™ 700 — 225-300kVA SCR Heatsink Assembly. POWER MODULE CABLE TO TRANSFORMER (TYPICAL) GATE LEADS (TYPICAL) FUSIBLE LINK (CONTINUOUS THROUGH EACH POWER MODULE) HEATSINK THERMAL SENSOR INPUT CABLE DIODE 3.9 Field Adjustments of Circuit Cards 3.9.1 Power-Sure™ 700 Control Card #49120/407415 WARNING: 86-108814-00 B01 ALL SERVICE TO THIS PIECE OF EQUIPMENT MUST BY PERFORMED BY QUALIFIED PERSONNEL. Maintenance 3 —15 Power-Sure™ 700 — Three Phase Power Conditioners CAUTION: THE CONTROL BOARD (#49120/407415) IS ELECTRICALLY REFERENCED TO HIGH VOLTAGE, NOT EARTH OR CHASSIS GROUND. EXTREME CARE MUST BE USED WHEN TAKING MEASUREMENTS ON THE CONTROL BOARD. ANY AC POWERED INSTRUMENTS MUST BE GROUND ISOLATED PRIOR TO TAKING MEASUREMENTS. A GROUND ISOLATED INSTRUMENT CASE WILL BE AT THE HIGH VOLTAGE LINE POTENTIAL. 3.9.2 Control Card Adjustment Procedure 1. Prior to attempting any adjustment, measure the incoming voltage to the unit. Assure the voltage level is within the specified input range of the unit. 2. Turn off power to unit. 3. Remove all loads from the output of unit under adjustment. 4. Remove both TB2 connectors on all control boards #49120/407415. Turn power on. 5. With DC voltmeter on the millivolt scale check between TP1 and TP GND and adjust P2 so meter reads “0” millivolts or as close as possible. GRND TB2 1 1 TB3 Figure 3-11: Power-Sure™ 700 Controller Card (Top View). 17 TP1 TB2 TB2 P1 P2 TP2 TP GND 49120 / 407415 115V 208V 240V 6. 3 —16 Use Formula X below to calculate the next adjustments. You must calculate each input phase for each control card or a total of 3 calculations: ◗ For phase 1 control card, measure AC input at Line 1 to Line 2. ◗ For phase 2 control card, measure AC input at Line 2 to Line 3. ◗ For phase 3 control card, measure AC input at Line 1 to Line 3. Maintenance 86-108814-00 B01 Installation and User Manual FORMULA X AC Input x 2.47 480 (Nominal) 7. = Volts DC at TP2 Example: 475 Volts AC Input x 2.47 = 2.44 Volts DC at TP2 480 (Nominal) NOTE: Be sure AC input is stable when making this adjustment. If the input changes, you must re-calculate. After calculations are complete, place DC voltmeter on 20 volt scale and check between TP2 and TP GND on control card. Adjust pot P1 so meter reads DC level calculated in Step 6 for all 3 phases. NOTE: Output voltage correction is a “stepped correction”, adjusting P1 will not cause a smooth change in output voltage as it is adjusted. 8. Turn unit off and reconnect TB2 connectors on all control boards. 9. Turn unit on and verify output is correct by monitoring the output from each line to neutral. If output is not correct, make sure input power is stable and repeat adjustment procedure. NOTE: 3.9.3 P1 Pot turned clockwise = decrease in output voltage and counter-clockwise = increase in output voltage. By changing this adjustment on 1 phase you may see the output voltage change from line to neutral on 2 phases. It is best to use procedures in Steps 1-9 when adjusting. Over/Under Voltage Detection Board #35867 NOTE: Adjustments are referenced from the units output. 3.9.3.1 Undervoltage Adjustment 1. The under voltage adjustment can be adjusted from -1% (118.5 VAC) to -20% (95 VAC) The standard setpoint is -10% (108 VAC). 2. P2 will adjust the undervoltage set point. One turn on P2 will change the voltage level approximately 1 volt. Clockwise = Increase in sensitivity. Counter-clockwise = Decrease in sensitivity. 3.9.3.2 Overvoltage Adjustment 1. The over voltage adjustment can be adjusted from +1% (121 VAC) to +20% (145 VAC). The standard set point is +10% (132 VAC). 86-108814-00 B01 Maintenance 3 —17 Power-Sure™ 700 — Three Phase Power Conditioners 2. P1 will adjust the overvoltage set point. One turn on P1 will change the voltage level approximately 1 volt. Clockwise = Decrease Sensitivity. Counter-clockwise = Increase Sensitivity. 3.9.3.3 Delay Adjustment 1. The delay adjustment can be adjusted for a minimum of 5 cycles to a maximum of 15 seconds. The standard set point is 6 seconds. 2. P3 adjusts the delay. ◗ All the way counter-clockwise = 5 cycles. ◗ All the way clockwise = 15 seconds. After two turns clockwise from the full counter-clockwise position, each turn equals approximately 1/2 second. 3.10 Manual Bypass Switch Option The manual bypass switch is a break before make switch located on the Power-Sure™ 700. The manual bypass switch is used to bypass all power electronics in case of failure. NOTE: This switch may be added in the field. 3.10.1 Normal Mode With the switch in the normal position, the Power-Sure™ 700 will provide clean and regulated power to the critical loads. The Power-Sure™ 700 should have the switch in the normal position unless a failure has occurred. 3.10.2 Bypass Mode With the switch in the bypass position, the Power-Sure™ 700 will provide clean power to the critical loads. In the bypass position, the unit will not regulate the incoming voltage. The Power-Sure™ 700 should be placed in the bypass position when a failure of the system has occurred. This provides the user with some protection until a service technician arrives. CAUTION: PRIOR TO SWITCHING FROM ONE POSITION TO ANOTHER, TURN OFF THE AC INPUT BREAKER. SOME SYSTEMS ARE EQUIPPED WITH PUSH-TO-TURN SWITCHES. WITH THESE SWITCHES THE SWITCH WILL SHUNT TRIP THE INPUT BREAKER WHEN PRESSED IN. 3.10.3 Remote Emergency Power OFF (REPO) (Optional) The REPO is operated by a remote push button that when depressed will shunt trip the Power-Sure™ 700 input breaker and disable the unit. This option may be added to units in the field. Contact the Customer Care Center if you wish to add these options. 3 —18 Maintenance 86-108814-00 B01 Installation and User Manual 3.11 Replacement Parts Individual components are available upon request. Please contact MGE Office Protection Systems for specific part numbers and prices. See Section 3.7 in this manual for component location and description. When contacting MGE Office Protection Systems Service at (949) 268-2800, please have the unit’s full model number and serial number for identification. 3.12 Part Numbers Table 3-1: Power-Sure™ 700 Power Conditioners Part Numbers. Part Number TBN-010K-6 TBN-015K-6 TBN-025K-6 TBN-030K-6 TBN-045K-6 TBN-050K-6 TBN-075K-6 TBL-010K-6 TBL-015K-6 TBL-025K-6 TBL-030K-6 TBL-045K-6 TBL-050K-6 TBL-075K-6 TBL-100K-6 TBL-125K-6 TBL-150K-6 TBL-225K-6 TBL-300K-6 TCN-010K-6 TCN-015K-6 TCN-025K-6 TCN-030K-6 TCN-045K-6 TCN-050K-6 TCL-010K-6 TCL-015K-6 TCL-025K-6 TCL-030K-6 TCL-045K-6 TCL-050K-6 TCL-075K-6 TCL-100K-6 86-108814-00 B01 kVA 10 15 25 30 45 50 75 10 15 25 30 45 50 75 100 125 150 225 300 10 15 25 30 45 50 10 15 25 30 45 50 75 100 Input Voltage Output Voltage Hz 208 480/277 60 208 208/120 60 240 480/277 60 240 208/120 60 Maintenance 3 —19 Power-Sure™ 700 — Three Phase Power Conditioners Table 3-1: Power-Sure™ 700 Power Conditioners Part Numbers (Continued). Part Number TDL-010K-6 TDL-015K-6 TDL-025K-6 TDL-030K-6 TDL-045K-6 TDL-050K-6 TDL-075K-6 TDL-100K-6 TDL-125K-6 TDL-150K-6 TDL-225K-6 TDL-300K-6 TDN-010K-6 TDN-015K-6 TDN-025K-6 TDN-030K-6 TDN-045K-6 TDN-050K-6 TDN-075K-6 TDN-100K-6 TDN-125K-6 TDN-150K-6 TDN-225K-6 TDN-300K-6 TEL-010K-6 TEL-015K-6 TEL-025K-6 TEL-030K-6 TEL-045K-6 TEL-050K-6 TEL-075K-6 TEL-100K-6 TEL-125K-6 TEL-150K-6 TEL-225K-6 TEL-300K-6 TEN-010K-6 TEN-015K-6 TEN-025K-6 TEN-030K-6 TEN-045K-6 TEN-050K-6 TEN-075K-6 TEN-100K-6 TEN-125K-6 TEN-150K-6 TEN-225K-6 TEN-300K-6 3 —20 kVA 10 15 25 30 45 50 75 100 125 150 225 300 10 15 25 30 45 50 75 100 125 150 225 300 10 15 25 30 45 50 75 100 125 150 225 300 10 15 25 30 45 50 75 100 125 150 225 300 Input Voltage Output Voltage Hz 480 208/120 60 480 480/277 60 600 208/120 60 600 480/277 60 Maintenance 86-108814-00 B01 MODEL NUMBER 200?C. 180?F. 180?F. 10(A) 73(A) 180?F. 9 REFERANCE SPEC. TAG FOR PROPER KVA & VOLTAGE'S TDL-010K-6 TCL-010K-6 TBL-010K-6 TRANS. OVERTEMP. 10(A) SCR OVERTEMP. RL1 5 M M 2 1 2 6 4 5 10(A) 7 (A) 7 (A) 34(A) 32(A) 33(A) 56(A) 10 RL1 6 1 2 208VAC 240VAC 480VAC 8CLX-10K-7A 8DLX-10K-7A REV. 3 TB-3 INPUT VOLTAGE 8BLX-10K-7A BLACK/WHITE TWIST 18 GAGE (TYP.) 73(A) 7 (A) 14 COOLING FANS R "ALERT" 13 RL1 10(A) K2 3 K1 3 57(A) UNDER/OVER VOLTAGE BOARD #35867 58(A) OPTIONAL 4 1 2 34 5 6 7 8 SNUBBER BOARD #25723 56(A) 5 6 10 (E) G1-5 K1-5 K2-6 G2-6 G1-3 K1-3 K2-4 G2-4 CONTROL BOARD #49120 3 3 12 (E) 6 G1-2 K1-2 K2-3 G2-3 13 (E) 1 7 4 5 TB-1 8 6 SEMICONDUCTOR FUSE FWA-100 5 FILTER CARD #23888-1 G1-4 K1-4 K2-5 G2-5 11 (E) 1 2 4 7(A) 10(A) SHUNT 29(B) FUSE LINK 18 GAGE G1-6 K1-6 K2-7 G2-7 3 9 (E) 14 (E) 4 G1-1 K1-1 K2-2 G2-2 TB-2 2 7 14 K2-1 G2-1 BRAIDED WIRE MT-24 4-COND. 32(J) WIRE SIZED AT (A) 8 1 7 (E) 9 3 TB-3 1 2 4 1 2 3 4 5 6 7 8 SNUBBER BOARD #25723 15A 30A 40A INPUT CIRCUIT BREAKER #10 #10 #8 #10 #10 #10 (**)MINIMUM WIRE SIZE INPUT OUTPUT 5 6 G1-7 K1-7 15 (E) G1-4 K1-4 K2-5 G2-5 18 (E) G1-3 K1-3 K2-4 G2-4 7(A) 1 2 19 (E) 6 1 7 TB-1 8 6 5 4 3 3 G1-2 K1-2 K2-3 G2-3 20 (E) 13 SEMICONDUCTOR FUSE FWA-100 5 FILTER CARD #23888-1 CONTROL BOARD #49120 17(A) SHUNT 4 30(B) G1-5 K1-5 K2-6 G2-6 17 (E) 12 480V.* FUSE LINK 18 GAGE G1-6 K1-6 K2-7 G2-7 3 2 16 (E) 11 10 9 LINE 10 LINE 11 12 INPUT VOLTAGE'S NOTE: 10 11 LINE 12 TRANSFORMER PRIMARY 240V. WIRING 9 LINE TRANSFORMER PRIMARY 208V. WIRING K2-1 G2-1 WIRE SIZED AT (A) G1-7 K1-7 57(A) 2 39(A) 8 (E) 40(A) 1 7 (E) 41(A) 7 TB-2 2 G1-1 K1-1 K2-2 G2-2 21 (E) 14 4 K2-1 G2-1 BRAIDED WIRE MT-24 4-COND. 33(J) WIRE SIZED AT (A) 8 7 (E) 1 9 1 2 TB-3 3 4 SNUBBER BOARD #25723 1 2 34 5 6 7 8 5 6 G1-7 K1-7 22 (E) 3 24 (E) G1-3 K1-3 K2-4 G2-4 26 (E) 6 1 7 TB-1 8 6 5 4 3 3 G1-2 K1-2 K2-3 G2-3 27 (E) 13 SEMICONDUCTOR FUSE FWA-100 5 FILTER CARD #23888-1 G1-4 K1-4 K2-5 G2-5 25 (E) 1 2 7(A) 24(A) SHUNT 4 12 31(B) G1-5 K1-5 K2-6 G2-6 FUSE LINK 18 GAGE G1-6 K1-6 K2-7 G2-7 23 (E) 480V.* 11 CONTROL BOARD #49120 2 10 28 (E) 4 G1-1 K1-1 K2-2 G2-2 TB-2 2 7 14 13 13 14 14 A - 18GA B - 16GA C - 14GA D - 12GA E - 10GA F - 8GA G - 6GA H - 4GA J - 2GA K - 1GA L - 1/0 GA M - 2/0 GA N - 3/0 GA P - 4/0 GA Q - 250MCM R - 350MCM T - 500MCM WIRE LIST WIRE #(WIRE SIZE) K2-1 G2-1 7 (E) 7 (E) BRAIDED WIRE MT-24 4-COND. 32(E) 33(E) 34(E) 8 CIRCUIT DIAGRAM POWER-SURE™ 700 WITH OPTIONAL UNDER/OVER VOLTAGE PROTECTION INPUT VOLTAGE 480/240/208V OUTPUT VOLTAGE 208/120V WYE 13 Whatney, Suite #101 Irvine, CA 92618 U.S.A 35(B) 36(B) 37(B) 34(B) 32(B) NO. SHEET CHECKED DATE 1 414027-0 OF DATE 1 OUTPUT FILTER ASSEMBLY T.SZWAST 11/03/00 DRAWN C G L1 L2 L3 N G 7(B) OUTPUT TERMINALS B A G G OUTPUT CONDITIONED POWER 33(B) MGE Office Protection Systems 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 K2-1 G2-1 G1-1 K1-1 K2-2 G2-2 G1-2 K1-2 K2-3 G2-3 G1-3 K1-3 K2-4 G2-4 G1-4 K1-4 K2-5 G2-5 G1-5 K1-5 K2-6 G2-6 G1-6 K1-6 K2-7 G2-7 G1-7 K1-7 38(A) 13 50 12 51 480V.* 57(A) 11 56(A) 58(A) 10 42(A) 9 43(A) 6(**) 44(A) G 45(A) 5(**) 52 3(**) 53 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 G1-1 K1-1 K2-2 G2-2 G1-2 K1-2 K2-3 G2-3 G1-3 K1-3 K2-4 G2-4 G1-4 K1-4 K2-5 G2-5 G1-5 K1-5 K2-6 G2-6 G1-6 K1-6 K2-7 G2-7 G1-7 K1-7 H3 56(A) 4(**) 57(A) 2(**) 58(A) 1(**) 46(A) H2 47(A) H1 48(A) INPUT TERMINALS 49(A) Figure A-1: 10-50kVA Wiring Diagram. 54 INPUT AC CIRCUIT BREAKER 55 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 K2-1 G2-1 G1-1 K1-1 K2-2 G2-2 G1-2 K1-2 K2-3 G2-3 G1-3 K1-3 K2-4 G2-4 G1-4 K1-4 K2-5 G2-5 G1-5 K1-5 K2-6 G2-6 G1-6 K1-6 K2-7 G2-7 G1-7 K1-7 86-108814-00 B01 Appendices 86-108814-00 B01 47 (A) TRANS. OVERTEMP. SCR OVERTEMP. 40 (A) 480V 5 1 H4 H3 H2 RL1 3 200ºC. 180ºF. 180ºF. 180ºF. 9 TD1 X2 7 73 (A) 120V TD1 2 13 M R "ALERT" RL1 14 80 (A) COOLING FANS (7) IN PARALLEL CONTROL TRANSFORMER 250VA 48 (A) 47 (A) 73 (A) 3 REV. 8DNX-150K-7A TDN-150K-6 480VAC 480VAC 480VAC 8DNX-75K-7A 8DNX-125K-7A TDN-075K-6 TDN-125K-6 INPUT VOLTAGE REFERANCE SPEC. TAG FOR PROPER KVA & VOLTAGE'S TB-2 4 1 2 3 TB-3 4 5 6 CONTROL BOARD #407415 7 1 3 8 TB-1 TB-2 2 4 WIRE #(WIRE SIZE) 1 2 3 TB-3 4 5 6 CONTROL BOARD #407415 7 1 3 8 TB-1 TB-2 2 225A 200A 125A INPUT CIRCUIT BREAKER BLACK/WHITE TWIST 18 GAGE (TYP.) #1/0 #1/0 #4 #1/0 #1/0 #4 (**)MINIMUM WIRE SIZE INPUT OUTPUT FWH-600 FWH-600 FWH-200 SEMI-CONDUCTOR FUSES A - 18GA B - 16GA C - 14GA D - 12GA E - 10GA F - 8GA G - 6GA H - 4GA J - 2GA K - 1GA L - 1/0 GA M - 2/0 GA N - 3/0 GA P - 4/0 GA Q - 250MCM R - 350MCM T - 500MCM WIRE LIST 4 CIRCUIT DIAGRAM POWER-SURE™ 700 WITH OPTIONAL UNDER/OVER VOLTAGE PROTECTION INPUT VOLTAGE 480V OUTPUT VOLTAGE 480/277V WYE 13 Whatney, Suite #101 Irvine, CA 92618 U.S.A NO. SHEET CHECKED DATE 414194-0 OF 1 DATE T.SZWAST 12/15/00 DRAWN 1 MGE Office Protection Systems 1 K2-1 2 2 G2-1 MODEL NUMBER 75,125,150KVA 8 3 G1-1 63 4 K1-1 TB-1 62 5 K2-2 3 48 59 60 61 (A) (A) (A) (A) 6 G2-2 1 64 65 66 (A) (A) (A) 7 G1-2 7 58 8 K1-2 CONTROL BOARD #407415 57 9 K2-3 6 48 54 55 56 (A) (A) (A) (A) 10 G2-3 5 64 65 66 (A) (A) (A) 11 G1-3 4 53 12 K1-3 TB-3 52 13 K2-4 2 48 49 50 51 (A) (A) (A) (A) 14 G2-4 1 64 65 (A) (A) 15 G1-4 X1 64 65 66 (A) (A) (A) 6 16 K1-4 H1 10 RL1 4 17 K2-5 46 (A) 6 3 18 G2-5 39 (A) 18 48 (A) 48 (A) 1 19 G1-5 24 48 (A) 5 FILTER CARD #28173 20 K1-5 17 48 (A) 45(A) 47(A) 46(A) 2 21 K2-6 16 47(A) BRAIDED WIRE MT-24 4-COND. 22 G2-6 15 47 (A) 6 23 G1-6 45 (A) 47(A) 4 24 K1-6 23 45(A) 46(A) 3 25 K2-7 14 44(A) 45(A) 46(A) 1 26 G2-7 44 (A) 5 FILTER CARD #28173 27 G1-7 12 44(A) 43(A) 2 28 K1-7 13 43(A) BRAIDED WIRE MT-24 4-COND. 1 K2-1 22 6 2 G2-1 40(A) 41(A) 42(A) 4 4 12 3 G1-1 11 3 32(**) 33(**) 34(**) 31(**) 11 4 K1-1 21 1 10 5 K2-2 73 (A) 5 FILTER CARD #28173 9 6 G2-2 2 8 7 G1-2 7 8 K1-2 10 11 12 6 30 (**) 9 K2-3 9 9 32(**) 5 28 (E) 29 (**) 10 G2-3 10 80 (A) 8 32(A) 2 28 (**) 11 G1-3 6 3 1 27 (**) 12 K1-3 5 4 12 26 (**) 13 K2-4 8 7 4 11 25 (**) 14 G2-4 43 (A) 3 10 24 (**) 15 G1-4 7 2 7 RESISTOR 1K OHM 16 K1-4 39(A) 1 8 62(E) 17 K2-5 23 (**) 18 G2-5 6 7 22 (**) 19 G1-5 42 (A) 6 21 (**) G2-7 K2-7 20 K1-5 20 5 21(E) 20 (**) G2-6 K2-6 K1-7 G1-7 21 K2-6 5 2 19 (**) G2-5 K2-5 K1-6 G1-6 22 G2-6 4 33(**) 34(**) 31(**) 3 1 18 (**) G2-4 K2-4 K1-5 G1-5 23 G1-6 33(A) 4 12 17 (**) G2-3 K2-3 K1-4 G1-4 24 K1-6 3 3 11 RESISTOR 1K OHM K1-1 G1-1 G2-2 K2-2 K1-3 G1-3 25 K2-7 34(A) 10 57(E) 2 34 567 8 G2-1 K2-1 K1-2 G1-2 26 G2-7 16 (**) G2-7 K2-7 27 G1-7 19 9 15 (**) G2-6 K2-6 K1-7 G1-7 28 K1-7 2 8 14 (**) G2-5 K2-5 K1-6 G1-6 1 OPTIONAL THREE PHASE SEQUENCE & VOLTAGE BAND MONITIOR RELAY DIVERSIFIED ELECTRONICS #PBD-440-ALE 7 13 (**) G2-4 K2-4 K1-5 G1-5 2 K2-1 41 (A) 6 12 (**) G2-3 K2-3 K1-4 G1-4 3 G2-1 1 5 14 (E) 11 (**) K1-1 G1-1 G2-2 K2-2 K1-3 G1-3 4 G1-1 38(A) 2 10 (**) 2 34 567 8 G2-1 K2-1 K1-2 G1-2 5 K1-1 THREE PHASE CONTROL TRANSFORMER 10VA. #24747-1 1 RESISTOR 1K OHM G2-7 K2-7 62 6 K2-2 52(E) G2-6 K2-6 K1-7 G1-7 FUSE LINK 16 GAGE(2PC) 7 G2-2 6(A) K1-1 G1-1 G2-5 K2-5 K1-6 G1-6 62(B) 1 63 8 G1-2 40(A) 2 34 5 6 7 8 G2-4 K2-4 K1-5 G1-5 SNUBBER BOARD ASSEMBLY #25723 62(**) 9 K1-2 5(A) G2-3 K2-3 K1-4 G1-4 57 SEMICONDUCTOR FUSE 4(**) 10 K2-3 FUSE #3 600V 3A. G2-2 K2-2 K1-3 G1-3 FUSE LINK 16 GAGE(2PC) 58 11 G2-3 39(A) G2-1 K2-1 K1-2 G1-2 1 57(B) 57(**) 12 G1-3 WIRE SIZED AT (A) (TYP) SNUBBER BOARD ASSEMBLY #25723 SEMICONDUCTOR FUSE 6(**) 13 K1-3 4(A) 52 53 14 K2-4 FUSE #2 600V 3A. FUSE LINK 16 GAGE(2PC) 52(**) 15 G2-4 38(A) 52(B) 1 SNUBBER BOARD ASSEMBLY #25723 SEMICONDUCTOR FUSE 5(**) 16 G1-4 FUSE #1 600V 3A. 6(**) 5(**) 17 K1-4 G 18 K2-5 H3 4(**) 19 G2-5 Z3 20 G1-5 3(**) 21 K1-5 Z2 22 K2-6 2(**) 23 G2-6 H2 24 G1-6 INPUT TERMINALS 25 K1-6 INPUT AC CIRCUIT BREAKER 26 K2-7 G2-7 1(**) 27 G1-7 H1 Figure A-2: 75-150kVA Wiring Diagram. 28 K1-7 C G OUTPUT FILTER ASSEMBLY 36(B) 37(B) 33(B) 32(B) 31(B) 35(B) BRAIDED WIRE MT-24 4-COND. N G L1 L2 L3 OUTPUT TERMINALS 34(B) Z6 Z5 OUTPUT SURGE PROTECTION B G Z4 A G OUTPUT CONDITIONED POWER 40 (A) 47 (A) TRANS. OVERTEMP. SCR OVERTEMP. 480V 39 (A) 5 1 RL1 3 X1 7 TD1 73 (A) X2 120V 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 200ºC. 180ºF. 180ºF. 180ºF. 9 TD1 H4 H3 H2 H1 40(A) 39(A) 38(A) 46 (A) 45 (A) 44 (A) 43 (A) 42 (A) 41 (A) 2 RL1 M R "ALERT" 13 48 (A) 47 (A) 14 7 COOLING FANS (7) IN PARALLEL 80 (A) 80 (A) 1 8 2 9 3 5 6 47 (A) 73 (A) 10 11 12 73 (A) 4 OPTIONAL THREE PHASE SEQUENCE & VOLTAGE BAND MONITIOR RELAY DIVERSIFIED ELECTRONICS #PBD-440-ALE CONTROL TRANSFORMER 250VA 24 23 22 21 20 19 THREE PHASE CONTROL TRANSFORMER 10VA. #24747-1 34(A) 3 5 1 2 TB-3 3 64 65 66 (A) (A) (A) 14 (E) 4 5 6 64 65 (A) (A) 6 7 2 10 5 7 REFERANCE SPEC. TAG FOR PROPER KVA & VOLTAGE'S REV. 480VAC 8DNX-150K-7A TDN-150K-6 480VAC INPUT VOLTAGE 480VAC 8DNX-75K-7A 8DNX-125K-7A 75,125,150KVA 3 4 11 15 (**) 6 1 3 4 12 TB-1 8 48 49 50 51 (A) (A) (A) (A) 1 FILTER CARD #28173 48 (A) 9 CONTROL BOARD #407415 47(A) 46(A) 45(A) 44(A) 43(A) 42(A) 41(A) 8 TDN-125K-6 TDN-075K-6 10 RL1 6 2 MODEL NUMBER 48 (A) 32(A) 33(A) 1 14 (**) 4 2 225A 200A INPUT CIRCUIT BREAKER 125A 3 32(**) 33(**) 34(**) 31(**) BRAIDED WIRE MT-24 4-COND. 1 57(E) 21(E) 5 1 5 6 #1/O #1/O #4 48 (A) 47(A) 46(A) 45(A) 44(A) 43(A) 7 20 (**) 2 10 21 (**) 5 3 4 11 22 (**) 6 7 1 3 8 48 54 55 56 (A) (A) (A) (A) 1 FILTER CARD #28173 CONTROL BOARD #407415 8 19 (**) 4 12 23 (**) TB-2 57 58 3 BRAIDED WIRE MT-24 4-COND. 1 62(E) 28 (E) 5 2 64 65 66 (A) (A) (A) 2 RESISTOR 1K OHM 3 4 6 24 (**) 5 6 7 25 (**) 48 (A) 47(A) 46(A) 45(A) 9 27 (**) 2 10 28 (**) 34(**) 5 3 6 7 1 3 48 59 60 61 (A) (A) (A) (A) 1 4 32(**) 33(**) 11 29 (**) 31(**) FILTER CARD #28173 CONTROL BOARD #407415 8 26 (**) 8 4 12 30 (**) TB-2 62 2 63 TB-3 #1/O #1/O #4 FWH-600 FWH-600 FWH-200 SEMI-CONDUCTOR FUSES TB-1 A - 18GA B - 16GA C - 14GA D - 12GA E - 10GA F - 8GA G - 6GA H - 4GA J - 2GA K - 1GA L - 1/0 GA M - 2/0 GA N - 3/0 GA P - 4/0 GA Q - 250MCM R - 350MCM T - 500MCM WIRE LIST WIRE #(WIRE SIZE) TB-1 4 Z4 13 Whatney, Suite #101 Irvine, CA 92618 U.S.A NO. SHEET CHECKED DATE 1 414195-0 OF DATE T.SZWAST 12/15/00 DRAWN C G L1 L2 36(B) 37(B) 32(B) OUTPUT FILTER ASSEMBLY 35(B) 33(B) 31(B) OUTPUT TERMINALS 34(B) 1 N G L3 OUTPUT SURGE PROTECTION B G BRAIDED WIRE MT-24 4-COND. Z6 Z5 A G OUTPUT CONDITIONED POWER MGE Office Protection Systems CIRCUIT DIAGRAM POWER-SURE™ 700 WITH BY-PASS OPTIONAL UNDER/OVER VOLTAGE PROTECTION INPUT VOLTAGE 480V OUTPUT VOLTAGE 480/277V WYE TB-3 1 4 7 18 (**) 4 3 6 17 (**) 2 2 64 65 66 (A) (A) (A) 2 RESISTOR 1K OHM (**)MINIMUM WIRE SIZE INPUT OUTPUT BLACK/WHITE TWIST 18 GAGE (TYP.) 53 52 TB-2 16 (**) 1 K2-1 13 (**) G2-7 K2-7 2 G2-1 12 (**) G2-6 K2-6 K1-7 G1-7 3 G1-1 11 (**) G2-5 K2-5 K1-6 G1-6 4 K1-1 10 (**) G2-4 K2-4 K1-5 G1-5 5 K2-2 RESISTOR 1K OHM G2-3 K2-3 K1-4 G1-4 6 G2-2 52(E) G2-2 K2-2 K1-3 G1-3 7 G1-2 6(A) K1-1 2 3 4 5 6 7 8 G1-1 G2-1 K2-1 K1-2 G1-2 8 K1-2 40(A) K1-1 2 3 4 5 6 7 8 G1-1 G2-7 K2-7 9 K2-3 K1-1 G1-1 G2-6 K2-6 K1-7 G1-7 10 G2-3 2 3 45 6 7 8 G2-5 K2-5 K1-6 G1-6 11 G1-3 WIRE SIZED AT (A) (TYP) G2-4 K2-4 K1-5 G1-5 12 K1-3 5(A) G2-3 K2-3 K1-4 G1-4 13 K2-4 FUSE #3 600V 3A. G2-2 K2-2 K1-3 G1-3 14 G2-4 39(A) 1 K2-1 G2-1 K2-1 K1-2 G1-2 15 G1-4 G2-7 K2-7 2 G2-1 62 16 K1-4 G2-6 K2-6 K1-7 G1-7 3 G1-1 FUSE LINK 16 GAGE(2PC) 17 K2-5 G2-5 K2-5 K1-6 G1-6 4 K1-1 62(B) 18 G2-5 G2-4 K2-4 K1-5 G1-5 5 K2-2 1 19 G1-5 G2-3 K2-3 K1-4 G1-4 6 G2-2 SNUBBER BOARD ASSEMBLY #25723 20 K1-5 G2-2 K2-2 K1-3 G1-3 7 G1-2 57 21 K2-6 G2-1 K2-1 K1-2 G1-2 8 K1-2 FUSE LINK 16 GAGE(2PC) 22 G2-6 4(A) 9 K2-3 57(B) 23 G1-6 FUSE #2 600V 3A. 10 G2-3 1 24 K1-6 38(A) 11 G1-3 SNUBBER BOARD ASSEMBLY #25723 25 K2-7 52 26 G2-7 FUSE LINK 16 GAGE(2PC) 12 K1-3 63 27 G1-7 52(B) 13 K2-4 SEMICONDUCTOR FUSE 9(**) 62(**) 28 K1-7 1 14 G2-4 58 1 K2-1 SNUBBER BOARD ASSEMBLY #25723 15 G1-4 57(**) 2 G2-1 FUSE #1 600V 3A. 16 K1-4 SEMICONDUCTOR FUSE 8(**) 3 G1-1 53 4 K1-1 52(**) 5 K2-2 SEMICONDUCTOR FUSE 6 G2-2 7(**) 7 G1-2 6(**) 8 K1-2 G 9 K2-3 5(**) 10 G2-3 H3 11 G1-3 4(**) 12 K1-3 Z3 13 K2-4 Z2 17 K2-5 28 (**) 14 G2-4 3(**) 18 G2-5 12 15 G1-4 2(**) 19 G1-5 11 16 K1-4 1(**) 20 K1-5 21(**) 17 K2-5 H2 21 K2-6 7 18 G2-5 H1 22 G2-6 BY-PASS 19 G1-5 INPUT TERMINALS 23 G1-6 10 20 K1-5 14 (**) 24 K1-6 9 21 K2-6 3 25 K2-7 NORMAL 22 G2-6 INPUT SURGE PROTECTION 26 G2-7 8 23 G1-6 Z1 27 G1-7 6 24 K1-6 INPUT AC CIRCUIT BREAKER 28 K1-7 5 25 K2-7 4 26 G2-7 2 27 G1-7 1 Figure A-3: 225-300kVA Wiring Diagram. 28 K1-7 86-108814-00 B01 Power-Sure™ 700 — Three Phase Power Conditioners (This page left blank intentionally) A —4 86-108814-00 B01 MGE Office Protection Systems Customer Care Center Technical Support and Product Services ? Technical questions? If you encounter a problem while following the instructions in this manual, or have questions about the operation, repair, or servicing of your equipment, please visit our web site www.mgeops.com for complete service information. To insure that your questions are correctly answered, please obtain the part number, assembly number, and serial number of the unit and include them in any discussions or correspondence. Part Number: ________________________________________________________________________________________ Assembly Number: __________________________________________________________________________________ Serial number: ______________________________________________________________________________________ Who To Contact For Technical Support, Customer Care Center, Customer FAQ please visit our website: www.mgeops.com Scheduling Field Service Engineer Support Scheduling of the MGE Office Protection Systems Field Service Engineers typically should be done 7 to 10 days before they are required on-site. If the startup of the UPS is critical to maintaining your schedule, please contact MGE Office Protection Systems, to insure a safe installation and start-up that will maintain the MGE Office Protection Systems warranty and insure smooth performance. Return Policy for Single Phase Products (RMA) Should you require factory service for your equipment, contact MGE Office Protection Systems Customer Care Center and obtain a Return Materials Authorization (RMA) prior to shipping your unit. Never ship equipment to MGE Office Protection Systems without first obtaining an RMA number. For further details please visit our website: www.mgeops.com Date: ______________________________________________________________________________________________ RMA Number: ______________________________________________________________________________________ Contact Name: ______________________________________________________________________________________ w w w. m g e o p s . c o m Contact MGE Office Protection Systems United States MGE Office Protection Systems 13 Whatney, Suite #101 Irvine, CA 92618 (949) 268-2800 www.mgeops.com 1 3 W h a t n e y, S u i t e # 1 0 1 , I r v i n e , C a l i f o r n i a 9 2 6 1 8 • w w w. m g e o p s . c o m