Download Bartell B436 Owner`s manual

Transcript

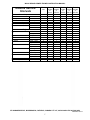

artell BARTELL MORRISON INC. Bartell Morrison Inc. 375 Annagem Blvd., Mississauga, ON, Canada L5T 2A7 Toll Free (N.A.): 1 866 501 1683 Local: +1 905 364 4200 Fax: +1 905 364 4201 OWNER’S OWNER’S MANUAL MANUAL AND PARTS BOOK WALK-BEHIND POWER TROWELS BC90/BC436 BC120/BC446 BC90/BC436 BC120/BC446 ORIGINAL LANGUAGE Doc. OI-B09001 Doc. # # OI-B09032 Orig. Rel. Rel. - 05-2012 Orig. Curr. Rev. Rev. --02 00 Curr. Rev. Date - 05-2012 Rev. 08-2012 Bartell Morrison Inc. Bartell Morrison (USA) LLC 25 Industrial Drive, 12 375 Annagem Blvd. Mississauga, Ontario, Canada Keyport, New Jersey, USA L5T 3A7 07735 Toll Free (N.A.): (866) 501-1683 Toll Free: 888-999-1570 Phone: (905) 364-4200 Phone: (732) 566-5400 Facsimile: (905) 364-4201 Facsimile: (732) 566-5444 www.bartellmorrison.com www.bmiamerica.com ORIGINAL LANGUAGE OPERATING INSTRUCTIONS FOR BARTELL WALK-BEHIND POWER TROWELS © 2010 Bartell Morrison Inc. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage or retrieval system without the prior written permission of Bartell Morrison Inc. unless such copying is permitted by federal copyright laws. Address inquiries or reference permissions care of: Bartell Morrison Inc., 375 Annagem Blvd., Mississauga, Ontario, Canada, L5T 3A7 Revision Date 0 05/2010 05/2012 Initial Release release RL AL 1 07/2012 Spiderplate assembly part number update. AL 2 08/2012 BC90 and BC120 throttle cables updated. AL Description Approved by. WALK BEHIND POWER TROWEL INSTRUCTION MANUAL SAFETY PRECAUTIONS ! DANGER EXPLOSION HAZARD Never operate the machine in an explosive atmosphere, near combustible materials or where ventilation does not clear exhaust fumes. WARNING BURN HAZARD Never come into contact with the engine or muffler when engine is operating or shortly after it is turned off. Serious burns may occur. ! CAUTION ROTATING HAZARD Never place hands or feet inside safety guard rings. Serious injury will result from contact with rotating blades. ! CAUTION MOVING PARTS Before starting the machine ensure that all guards and safety devices are in place and functioning properly. ! ATTENTION READ OWNERS MANUAL Read and understand operator's manual before using this machine. Failure to follow operating instructions could result in serious injury or death. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL TABLE OF CONTENTS QUALITY ASSURRANCE MACHINE BREAK-IN ................................................................................................... 4 QUALITY ASSURANCE/MACHINE BREAK-IN .......................................................................................................4 WALK-BEHIND POWER TROWEL WARRANTY ................................................................................................... 5 WALK-BEHIND POWER TROWEL WARRANTY ....................................................................................................5 MAINTENANCE RECORD ...................................................................................................................................... 6 MAINTENANCE RECORD ........................................................................................................................................6 ROUTINE SERVICE INTERVALS ........................................................................................................................... 7 ROUTINE SERVICE INTERVALS.............................................................................................................................7 SAFETY PRECAUTIONS ........................................................................................................................................ 9 FOREWORD..............................................................................................................................................................9 ASSEMBLY INSTRUCTIONS ................................................................................................................................. 9 SAFETY PRECAUTIONS..........................................................................................................................................9 9 1. TROWELSINSTRUCTIONS ........................................................................................................................................................... ASSEMBLY ...................................................................................................................................9 2. RING .............................................................................................................................................. 9 1. STABILIZER TROWELS .............................................................................................................................................................9 3. ASSEMBLY .......................................................................................................................................... 9 2. HANDLE STABILIZER RING.................................................................................................................................................9 9 4. RING ............................................................................................................................................ 3. STATIONARY HANDLE ASSEMBLY ............................................................................................................................................9 5. CONTROLS .......................................................................................................................................... 9 4. ENGINE STATIONARY RING ..............................................................................................................................................9 9 6. GUARD ...................................................................................................................................................... 5. BELT ENGINE CONTROLS ............................................................................................................................................9 6. BELT GUARD ........................................................................................................................................................9 10 DIAGRAM 1 ............................................................................................................................................................. DIAGRAM 1 .............................................................................................................................................................10 OPERATION (FLOATING) ...................................................................................................................................... 11 OPERATION(FINISHING) (FLOATING)...................................................................................................................................... ......................................................................................................................................11 11 OPERATION OPERATION (FINSHING) .......................................................................................................................................11 1. STARTING PROCEDURES - WARM TEMPERATURES .................................................................................... 11 1. STARTING STARTINGPROCEDURES PROCEDURES--COLD WARMTEMPERATURES TEMPERATURES ...................................................................................11 11 2. ..................................................................................... 2. STOPPING STARTING PROCEDURES PROCEDURES ................................................................................................................................ - COLD TEMPERATURES.....................................................................................11 11 3. 3. STOPPING PROCEDURES ................................................................................................................................11 LUBRICATION ........................................................................................................................................................ 11 LUBRICATION ........................................................................................................................................................11 1. ENGINE OIL ........................................................................................................................................................ 11 1. ENGINE OIL.........................................................................................................................................................11 2. SPIDER PLATE ................................................................................................................................................... 11 2. SPIDER PLATE ...................................................................................................................................................11 3. GEARBOX ........................................................................................................................................................... 11 3. GEARBOX ...........................................................................................................................................................11 4. GEARBOX OIL CHANGE .................................................................................................................................... 11 4. GEARBOX OIL CHANGE ....................................................................................................................................11 5. GREASE FITTINGS ............................................................................................................................................ 11 5. GREASE FITTINGS.............................................................................................................................................11 ENGINE ................................................................................................................................ 11 ENGINE OIL OIL SPECIFICATION SPECIFICATIONS..............................................................................................................................11 STORAGE ............................................................................................................................................................... 12 STORAGE................................................................................................................................................................12 MAINTENANCE ...................................................................................................................................................... 12 MAINTENANCE.......................................................................................................................................................12 12 1. 1.AIR AIR CLEANER CLEANER..................................................................................................................................................... .....................................................................................................................................................12 12 2. 2. LUBRICATION LUBRICATION..................................................................................................................................................... .....................................................................................................................................................12 12 3. 3. SPARK SPARKPLUG PLUG...................................................................................................................................................... ......................................................................................................................................................12 4. BELT BELTTENSION TENSION................................................................................................................................................... ...................................................................................................................................................12 12 4. ELECTRIC POWER TROWEL OPERATION..........................................................................................................13 TROWEL ARM ADJUSTMENT FIXTURE .............................................................................................................. 13 SETTING UP THEPROCEDURE ELECTRIC POWER TROWEL .................................................................................................14 13 1. ADJUSTMENT ............................................................................................................................. STARTING THE ELECTRIC POWER TROWEL ....................................................................................................14 14 PARTS MANUAL (BC90/BC436) ........................................................................................................................... ELECTRIC POWER TROWEL WIRING DIAGRAM ...............................................................................................16 15 SPIDERPLATE ASSEMBLY (BC90/BC4336) .......................................................................................................... TROWELASSEMBLY ARM ADJUSTMENT FIXTURE ..............................................................................................................17 HANDLE - COMPLETE (BC90/BC436) ............................................................................................... 16 1. ADJUSTMENT PROCEDURE .............................................................................................................................17 GEARBOX ASSEMBLY - COMPLETE (BC90/BC436)............................................................................................. 17 TROUBLESHOOTING.............................................................................................................................................18 SAFETY RING ASSEMBLY/MTG PLATE (BC90/BC436)........................................................................................ 18 SPECIFICATIONS ...................................................................................................................................................19 ENGINE/CLUTCH/HOIST HOOK ASSEMBLIES (BC90/BC436)............................................................................. 19 COMPANY INFORMATION ....................................................................................................................................20 PARTS MANUAL (BC120/BC446) ......................................................................................................................... 20 NOTES.....................................................................................................................................................................22 SPIDERPLATE ASSEMBLY (BC120/BC446) .......................................................................................................... 21 HANDLE ASSEMBLY - COMPLETE (BC120/BC446) ............................................................................................. 22 GEARBOX ASSEMBLY - COMPLETE (BC120/BC446)........................................................................................... 23 SAFETY RING ASSEMBLY/MTG PLATE (BC120/BC446)...................................................................................... 24 ENGINE/CLUTCH/HOIST HOOK ASSEMBLIES (BC120/BC446)........................................................................... 25 TROUBLESHOOTING ............................................................................................................................................ 26 SPECIFICATIONS ................................................................................................................................................... 27 COMPANY INFORMATION .................................................................................................................................... 28 NOTES .................................................................................................................................................................... 30 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL QUALITY ASSURANCE / MACHINE BREAK IN The Bartell Walk-Behind Power Trowel is the product of extensive engineering development designed to give long life and unmatched performance. The Walk-Behind Power Trowels are shipped partially assemble, and only require filling with fuel and a brief check of lubricant levels in preparation for operation. You can help ensure that your Power Trowel will perform at top levels by observing a simple routing on first use. Consider that your new Power Trowel is like a new car. Just as you would break in a new car to the road or any new machine to the job, you should start gradually and build up to full use. Learn what your machine can do and how it will respond. Refer to the engine manufacturer’s manual for run-in times. Full throttle and control may be used after this time period, as allowed by material. This will serve to further break in the machine on your specific application, as well as provide you with additional practice using the machine. We thank you for the confidence you have placed in us by purchasing a Bartell WalkBehind Power Trowel and wish you many years of satisfied use. artell 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 44 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL WALK-BEHIND POWER TROWEL WARRANTY All products sold by Bartell Morrison Inc. and Bartell Morrison (USA) LLC (the “Company”) are warranted against defects in materials and/or workmanship; excluding normal wear on wearing components and components covered by a separate original manufacturers warranty, for a period of 24 months from the date of sale to the original end user purchaser provided that certain conditions have been met. Conditions: 1. The equipment serial number has been registered with the Company or its approved dealers, distributors, representatives or agents. 2. The equipment has been operated in an appropriate manner by qualified individuals. 3. The equipment has been properly maintained as per the instructions included in the Owner’s Manual. 4. All claims for warranty must be filed on proper forms and include the serial number of the equipment along with proof of purchase. Any evidence of failure to meet these conditions may result in a denial of the warranty claim. Consideration of warranty claims will be at the sole discretion of the Company, or its authorized dealers, distributors, representatives or agents. The Company may, at its discretion, request that the equipment to be considered for warranty be returned at the owner’s expense to an authorized repair facility for inspection. Under this warranty we may, at our discretion, repair or replace a part or the whole of the defective component or equipment. Our Warranty coverage is limited to the cost to repair or replace the defective portion of the equipment and a reasonable (as determined by the Company) amount of labour to conduct the repair or replacement. Under no circumstances shall the Company be liable for any additional or exceptional costs beyond the cost to repair or replace the defective portion of the equipment. The Company shall not be held accountable for; costs associated with travel to inspect or repair defective equipment, costs for transporting defective equipment to or from an authorized repair facility, costs incurred to repair or replace the defective equipment at any facility other than one authorized by the Company or ancillary damage caused by or as a result of the defective equipment. Under no circumstances shall equipment be returned to the Company or its authorized dealers, distributors, representatives or agents without the approval of the Company as evidenced by a Returned Goods Number. To obtain a Returned Goods Number contact the factory or your authorized dealer, distributor, representative or agent. This warranty is for the sole benefit of the original end user purchaser and is not transferable to any other company or person. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 55 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL MAINTENANCE RECORD PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN This Walk-Behind Power Trowel has been assembled with care and will provide years of service. Preventative maintenance and routine service are essential to the long life of your Power Trowel. Your dealer is interested in your new machine and has the desire to help you get the most value from it. After reading through this manual thoroughly, you will find that you can do some of the regular maintenance yourself. However, when in need of parts or major service, be sure to see your Bartell dealer. For your convenience we have provided this space to record relevant data about your Walk-Behind Power Trowel. When in need of parts or service be prepared to provide your Trowel serial number. Locate the serial number now and record in the space below. Date Purchased: Type of Machine: Dealer Name: Model: Dealer Phone: Serial Number: REPLACEMENT PARTS USED PART NO. QUANTITY COST MAINTENANCE LOG DATE DATE OPERATION 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 66 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL Routine Service Intervals Each use General Inspection: Guards Warning stickers Test run: Controls: Dead-man switch operation Pitch control Engine oil Engine oil filter Oil cooler Cooling Fins Air cleaner Air Intake Line Drive Belt Valve clearance Fuel filter Fuel Tank Engine wiring Engine: Check Check Check operation After 1.5 Each 3 months months or or 50 hrs 100 hrs Each 6 Each 9 Each 12 months months months or or or 200 hrs 300 hrs 400 hrs o o o o o o o o o o o o o o o Check Check Lubricate o o o o o o o o o o o o o o o o o Check Level Change Replace Clean Clean Check - clean Replace Check Replace Check tightness Replace Check-adjust Check & Clean Replace Clean Check o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o 2 yrs o 500 hrs o o o 500 hrs o 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 77 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL Routine Service Intervals Due to the nature and environment of use, Walk-Behind Power Trowels could be exposed to severe operating conditions. Some general maintenance guidelines will extend the useful life of your trowel. The initial service for your power trowel should be performed after 25 hours of use, at which time your mechanic (or authorized repair shop) should complete all of the recommended checks in the schedule above. The chart on page 6 (six) is handy for keeping a record of the maintenance performed and the parts used for servicing your trowel. Regular service according to the schedule above will prolong the life of the Walk-Behind Power Trowel and prevent expensive repairs. Keeping your Walk-Behind Power Trowel clean and free from debris is the single most important regular maintenance operation, over and above the checks in the service schedule above, that can be performed. After each use your Walk-Behind Power Trowel should be cleaned to remove any dust and debris from the undercarriage and surrounding components. Use of a power washer will make clean up quick and easy, especially if a non-stick coating was applied prior to use. In the Service Schedule above, items that should be checked, replaced or adjusted are indicated by “o” in the appropriate column. Not all Walk-Behind Power Trowel models include the same features and options and as such not all service operations may have to be performed. For ease of recording place a checkmark (√) through the “o” when the item is complete. If an item is not required or not completed place an “x” through the “o” in the box. All Walk-Behind Power Trowels have governed engine speed of 3600 rpm. See engine manufacturer’s manual for exact specifications. Care should be used when making any adjustments to the Walk-Behind Power Trowel not to change the governed speed. Failure to have your Walk-Behind Power Trowel regularly serviced and properly maintained in accordance with the manufacturer’s instructions will lead to premature failure and void the warranty. artell 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 88 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 SAFETY PRECAUTIONS RING – Install stationary ring as 4. STATIONARY WALK BEHIND POWER TROWEL INSTRUCTION MANUAL Always keep unauthorized, inexperienced, untrained shown in Fig. 5 with the side bar on engine recoil people away from this machine. side. (May not be exactly as shown). Install rubber Rotating and moving parts will cause injury if bushings (A) on top and bottom of mounting plate. SAFETY PRECAUTIONS contacted. Make sure guards are in place. Keep 4. STATIONARY RING Install ring run as Install metal caps (B). –Place ringstationary on top and Always keepfeet unauthorized, inexperienced, hands and away from moving parts. untrained shown in Fig. 5 with side bar on enginelock recoil screw (C) through capsthe and rubbers. Tighten nut people away from this Fuel the machine onlymachine. when the engine is stopped, side. (May not exactly shown). rubber (D) securely on be bottom. It isasbest to startInstall nuts on all 4 Rotating and moving parts will cause injury if using all necessary safety precautions. bushings (A) ontightening. top and bottom of mounting plate. corners before contacted. Make surealways guards be are stopped in place. before Keep The engine must Install metal caps (B). Place ring on top and run hands and feet moving parts. attempting any away repairfrom or adjustments. Ignition switch 5. screw (C) through caps and Tightencontrol lock nut ENGINE CONTROLS – rubbers. Attach throttle to Fuel thebemachine only when the engine is stopped, should off. (D) securely on bottom. It is best to start nuts onbelow all 4 handle with screws provided. See DIAGRAM 1 using all necessary safetyinprecautions. Be careful not to come contact with the muffler corners tightening. for yourbefore engine model hook-up. For safety switch The must always stopped before when engine the engine is hot, seriousbe burns may result! connection, attach wire to terminal provided at attempting any repair or adjustments. Ignition switch 5. ENGINE – Attach throttle control to “ON/OFF” CONTROLS location. DANGER: should be off. handle with screws provided. 1 below The throttle cable must be cutSee andDIAGRAM formed to fit. Feed Never operate thecome machine in with an the explosive Be careful not to in contact muffler for hook-up. Forthe safety switch the your cable engine throughmodel the cable clamp on engine. Pull atmosphere, near combustible where when the engine is hot, seriousmaterials burns mayor result! connection, attachthewire to until terminal provided at the cable through clamp it forms a smooth ventilation does not clear exhaust fumes. Repair “ON/OFF” location. arc from the handle to the engine. Mark the cable at DANGER: fuel leaks immediately. Refer to your engine The throttleand cable cutback and formed to casing fit. Feed the clamp pullmust the be cable from the at owner’soperate manual for safety instructions. Never themore machine in an explosive the through the cutting cable clamp on theCut engine. Pull the cable throttle. Without the cable, casing at atmosphere, near combustible materials or where the through forms afresh smooth the cable mark and pushthe theclamp cable until backit through cut ventilation does not clear exhaust fumes. Repair ASSEMBLY INSTRUCTIONS arc theahandle engine. the hook cablethe at end.from Form small to “L”the bend in theMark cable, fuel leaks immediately. Refer to Trowel your has engine Your new Bartell Walk-Behind Power been the clamp pull thethrottle cable back casing at inner cableand into the block from and the tighten cable owner’sto manual for more safety instructions. shipped you partially assembled. Filling the fuel tank the throttle. cutting theWith cable, Cut casing at clamp downWithout onto the casing. thumb lever and and a brief check of lubricant levels in preparation for the markblock and in push through cut throttle the the fullycable openback position, cut fresh the inner ASSEMBLY operation is INSTRUCTIONS required. To complete the assembly the end. a small “L” bend the cable, hook wire the cableForm by the thumb lever, inleaving enough Your newinstructions Bartell Walk-Behind Power Trowel has been following will be helpful. inner cable thetothrottle blockInsert and the tighten cable exposed to into secure the lever. cable into shipped to you partially assembled. Filling the fuel tank clamp down onto the casing. WithRestore thumb lever and the fitting and tighten the screw. throttle to and a brief check of lubricant preparation for 1. TROWELS – Attach trowellevels bladesinwith screws and throttle block in the fully open position, cut the inner idle position. operation is required. To complete the assembly lock washers supplied. See (A) and (B) Fig. 1. the Be cable by the thumb lever, leaving enough wire following instructions will bescrew helpful. careful that adjusting (C) does not protrude IMPORTANT: exposed to secure to the lever. Insert the cable into below arm when attaching blades. This could cause Before the fitting and machine tighten the screw. Restore throttle to running with belt installed, ensure 1. TROWELS trowel bladesexcessive with screws and the machine–toAttach jump and promote wear in that idle position. engine idles properly and that the safety -switch lock washers supplied. See (A) and (B) Fig. 1. Be operation. shuts off the engine. that adjusting screw (C) does not protrude 2. careful STABILIZER RING – (if supplied) Install using IMPORTANT: below arm when attaching Thissupplied. could cause screws, bushings and lockblades. washers See Before running machine with belt installed, ensure 6. BELT GUARD – Install after machine has been the Fig.machine 1 (D) to jump and promote excessive wear in that engine idles properly and that the safety -switch tested, taking care that it does not touch clutch or 3. operation. HANDLE ASSEMBLY – Put cable end Fig. 2 (A) shuts off the engine. pulley. 2. STABILIZER RING supplied) through hole in yoke –(B)(if and secure Install with nutusing (C), screws, bushings andbracket lock washers supplied. then install handle on gearbox. To See get 6. BELT GUARD – Install after machine has been Fig. 1 (D)cable tension, turn control knob Fig. 3, ATTENTION: proper tested, taking care that it does not touch clutch or 3. HANDLE ASSEMBLY – Put cableGuide end Fig. 2 (A) counter-clockwise to stop position. screw (B) For any information regarding engine adjustments, pulley. please refer to the engine manual supplied. through yoke (B) slot. and Tighten secure with nut 4(C), will now hole be atinthe bottom nut Fig. (A) then installis handle on (B) gearbox. To getIf until slack removedbracket from point as indicated. proper cable tension, turnshow control knob then Fig. nut 3, ATTENTION: more than 2 or 3 threads through, counter-clockwise to stop position. Guide screw (B) For any information regarding engine adjustments, should be turned back. will nowscrew, be at the Tighten nut Fig. (A) please refer to the engine manual supplied. Guide Fig.bottom 3 (B) slot. should be moved to4next until from and pointcable (B) as indicated.as If lowerslack hole is in removed slide bushing re-adjusted more or 3 threads show through, then and nut above.than Turn2 hand knob completely clockwise should be turned back. check for clearance between yoke and gearbox at Guide screw, 3 (B)should shouldbebeenough movedspace to next point (C) Fig. Fig. 4. There to lower in slidecard bushing and cable re-adjusted as pass ahole business through. above. Turn hand knob completely clockwise and check for clearance between yoke and gearbox at point (C) Fig. 4. There should be enough space to pass a business card through. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 9 CREATED: 07/04 REVISED: 05/10 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 99 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK-BEHIND TROWEL INSTRUCTION MANUAL DIAGRAM 1 Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig. 5 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 10 10 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 OPERATION (Floating) STOPPING PROCEDURE When the slab has set sufficiently firm that the 1. Throttle engine down. WALK BEHIND POWER TROWEL INSTRUCTION MANUAL operator’s footprint leaves a very slight depression on 2. Turn off stop switch. the surface of the slab, it is ready for the floating operation. LUBRICATION OPERATION PROCEDURE Under normal(Floating) operating conditions the machine should STOPPING 1. ENGINE OIL When the slab has set sufficiently firm that the 1. Throttle engine down. cover as much as 1000 sq. ft. in about 15 minutes. It is The long life and successful operation of any piece of operator’s footprint leaves a very slight depression on 2. Turn off stop switch. recommended that a slight tension on the trowel control machinery is dependent on frequent and thorough the surface the aslab, it is tilt), readyduring for the cable, (butofnot definite thefloating floating lubrication. operation. operation will cause the machine to operate much LUBRICATION Before using the trowel, always check your engine for Under normal operating conditions theset machine should OIL smoother. After the floated slab has sufficiently, it is 1. ENGINE oil. Use proper engine oil as recommended in the cover asfor much as 1000 operation. sq. ft. in about 15 minutes. It is The long and successfulmanual. operation piece ofto ready the finishing engine life manufacturer’s Fillof any crankcase recommended that a slight tension on the trowel control machinery is dependent on frequent and thorough levels as recommended. CAUTION: cable, (but not a definite tilt), during the floating lubrication. Do not let the machine stand in one spot on the operation will cause the machine to operate much Before using the trowel, always check your engine for ENGINE OIL SPECIFICATIONS soft cement. Lift from the slab when the floating smoother. After the floated slab has set sufficiently, it is oil. Use proper engine oil as recommended in the operation is complete. ready for the finishing operation. engine manufacturer’s manual. Fill crankcase to levels as recommended. CAUTION: OPERATION (Finishing) Do not let the machine stand in one spot on the When starting the finishing operation, never set the ENGINE OIL SPECIFICATIONS soft cement. Lift from the slab when the floating trowels up over 1/4” pitch. This is important. Guiding the operation is complete. machine on the slab is very simple, a slight upward lift of the handle causes the machine to travel to the left. OPERATION All Seasons SAE 10W-30 Holding the (Finishing) handle in the neutral position, will slowly When starting the finishing operation, never set the cause the machine to spin in one spot. Slight downward trowels up over 1/4” pitch. causes This is important. Guiding theto pressure on the handle the machine to travel 2. SPIDER PLATE machine on the slab results is very simple, a slight upward lift of the right. Best are obtained by covering There are 4 (four) grease fittings on the spider plate, the handle causes theeach machine to other travel words, to the let left. approximately 4” on turn. In the each must be greased daily. THE SPIDER PLATE Holding themove handleright in the neutral position, or willforwards, slowly machine or left, backwards MUST BE GREASED EVERY TIME MACHINE IS cause the machine to spin in one spot. Slight approximately 4” with each revolution of thedownward trowels. To USED. pressure onor the machine to travel to 2. SPIDER PLATE fill a hole cuthandle down causes a hump,the move the unit back and the right. Bestproblem resultsarea. are obtained by covering are 4 (four) grease fittings on the spider plate, forth over the 3. There GEARBOX approximately 4” on each turn. In other words, let the each must daily.plugs THEon SPIDER PLATE After the first pass over the slab, the waiting time Check thebeoilgreased level sight both gearboxes machine move right or left, backwards or forwards, MUST BE GREASED EVERY TIME MACHINE IS between operations is determined in the same manner daily to ensure the oil is half way on the site glass. approximately 4” with each revolution of the trowels. To USED. as if you were hand troweling. To repeat; the entire Top up with Agma 8 compounded gear oil only. fillapplication a hole or cut move the unit back and anddown actionaofhump, the troweling machine in regard Gearbox capacity 16 oz. to 19 oz. (473ml. To 562ml.) forth over theon problem area.and the correct pitch of the 3. GEARBOX to getting the slab, Example: Esso/Exxon Cylesstic TK680. After the is first pass over thesame slab,manner the waiting timebe Check the oil level sight plugs on both gearboxes trowels, determined in the as would between is determined in the same manner ensure GEARBOX the oil is half way on the site glass. used byoperations a cement finisher when troweling by hand. 4. daily TO to CHANGE OIL as if you were hand troweling. To repeat; the entire Top up with Agma 8 compounded oil the only.oil. Place a pan beneath the drain plug gear to catch application and action of the troweling machine in regard Gearbox capacity 16 oz. to 19 oz. (473ml. To 562ml.) Remove the drain plug and the filler plug from the STARTING PROCEDURE: *WARM CLIMATE to getting on the slab, and the correct pitch of the Example: TK680. gearbox.Esso/Exxon After the oilCylesstic has drained completely, replace Open fuel valve on gas tank. Set throttle lever to “Fast” trowels, is determined in the same manner as would be the drain plug and tighten. Fill the gearbox through idle position, set choke to closed position, start engine. used by a cement finisher when troweling by hand. 4. TO theCHANGE filler plugGEARBOX with 16 oz. OIL to 19 oz. (473ml. To 562ml.) Open choke slightly to prevent flooding. Move to “Open” Place a pan beneath the drain catch the of Agma 8 compounded gearplug oil. to Replace the oil. filler or “Run” position when engine is warm, increase throttle Remove the drain plug and the filler plug from the *WARM STARTING plug and tighten. to maximumPROCEDURE: operation position (3600 CLIMATE rpm). gearbox. After the oil has drained completely, replace Open fuel valve on gas tank. Set throttle lever to “Fast” the drain plug and tighten. Fill the gearbox through idle position, set choke to closed position, start engine. STARTING PROCEDURE: *COLD CLIMATE the filler plug with 16 oz. to 19 oz. (473ml. To 562ml.) Open choke slightly to prevent flooding. Move to “Open” Follow same procedure as above but allow longer of Agma 8 compounded gear oil. Replace the filler or “Run” position when engine is warm, increase throttle warm-up period – 3 to 5 minutes. In cold weather, oil is plug and tighten. to maximum operation position (3600 rpm). much heavier to move and requires more time to work its way into the moving parts. If maximum power is not STARTING PROCEDURE: *COLD attained, allow further warm-up time.CLIMATE Fill fuel tank with Follow same procedure as above but gas allow longer clean gasoline, use safety approved containers. warm-up period – 3 to 5 minutes. In cold weather, oil is DO NOT MIX OIL WITH GASOLINE – USE UNLEADED much heavier to move and requires more time to work GAS ONLY. its way into the moving parts. If maximum power is not attained, allow further warm-up time. Fill fuel tank with clean gasoline, use safety approved gas containers. 375MIX ANNAGEM MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 DO NOT OIL WITHBLVD., GASOLINE – USE UNLEADED CREATED: 07/04 GAS ONLY. 11 REVISED: 05/10 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 11 11 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL STORAGE The following steps should be taken to prepare your Walk-Behind Power Trowel for extended storage. 1. Close fuel shut off valve. 2. Siphon excess gasoline from tank. 3. Start engine until it stops from lack of fuel. This will use up all the fuel in the carburetor and prevent formation of deposits due to evaporation of fuel. 4. Remove spark plug and pour 2 oz. of SAE 10W 30 motor oil into the cylinder. Slowly crank the engine 2 or 3 times to distribute the oil throughout the cylinder. This will help prevent rust during storage. Replace spark plug. 5. Store the unit in an upright position in a cool, dry, well ventilated area. MAINTENANCE Maintaining your Walk-Behind Power Trowel will insure long life to the machine and its components. AIR CLEANER - Keep air filter clean at all times. Wash away dust and debris using a non-oil based cleaning solvent. Let the filter dry before re-installing. LUBRICATION – Check engine oil regularly. Use proper engine oil as recommended. See previous chart. Fill crankcase to levels as recommended in manufacture’s engine manual. SPARK PLUG – Check and clean spark plugs regularly. A fouled, dirty or carboned spark plug causes hard starting and poor engine performance. Set spark plug gap to recommended clearance. Refer to engine manual. BELT TENSION – IMPORTANT! If there is excessive belt play, there will be a decrease in the power transmission capability which could lead to premature wear and failure of the belt. The normal belt play should be 1/2” to 5/8” which is attained by depressing one side of the belt at the mid-point of the span between pulleys. Tighten all engine mount fasteners. CHART FOR MINIMUM WIRE SIZE OF EXTENSION CORD Nameplate AMPS CORD LENGTH 25’ 50’ 100’ 150’ 0-6 18 AWG 16 AWG 16 AWG 14 AWG 6-10 18 AWG 16 AWG 14 AWG 12 AWG 10-12 16 AWG 16 AWG 14 AWG 12 AWG 12-16 14 AWG 12 AWG (NOT RECOMMENDED) 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 12 12 CREATED: CREATED: 05/12 07/04 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL TROWEL ARM ADJUSTMEN T FIXTURE PART #20801 Ex: Unit 36” (B436) 1)10810A – Trowel arm 1) Trowel arm 2)10817A 2) Lift lever– Lift lever 3) Jam nut 3)10808 – Jam nut 4) Set screw 4)10809 – Set screw 5)10824 – Block top 5) Block top 6) Bolt – Bolt 6)10507 7) Jam nut 7)10808 – Jam nut 8) Carriage bolt 8)10807 – Carriage bolt 9) Adjustment bar 9)10832 – Adjustment bar 10) 10507 Bolt – Bolt 10) Figure 5a. The trowel arm adjustment fixture (20801) is reversible. By rotating the arm clamping fixture and the ring bolt, both left hand and right hand trowel arms may be adjusted. Before attempting adjustment, determine whether the trowel arm is right handed or left handed. When adjusting left hand trowel arms use the side of the fixture marked “L”. When adjusting right hand trowels arms use the opposite side. The adjustment bar will be set on “36” for the Walk-behind trowel arm. ADJUSTMENT PROCEDURE 1. Remove all trowel arm assemblies (1 & 2 arm and attached lift lever) from suspected maladjusted spider plate. 2. Remove lift lever (2) from trowel arm (1) by first loosening jam nut (3) then square head screw (4). If upon inspection (method left to discretion of serviceman) any trowel arm (1) is found to be in a bent condition, it must either be brought back to its original straight condition (method left to the serviceman’s discretion) or replaced with new part. 3. Replace lift levers (2) on new or straightened arms (1) by reversing procedure as described above. NOTE: IT IS IMPORTANT THAT WHEN TIGHT ENING SQUARE HEAD NUT (4), IT SEATS ITSELF SECURELY INTO DIMPLE MACHINED IN ARM. 4. Place trowel arm assembly (1 and 2) in fixture (5) with lift lever (2) butting up against fixture. Clamp in place with bolts (6). 5. Loosen locknut (7) and screw carriage bolt (8) down to full depth allowable. This will provide for ample clearance to swing precision ground adjustment bar (9) over head of carriage bolt. Adjustment bar (9) is stamped for appropriate size of machine. Swing appropriate side directly over carriage bolt (8) and secure in place with bolt (10). 6. Adjust carriage bolt (8) upwards until contact is made with adjustment bar (9); holding carriage bolt in position with one wrench, tighten locknut (7) to secure in position with second wrench. NOTE: IT IS VITALLY IMPO RTANT TO ENSURE THAT ONCE THE CARRIAGE BOLT IS ADJUSTED TO THE CORRECT HEIGHT, IT DOES NOT MOVE BEFORE, OR DURING THE TIGHTENING OF LOCKNUT. 7. This same procedure is to be followed with ALL arms from spider plate assembly, and will ensure correct and exact adjustment. TROWEL ARM ADJUSTMENT SCREW The trowel arm adjustment screw is to be used for field adjustment of blade level, in the event of a damaged trowel arm, to enable completion of the job. At the end of the job repairs should be made to eliminate the damage. When assembling trowel blades to trowel arms, the adjustment screw should NEVER protrude below the under-side surface of a trowel arm. If the adjustment screw is not flush with the underside of the trowel arm, then this will cause the power trowel to bounce and vibrate especially at high speed. This will also cause the trowel blades to leave an uneven finish to the concrete due to the blades not being level to one another. Make certain that the adjusting screw is held firmly in place while tightening the bolt which secures the blade to the trowel arm. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 17 13 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL BC90/BC436 ASSEMBLY DRAWINGS AND PARTS LIST 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 14 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL SPIDERPLATE ASSEMBLY (BC90/BC436) 32 63 35 62 49 50 61 56 55 54 31 53 36 48 52 53 47 27 57 108 60 59 58 31 Item Qty. Item Part Number 27 10897 Flat Washer, 10mm 4 52 10755 Square head set screw, M10, 1.5 lg 4 31 11621 Lockwasher, M10 2 53 10867 Hex Jam Nut, M10-1.5 4 32 10200 Yoke Arm, sm 1 54 10757 Carriage Bolt 4 35 10349 Yoke Arm Pin 1 55 10758 Blade lock bolts 4 36 10743 Lock Pin, 10mm 1 56 10000 Spiderplate 1 20646 Finish Blade - metric 4 57 10681 Lift Lever, sm 1 20415 Clip on Float - 10”x14” 4 58 10059 SHCS, M10-1.5x25mm lg 1 20483 Combo Blade - metric 4 59 10760 Cap Plug 1 20414 Finish Blade, 6”x14” - imperial 4 60 10761 Grease Cap 4 20479 Combo Blade, 8”x14” - imperial 4 61 10002 Pressure Plate 1 10001 Trowel Arm 4 62 10664 Thrust Bearing 6009-2RS 1 10452 HHCS, M8-1.25x10mm - metric 4 63 10003 Press Plate Cap 1 10401 HHCS, 5/16-18”x1 1/2” lg - imperial 4 11614 Lockwasher, 8mm - metric 4 108 10286 Spiderplate assembly (blades and hardware not included) 1 10402 Lockwasher - imperial 4 47 48 49 50 Part Number Description Description Qty. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 15 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL HANDLE ASSEMBLY - COMPLETE (BC90/BC436) 1 3 2 4 6 5 7 8 11 14 9 10 13 15 16 20 12 17 19 17 18 21 23 27 26 25 28 27 22 107 24 30 29 30 31 27 Item Item Part Number 1 Part Number Description 10684 Handle Grips (ea) 17 10694 SHCS, M6-1.0x6mm lg Description 2 21728 PHMS, M5-0.8x8mm 18 14448 Lockwasher, 6mm 3 10703 Lockwasher, 5mm, internal 19 10345 Slide bushing 4 10508 Throttle Assembly 20 10696 Spring pin, 5mm-30 5 10687 PHMS M5-0.8x10mm 21 10291 Pitch control cable 6 10688 Flat washer, 5mm 22 10346 Pulley 7 10342 Handle (tube only) 23 10697 Pin, 6mm 8 20713 Deadman switch 24 10680 Cable support block 9 10343 Pitch control knob 25 10347 Handle clamp 10 10689 Pin, 5x50mm 26 10077 HHCS, M10-2.5x35mm lg 11 10609 Bearing 51204 27 10897 Flat washer, 10mm 12 10683 Pitch control bushing 28 13349 HHCS, M10-1.5x70mm lg 13 10609 Wave washer, 18mm 29 10348 Handle clamp 14 10692 Flat washer, 20mm x 34mm x 3mm 30 11802 Lock nut, M10-1.5x16mm 15 10693 Lock pin, 18mm 31 11621 Lokwasher, 10mm 16 10344 Screw shaft 107 20650 Handle assembly (complete) 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 16 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL GEARBOX ASSEMBLY - COMPLETE (BC90/BC436) 81 42 80 79 78 77 76 75 109 73 74 71 72 68 42 67 66 40 70 31 27 69 33 39 65 64 34 31 27 37 38 39 40 45 41 42 43 44 Item 27 Part Number Description Qty. Item Part Number 46 Description Qty. 10897 Flat washer, 10mm 1 68 10682 Sight glass/oil gauge 31 11621 Lockwasher, M10 2 69 10765 Gearbox (casing only) 1 33 10741 Stud 1 70 11802 Locknut, M10-1.5, nylon insert 1 34 11834 SHCS, M10-1.5x16mm 71 10767 Key 1 37 10284 Countershaft w/worm 1 72 10232 Mainshaft 1 38 10744 Bearing 32004 1 73 10768 Bearing 6206 1 39 10745 Gasket 2 74 10769 Woodruff key 1 40 10746 O-ring 2 75 10285 Main gear 1 41 10747 Flange, sm 1 76 10770 Bearing 30305 1 42 10748 SHCS, M6-1.0x16mm 16 77 10771 Washer 1 43 10750 Oil seal 20408 1 78 10772 M10x2.5 Hex Screw 1 44 10350 Pulley 1 79 10773 Gasket 1 45 10759 SHSS, M8-1.25x10mm 1 80 10774 Gearbox cover 1 46 10751 Key, 5mm x 35mm 1 81 10775 Release valve 1 64 10762 Oil seal 274710 1 109 10100 Gearbox assembly (complete) 1 65 10763 Bolt, oil drain 1 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 17 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 1 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL SAFETY RING ASSEMBLY/MTG PLATE (BC90/BC436) 100 99 101 102 103 98 106 104 105 Item Qty. Item Part Number 98 Part Number Description 10786 Hex lock nut, flanged, M8-1.25 4 103 10791 Flat washer, 8mm x 26mm 8 99 10787 SHCS, M801.25x40mm 4 10338 Mtg plate-GX160 1 100 10919 Flat washer, 5/16-8mm 4 10339 Mtg plate-GX270 1 101 10789 Bowl washer 4 105 10393 Guard ring, powder coated 1 102 10790 Rubber washer 4 106 10792 SHCS, M8-1.25x20mm 6 104 Description Qty. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 18 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL ENGINE/CLUTCH/HOIST HOOK ASSEMBLIES (BC90/BC436) 97 110 98 93 96 92 91 90 95 94 49 50 86 89 88 87 45 82 Item Part Number Description Qty. 45 10750 SHSS, M8-1.25x10mm 1 49 10452 HHCS, M10-1.5x35mm - GX160 1 50 11614 Lockwasher, 8mm - GX160 1 82 10287 Belt Guard - GX160 1 86 10777 Flat washer, 45mm x 10mm x 2.85mm 1 87 10778 Clutch Cover, sm - GX160 1 11015 Faceplate - GX270 1 88 10779 Weight - GX160 4 89 10780 Clutch Spring - GX160 1 11013 Spring - GX160 1 90 10781 Bushing, copper - GX160 1 11012 Bushing - GX270 1 91 10782 Clutch drum - GX160 1 21046 Spindle - GX270 1 Item 92 93 94 95 96 97 98 110 Part Number Description Qty. 14996 Bearing, 6006-2RS - GX160 1 11044 Bearing - GX270 1 10784 Spindle - GX160 1 11045 Spindle - GX270 1 50117 Set Screws (2) (not shown) 1 11030 Belt, A25 - GX160 1 11047 Belt, BP28 - GX270 1 30041 FHSCS, 5/16-24 x 3/4” 4 10201 Hoist Hook - GX160 1 10300 Hoist Hook - GX270 1 21333 GX160 Honda 1 21334 GX270 Honda 1 10786 Hex lock nut, flanged, M8-1.25 2 10293 Clutch Assm. Complete, 3/4” shaft - GX160 1 21005 Clutch Assm. Complete, 1” shaft - GX270 1 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 19 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL BC120/BC446 ASSEMBLY DRAWINGS AND PARTS LIST 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 20 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL SPIDERPLATE ASSEMBLY - COMPLETE w/o BLADES/HARDWARE (BC120/BC446) 32 35 65 36 64 49 50 51 63 56 48 113 52 53 55 54 31 53 47 27 57 115 62 61 60 58 59 Item Part Number Description Qty. Item Part Number Description Qty. 27 10897 Flat washer, 10mm 14 52 10755 Lock screw 4 31 11621 Lockwasher, M10 10 53 10867 M10 nut 8 32 10299 Yoke arm 1 54 10757 M10x35 square head bolt 4 35 10900 Yoke Pin 1 55 10758 Blade lock bolt 4 36 10743 Lock pin, 10mm 2 56 10294 Spider plate 1 20647 Finish blade, 140mm x 455mm (metric) 4 57 11337 Lift lever 4 20410 Finish blade, 6x18 (imperial) 4 58 11338 M12x25 boly 1 20411 Float blade, 10x18 (fits metric and imperial) 4 59 11339 Spring washer, 12mm 2 60 11340 Cap plug 1 47 48 49 50 51 20484 Combo blade (metric) 4 61 11341 SHCS, M8x16 4 20480 Combo blade, 6x18 (imperial) 4 62 10761 Grease cap 4 11336 Trowel arm, lg 4 63 10296 Press plate, lg 1 10452 M8x40 Hex bolt (metric) 8 64 11342 Press bearing, 6209-2RS 1 10401 HHCS, 5/16-18x1, 1/2”, lg (imperial) 8 65 10297 Press plate, cap 1 11614 Lock washer, 8mm 13 113 11745 M8-1.25 HHCS 4 10322 Spider assembly (blades and hardware not included) 1 11667 Flat washer, 8mm 12 115 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 21 CREATED: 07/04 05/12 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL HANDLE ASSEMBLY: FINE PITCH - COMPLETE (BC120/BC446) 1 3 2 4 6 5 7 8 11 14 9 10 13 15 16 12 17 19 20 116 17 18 21 23 27 26 25 28 27 22 24 30 29 30 31 27 Item Qty. Item Part Number 1 Part Number Description 10684 Handle Grips (ea) 2 17 10694 Description M6-8 inner hex bolt Qty. 2 2 21728 RHMS, M5-0.8x8mm 2 18 14448 6mm spring washer 1 3 10793 Flat washer, 4mm 2 19 10800 Slide bushing 1 4 10508 Throttle cable assembly 1 20 10696 5mm-30 spring pin 1 5 21728 RHMS, M5-0.8x8mm 2 21 10876 Pitch control cable 1 6 10703 Lockwasher, 5mm 2 22 10877 Pulley 1 7 10794 Handle (tube only) - powder coated 1 23 10878 6mm-30 pin 1 8 20713 Deadman switch (centrifugal style) 1 24 10879 Cable support block 1 9 10795 Pitch adjust knob 1 25 10880 Handle clamp (upper) 1 10 10689 Pin, 5x50 1 26 10077 M10x35 hex bolt 4 11 10796 Bearing 51204 1 27 10897 Flat washer, 10mm 14 12 10797 Pitch control bushing 1 28 13349 M10x70-30 hex bolt 1 13 10798 Wave washer, 18mm 1 29 10898 Handle clamp (low) 1 14 10692 20mm x 34mm x 3mm plate washer 1 30 11802 M10 self lock nut 6 15 10693 Lock pin, 18mm 1 31 11621 Spring washer, 10mm 10 16 10799 Pitch adjust shaft 12 116 20670 Handle assembly (complete) 1 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 22 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL HANDLE ASSEMBLY: EUROPEAN SPEC. - COMPLETE (BC120/BC446) Item Part Number Description Qty. Item Part Number Description Qty. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 22 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL GEARBOX ASSEMBLY - COMPLETE (BC120/BC446) 83 82 81 80 79 78 77 76 74 75 72 115 73 70 42 69 68 40 34 31 27 71 33 39 67 66 37 38 39 40 45 41 42 43 44 Item Part Number Description 46 Qty. Item Part Number 27 10897 Flat washer, 10mm 14 69 11345 Description Flange Qty. 1 31 11621 Lockwasher, M10 10 70 10682 Sight glass 1 33 10899 Stud, lg 4 71 11346 Casing-unpainted 1 34 11834 SHCS M10-1.5x16mm 1 72 11347 6x30 key 1 37 11075 Countershaft, lg 1 73 10316 Main shaft 1 38 10744 Bearing 32004 1 74 14256 Bearing 6207 1 39 11318 Gasket 2 75 11348 Moon key 1 40 10746 O-ring 2 76 10321 Main gear 1 41 11334 Flange 1 77 11349 Bearing 30306 1 42 31135 M6x16, inner hext bolt 16 78 11350 Worm shaft washer 1 43 10749 Oil seal 20408 1 79 10772 M10x25, hex screw 1 44 11335 Pully 1 80 11351 Gasket 1 45 10750 M8x10 bolt 2 81 11352 Gearbox cover plate 1 46 10751 Key, 5mm x 35mm 1 82 10792 M8x20 inner hex bolt 8 66 11343 Oil seal 355410 1 83 11353 Release valve 1 67 11344 Oil drain bolt 2 115 10298 Gearbox Assembly (complete) 1 68 31369 Bearing 6204 1 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL SAFETY RING ASSEMBLY/MTG PLATE (BC120/BC446) 104 103 108 105 106 107 102 111 109 110 50 104 112 Item Part Number Description Qty. Item Part Number 108 10792 M8x20 inner hex bolt 1 10340 Mtg plate-GX270 1 10341 Mtg plate-GX340/GX390 1 50 11614 Lock washer, 8mm 13 102 11802 M10 nut 8 103 10787 M8x40 bolt 4 109 Description Qty. 104 10788 Plate washer, 8mm x 20mm x 2mm 4 110 11359 M8x16 hex bolt 2 105 11358 Steel bowl 4 111 20655 Guard ring (removable) 46” 1 106 10790 Rubber vibration absorber 4 112 11360 Inner stab ring 1 107 10791 Plate washer, 8mm x 26mm x 3mm 4 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 24 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL ENGINE/CLUTCH/HOIST HOOK ASSEMBLIES (BC120/BC446) 101 114 102 97 100 96 95 94 99 93 98 88 90 59 89 92 91 84 Item Part Number Description Qty. Item Part Number Description Qty. 59 11339 Spring washer, 12mm 2 96 11044 Bearing 6007-2RS 1 84 10331 Belt guard 1 97 11045 Spindle 1 88 11354 Hex bolt, 7/16-20 1 98 11178 Belt - B29 (Gates Only) GX270/GX340/GX390 1 89 11355 Plate washer, 10mm x 50mm x 4mm 1 99 11357 Screw bolt 4 90 11015 Faceplate 1 100 10300 Hook liift, black 1 91 11356 HHCS, M10x10 1 21334 Engine-GX270 1 92 11014 Weight 1 21321 Engine-GX340 1 93 11013 Clutch spring 1 21335 Engine-GX390 1 94 11012 Copper bushing 1 102 11802 M10 nut 8 95 21046 Clutch drum w/bushing 1 114 21005 Clutch assembly (complete), lg 1 101 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 25 23 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL TROUBLESHOOTING WON’T START • Throttle fully open • Hand lever wire broken • No gas • Dirty gas • Gas filter plugged • Gas line plugged • Hole in gas line • Gas supply valve turned off • Dead-man safety switch • Safety switch wire or connectors not making good contact • Other engine problems (Refer to engine manual) STARTS BUT NO HIGH SPEED • Engine problems • Throttle cable broken or seized • Throttle lever and connectors loose or out of adjustment • Clutch shoes worn STARTS AT HIGH SPEED, WON’T SLOW DOWN • Same as above ENGINE WON’T STOP • Safety switch, wire or connectors not making good contact ENGINE STARTS BUT WON’T TU RN TROWELS AT ANY SPEED • Clutch seized • No weights or broken clutch • Wrong belt • Broken or missing key - Clutch - Pulley - Worm gear (countershaft) - Main gear - Spider plate • Gearbox seized TROWELS TURN, ENGINE AT IDLE • Idle too fast • Belt too tight • Clutch seized • Pulley out of alignment TROWELS BLADES WEARING UNEVENLY • Spider plate seized • Arms bent • Adjusting screws (carriage bolts) incorrectly set MACHINE JUMPS ON FLOOR • Concrete hardened on bottom of spider plate • Trowels unevenly worn • Spider plate seized • Spider plate loose • Trowel arms bent • Adjusting screws (carriage bolts) incorrectly set use spider plate adjustment jig (pg,13) • Mainshaft bent PITCH CONTROLS WILL NOT OPERATE BLADES • Cable broken or out of adjustment • Slot screw missing (under-side of handle) • Spider plate seized • Pressure plate and/or yoke arm broken or badly worn • Hand crank adjuster malfunctioning BELT WEARING RAPIDLY • Belt adjusted improperly • Pulley out of alignment • Wrong belt/defective belt • Clutch sticking • Gearbox seizing OIL LEAKS a) Top of gearbox • Engine leaks • Relief valve broken • Too much oil in gearbox • Set screw missing in cover b) Between end cap and gearbox (recoil side) • “O” ring damaged • End cap not tight c) At mainshaft or countershaft • Relief valve seized • Shaft and/or seal worn TROWEL BLADES WILL NOT TURN • Yoke arm broken • Key sheared SPIDER PLATE HARD TO GREASE • Fittings plugged • Cement in grease grooves of arms • Grease fittings too tight 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 18 26 07/04 CREATED: 05/12 REVISED: 05/10 B430 30" (75 cm) 5.5 hp Honda OHV B436 36" (90 cm) B436E 36" (90 cm) B440 Model Model N/A Up to 165 lb. (75 kg) 5.5WALK hp Honda OHV POWER 10” x 14" 6” xINSTRUCTION 14" 8” xMANUAL 14" BEHIND TROWEL 9 hp Honda OHV (25 x 36 cm) (15 x 36 cm) (20 x 36 cm) 38 ½" (98 cm) Up to 165 lb. (75 kg) 10” x 14" 6” x 14" SPECIFICATIONS (25 x 36 cm) (15 x 36 cm) 8” x 14" (20 x 36 cm) 38 ½" (98 cm) Up to 165 lb. (75 kg) 10” x 14" (25 x 36 cm) 8” x 14" (20 x 36 cm) NA Up to 165 lb. (75 kg) 3 hp, 230V, 1 Phase Electric Motor 40" WALK-BEHIND 9 hp TROWEL Honda OHV (100 cm) Path 6” x 10-1/2" (15 x 27 cm) N/A Power Source Float Blade 9 hp Honda OHV SizeFloat Power Source (gas option) Path 6” x 14" (15 x 36 cm) Finish Trowel N/A Combination Float Plan Operating Blade Size Finish BladeCombination Float Weight Operating Size 46" 9 hp Subaru OHV 10”Size x 18" 6” x 18" 8” x 18" 48 ½" UpWeight to 245 lb. (gas option) Trowel Size Blade Size Pan 30”(120 cm) Honda GX160 OHV OHV 10” x 14” 14” x 46 cm) 8” x 14” 11 hp Honda (25 x 46 cm)6” x (15 (20 x 46 cm) 38.5”(123 cm) Up to 195 (110lb.kg) B446 BC90 BC436 (75 cm) B430 BC120 BC446 B436 B436E OHV (25 x 26 cm) (15 x 36 cm) (20 x 36 cm) (20 x 26 cm) 30"Honda GX270 6” x 10-1/2" 11 hp Subaru OHV 5.5 hp Honda OHV N/A N/A N/A Honda GX270 OHV (15 x 27 cm) 8” x 18” 46” (75 cm) 10” x 18” 6” x 18” 48.5” (120 cm) Honda GX360 OHV (25 x 46 cm) 36"Honda GX390 5.5 hpOHV Honda OHV 10” x 14"(15 x 46 cm) 6” x 14" (20 x 46 cm) 8” x 14"(20 x 46 cm) 38 ½" (90 cm) 9 hp Honda OHV (25 x 36 cm) (15 x 36 cm) (20 x 36 cm) (98 cm) 36" (90 cm) 3 hp, 230V, 1 Walk Phase Behind 10” x 14"Trowel6”(GASOLINE) x 14" 8” x 14" Electric Motor (25 x 36 cm) (15 x 36 cm) (20 x 36 cm) 38 ½" (98 cm) (88 Kg) Up to 165 lb. (75lb.kg) Up to 255 (115 Kg) Blade Speed (RPM) 130-160 40" 10” x 14" 8” x 14" Engine Speed (RPM) 36006” x 14" B440 9 hp Honda OHV NA (100 cm) (25 x 36 cm) (15 x 36 cm) (20 x 36 cm) Clutch Type Centrifugal hp Honda OHV Variable46" Speed 99 hp Yes 6” x 18" Subaru OHV 10” x 18" 8” x 18" 48 ½" B446 Gearbox Oil gear oil(123 cm) (120 cm) 11 hp Honda OHV (25 x 46 cm) Agma (15 x 8 46compounded cm) (20 x 46 cm) 11 hp Subaru OHV Gearbox Oil Capacity 16 oz. (473 ml), 19 oz. (562 ml) Engine Fuel Gasoline – Unleaded Engine Oil Alert Yes Cooling Air Walk Behind Trowel Starting Recoil(GASOLINE) Starter - Manual Blade Speed (RPM) 130-160 Dead-man Safety Switch Yes Engine Speed(approximately) (RPM) Fuel Capacity 33600 Gal. (12.5 L) Clutch Type Running Time (approximately) 2Centrifugal ½ hours Variable of Speed Number Blades 4Yes Gearbox Oil Agma 8 compounded gear oil Engine Acoustic Power Lwa (dB) 97-103 Gearbox Oil Capacity 16 oz. (473 ml), 19 oz. (562 ml) Engine Acoustic Pressure Lpa (Db) 82-86 Engine Fuel Gasoline – Unleaded Level of Vibration 1.1-1.5 Engine Oil Alert Yesaw Vibration value on the handle 7.0 Cooling Air Options Oil-Bath Spider Assembly Starting Recoil Starter - Manual Insta-Pitch Lever Quick-Pitch Lever Dead-man Safety Switch Yes Hoist Hook Fuel Capacity (approximately) 3 Gal. (12.5 L) Carry Bar Running Time (approximately) 2 ½ hours Folding Handle Number of Blades Power rating conforming to DIN 6270 & ISO 3048/1 4 Std. Up to 165 lb. (75 kg) Up to 165 lb. (75 kg) Up to 165 lb. (75 kg) Up to 245 lb. (110 kg) RPM results may vary by engine option. Engine Acoustic Power Lwa (dB) 97-103 Power rating conforming to DIN 6270 & ISO 3048/1 Std. Engine Acoustic Pressure Lpa (Db) 82-86 RPM results may vary by engine option. Level of Vibration 1.1-1.5 Vibration value on the handle 7.0 aw 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 Options Oil-Bath Spider Assembly CREATED: 07/04 REVISED: 05/10 Insta-Pitch Lever 19 Hoist Hook Carry Bar Folding Handle Power rating conforming to DIN 6270 & ISO 3048/1 Std. RPM results may vary by engine option. 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 19 27 CREATED: 07/04 05/12 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL Declaration of Conformity / Certificat de conformité / Gelijkvormigheids certificaat Declaración de Conformidad/Declaração de Conformidade/Dichiarazione Di Conformita We: Bartell Morrison Inc. 375 Annagem Blvd. Mississauga, Ontario, Canada L5T 3A7 Tel: 905-364-4200 Fax: 905-364-4201 Bartell Morrison (USA) LLC. 12 Industrial Drive Keyport, New Jersey, United States of America 07735 Tel: 732-566-5400 Fax: 732-566-5444 Declare under our sole responsibility that the product to which this declaration relates is in conformity with the following standard(s) or other normative documents. Déclarons sous notre responsabilité que le produit cette déclaration est conforme aux normes suivantes ou d’autres documents habituels. Verklaren onder onze verantwoordelijkheid dat het product naar welke de verklaring verwijst conform de volgende standaards of anders gebruikelijke documenten is. Declaramos bajo nuestra única responsabilidad que el producto en lo que esta declaración concierne, es conforme con la siguiente normativa u otros documentos. Declara sob sua responsabilidade que o produto a quem esta declaração interessar, está em comformidade com os seguintes documentos legais ou normas directivas. Dichiariamo sotto la ns. unica responsibilita che il prodotto al quale questa dichiarazione si riferisce, è fabbricato in conformità ai seguenti standard e documenti di normative. EN 349:1993 EN 418:1993 EN 12100-1:2003 EN 12100-2:2003 EN ISO 4872:1978 EN ISO 5349-1:2001 EN ISO 5349-2:2001 Safety of Machinery - Minimum gaps to avoid crushing of parts of the human body. Safety of Machinery - Emergency stop equipment, functional aspects - Principles for design Safety of Machinery - Basic Concepts, general principles for design - Part 1: Basic Terminology, methodology Safety of Machinery - Basic Concepts, general principles for design - Part 2: Technical Principles Acoustics - Measurement of Airborne noise emitted by construction equipment intended for outdoor use - Method for determining compliance with noise limits. Mechanical vibration. Measurement and evaluation of human exposure to handtransmitted vibration. General requirements Mechanical vibration. Measurement and assessment of human exposure to handtransmitted vibration. Practical guidance for measurement at the workplace. Following the provisions of Directive(s): Suivant les directive(s) déterminées: Volgens de vastgestelde richtlijnen: Siguiendo las directiva(s): No sequimento das clausulas da Directiva(s): Seguendo quanto indicato dalla Direttiva(s): 98/37/EC 2000/14/EC 2001/95/EC 2002/95/EC Machinery Directive Noise Directive General Product Safety Directive Reduction of Hazardous Waste Directive 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 20 28 CREATED: 07/04 05/12 REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL Technical Characteristics: Caractéristiques techniques: Technisch gegevens: Características Técnicas: Caracteristicas Técnicas: Qualitàs di tecnico: Model Modéle Type Modelo Modelo Modello MachineSerial Number Numéro de Série machine Serienummer machine Máquina número de série Numero de serie da maquina Numero di seria la macchina Engine Serial Number Numéro de Série moteur Serienummer motor Motor número de série Numero de serie do motor Numero di seria la motore B436 Walk Behind Power Trowel Noise Level Puissance acoustique Geluidniveau Nivel Sonoro Nivel del Ruido Potenza Acustica Lwa (dB) 98 Pressure level Pression acoustique Geluidsdrukniveau Nivel Acustico Vibration level Niveau de vibration Vibratieniveau Nivel de Vibracion Pressione Acustica Lpa (Db) 99 Livello di Vibrazione ahv 2 (m/s ) 1.5 Pressão Acústica Weight Masse Gewicht Masa Massa Massa Lbs (kg) 125 (56.8) Nivel de Vibração Bartell Morrison Inc. 375 Annagem Blvd. Mississauga, Ontario, Canada L5T 3A7 Telephone: 905-364-4200 Facsimile: 905-364-4201 The Technical Construction file is maintained at: Les fiches techniques de construction sont gardées à: Het technische constructie document wordt bewaard te: El archivo técnico de construcción se mantiene en: O arquivo técnico de construção é mantido no (a): L’originale dossier tecnico di construzione è conservato presso: The authorized representative is: Le représentant autorisé est: Gemachtigd vertegenwoordiger is: La representación autorizada es: O representante autorizado é: Il rappresentate autorizzato: Stanley Mr. Richard Robert Leggitt Manager - Engineering V.P. of Operations Bartell Morrison Inc. 375 Annagem Blvd. Mississauga, Ontario, Canada L5T 3A7 Telephone: 905-364-4188 905-364-4185 Facsimile: 905-364-4202 Signature of Authorized Person: Signature de la personne autorisée: Handtekening van gemachtigd persoon: Firma de la persona autorizada: Assinatura de pessoa autorizada: Firma della persona autorizzata: Typed name of Authorized Person: Nom dactlyographié de la personne autorisée: Getypte naam van gemachtigd persoon: Nombre de la persona autorizada: Nome datilografado da pessoa autorizada: Nome della persona autorizzata: Title of Authorized Person: Titre de la personne autorisée: Functie van gemachtigd persoon: Cargo de la persona autorizada: Titulo da pessoa autorizada: Posizione della persona autorizzata: Robert Leggitt RichardS.Stanley Manager - Engineering V.P. of Operations Date and place of issue: Date et place d’émission: Datum en plaats van afgifte: Fecha y lugar de emision: Data e lugar de emissão: Data e luogo di emissione: 05.03.2010 08.29.2012 Mississauga, Ontario, Canada 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 21 29 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 WALK BEHIND POWER TROWEL INSTRUCTION MANUAL 375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201 23 30 CREATED: 07/04 05/12 CREATED: REVISED: 05/10 BARTELL MORRISON BARTELL MORRISON INC. 375 Annagem Blvd. Mississauga, Ontario, Canada L5T3A7 Toll Free: 866-501-1683 Local: 905-364-4200 Fax: 905-364-4202 www.bartellmorrison.com BARTELL MORRISON (USA) LLC. 25 12 Industrial Drive. Keyport, New Jersey, USA 07735 Toll Free: 888-999-1570 Local: 732-566-5400 Fax: 732-566-5444 www.bmiamerica.com