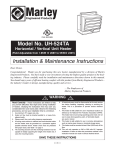

Download Marley Engineered Products G Series Specifications

Transcript

14-3/8" (365mm) 1-5/16" (33mm) 2" (50.8mm) Knockout 15-21/64" (389mm) WH Series Fan Forced Wall Heaters 5/14" (133mm) 1-21/32" (42mm) 18-1/4" 464mm 19-3/16" (487mm) File E21609 Installation & Maintenance Instructions Dear Owner, Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products. You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance directions shown in this manual. You should enjoy years of efficient heating comfort with this heater from Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service. ... The Employees of Marley Engineered Products ! WARNING Read Carefully - These instructions are written to help you prevent difficulties that might arise during installation of heaters. Studying the instructions first may save you considerable time and money later. Observe the following procedures, and cut your installation time to a minimum. 5. 6. TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK: 1. 2. 3. 4. Disconnect all power coming to heater at main service panel before wiring or servicing. All wiring must be in accordance with the National and Local Electrical Codes and the heater must be grounded. Verify the power supply voltage coming to heater matches the ratings printed on the heater nameplate before energizing. This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. 7. 8. 9. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause an electric shock, fire,or damage to the heater. Do not block air intakes or exhaust in any manner. Keep combustible materials, such as crates, drapes, etc., away from heater. Do not install behind doors, furniture, towels, or boxes. A heater has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or flammable liquids are stored. Use this heater only as described in this manual. Any other use not recommended by the manufacturer may cause fire, electric shock, or injury to persons. This heater is not approved for use in corrosive atmospheres such as marine, green house, or chemical storage areas. SAVE THESE INSTRUCTIONS CAUTION ! Installation of Recessed Back Box in Existing Construction ! 1. Provide a wall opening 14-1/2" (362mm) wide by 18-1/2" (470mm) high at the desired mounting height, but no closer than 8" (203mm) from floor. (See Figure 2.) FOR SAFE OPERATION AND REDUCED RISK OF FIRE, INJURY OR HEATER DAMAGE, OBSERVE THE FOLLOWING: 1. Do NOT use a remote thermostat with this heater. Built in thermostat cycles the heating element only. Fan delay control automatically turns fan ON and OFF, and provides a fan delay OFF feature to remove residual heat after thermostat has turned heating elements off. Wiring of heater in any manner which defeats the fan delay OFF feature can result in overheating and permanent damage to heater, and will void the warranty. 2. For wall mounting only with air discharge downward. Do NOT install in floor, ceiling, upside down (air discharge upward), or sideways. 3. Do NOT operate heater without grille installed. 4. Maintain the following clearances: • Bottom of heater to floor – 8” (203mm) • Sides of heater to adjacent wall – 8” (203mm) • Top of heater to ceiling – 36” (915mm) 5. This heater is hot when in use. Do NOT install heater behind door, behind towel rack, inside closet, where drapery could touch heater or be damaged by heat, or where airflow to heater may be obstructed. Keep electrical cords, bedding, furniture, and other items away from heater. 6. Heater must be cleaned periodically (at least annually) to assure proper performance and prevent overheating. See section on cleaning and maintenance. Note: Locate so at least one side of opening is at wall stud. 8” (203mm) MIN Back Box Fig. 2: Locating Back Box in Existing Construction 2. Power Supply Wiring Note: Wiring Compartment Volume - 119in3 (1950cm3). a. Run a power supply cable into the area above the top of the wall opening. All wiring must be in accordance with National and Local electrical codes. Refer to Table 1 for correct wire size. b. Remove disconnect switch bracket by loosening the two screws on the right side. c. Install a cable clamp in the “knockout” in the top of back box. d. Insert power supply cable through cable clamp, allowing approximately 6" (152mm) of cable length to remain inside the back box to facilitate connections. Back Box 3. Mounting Back Box a. Place the back box into wall opening flush with finished wall surface on bottom and sides of box. (Top flange of back box should protrude approximately 1/2" or 12.7mm from finished wall surface). b. Secure the back box in place with wood screws or nails. Fig. 1: Locating Back Box in New Construction 4. Wiring Disconnect Switch Installation of Recessed Back a. Connect the power supply wires to the blue wires of the disconnect switch using wire connectors (see wiring diagram,pg. 4.) 1. Mounting Back Box (See Figure 1). a. Place the back box between two 16" (406 mm) center-to-center wall studs at the desired mounting height but no closer than 8" (203 mm) to adjacent wall or floor. Note: If wall studs are spaced greater than 16” on center, additional framing supports may be necessary. b. Align back box such that the bottom and sides will be flush with finished wall surface (top flange of back box should protrude approximately 1/2" (12.7 mm) from finished wall surface). c. Secure the back box in position with wood screws or nails as shown in Figure 1. 2. Power Supply Wiring (See Figure 1) Note: Wire compartment volume - 119in3 (1950cm3). a. Run a power supply cable into the knockout area in the upper right hand corner of the back box. All wiring must be in accordance with National and Local Electrical Codes. Refer to Table 1 for correct wire size. b. Remove disconnect switch bracket by loosening two screws on the right side. c. Install a cable clamp in the “knockout” in the top of the back box. d. Insert power supply cable through cable clamp, allowing at least 6" (152mm) of leads to extend inside the back box. Connect the blue lead wires of disconnect switch to the supply wire leads using wire connectors (see wiring diagram, pg. 4). e. Ground the back box using the green screw located in the inside top of the back box. f. Secure disconnect switch bracket in place by tightening screws. b. Ground the back box using the green ground screw located in the inside top of the back box. Box in New Construction c. Secure disconnect switch bracket in place by tightening screws. Table 1 Catalog Number WH3150 WH3180 Volts 120 120 WH4404* 240/208 1 WH4407* 277/240 1 WH4307* WH4408* WH44083 WH44043 WH4303 WH4306 WH4508 WH4504 WH4507 WH45083 WH45043 WH4503 WH4506 277 208 208 240 347 600 208 208/240 240/277 208 240 347 600 1 1 3 3 1 3 1 1 1 3 3 1 1 Phase 1 1 Watts 1500 1800 4000/3000 2000/1500 4000/3000 2000/1500 3000/1500 4000/2000 4000 4000 3000 3000 4800 3600/4800 3600/4800 4800 4800 4800 4800 Amps 12.5 15.0 16.7/14.5 8.3/7.2 14.5/12.5 7.2/6.3 10.8/5.4 19.2/9.6 11.1 9.7 8.6 3 23.1 17.3/20.0 15.0/17.3 13.3 11.6 13.8 8 Min. Supply Wire Gauge 12 12 10 12 12 12 12 10 14 14 14 14 10 10 10 12 14 12 14 *NOTE: Factory wired for higher wattage, field convertible to half wattage. 2 Note to Installer: Converting heater to half wattage (Not applicable to WH3150 and WH3180, 120 Volt Models) The WH Series wall heaters are manufactured and shipped at the higher rated wattage. Full wattage heaters can be converted to half wattage by doing the following steps. 1. Remove the red jumper wire as shown in Figure 3 and discard. 2. To permanently make the heater half wattage, cut the male terminal spade, carefully not to damage the cold pin and discard. 3. Mark the wattage of the heater on the white label inside the backbox. Male terminal spade Installation of Heater Assembly and Grille After back box is completely installed and no further construction dirt is expected, clean debris from back box and remove heater assembly from its carton. Then refer to Figure 5 and proceed as follows: 1. Insert the heater assembly into back box, placing the four mounting holes (with key-hole slots) over the screws in the box. Tighten all screws securely. 2. If surface-mounting frame is used, ensure that the frame is even with all four heater assembly tabs before tightening screws. 3. Connect the two disconnected switch wires to the heat control switch (thermostat) leads using wirenuts. After connection, push wires back into the opening. 4. Turn thermostat to the extreme counterclockwise position. 5. Push disconnect switch into ON position. 6. Latch at bottom of heater assembly should be in up position. 7. Mount grille over tabs on fan deck and push down until grille is secure. 8. Insert screwdriver through bottom louver in grille and loosen screw while holding bottom of grille against wall. This will allow latch to drop in place. Tighten screw. Red jumper wire Fig. 3 Installation of Back Box with Optional Surface-Mounting Frame WHSM (See Figure 4) 1. Secure back box to wall with knockouts in upper right hand corner using screws and anchors. 2. Hang the surface-mounting frame on the back box. Ensure that the back edge of the surface-mounting frame is flush against the wall. NOTE: If heater is located in a high traffic area, where it may be subjected to vandalism or abuse, take extreme care to see that the box is firmly attached to the wall. Fig. 5 3. Power Supply Wiring NOTE: Wiring Compartment Volume - 119in3 (1950cm3). a. Run a power supply cable into the area to the right of the mounting frame. Arrangement of wiring to this point must be in accordance with National and Local codes.Refer to specifications on page 2 for proper wire size. MOUNT BACK BOX TO WALL USING REAR MOUNTING HOLES. Operation 1. Rotate the thermostat fully clockwise. This should energize the heating elements and cause warm air to flow from the hot air discharge at the openings in the bottom of the grille. 2. After the operation check, rotate the thermostat to the desired position to obtain room comfort. NOTE: For best results, the heater should be left “ON” constantly during the heating season because the thermostat, when properly set, will maintain the desired temperature. 3-13/16" (97mm) Cleaning & Maintenance To maintain optimum performance and efficiency, heater should be cleaned and checked periodically. It is recommended the heater be cleaned at least annually. (more often if used in a dirty environment) 19" (482mm) HANG FRAME ON BACK BOX. Fig. 4: Surface Mounting Installation ! 15-5/32 " (385mm) CAUTION ! TO PREVENT POSSIBLE ELECTRIC SHOCK, ALWAYS DISCONNECT ALL POWER TO HEATER AT MAIN DISCONNECT PANEL OR FUSE BOX BEFORE CLEANING OR MAINTENANCE TO HEATER. NOTE: If the wiring is to run through the wall, cut a hole in the area of the top of the back box. Run the supply wire through this hole. Then remove the “knockout” from the top of the box and proceed to step C. b. Remove the “knockout” on the top side of the frame. c. Remove disconnect switch bracket by loosening the two screws on the right side. d. Feed the power supply cable through the frame allowing 6" (152mm) of lead to remain inside the back box (using cable clamp, connector, or other suitable strain relief). e. Secure the power supply cable to the back box (using cable clamp, connector, or other suitable strain relief) allowing 6" (152mm) of lead to remain inside the back box. f. Connect supply wires to blue wires of disconnect switch using wiring connectors (see wiring diagram, pg. 4). g. Ground the back box by connecting the supply ground leadwire to the green ground screw located in the inside top of the back box. h. Secure disconnect switch bracket in place. TO CLEAN HEATER: 1. Disconnect power to heater at main panel or breaker. 2. Remove thermostat knob (if provided) and remove front cover (grille) as follows: (See figure 4) –Insert screw driver through bottom louver and loosen one screw that holds latch mechanism. –Lift front cover upward and pull top outward to remove. 3. Push ON/OFF switch to OFF position. 4. Using vacuum cleaner knozzle, brush, or dust cloth, remove dust and any foreign material from heater. Use care to not bend fan blade or damage heater wiring. (Spin blade by hand to make sure it turns freely.) 5. Push ON/OFF switch to ON position. 6. Replace front cover and secure latch mechanism. (See installation of Heater Assembly and Grille.) 7. Reconnect power to heater and verify that heater operates properly. 3 TO RESET MANUAL RESET LIMIT: Your heater is equipped with a manual reset safety thermal limit control that will automatically turn the heater off to prevent a fire if the heater overheats. This control is located on the fan panel assembly between the element and fan blade and marked “reset”. The red reset button can be seen through the front grille when the heater is installed. To reset, allow the heater to cool, then push the red button that is visible through the hole in the fan panel. The heater should immediately return to normal operation. Wiring Diagrams Diagram 1 FAN MOTOR 1 NAMEPLATE FIELD WIRING WH45083 MODEL NO. DATE CODE: 0206 FAN FORCED WALL HEATER APPAREIL DE CHAUFFAGE MURAL À AIR PULSÉ VOLTS AC 60HZ WATTS PHASE HI LO 208 4800 3 774G LISTED MUST BE USED WITH AWH-BB BACK BOX ROOM HEATER DO NOT OPERATE WITHOUT FRONT COVER IN PLACE. DOIT ÉTRE UTILISÉ AVEC BOÎTIER ARRIÈRE AWH-BB NE PAS UTILISER SI LE COUVERCLE AVANT N’EST PAS EN PLACE. MARLEY ENGINEERED PRODUCTS BENNETTSVILLE, SC 29512 GND FAN DELAY DISCONNECT 2 3 1 8 6 6 4 2 RELAY ELEMENTS L1 CYC THERMOSTAT MANUAL RESET WIRING DIAGRAM FOR THREE PHASE WALL HEATERS FIELD WIRING Diagram 2 FAN MOTOR GND DISCONNECT THERMOSTAT CYC L2 MANUAL RESET 1 FAN DELAY 2 3 1 8 6 0 4 2 RELAY ELEMENTS WIRING DIAGRAM FOR 4800 WATT 208 VOLT SINGLE PHASE WALL HEATER Diagram 3 DISCONNECT 1500, 1800,4800, 4000, & 3000 WATT HEATERS 120V, 208V, 240V, OR 277V (See diagram no.2 for 4800W, 208V 1Ph) (Full wattage heaters can be converted to half wattage by moving the red jumper wire connecting the top and bottom element terminals.) NOTE: Conversion not applicable to 120V models. Diagram 4 2000 & 1500 WATT HEATERS 208V, 240V, OR 277V Diagram 5 TRANSFORMER DISCONNECT 4800, 4000 & 3000 WATT HEATERS 347V OR 600V 4 Replacement Parts Key No. 1 2 3 4 5 6 7 8 — Description Grille Assembly : White Standard Element, Single Phase: 208V; 4000W 208/240V; 3000/4000W 240/277V; 3000/4000W 277V; 3000W 208V; 4800W 208/240V; 3600/4800W 240/277V; 3600/4800W 120V; 1500W 120V; 1800W Element, 3-Phase: 208V; 4000W 208/240V; 3000/4000W 208V; 4800W 208/240V; 3600/4800W Limit, Manual Reset Fan Delay Fan Delay, 3 phase Fan Blade Motor: 208V 208/240V 120V Thermostat Disconnect Relay: 208/240V Part Number 2501-2003-004 2501-2003-007 7 8 1 6 302015807 302015808 302012809 302012806 1802-2075-801 302012810 302012811 302012827 302012828 5 4 3 2 1802-2075-800 1802-2075-802 1802-2075-801 1802-2075-803 4520-0015-000 410074001 4520-2024-000 490030103 3900-2010-000 3900-2010-001 3900-2010-003 410168002 410170001 5018-2017-000 LIMITED WARRANTY All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation. The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products. THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT. Some states do allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products. HOW TO OBTAIN WARRANTY SERVICE AND WARRANTY PARTS PLUS GENERAL INFORMATION 1. Warranty Service or Parts 2. Purchase Replacement Parts 3. General Product Information 1-800-642-4328 1-800-654-3545 www.marleymep.com Note: When obtaining service always have the following: 1. Model number of the product 2. Date of manufacture 3. Part number or description 470 Beauty Spot Rd. East Bennettsville, SC 29512 USA Part No. 5200-2630-002 PPD 058 2/06