Download Eaton 825 UPS Specifications

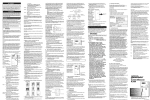

Transcript