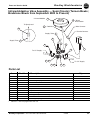

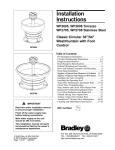

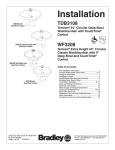

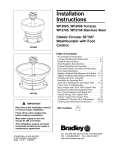

Download Bradley WF3203 Troubleshooting guide

Transcript