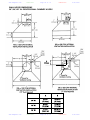

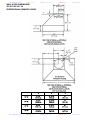

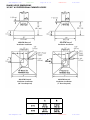

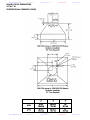

Download Viking Professional VEDO530T Specifications

Transcript