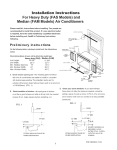

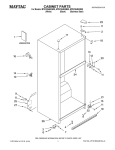

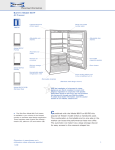

Download 600 Series

Transcript