Download Wells WVPE-30F Operating instructions

Transcript

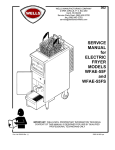

381 WELLS BLOOMFIELD, LLC 2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439 telephone: 775-689-5703 fax: 775-689-5976 www.wellsbloomfield.com SUPPLEMENTAL SERVICE INSTRUCTIONS for VENTILATOR HOOD SECTION FRYER MODELS WVAE_30F WVPE-30F WVAE-55F WVAE-55FS IMPORTANT: WELLS MANUFACTURING PROPRIETARY INFORMATION. DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED. TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY. PRINTED IN UNITED STATES OF AMERICA p/n 502944 Rev. E ECN-13391 S381 071128 cps PRECAUTIONS AND GENERAL INFORMATION WARNING: RISK OF INJURY Installation procedures must be performed by a qualified technician with full knowledge of all applicable electrical and plumbing codes. Failure can result in personal injury and property damage. WARNING: BURN HAZARD POSSIBLE HOT OIL SPILL AVOID CONTACT WITH HOT OIL USE CARE WHEN HANDLING OIL TO AVOID SPILLS Discharge of the Ansul® fire suppression system may result in foaming of the oil in the frypot. Serious burns and other injuries can result from contact with hot oil and from slipping in spilled oil. Clean up oil spills promptly. SHOCK HAZARD All servicing requiring access to non-insulated electrical components must be performed by a qualified technician. DO NOT open any access panel that requires the use of tools unless you are qualified to do so. Failure to follow this warning can result in severe electrical shock. CAUTION: RISK OF DAMAGE This ventilator and attendant fryer are intended for use only in commercial establishments, where all operators are familiar with the appliance use, limitations and associated hazards. Operating instructions and warnings must be read and understood by all operators and users. This ventilator hood system is designed to reduce odor emissions, but will not completely eliminate cooking odors. Air exchange at the installation site must comply with the requirements of the local jurisdictional authority. To ensure that odors do not build-up, recommended minimum air exchange is 400 cfm into and out of the site. Cleanliness of this appliance is essential to good sanitation. Read and follow all included cleaning instructions and schedules to ensure the safety of the food product. Disconnect this appliance from electrical power before performing any maintenance or servicing. DO NOT splash or pour water on, in or over any controls, control panel or wiring. The technical content of this manual, including any wiring diagrams, schematics, parts breakdown illustrations and/or adjustment procedures, is intended for use by qualified technical personnel. Any procedure which requires the use of tools must be performed by a qualified technician. This appliance is made in the USA. Unless otherwise noted, this appliance has American sizes on all hardware. xi 381 502944 Service Manual for NFPA Hood DO NOT connect or energize this appliance until all installation instructions are read and followed. Damage to the appliance will result if these instructions are not followed. This ventilator hood system is designed as part of a fryer intended to prepare food for human consumption. No other use of this product is authorized or recommended by the manufacturer or its agents. TABLE OF CONTENTS Precautions & General Information …………………………… xi Features & Operating Controls …………………………………. 2 Hood Operation …………………………………………...……… 4 Troubleshooting Suggestions …………………………………… 6 Servicing Instructions Fire Damper …………………………………………………… 7 Filter Interlock …………………………………………………. 8 Blower & Status Sensor System ……………………………. 10 Ansul® System ………………………………………………… 12 Exploded Views & Parts Lists ………………………………….. 14 Wiring Diagrams …………………………………………..……… 16 INTRODUCTION This manual contains information needed to properly service and repair the hood portion of ventless floor fryers. This manual applies to the following Wells Manufacturing models: WVAE-30F, WVPE-30F, WVAE-55F, WVAE-55FS SPECIFICATIONS 381 502944 Service Manual for NFPA Hood This hood system is common to several Wells Manufacturing products. For installation, operation and maintenance instructions, electrical specifications and general dimensions, refer to the General Layout Data, Installation Instructions and Operation Manual for the specific model. 1 FEATURES & OPERATING CONTROLS VENTILATOR WARNINGLIGHT PANEL SIDE VIEW BACK VIEW f.17 a.18 a.19 FRONT VIEW f.20 v.6 v.7 v.2 v.8 v.3 v.4 v.5 f.21 f.22 v.9 f.23 v.25 f.24 a.10 a.15 a.15 a.11 v.12 f.1 a.13 a.14 FRYER WVAE-30, WVAE-55 or WVPE-30 f.26 f.16 Note: Items beginning with “a. ...” are part of the Ansul® fire suppression system Items beginning “f. ...” are part of the FRYER Items beginning “v. ...” are part of the VENTILATOR FRYER position turns ON the VENTILATOR POWER LIGHT and BLOWER. If, within 10 seconds, there is sufficient AIR FLOW for proper operation, the POWER LIGHT will remain ON and the fryer will operate. If, after 10 seconds, there is not sufficient AIR FLOW for proper operation, the BLOWER and VENTILATOR POWER LIGHT will turn OFF and the SERVICE REQUIRED LIGHT will turn ON. Note: The POWER SWITCH must be turned OFF to reset the system before the fryer can be operated. v.2 VENTILATOR POWER LIGHT (green) Glows when the FRYER POWER SWITCH is ON. v.3 CHECK FILTERS LIGHT (amber) Glows when GREASE BAFFLE and/or HEPA AIR FILTER are not properly installed. When ON, the fryer heating elements are de-activated. Make sure both the HEPA FILTER and the GREASE BAFFLE fully depresses their respective filter sensor tang (f.25, lower left corner of the filter rail), which proves the filters are in the proper position. When the filters are in the proper position, the CHECK FILTER light will not be lit. 2 381 502944 Service Manual for NFPA Hood f.1 POWER SWITCH (FRYER - OFF - FILTER) FEATURES & OPERATING CONTROLS (continued) v.4 REPLACE FILTERS LIGHT (amber) Will turn ON if either or both the HEPA AIR FILTER and/or CHARCOAL FILTER are due for replacement. The fryer will continue to operate, but the air filter(s) must be changed in a timely manner or it (they) will clog, the SERVICE REQUIRED LIGHT will turn ON and the fryer will shutdown until the filter(s) have been replaced. v.5 SERVICE REQUIRED LIGHT (red) Will turn ON and the fryer will shut down whenever dirty filters cause insufficient ventilator AIR FLOW for proper operation. Replace both the HEPA FILTER and the CHARCOAL FILTER to resume operation. v.6 EXHAUST COLLAR Contains fire damper with pre-installed 285ºF (141ºC) fusible link. v.7 VENTILATION BLOWER Provides airflow. v.8 UPPER REAR REMOVABLE PANEL Provides access to BLOWER and PRESSURE SWITCHES. v.9 PRESSURE SWITCHES Detect blower operation and filter status. a.10 ANSUL® ACTUATOR Controls the release of the fire suppression media 381 502944 Service Manual for NFPA Hood a.11 ANSUL® SYSTEM Provides pressurization of the fire suppression system PRESSURE CARTRIDGE v.12 LOWER REAR REMOVABLE PANEL Provides access to fire suppression system components. a.13 FIRE SUPPRESSION MEDIA TANK 1.5 gal. container of Ansulex® R-102 liquid fire suppression media. a.14 FRYPOT FUSIBLE LINK 450ºF link protects against run-away heater. a.15 MANUAL PULL STATION Provides for manual activation of the fire suppression system f. 16 REAR LEGS REPLACE CASTERS WHEN A REMOTE MANUAL PULL STATION IS INSTALLED. v.17 VACUUM TAP Senses low-pressure side of BLOWER. a.18 FILTER CHAMBER FUSIBLE LINK 280ºF fusible link provides protection against fire in the upper portion of the hood. a.19 DISCHARGE NOZZLES Control dispersal of the fire suppression media. v.20 TOP REMOVABLE PANEL Provides access to warning light panel wiring. v.21 CHARCOAL FILTER Provides for some odor control. Replace this filter each time the HEPA FILTER is replaced. v.22 HEPA FILTER Traps most grease and other cooking vapor particles. Replace the HEPA FILTER and the CHARCOAL FILTER at the same time. v.23 GREASE BAFFLE Separates grease and other liquids from the air stream. v.24 GREASE CUP Catches liquids trapped by the GREASE BAFFLE. f.25 FILTER SENSORS Detect GREASE BAFFLE and HEPA FILTER. f.26 GREASE TRAY Collects liquids that drain from the top of the fryer. 3 OPERATION VENTILATOR POWER ON CHECK FILTERS REPLACE FILTERS SERVICE REQUIRED NOTE: Never press the POWER SWITCH to FRYER unless the HEATING ELEMENTS are covered with either shortening (or, in the case of cleaning, water - NEVER MIX OIL AND WATER ). Check the COLD OIL LINE for the proper shortening level. NOTE: This fryer is designed to be used with LIQUID SHORTENING ONLY, unless it is equipped with the solid shortening option (available only on model WVAE-55FS). Lard and solid shortening will solidify in the filter pump, causing pump failure. 1. Verify that the CHARCOAL FILTER (if used), HEPA FILTER and GREASE BAFFLE are properly installed in their respective locations. The HEPA FILTER and GREASE BAFFLE activate MECHANICAL INTERLOCK SWITCHES when they are in their proper position. Activating both mechanical interlock switches energizes the heating element. The CHARCOAL FILTER does not activate a position sensor, thus the ventilator may be operated without this optional filter. A pressure tap on the blower housing and a vacuum tap downstream of the filters (but before the blower) feed pneumatic signals to the AIRFLOW VACUUM SWITCH and to the SERVICE FILTER VACUUM SWITCH. 2. Press the POWER SWITCH to the FRYER position: The BLOWER will start and the VENTILATOR POWER ON (green light) will light. b. The TEN SECOND DELAY RELAY will be energized, bypassing the AIRFLOW VACUUM SWITCH during the ten-second countdown. 3. If, after the ten second delay, sufficient air flow is sensed by the AIRFLOW VACUUM SWITCH , the BLOWER will continue to run and the fryer will be energized. 4. If, after the ten second delay, sufficient air flow has not been sensed by the AIR FLOW VACUUM SWITCH, the BLOWER will shut down and the SERVICE REQUIRED (red light) will be lit. 5. If either the HEPA FILTER or GREASE BAFFLE should be removed or become dislodged, the respective MECHANICAL INTERLOCK SWITCH will open, the fryer will be de-energized and the CHECK FILTERS (amber light) will light. 6. If either the HEPA FILTER or the CHARCOAL FILTER, or in combination, become partially clogged, the SERVICE FILTER VACUUM SWITCH will close and the REPLACE FILTERS (amber light) will light. The fryer will continue to operate. This is a WARNING that the filters are approaching the end of their service life. The filter(s) must be replaced before they become so clogged that the fryer/ blower is shut down by the AIR FLOW VACUUM SWITCH. 4 381 502944 Service Manual for NFPA Hood a. OPERATION (continued) IMPORTANT: When the REPLACE FILTERS (amber light) comes on, the fryer will soon shut down. The actual time between the light coming on and the fryer shutting down depends upon the type and quantity of product being cooked. The operator must prepare to change the filter(s) by making sure that fresh replacement filters are on hand at the fryer location. 7. If either the HEPA FILTER or the CHARCOAL FILTER, or in combination, become clogged to the point that sufficient airflow is not sensed by the AIRFLOW VACUUM SWITCH, the switch will open. The BLOWER will shut down, the fryer will be de-energized and the SERVICE REQUIRED (red light) will light. The manufacturer recommends replacing both the HEPA FILTER and the CHARCOAL FILTER at the same time. Verify that the air flow arrows point toward the fan. After the filter(s) are replaced, the POWER SWITCH must be pressed to OFF, then back to FRYER to reset. 8. Any loss of electrical power will disable the fryer. After power is restored, the POWER SWITCH must be pressed to OFF, then back to FRYER to reset. 9. The fryer is de-energized anytime the Ansul® fire suppression system has discharged, or is otherwise is not CHARGED and COCKED. The BLOWER will continue to run. 10. Both the fryer and the BLOWER are de-energized when the POWER SWITCH is in the FILTER position. 11. Control power is routed through a jumper at the REMOTE INTERLOCK TERMINAL BLOCK. For installations where remote shut-down is required, the jumper is removed and power is routed through the remote interlock circuit. Both the fryer and the BLOWER are de-energized when the remote interlock circuit is open. 381 502944 Service Manual for NFPA Hood 12. Some jurisdictions require that an alarm signal be generated should the fire suppression system be activated. A set of dry contacts are provided at the BUILDING ALARM RELAY for this purpose. IMPORTANT: DO NOT connect power to the building alarm relay. 5 TROUBLESHOOTING SUGGESTIONS SYMPTOM BLOWER/FRYER NOT OPERATING VENTILATOR POWER (green light) not lit BLOWER/FRYER NOT OPERATING VENTILATOR POWER (green light) lit BLOWER/FRYER NOT OPERATING SERVICE REQUIRED (red light) lit REPLACE FILTERS (amber light) lit Blower/Fryer operating normally CHECK FILTERS (amber light) lit Blower operating normally Fryer not operating VENTILATOR POWER (green light) not lit All other operations normal SUGGESTED REMEDY POWER SWITCH not in FRYER Press POWER SWITCH to FRYER position Fryer POWER SWITCH defective Replace power switch 10-20 -second timer defective Replace timer Remote interlock circuit open Locate and rectify open circuit condition Blower wiring defective Repair wiring Blower fan jammed Clean blower fan Blower motor defective Repair/replace motor HEPA FILTER and/or CHARCOAL filters plugged Replace both HEPA and CHARCOAL FILTER AIRFLOW VACUUM switch not made Locate and rectify reason SWITCH not Vacuum tap on blower fan housing plugged Clean vacuum tap For continuing problems with plugged tap, upgrade to new-style fan housing. AIRFLOW vacuum switch defective Replace vacuum switch HEPA FILTER and/or CHARCOAL filters becoming plugged Replace both HEPA and CHARCOAL FILTER Vacuum tap on blower fan housing restricted Clean vacuum tap For continuing problems with plugged tap, upgrade to new-style fan housing. SERVICE FILTERS vacuum switch defective Replace vacuum switch GREASE BAFFLE and/or HEPA FILTER out of place Install BAFFLE / HEPA FILTER properly. Filter sensing switch defective or out of Adjust or replace switch Defective CONTROLLER or TEMP CONTROL ‘STAT Repair or replace HI-LIMIT ‘STAT tripped Clean frypot & reset ’stat HI-LIMIT ‘STAT defective Replace hi-limit thermostat Defective relay Replace relay Fryer with Solid State Controller - Programmed temp too low Program proper temperature Fryer with Solid State Controller - STANDBY or CLEANING mode selected Select a menu key Indicator light defective Repair/replace light 6 381 502944 Service Manual for NFPA Hood FRYER NOT OPERATING Blower operating normally Check Filters (amber light) not lit POSSIBLE CAUSE SERVICING INSTRUCTIONS FIRE DAMPER COMPONENTS ITEM DESCRIPTION 5 9 DAMPER SUPPORT FIRE DAMPER ASSEMBLY, (fusible link rated at 285ºF/141ºC) SERVICE PART 501187 FIRE DAMPER ASSEMBLY INSTRUCTIONS 1. The FIRE DAMPER is accessible by removing the UPPER REAR cover. The FIRE DAMPER sets in the DAMPER SUPPORT and may be removed by lifting straight out. 2. The FIRE DAMPER normally needs no maintenance. If it becomes heavily covered in grease and/or dust it must be replaced. 381 502944 Service Manual for NFPA Hood 3. If the FIRE DAMPER malfunctions or if the fusible link releases, the manufacturer recommends that the entire FIRE DAMPER ASSEMBLY be replaced. 4. Reinstall the FIRE DAMPER with the “THIS SIDE UP FOR HORIZONTAL MOUNTING” arrow pointing away from the BLOWER, and the shutter assembly on the wide side of the DAMPER SUPPORT (i.e. on the left as seen from the rear of the hood). 7 SERVICING INSTRUCTIONS (continued) FILTER INTERLOCK COMPONENTS DESCRIPTION SERVICE PART NO. 13 15 24 25 34 37 41 43 48 MAGNET ARM INTERLOCK BLOCK SHORT LINK COVER, INTERLOCK ASSEMBLY LONG LINK PROXIMITY SWITCH BUSHING PAWL MAGNET AA BB CC DD EE FF GG HH JJ “E” CLIP, .122ID SS NUT 8-32 (pk100) SET SCREW 8-32 x 3/4 ALLEN SOCKET SCREW 8-32 x FLAT HEAD (pk 50) SCREW 8-32 x 5/16 SCREW 4-40 x 3/8 WASHER #4 LOCK WASHER #4 NUT 4-40 501409 501448 63948 8 50136 50153 65193 7506-39 68748 8543-74 381 502944 Service Manual for NFPA Hood ITEM SERVICING INSTRUCTIONS (continued) FILTER INTERLOCK ASSEMBLY INSTRUCTIONS There are two FILTER INTERLOCK assemblies. a. The GREASE BAFFLE interlock is on the left. This assembly uses the LONG LINK so that the PAWL fits into the front filter rail. b. The HEPA FILTER interlock is on the right. This assembly uses the SHORT LINK so that the PAWL fits into the rear filter rail. 1. Install two SET SCREWS into the edge of each INTERLOCK BLOCK. 2. With the INTERLOCK BLOCK laying flat, the set screws pointing away from you, and the set screw that is closest to the end in the upper right corner, insert a BUSHING in the right hole, and insert a BUSHING in the left hole (for the GREASE BAFFLE INTERLOCK), or in the middle hole (for the HEPA FILTER INTERLOCK). (Fig. A) 3. Install a MAGNET in the MAGNET ARM. Align the magnets so they repel each other when they are in the normal operating position. (Fig. B) 4. Assemble the PAWL and the MAGNET ARM to the LINK. The short leg of the “L” slot will point down. Slide the link into the top slot of the small studs. Use the LONG LINK for the GREASE BAFFLE INTERLOCK, and the SHORT LINK for the HEPA FILTER INTERLOCK. (Fig. C) 381 502944 Service Manual for NFPA Hood Slide the large studs into the BUSHINGS and secure with “E” CLIPS. The pawl and arm should operate freely. 5. Push the SET SCREWS through the appropriate holes in the filter rail and secure with nuts. The pawl and arm should continue to operate freely. 6. Install the COVER and secure with two screws from the filter rail side. 7. Install the PROXIMITY SWITCHES on the ledge in the blower section. The switches must be installed with the thickest edge against the wall. Before tightening the screws, push the switches as far forward and as far apart as they will go. 8. Check operation with an ohm meter on the leads of the PROXIMITY SWITCHES while pressing and releasing the PAWLS. With the pawl depressed, the reading should be zero ohms. 9 SERVICING INSTRUCTIONS (continued) BLOWER AND STATUS SENSOR COMPONENTS ITEM SERVICE PART NO. BLOWER ASSEMBLY 501731 VACUUM SWITCH, SHUTDOWN (& RED LIGHT) 501379 VACUUM SWITCH, REPLACE FILTER 501380 TUBING, HOSE (LOW PRESS TO SWITCHES) 501516 “TEE” CONNECTOR ELBOW QUICK SEAL FITTING, 1/4” x 1/4” 3/8 MPT CLOSE NIPPLE HOSE BARB (TUBING TO HOSE) “TEE” CONNECTOR (HI PRESS) S/S TUBING (HI PRESS TO SHUTDOWN SWITCH) S/S TUBING (HI PRESS TO REPLACE FILTER SWITCH) S/S TUBING (TO SWITCHES) S/S TUBING (TO SHUTDOWN SWITCH) S/S TUBING (TO REPLACE FILTER SWITCH) 10 381 502944 Service Manual for NFPA Hood 14 32 33 42 54 55a 55b 55c 56 57 58 59 60 61 62 DESCRIPTION SERVICING INSTRUCTIONS (continued) STATUS SENSOR CHECKOUT PROCEDURES 1. The Ansul® system must be ”cocked” before system operation and checkout is possible. Make sure the heating elements are covered with oil before beginning checkout. 2. Remove GREASE BAFFLE, HEPA FILTER and CHARCOAL FILTER. Press the POWER SWITCH to FRYER. You should see: VENTILATOR POWER (green light) ON CHECK FILTERS and REPLACE FILTERS (amber lights) ON Within 2 - 4 seconds, REPLACE FILTERS (amber light) should go OFF Heating element will be OFF 3. Verify that the FILTER MECHANICAL INTERLOCK PAWLS operate independently of each other. If not, the magnets will need to be re-aligned (see page 9). With both pawls pressed, CHECK FILTERS (amber light) should go OFF, and the heating elements should be energized. 381 502944 Service Manual for NFPA Hood 4. Install the CHARCOAL FILTER first (be sure the plastic shipping bag is removed), then the HEPA FILTER, followed by the GREASE BAFFLE. Note the airflow arrows. The arrow must point toward the blower. The CHECK FILTERS (amber light) should go OFF. 5. Begin covering the GREASE BAFFLE with cardboard. Work slowly so that the sensors have time to react. To be sure the sensor does not “flutter”, wait at least 20 seconds after a response before proceeding. With fresh, clean filters: a. When 90% of the filter is covered, REPLACE FILTERS (amber light) will go ON b. When only 1” of the GREASE BAFFLE remains uncovered, SERVICE REQUIRED (red light) will go ON and the unit will shut down (i.e. elements de-energized and all other indicator lights OFF). 6. Reset the fryer by removing the cardboard blocking the filter, then pressing the POWER SWITCH to OFF then back to ON. 7. If the Ansul® systems trips, a continuous buzzer will sound. VENTILATOR POWER (green light) will remain ON, but the heating elements will be de-energized. 11 NOTE: On units with solid state control, the HEAT light being on is not a guarantee the elements are in fact energized! IMPORTANT: Before installing the CHARCOAL FILTER, be sure the plastic shipping bag is removed. Simulate grease build-up by using an 18” wide X 24” long piece of cardboard. Working from the bottom, cover the ventilator opening gradually until the sensors react. SERVICING INSTRUCTIONS (continued) ANSUL® FIRE SUPPRESSION SYSTEM - DETECTION SYSTEM (EMT) PIPING FOR GENERAL REFERENCE ONLY All servicing of Ansul® system must be performed by an authorized Ansul® Service representative only. ITEM 27 31 DESCRIPTION SERIES DETECTOR ANSUL® P/N 56837 FUSIBLE LINK 280ºF plenum 415743-TYP K FUSIBLE LINK 450ºF frypot (ref. item 51) 415741-TYP K 15751 35 REMOTE PULL STATION ASSY 4835 80 COMPRESSION SEAL - 1/2” EMT 79152 84 PULLEY ELBOW 45771 WIRE ROPE (1/16” x 500’) 301403 SLEEVE, STOP 26317 SLEEVE, OVAL 4596 85 381 502944 Service Manual for NFPA Hood TEST LINK This parts list is for reference only and is intended for use only by an authorized Ansul® Service representative. 80 84 12 SERVICING INSTRUCTIONS (continued) ANSUL® FIRE SUPPRESSION SYSTEM - FIRE SUPPRESSION MEDIA PIPING FOR GENERAL REFERENCE ONLY All servicing of Ansul® system must be performed by an authorized Ansul® Service representative only. ITEM DESCRIPTION ANSUL® P/N BRACKET & RELEASE ASSY 79493 NITROGEN CARTRIDGE LT-20-R 7032 MICROSWITCH 15549 1.5 GAL. TANK (R-102 SYSTEM) 415961 FIRE SUPPRESSION AGENT (1.5 GAL.) 79694 ADAPTER, QUICK-SEAL 1/4” 78196 ADAPTER, QUICK-SEAL 3/8” 77284 99 NOZZLE (1N) plenum 419335 100 NOZZLE (3N) fryer 419338 52 53 381 502944 Service Manual for NFPA Hood 95 This parts list is for reference only and is intended for use only by an authorized Ansul® Service representative. 95 13 DETAIL A 41 15 58 64 53 19 TO FRYER LOCATION VARIES ON FRYER. 19 51 27 31 30 39 14 LOCATED ON FRYER DOOR. 29 2 1 3 47 22 12 44 26 11 46 21 25 40 20 16 8 PARTS ORDERING INFORMATION: Wells Manufacturing, Inc. 2 Erik Circle / P.O.Box 280 Verdi NV 89439 USA Phone: 888-492-2872 Fax: REV.(-) 888-492-2873 P/N 303097 http://www.wellsbloomfield.com 381 502944 Service Manual for NFPA Hood SEE DETAIL A 4 7 2 PL 45 63 49 14 5 9 52 6 50 6 37 42 17 32 63 18 28 61 33 54 62 55 36 10 59 60 56 57 43 41 34 13 48 15 41 41 43 13 EXPLODED VIEW - HOOD SYSTEM WVAE-30F WVAE-55F/FS WVPE-30F p/n 303097 rev.(-) 48 24 EXPLODED VIEW & PARTS LIST EXPLODED VIEW & PARTS LIST (continued) ITEM ITEM P/N 1 CHANNEL, FILTER SUPPORT 51 67274 2 SUPPORT, FILTER FRONT 52 3 SUPPORT, FILTER REAR 53 4 SUPPORT, HOOD REAR 54 FITTING, COMPRESSION BRASS TEE 5 DAMPER SUPPORT, WELDED ASSY 55 FITTING, COMPRESSION BRASS ELBOW 6 SUPPORT, COVER REAR 56 FITTING, COMPRESSION HOSE BARB 7 SUPPORT, COVER TOP REAR 57 FITTING, COMPRESSION MALE RUN TEE 8 COVER, PLUMBING 58 TUBING, ALUM 1/4 x 7-1/4 501187 DAMPER 59 TUBING, ALUM 1/4 x 1-1/4 COVER, ANSUL® 60 TUBING, ALUM 1/4 x 36 501189 GREASE CUP 61 TUBING, ALUM 1/4 x 6 12 FACEPLATE, WARNING 62 TUBING, ALUM 1/4 x 6 “U” 13 ARM, MAGNET 63 FTG STRAIGHT 1/2 FLEX BLOWER ASSY 64 CONDUIT 1/2EMT x 54” INTERLOCK BLOCK 65 CONDUIT 1/2EMT x 8-1/2” 9 P/N 10 11 14 501224 15 DESCRIPTION FUSIBLE LINK , 450ºF (frypot) MOUNTING BRACKET ASSY, R-102 67393 TANK, FIRE SUPPRESSION AGENT 1.5 GAL. HOOD WELDED ASSY 66 CONDUIT 1/2EMT x 5-3/4” TIMER CUBE / RELAY 67 CONDUIT 1/2EMT x 3” 18 SUPPORT, COMPONENT MOUNTING 68 FTG STRAIGHT 1/2EMT 19 BRACKET, TANK SUPPORT 69 CONDUIT 1/2EMT x 17” 16 17 501238 20 22403 FILTER, CHARCOAL 70 CONDUIT 1/2EMT x 8” 21 501253 GREASE BAFFLE 71 CONDUIT 1/2EMT x 5-7/8” 22 22402 FILTER, HEPA 72 CONDUIT 1/2EMT x 1-1/2” 23 BOX, MANUAL PULL 73 CONDUIT 1/2EMT x 37-1/2” 24 LINKAGE PLATE, SHORT 74 CONDUIT 1/2EMT x 13-1/2” 25 COVER, INTERLOCK 75 CONDUIT 1/2EMT x 14-1/2” 26 LIGHT PANEL 76 ELBOW 3/8NPT x 45º Ni PLTD 27 HOLDER, FUSIBLE LINK (INLINE DETECTOR) 77 NIPPLE 3/8NPT x 3” Ni PLTD 28 PANEL, RIGHT SIDE 78 NIPPLE 3/8NPT x 4” BI 29 PANEL, LEFT SIDE 79 NIPPLE 3/8NPT x 3” BI 30 31 381 502944 Service Manual for NFPA Hood DESCRIPTION 501378 LABEL, FILTER INSTALL INSTRUCTION 80 COMPRESSION SEAL 1/2EMT FUSIBLE LINK, 280ºF (plenum) 81 CONDUIT 1/2EMT x 4-1/2” 32 501379 SWITCH, AIRFLOW (.40 VAC.) 82 CONDUIT 1/2EMT x 3-5/8” 33 501380 SWITCH, FILTER (.55” VAC.) 83 CONDUIT 1/2EMT x 2” LINKAGE PLATE, LONG 84 PULLEY ELBOW 501389 REMOTE PULL STATION ASSY 85 WIRE ROPE, 1/16” x 500” COVER, BLOWER WELD ASSY 86 NIPPLE 3/8NPT x 6” BI 501409 SWITCH, PROXIMITY 87 WIRE SET (not shown) 88 501435 HANDLE, FILTER 89 NIPPLE 3/8NPT x 2” Ni PLTD HANDLE, FILTER SMALL 90 TEE NPT 3/8 x 3/8 x 3/8 34 35 36 37 38 39 40 41 501448 BUSHING, INTERLOCK 91 42 501516 TUBING, VACUUM 92 43 501588 INTERLOCK PAWL ASSY 93 FTG, ELBOW 3/8NPT 90º BI 44 50516 LIGHT, SIGNAL AMBER 94 NIPPLE 3/8NPT x 1-1/2” BI 45 51040 GROMMET INSUL 7/8” DIA. 95 ADAPTER, 3/8” QUICK-CON ANSUL® 46 51157 LIGHT, SIGNAL RED 96 NIPPLE 3/8NPT x 5-1/2” Ni PLTD 47 55697 LIGHT, SIGNAL GREEN 97 ELBOW 3/8NPT x 90º Ni PLTD 48 63948 MAGNET, PERM 98 NIPPLE 3/8NPT x CLOSE Ni PLTD 49 67099 CARTRIDGE, NITROGEN LT-20-R 99 NOZZLE, 1N ANSUL® 50 67273 MICROSWITCH 100 NOZZLE, 3N ANSUL® 15 WIRING DIAGRAMS WIRING DIAGRAM FOR WVAE-30F, VAE-30F 208V OR 240V, 9KW w/BUZZER SINGLE OR 3 PHASE - WIRED 3 PHASE AS SHOWN CHECK FILTER REPLACE FILTER SERVICE REQUIRED 46 VENTILATOR POWER 53 50 51 51 44 48 47 45 BLOWER MOTOR WIRE NUT(2) REPLACE FILTER SWITCH 49 41 HEPA FILTER INTLK 1/4 INS MALE M 1/4 INS MALE 1/4 INS MALE 1/4 INS FEMALE 1/4 INS FEMALE BAFFLE FILTER INTLK 41 56 57 INTERVAL TIMER AIR FLOW INTLK. 2 3 C 56 52 1 58 NO 44 NC 45 1/4 INS FEMALE C 54 55 44 BUZZER 44 COIL BLACK UPPER CONTROL BOX 1 59 RED 58 HOOD MICRO SWITCH 40 42 41 59 5 2 NC NO 4 3 COM BROWN 1/4 INS MALE HOOD BUZZER SWITCH 1/4 INS FEMALE BLD’G ALARM RELAY BEHIND REAR BOTTOM COVER ON RIGHT HAND SIDE OF BOTTOM PANEL. BUZZER LIGHT 31 25 35 33 POWER SWITCH 25 COOK LIGHT BUZZER 26 32 43 42 C 24 HEATON LIGHT POWER LIGHT 17 TIMER 31 40 34 36 9 8 18 8 LIFT MOTOR 1/4 INS MALE 11 32 7 C NC M 10 15 20 LIFT MOTOR POSITION SWITCH NO 14 UPPER CONTROL BOX 1/4 INS FEMALE LIFT MOTOR HOUSING LOWER CONTROL BOX 15 CONTACTOR 2 32 31 22 21 3 1L2 1L3 L2 HEATER ELEMENT FILTER MOTOR L3 HEATER ELEMENT 6 12 41 20 11 1L1 1L2 1L3 11 22 L2 1L1 11 12 21 22 31 FILTER SWITCH L3 TERMINAL BLOCK M 21 24 32 HI LIMIT THERMOSTAT 23 SINGLE PHASE CONVERSION FILTER TERMINAL BLOCK 208 240 24 22 24 1 4 2 5 3 6 11 2 7 1L1 1L2 1L3 60 HZ 40 CONTACTOR 3 1 NOM AMPS PER LINE THREE PHASE ONE PHASE L1 L2 L3 45 27 25 27 VOLTS 12 5 7 L1 15 L1 HEATER ELEMENT 19 4 1 12 CONTROLLER THERMOSTAT 381 502944 Service Manual for NFPA Hood 22 24 20 P/N 301413 REV.F SINGLE PHASE WIRING L1 16 L2 L3 WIRING DIAGRAMS (continued) WIRING DIAGRAM FOR VPE-30F & WVPE-30F 208V OR 240V, 9KW SINGLE OR 3 PHASE - WIRED 3 PHASE AS SHOWN VENTILATOR POWER CHECK FILTER REPLACE FILTER SERVICE REQUIRED 44 53 50 45 51 51 41 48 46 1/4 INS MALE 47 BLOWER MOTOR 1/4 INS FEMALE M 1/4 INS MALE HEPA FILTER INTLK WIRE NUT (2) 56 3 C NC BAFFLE FILTER INTLK BUZZER 220V 60HZ 58 NO 52 2 54 1 42 1/4 INS FEMALE AIR FLOW INTLK. 57 REPLACE FILTER SWITCH 1/4 INS MALE 1/4 INS FEMALE 49 44 C 59 56 40 1 55 45 COIL 58 44 BLACK MICRO SWITCH HOOD ON-OFF SWITCH BROWN 40 10 19 8 22 14 42 MICRO SWITCH N.C. COM N.O. M 18 UPPER CONTROL BOX LOWER CONTROL BOX 17 11 7 1/4 INS FEMALE TIMER MOTOR WITH BUZZER 9 C 24 1/4 INS MALE COOK LIGHT AMBER HEAT-ON AMBER ON-OFF AMBER 43 15 12 12 CONTROLLER THERMOSTAT CONTACTOR 20 381 502944 Service Manual for NFPA Hood 32 1 1L1 4 2 5 19 11 31 12 21 22 21 6 1L2 22 12 3 31 11 1L1 1L2 41 1L3 32 L1 HEATER ELEMENT 1L3 HI-LIMIT THERMOSTAT 22 L1 L2 L2 HEATER ELEMENT FILTER MOTOR L3 FILTER ON-OFF SWITCH 24 TERMINAL BLOCK M 23 L3 HEATER ELEMENT FILTER 21 SINGLE PHASE CONVERSION TERMINAL BLOCK NOM AMPS PER LINE VOLTS L1 208 240 THREE PHASE L2 L3 26 23 25 22 26 23 44 CONTACTOR 1 4 2 5 3 1 ONE PHASE 11 2 7 1L1 60 HZ 1L2 1L3 39 REV. D P/N 301412 20 17 3 6 SINGLE PHASE WIRING L1 L2 L3 COM BLD'G ALARM RELAY (2&4) BEHIND REAR BOTTOM COVER ON RIGHT HAND SIDE OF BOTTOM PANEL. RED UPPER CONTROL BOX NO 4 3 59 41 2 5 NC WIRING DIAGRAMS (continued) WIRING DIAGRAM FOR VAE-55F/WVAE-55F 3Ø, 208 OR 240V, 17KW HEATING ELEMENT (2) SERVICE REQUIRED VENTILATOR POWER CHECK FILTER REPLACE FILTER 46 53 50 51 41 48 49 44 47 45 BLOWER MOTOR 1/4 INS FEMALE 1/4 INS FEMALE 1/4 INS MALE M 41 WIRE NUT(2) 57 INTERVAL TIMER 45 HEPA FILTER INTLK 56 1 NC 55 44 58 44 44 1/4 INS MALE 1/4 INS 1/4 INS FEMALE MALE BAFFLE FILTER INTLK AIR FLOW INTLK. NO 56 52 3 2 C REPLACE FILTER SWITCH 51 58 C 40 54 RED 41 42 BUZZER 220V BLACK MICRO SWITCH 1 1L2 2 1L3 3 1L1 1 1L2 2 1L3 3 10 MERCURY RELAY 9 2 9 BUZZER LIGHT TERMINAL BLOCK 6 L1 L2 7 35 BUZZER 32 23 SWITCH 26 30 BUZZER 20 29 31 34 42 EXTERNAL INTERLOCK TERMINAL BLOCK (REMOVE JUMPER WHEN EXTERNAL CONTROL IS USED) 22 24 TIMER 17 COOK LIGHT HEAT HI LIMIT ON 14 THERMOSTAT LIGHT POWER ON LIGHT 19 15 TEMPERATURE CONTROL THERMOSTAT FILTER PUMP 43 21 GREEN 26 27 36 16 LIMIT SWITCHES INSIDE MOTOR HOUSING WHITE GREEN M BLACK RED 18 BASKET LIFT ACTUATOR 18 FRYER RATING AMPS L2 L3 L1 48 48 47 208 240 42 42 41 P/N 301584 REV.B VOLTS 17 50/60 HZ 381 502944 Service Manual for NFPA Hood 8 POWER SWITCH 40 5 3 L3 8 BEHIND REAR BOTTOM COVER ON RIGHT HAND SIDE OF BOTTOM PANEL 43 JUMPER C COM 4 14 33 27 3 2 NO BLD'G ALARM RELAY 1/4 INS FEMALE 4 1 NC 5 11 SAFETY CONTACTOR 13 15 1 COIL 59 BROWN 1/4 INS MALE 1L1 59 WIRING DIAGRAMS (continued) WIRING DIAGRAM FOR VAE-55FS/WVAE-55FS 3Ø, 208 OR 240V, 17KW HEATING ELEMENT CHECK FILTER LIGHT (AMBER) REPLACE FILTER LIGHT SERVICE REQUIRED LIGHT (RED) VENTILATOR POWER LIGHT (AMBER) (GREEN) 46 53 50 51 51 41 44 47 45 1/4 INS FEMALE(2) 49 48 BLOWER MOTOR 1/4 INS MALE M 1/4 INS FEMALE 57 REPLACE FILTER VACUUM SWITCH HEPA FILTER MAGNET OPERATED SWITCH 41 WIRE NUT(2) 56 INTERVAL TIMER 3 C 1/4 INS MALE(2) BAFFLE FILTER MAGNET OPERATED SWITCH AIR FLOW VACUUM 56 SWITCH 52 2 NO 58 (SMALL) 44 1 NC C 54 40 55 45 BUZZER 58 44 44 BLACK HOOD UPPER CONTROL BOX MICRO SWITCH 41 42 1L3 3 1L1 1 1L2 2 1L3 3 59 1/4 INS MALE 8500W ELEMENT 1L1 1 2 5 1 COI 2 NO NC 4 3 COM BROWN HOOD 1L2 59 220V 60HZ RED BLD'G ALARM RELAY 1/4 INS FEMALE BEHIND REAR BOTTOM COVER ON RIGHT HAND SIDE OF BOTTOM PANEL. UPPER CONTROL BOX 43 8500W ELEMENT MERCURY RELAY 15 S S 15 SAFETY CONTACTOR 14 9 6 5 4 3 2 1 MAIN TERMINAL BLOCK * 11 9 L1 L2 * NOT UL L3 LISTED ON SINGLE PHASE 10 CONTROLLER 16 26 42 12 8 50VA TRANSFORMER 13 C 3 2 1 6 5 4 9 8 7 6 12 11 10 5 9 6 3 8 5 2 7 4 1 THERMOCOUPLE 16 4 (IN REAR) 40 24V 25 POWER SWITCH + 22 COM UP + - RED 3 2 14 WHITE 1 21 (BASKET DOWN) SOLID STATE 30 RELAY AUDIBLE ALARM 31 1 TOP 17 19 - DOWN SOLID SHORTENING MELT(OPTIONAL ) 30 1 S GREEN 36 UP 30 BASKET LIFT ACTUATOR FILTER PUMP GREEN 20 18 M 19 SPARK QUENCHER (SNUBBER) - DC + 3 31 23 23 (COM) WHITE (DN) BLACK (UP) RED LIMIT SWITCHES INSIDE MOTOR HOUSING S 2 16 43 32 AC BOTTOM 4 HI LIMIT THERMOST 10 26 27 33 3 SOLID STATE RELAY 208V 24V + DC 4 (BASKET UP) 240V 24 V. FILTER PAN HTR. PAD 2 AC 22 21 CONTROLLER TRANSFORMER 24 V. PLUMBING HTR. TAPE EXTERNAL INTERLOCK TERMINAL BLOCK (REMOVE JUMPER WHEN EXTERNAL CONTROL IS USED) 8 - 27 7 + 381 502944 Service Manual for NFPA Hood JUMPER 17 18 S S VOLTS 208 240 REV G FRYER RATING AMPS L1 L2 L3 48 48 47 42 42 41 P/N 301466 50 - 60 HZ