Download Craftsman 113.29501 Operating instructions

Transcript

A

i4---.

ii------,

i I?.-j. :....;-

,. .:,

?

ASSEMBLY, OPERATING INSTRUCTIONS

AND PARTS LIST FOR

CRAFTSMAN .I2INCH RADIAL SAW

I

,j

t'

...;.

...

.,,:.,...

L-.

/

.. <* .,:! . *>.

ka

$;:... i-:.....

*:,;>:

,$

,.-..

/

;- :.

2.

--

,i

-...

__

.

II

MODEL NUMBER 1 13.29501 p

The Model Number will b e found on a plate attached t o your saw,

a t the left side of the base. Always mention the Model Number i n

a l l correspondence regarding the CRAFTSMAN RADIAL SAW or when

ordering repair parts.

C a r e f u l l y r e a d t h e instructions provided, observe t h e simple

s a f e t y precautions and you w i l l h a v e m a n y hours of satisfactory

use from your n e w Craftsman tool.

H O W TO

1

ORDER REPAIR PARTS--,

All parts listed herein may be ordered through SEARS, ROEBUCK A N D

CO. or SIMPSONS-SEARS LIMITED. When ordering parts by mail from

the catalog order house which serves the territory in which you live,

selling prices will be furnished on request or parts will be shipped a t

prevailing prices and you will be billed accordingly.

/

I

I

I

W H E N ORDERING

REPAIR PARTS, ALWAYS GlVE THE FOLLOWlNG

INFORMATION AS S H O W N IN TH!S LIST:

1. The PART NUMBER

2. The PART NAME

3. The MODEL NUMBER 113.29501

4. The NAME of item - RADIAL SAW

COAST T O COAST NATION-WIDE

SERVICE FROM SEARS

F O R YOUR CRAFTSMAN RADIAL S A W

SEARS, ROEBUCK A N D CO. and

SIMPSONS-SEARS LIMITED i n Canada

back u p your investment with quick,

expert mechanical service and genuine CRAFTSMAN replacement parts.

If a n d when you need repairs or service, call on us t o protect your investment in this fine piece of equipment.

I

J

SEARS, R O E B U C K AND C 0 . - U. S. A.

IN CANADA, SIMPSONS- SEARS LIMITED

1

Ptinted in U. S . A .

Part

No. 63161

PObVER TOOL SAFETY ...APdD YOU

3 M I N U T E S of required reading for the home Crafts-

man.. . whether this i s your first purchase or you're

an old hand at power tools.

YOU'VE J U S T B O U G H T A Q U A L I T Y SEARS T O O L .

d e s i g n e d to give you many years of top performance

and trouble-free operation. It's also designed with'

2. INSPECT THE POWER TOOL

1. READ THE INSTRUCTION

MANUAL. . .

THOROUGHLY

completely

accurately.

Pay special attention to safety prec a t i o n s and usc of safety features.

Set up Ihe machine according to rnstructions. Make certain all parts

are included.

safety in mind, permitting you to use the tool without

c o n c e r n so long as certain basic rules are observed.

We'd l i k e to call particular attention to some of the

more important rules to follow for maximum enjoyrnent of your Sears power tools.

3. FOLLOW OPERATING

It4STRUCTIONS CAREFULLY

4. DRESS PROPERLY FOR

WORKSHOP

THE

They have been developed to insure correct procedure and prevent accidents.

Gel rid of loose clothing, roll up

sleeves (or fasten securely). remove

your tie, wear a snug-fitting shop

apion.

7. DOUBLE-CHECK HOLDING

FIXTURES

8. KEEP CUTTING TOOLS SHARP

6. USE PROPER ELECTRICAL

CONNECTIONS

5.

WEAR SAFETY GLASSES

Safety glasses or eye shields are

recommended for all power tool

operations.

9. DON'T EXCEED THE LIMITS

OF THE POWER TOOL

Abusing the power tool by doing

work lleyond its capacity reduces

its Itfe and increases the chance of

l n ~ c ~ to

f y the operator. Watch espei n ! : y the sizes of the wcrk and

15cd rate.

Make certain proper v o l t a g ~(110 or

220) is used. USE A GROUND \'/IRE;

AND A SUITABLE PLUG. IF REQUIRED.

Check fusing reqclireme~ts of the

tool as outlined in the instruction

manual.

Get in the habit of turning of! the

tool when not in use.

Lock all clamps tightly.

Spin pzrts by hand t o check against

misalignment or looseness before

turning on tool.

10. KEEP SPECTATORS AWAY

11. SAFETY GUARDS

Curiosity and Interest on the part

of the family IS ffne, but a v a d inspections when the poner tool IS

runfllne.

Accessory safety guards are available for .most tools. Use of these

guards is highly recommended.

n-

T H NI.(

IS A F E T Y I

Keep protective caps on ends of

er[~osrd, rotating shafts.

Make certain blades, drills. cutters,

etc.. zre i n top shape. Dull tools

c a n c a u s e rough cuts, excessive

c h i p ~ l n g .. . and accidents.

12. AVOID AWKWARD HAND

POSITIONS

IICI~

p l ~ c ehands i n a position

whe:e a sudden slip could cause

t h ~ r n!o move into a cutting tool.

Do POI inrcc work abnormally into

any cutting tool.

cart?fdr~

plan each operofiotl before t u r n i n g on t o o l

.

ASSEMBLING AND ADJUSTING YOUR SAW

.

-

POWER SMPPLY & MOTOR CONNECTIONS

MOTOR SPECIFiCATtONS

Single

RPM

3450

.............

..............

..............

................

;: ;.

;..

..

-

'.

.+?';

i

,. .> 1

lead.

120 / 240

13 / 6.5

d.

60

Push all leads carefully into motor terminal box a n d

install terminal box cover.

2. Connections For 240- Volts AC. (See figure 2.) When

connecting the motor for 240-volt operation, the following connections must be made inside the motor terminal box:

CAUTION: The motor i s wired for 115-120

volt operation. Connect to a 2 0 amp. branch

circuit a n d use a 20 amp., time-delay fuse.

a. Connect the YELLOW, WHITE a n d BLACK leads

from mator terminal box to the WHITE motor cord

lead. Twist bare ends together and install a wire

nut as shown in figure 2.

ELECTRICAL CONNECTiONS

NOTE: This.saw motor i s wired at the factory

for 120-volt, 60 cycle, AC service as shown

in figure 1 and described in paragraph 1,

below. Under normal home workshop use

with proper voltage to the motor, the saw

will operote with adequate efficiency. However, i f any of the following conditions exist,

it may b e necessary to reconnect the sow

for 240 volts AC as described in paragraph

2, below.

b.

Leave the BROWN lead (from overload protector)

disconnected and insulate it with tape to prevent

short circuiting inside motor terminal box.

c. Connect the GREEN, RED a n d BLUE leads together,

twist bare ends and install a wire nut.

d.

Push all leads carefully into motor terminal box and

install terminal box cover.

3. M o d i f y i n g the Power Cord.

a. Cut off the existing molded plug (for 120-volts).

1. Continuous heavy-duty use.

b. Attach an appropriate 240-volt plug.

2. Undersize wiring i n circuit from motor to

power source, or overloaded circuit.

Low voltage from power source to motor

(which may be due to overlooded power

source).

The power cord must also be changed from the 120-volt type

to the 240-volt type, when changing to 240-volt operation.

1. Connections For 120-Volts AC. (See figure 1.) When

replacing a motor or connecting the saw to 120-volts

for any reason, make sure the wires inside the motor

terminal box are connected as follows:

a. Connect the YELLOW, WHITE, BLACK and RED leads

from the motor terminal box to the WHlTE motor cord

CAUTION: Do notconnect the stcndard 120volt plug t o a 240-volt receptacle.

MOTOR SAFETY PROTECTION

The saw motor i s equipped with a manual-reset thermal

overload protector, designed t o open the power line circuit

when the motor temperature exceeds a safe value.

1. If the protector opens the line a n d stops the saw motor,

press the saw switch to the "OFF' position immediately

and allow the motor to cool.

2.

After cooling to a safe operating temperature, the overload protector can be closed manually by pushing in

the red button on the motar capacitor cover. If the red

I

I

WIRE

NUTS

WIRE

NUTS

YELLOW

BLACK

PROTECTOR

BLACK

GREEN

BROWN

GREEN

BLUE

110 VOLTS

BLUE

240 VOLTS

figure

1

Figure 2

:

J,'

:'

c. Twist bare ends of wires together and install a wire

nut on each connection.

3

.

. .. .Ii

/:::...i;:d::..::j

; ,y;.,;

b. Connect the GREEN and BROWN leads t o the BLUE

Rotation (viewed from

saw b l a d e end) . . . . . Clockwise

3.

.

:,

.. .

.

.,

lead. (The black motor cord l e a d is al!Zidy-con

nected to the overload protector.)

The AC motor used in this saw i s a capacitor start, nonreversible type, with the following specifications:

Horsepower . . . . . . . . .

Voltage

Amperes . . . . . . . . . . . .

Cycles

~l;ase

. .

TAPE

UNCONNECTED

EXPOSED WlRE

'

button will not snap into place immediately, the motor

i s still too hot and must be allowed to cool for a while

longer. (An audible click will indicate protector is closed.)

3. As soori os the red button will snap into running position,

the saw moy be started and operated normally by pressing the saw switch to the "ON" position.

4. Frequent opening of fuses or circuit breakers may result

if motor i s overloaded, or i f the motor circuit i s fused

with a fuse other than those recommended. Do not use

a fuse of greater copocity without consulting the power

company.

5. Although the motor i s designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the narneplote voltage.

Heavy loads, however, require that voltage at motor

terminals be not less than the voltage specified on

nameplate.

6. Most motor troubles may be traced to loose or incorrect

connections, overloading, reduced input voltage (which

results when small size wires are used in the supply

circui:) or when the supply circuit i s extremely long.

Always check connections, load and supply circuit when

the motor fails to perform satisfactorily. Check wire

sizes and lengths with the table in the next poragraph.

WIRE SIZES

The following table lists recommended wire sizes for connecting the motor to the power source. These sizes should

be maintained for trouble-free operotion of the saw.

Length of

Condurtor

50

100

100

150

200

feet

feet

feet

feet

feet

or

or

to

to

to

less

less

150 feet

200 feet

400 feet

Wire Sire Required

(American Wire Gauge No.)

120 Volt Lines

No. 12

No. 10

No. 8

No. 6

No. 4

240 Volt Lines

No. 14

No. 12

No. 10

No. 8

No. 6

NOTE: For circuits of greater length, the wire

size must be increased proportionately in order to deliver ample voltage to the saw motor.

TABLE SUPPORT

MOUNTING SCREtAJS

NOTE: The seven basic "steps" that follow

are essential in order to insure correct alignment of the saw.

WARNING: Make sure the power cord is

not plugged into an electrical outlet when

working on the saw.

:-.. -'---..

/ ic::.;-.:;. ... .

.,

,

I.

:.'

_

;&, '. 3'L.

,p..

I

C

7>

,\..

:'

t;.

4 --2

-..__.

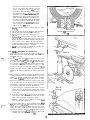

STEP ONE - INSTALLATION OF FRONT TABLE

1. Place the large front table board on toble supports so

that holes in board match holes in supports. (See figure 3.)

2. Place a l / d i n c h plain wosher and a l/4-2Ox l-inch

screw in eoch of the seven counterbored holes located

above the table supports. One screw i s threaded into

a "U"-clip nut mounted on the No. 2 support.

3. Attach lockwashers and nuts to the six screws in the

table supports. Do not tighten these screws at this time.

STEP TWO - CHECKING F O R LOOSENESS OF

COLUMN TUBE IN COLUMN SUPPORT

1. Tighten arm latch handle (22, figure 20.)

2. Grasp arm latch handle (22, figure 20) with one hand

and hold fingers of other hand at parting line between

column tube and column support. (See figure 4.) Apply

gentle side force to the radial arm in opposing directions.

Any looseness between column and column support (indicated by arrow in figure 4) can be felt with fingers.

3. If looseness can be felt, at point indicated b y the arrow

in figure 4, perform operations outlined in instructions

h a t follow:

N O T E Before attempting to adjust the column tube key, the function of this adjustment

should be understood. Figure 5 shows a sectional view through the column tube support

(looking downward) at this location. By loosening the left-hand set screw and tightening

the right-hand set screw the column tube key

will be forced tighter into the column tube

keyway. Conversely, loosening the righthand set screw and tightening the left-hand

..

2.

... ....~...

b?,

set screw, the column key will be retracted

out of the column tube keyway. The set

screw in outer end of column tube key must

b e loosened while adjustment i s being made

and tightened with medium firm~icssafter

adjustment i s completed. This screw applies

pressure on the Nylon friction plug and provides smoother elevation movement of column tube. This set screw should be tightened

to provide maximum smoothness of operation. Right and l e f t positions a r e given

w i t h operator facing the s a w standing in f r o n t o f s a w table.

-

-

S E T SCREVJ

(RIGHT HAND!

-

Si 1 5C2E .';

CLEFT H A h D i

a. Loosen set screw in center of column tube key. (See

figure 5.)

b.

Loosen left-hand set screw 1 / 4 turn. (See figure 5.)

c. Tighten right-hand set screw. (See figure 5.)

d.

Tighten left-hand set screw. (See figure 5.)

C O L U M N T U B E KEY

S E C T I O N A L VIEW L O O K I N G OOAN

Figure

5

e. Turn.elevution crank to raise and lower radial arm.

(See figure 6.) If too tight, loosen right-hond set screw

(figure 5) slightl y ond check again for smooth operation. When correct, tighten left-hand set screw

f. Tighten set screw in center of column tube key (figure

5) until smoothest operation i s obtained.

g. Lock the y o k e clamp h a n d l e (7, figure

b e v e l lock k n o b (17) securely.

20) a n d

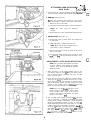

STEP THREE- SQUARING THE CROSS CUT

r l

1.

Loosen the arm latch handle (22, figure 20) 1 / 4 turn.

Make sure the yoke clamp handle (7) and bevel lock

knob ( 1 7) are tight.

2.

Pull the arm latch lever (1) outward and move radial

arm approximately l o 0 to the right. Release arm latch

lever and move radial arm into the O0 (index) position.

Do not bump or jar the arm. Push the arm latch handle,

or arm. latch lever solidly with palm of hand in order

to seat arm lock pin in the arm latch. (Refer to figure 24.)

3. Tighten arm latch handle. (Refer to "PRECISION INDEXING" for detailed instructions on indexing the radial

arm.)

4. Place a framing square on the table as shown in figure

7

and position the saw and square until the leg of the

square iust contacts a tooth of the saw blade. (Position

"A", figure 7.) Mark this tooth with crayon or chalk.

5. When the carriage

i s moved back and forth on the radial

arm, the saw tooth "A" should just touch the square at

a l l positions. If saw tooth "A" does not touch the square

a t all points, make the following adjustments:

a. If saw tooth ("A", figure 7) moves away from the

square when moving the blade from the rear toward

the front of the table, tap the right-hand front edge

of the table.

b. I f the saw tooth ("A", figure 7) moves into the square

when moving saw from the rear to the front of saw

table, tap the left-hand front edge of table.

c. Recheck . . . and, if correct, tighten all table holddown screws. (See figure 3.)

6. In extreme cases, due to rough handling during ship-

C

ment, the above adiustment procedure may not b e sufficient. Make the following adjustment only after tightening the table screws and the cross-cut cannot b e

squared according to the preceding adjustment routine.

a. Remove three screws ( 1 ancl 2, figure 8), miter-scale

indicator (3) and radial arm cap ( 4 ) .

-7'w

Figure 6

b. Turn the arm latch handle (22, fig ure 20) one-quarter

turn countcrclockwisc b u t d o not. pull it out.

c. Loosen (do not remove) two hex-head screws

(5, fig-

ure 8) located inside the column tube.

d. Move radial arm slightly i n the proper direction to

make saw tooth ("A", figure 7) follow edge o f square

when the saw blade i s moved in and out in a "crosscut" manner.

e. Re-tighten the hex-head screws (5, figure

latch handle.

8) a n d arm

f.

Recheck travel of blade tooth ("A") wilh the square.

g. After the cross-cut has been accurately squared,

install the radial arm cap ( 4 , figure 81, miter-scale

indicator (3) and screws (1 and 2 ) . Set the indicator

(3) a t O0 position.

STEP FOUR- ADJUSTING THE TABLE PARALLEL

TO RADIAL ARM

NOTE: DO NOT USE A CARPENTER'S

LEVEL.

-

*3

.

....,. i>'

.. .'.s !.

I,.

:

!

.

$. )!

&

;$

!

.. \ .,

(,, 5 :i

1.. - ...-

8

$ 3

.

@

'

.--

1. Remove the saw guard.

2. Loosen table support mounting screws (figure 3) a t

both left a n d right sides of the base. Re-tighten to finger

tightness for adjustment of table.

3. Loosen arm latch handle (22, figure 20) enough to

obtain free movement o f r a d i a l arm. Release arm latch

lever (1, figure 20), and loosen carriage lock knob for

easy movement o f motor a n d carrioge assembly durin g

this operation. Move the motor and carriage assembly

out to the end o f radial arm and lower the saw blade

until it just touches the table at point A, which is the

front central position. (See figure 9.)

NOTE: Actual contact with table can b e determined by rotating saw blade and listening for

a light "pinging" sound as the carriage i s

lowered.

4. Move the blade to point B near the rear edge of table.

(See figure 10.) If saw blade starts t o ride on table as i t

i s moved rearward, loosen the nut near the rear of the

No. 2 table support a n d t a p the table downward until

the blade just contacts the table at this point. If table

i s too low a t the back, t a p it upward until a pinging

sound can b e heard os blade i s rotated. Recheck at both

A a n d B locations a n d correct as required. Tighten nut

a t rear of No. 2 table support when correct center height

i s obtained.

5. Move the blade to the left-rear of table at point C and

tap table up or down as required. (See figure 11.) Then

move blade to point D a n d adjust table as required.

Tighten screws in left-hond table support angle when

height i s correct. (See figure 3.)

6. Move blade to points E a n d F and adjust the right-hand

table support in the same manner as described for the

left-hand support. Tighten screws in right-hand support

when adjustment i s correct.

.. .

7. Move the saw blade to a l l six positions t o recheck for

proper leveling o f table. (See figures 9, 10 and 11.) Make

slight corrections if required, and make sure a l l support

mounting screws are tight. (See figure 3.)

8. Place the r i p fence i n vertical position behind the front

table board.

9. Place the rear table b o a r d behind the rip fence and the

table spacer board behind the rear table.

10. Insert -the three table clamps (9, figure 20) and tighten

them finger tight to secure

all

table boards.

STEP FIVE - SQUARING THE SAW BLADE

TO THE TABLE TOP

1. Place the edge of o framing square on the table t o p

a n d against the saw blade, as shown in figure 12.

9

L/

2. W h e n the saw blade is square with the table top, no

light will b e visible between the square a n d face o f saw

blode. Do not a:low the square t o rest against o tooth

o f the saw. I f light is visible between the square and

face of saw blade (with square leg held firm against

the table top) pcrform the following adjustments:

a. Using a 1/4-inch hex "L" Allen wrench, loosen iust

slightly the four socket-head screws (2, figure 12).

b. Tilt the motor until the saw blode is square with the

table top as shown in figure 12. Then, while holding

the square firmly against the saw blade a n d table

top. apply pressure against lower part o f saw blade

with the thumb until ~pproximately1 /32-inch clearance exists between the square and lower edge of

saw blade. This is to compensate for the possible

slight shifting of the motor while screws (2) ore bein g

tightened.

c. Tighten the four socket-head screws (2, figure 12).

..

NOTE: It may be necessary to perform more

thon one trial.opcration before the saw blade

remains perfectly square with table t o p after

screws have been tightened.

d.

BLADE TRAVEL

BLADE TRAVEL

Recheck for blade squoreness with table top.

e. The indicator (3, figure 12) should r e a d O0 o n the

bevel index scale. If not, loosen the indicator attaching screw, adjust indicator t o zero and tighten the

screw secure1y.

I

;I-BLADE

HEELING

'1:

BLADE HEELING-\\

TO LEFT

TO RIGHT

F i g u r e 13

I

STEP SIX- CHECKING THE S A W BLADE FOR

"HEEL" (LEFT AND RIGHT)

1. Place a square against the rip fence and the saw blade

as shown i n figure 14. The long leg of the square must

b e held firmly against the rip fence a n d table top

a n d the short leg must not touch any o f the teeth o n

the saw blade.

2. I f a g a p exists between the saw blade a n d the-square,

one of two types of "heel" exists. (See figure 13.) To

correct for either type of condition, proceed as follows:

(1, figure 14)

by removing the two attaching screws (2).

a. Remove the left-hand carriage cover

b. Loosen the yoke clamp handle (7, figure 20).

c. Loosen (slightly) two hex-head screws (1, figure 15).

d.

Rotate the yoke until the gap between saw blode

a n d square i s eliminated. (See figure 14.)

e. Lock the yake and tighten the two hex-head screws

(1; figure 15).

f.

Recheck for "heel" after tightening screws, a n d make

corrections if necessary.

g. Install left-hand carriage cover. (See figure 14.)

STEP SEVEN - DOUBLE CHECK SQUARING OF SAW

1. Recheck for correct adiustment of the saw b y performing "STEPS THREE, FIVE a n d SIX".

2. If the cross-cut

i s not perfectly squared, proceed with

"STEP THREE" (paragraphs 5 and 6). a n d "STEP SIX",

i f a correction i s re q uired.

NOTE: I f afier making all adjustments outlined in STEPS "ONE" through "SEVEN,"

refer to Trciublc Shooting Charts for any

existing problems.

LEFT HAND SIDE

figure

15

I

.

. .

.. -

. ..

,

.

:, -,

?

3

ATTACHING AND DETA C H I N G. . . . .?.

:i iI

.. :

.,:

., .,.,. .-... ._

.

...-.* :\

S A W BLADE

; .;:;. .,

!

'

1

1. Locate the motor carriage assembly midway k - - ~ i d i c i l - - . ' - ~

.I

arm ond tighten carriage lock knob

(6, figure 20).

L/

2. REMOVAL (See figure 16.)

a. Place the open-end shaft wrench on hex portion

of motor shaft on inside of saw blade. Allow end of

wrench to rest on saw table.

b. Using the box-end arbor wrench, loosen the shah nut.

NOTE: The motor

shaft

has

left-hand

threads.

c. Remove shaft nut, collar, saw blade and second collar.

3. INSTALLATION (See figure 17.)

a. Place inside collar o n motor shaft, with flange next

to saw blade.

b. Install saw blade, outside collar and nut.

NOTE: Make sure the larger (flange) face of

each collar i s next to saw blade.

c. Place box-end arbor wrench on shaft nut and let it

rest on saw table.

d. Use open-end shaft wrench on hex portion of shaft

- a n d tighten b y pushing downward as shown in figure 17.

/--

h

ADJUSTMENT O F RIP SCALE INDICATORS

NOTE: The rip scales and pointers are intended to b e used for quick settings. For greater

accuracy, toke direct measurement between

blade a n d fence.

1. When the fence i s in its normal position (next to the

front table), index the yoke 9

0' from the cross-cut position so that the blade i s between the motor and the

fence. Lock the yoke.

2. Move the motor along the radial arm until the blade,

when spun by hond, just touches the front face of the

fence. (See figure 18.) The indicator on the right-hand

side of radial arm should now reod 0-inches on lower

portion of the "In-Rip" scale. If not, logsen the two

screws and shift the indicator to reod 0-inches.

NOTE: With the saw bldde and fence in the

position shown in figure 18, the lower portion

of the "in-Rip" scale i s used. I f the fence is

moved to the extreme rear position, the upper

portion of the scale i s u.sed.

3. The "Out-Rip" scale pointer, located on the left-hand

side of radial arm, i s adjusted in essentially the same

manner as the "in-Rip" scale pointer, except the blade

should b e positioned as shown in figure 17. With 12inches measured between the fence (when in full rear

position) and face of saw blade, the pointer should be

set to the 12" position. The upper portion of the "OutRip" scale i s used when the fence i s in the rear position.

(See figure 19.) The lower portion of the scale i s used

when the fence i s located in the usual position

a t the

rear edge of front table board.

-

w

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Arm Latch Lever

Swivel Latch Pin Knoh

Rip Scale lndicator

Radial Arm Indicator

Radial Arm Scale

Carriage Lock Knob

Yoke Clamp Handle

Switch Lock and Key

Table Clamp

Arbor Wrench

Shaft Wrench

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

Allen Wrenches

Adapter Plug

Elevation Crank

Eevel lndex Indicator

Bevel lndex Scale

Bevel Lock Knoh

Anti-Kickback Pawl Assemhly

Bevel lndex Handle

Latch Pin Handle

On.Cff Switch

Arm Latch Handle

SET-UP GUIDE

A combined number and color code system, designated as

a "SET-UP GUIDE", has been applied to the saw in order

to simplify the location of tontrols req uired for a particular

set-up operation. The "SET-UP GUIDE" i s both a convenience and safety measure, particularly for inexperienced

operators., The operator should become familiar with this

feature before operating the saw. A brief explanotion of

the "SET-UP GUIDE" is as follows: (See figure 21.)

1. Notice the radial arm trim strip, the forward end of

..

which contains six diagrams numbered "1" through

6". Each number i s in a colored circle, and a corresponding number in an identical colored circle will b e

a n the particular operating control member involved.

2. Locate each control and become familiar with its operation.

a. "DEPTH OF CUT". Diagram shows :he elevation

crank which is used to raise a n d lower the blade. The

numeral "1" in a light-blue circle is on the crank

handle.

Figure 21

b. "ANGLE OF CUT". Two controls 'are involved in re-.

leasing, securing and indexing the angle of the radial

arm. These are: arm latch handle and arm latch

lever. The handle is marked with a dot:-blue circle.

c. "CARRIAGE PIVOT".'TWO controls are used i n this

operation. They are: swivel latch knob and yoke

clamp handle, each marked with the numeral "3"

in a n orange circle.

d. "CARRIAGE LOCK". The carriage lock knob is

rotated clockwise to secure the carriage on radial

arm, a n d counterclockwise to release it. The numeral

"4" i n a green circle is a t the center of the knob.

e. "BLADE ANGLE". The two controls used in angular

positioning a n d indexin g of the motor to provide the

desired saw blade angle are: bevel lock knob and

latch p i n handle. The numeral "5" in a yellow circle

is attached to the bevel lock knob. The latch p i n

handle i s painted yellow.

f . "POWER SWITCH". This switch is located in the

upper left a r e a of the carriage a n d has the numeral

"6" in a r e d circle directly under it.

USE OF KEY AND SWITCH

NOTE: This savt cannot be operated without

the key, and likewise, the key cannot be removed trom the lock while the sow motor is

running. This feature was designed into your

saw for safety and protection.

1. Insert key in slot and turn it. (See figure 22.)

2. Press the right-hand side of toggle switch lever to turn

the saw ON. Press left-hand side of switch to turn

saw

OFF.

RAISING AND LOWERING THE RADIAL A R M

This i s accomplished by the elevation crank (8, figure 23).

One complete t u r n o f this h a n d l e w i l l raise o r lower

the r a d i a l a r m 1/8-inch.

.

LOCKING THE CARRIAGE TO THE RADIAL ARM

This is accomplished by the carriage lock knob (3, fig"rb .;

23). Turn the knob clockwise to lock; counterclockwisq! tb'

unlock.

I -&

ANGULAR MOVEMENT A N D LOCKING

OF RADIAL ARM

These movements are controlled by the arm latch lever

(1, figure 23) and the arm latch handle (12). The radial

arm can be rotated 360° and locked in any position. The

arm i s unlocked from any position b y a slight counterclockwise rotation of the arm latch handle (12) and is locked

in any position b y rotating the arm latch handle clockwise

until tight. The radial arm has positive stops at O0 and 45O

left and right, and is released from these index positions

by unlocking the arm latch handle (12) and pulling out

the arm latch lever (1).

For most positive and accurate settings at the index positions, the following i s recommended:

1. If the radial arm is already indexed, rotate the arm

latch handle (12, figure 23) 1/4 turn counterclockwise from the locked position, pull out the arm latch

lever (1) and move the radial arm off the index position.

Release the arm latch lever (1).

2. Move the radial arm into the index position (do not

bump or jar it) and push on the handle (12) or arm

latch lever (1) solidly with the palm of the hand. (See

figure 24). This i s very important as it insures proper

seating of the arm lock pin in the arm latch, thus always

returning the arm to the correct cross-cut (0°) position.

3. Lock the radial arm by rotating the arm latch handle

(12, figure 23) clockwise until tight.

CAUTION: When moving the radial arm i n any

direction beyond 4S0 left or right, always pull

out the arm latch lever (at end of radial arm)

to prevent damaging the arm lock pin. If damage occurs, the radial arm will not index

properly a t '0 and 4S0 positions (left to right).

MOVEMENT AND POSITION OF MOTOR IN YOKE

These movements are controlled by th'e latch'pin handle

(6, figure 23) and bevel lock knob (7). The bevel scale

indicates the angular position of the motor with respect to

horizontal from O0 to 90° in either vertical position. The

latch pin handle (6) outornotically indexes the motor at

0°, 45O and 90° up and down. Lift the latch pin handle to

release. At any other position, the latch pin handle i s not

engaged. The bevel lock knob (7) locks the motor to the

yoke when the motor is i n any position. Rotate it clockwise

to lock; counterclockwise to unlock.

MOVEMENT AND POSITION OF THE YOKE

These are controlled b y the swivel latch pin knob (2, figure

25) and the yoke clamp handle (4). The swivel latch pin

automatically indexes the yoke at each 90° position. Lift

the knob to release. The yoke clamp handle (4) locks the

yokc to the carriage in any position. Pull the handle to

release. Push it to tighten.

r"l

kd

---

-

.

:

.

..

.

i

. t&

.. ....

.

..

'' ;-,tf

PRECISION INDEXING

-

/-

1

-.

Experiencrd operators o f precision equipment, such as this

Craftsman Sow, normally acquire the habit of indexing

the machine in one direction only whenever a new setting

is made in preparation for a different operotion. For example: When moving the radial arm to a new position, i t is

advisable to move it slightly post the desired index position

then move it back slowly a n d carefully to latch and lock it.

(See figure 24). Swivel indexing a n d bevel indexing can

b e accomplished in the some manner. This technique tends

to neutralize any stresses imposed upon saw components

and contributes to the high degree of accuracy this saw is

capable of producing when operated expertly.

REMOVAL OF M O T O R AND

CARRIAGE ASSEMBLY

The motor and carriage a.ssernbly m a y be easily removed

from the radial arm for servicing or storage at some loco-

tion, away from the remainder of the saw, when desired

Proceed .as follows:

1. Release the power cord from cord clamp a t rear of

radial arm.

- -..--,

a r m a n d ' ;:i

.

2. Insert the handle end of the arbor wrench tor shaft

wrench) between the lower surface of radial

carriage to raise the carriage stop. (See figure:27.j The

wrench need not b e held, as it will remain in ploc5: &Kin . j.;

,;.;-.

..;':

released.

r.

I

3. Grasp

motor a n d carriage assembly firmly antfnmptPpi

pull it forward, o f f radial arm.

NOTE' The wrench is not needed when installing the motor and carriage assembly o n

radial arm, as the carriage stop will raise automatically, then "snap" back into safety stop

position when the carriage is moved rearward

onto the radial arm.

ADJUSTMENTS TO COPvIPf NSATE FOR VJEAW

Even though the finest materials a n d precision workmanship have been used t o minimize wear, it i s reasonable to

expect some wear. Adjustments have been built into your

Craftsman saw to reduce or eliminate this wear.

ELIMINATING LOOSENESS BETWEEN

COLUMN TUBE AND C O L U M N SUPPORT

,'7

$\

This operation is explained fully i n "STEP TWO -CHECKING FO2 LOOSENESS OF COLUMN TUBE IN COLUMN

SUPPORT."

'.

YOKE CLAMP HANDLE ADJUSTMENT

The normal locking position of the yoke clamp handle (1).

figure 25) is approximately midway between the two

- sides

of the, yoke.

When the handle moves considerabl y to the rear, or strikes

the yoke before locking, the handle may be adjusted as

follows:

1. Remove saw guard a n d blade.

2. Set yoke clamp handle to Position "A", (figure 25),

which is just slightly ahead of the mid-position of handle.

3. Insert the handle e n d o f the arbor wrench (or shaft

wrench) between the lower inner surface of radial arm

and carriage to raise the carriage stop. (See figure 27.)

The wrench need not b e held, as it will remain in place

when releosed.

4. Grasp the motor a n d carriage assembly and move it

carefully off end o f radial arm.

CAUTION: When removing the motor ond

carriage assembly from radial arm, be sure

to hold the assembly parallel to the arm until

all bearing rollers are free of their tracks.

If the ossembly is allowed t o tilt after the

forward rollers are free, the adjustment of

rear rollers will b e altered. This same precaution should be taken when installing the

motor and carriage assembly on the radial

arm.

5. Rest the motor a n d carriage assembly on saw table.

6. Remove the lock screw (3, figure 26).

LOCKING POSITION

DUE TO WEAR

I:.

i

i

7.

Using a screwdriver or similar tool, rotate the yoke

clan~passembly (2, figure 25) clockwise (when looking

down) until the next hole will line up with the lock screw

(See figure 28). Usually, rotating the yoke clamp assembly one hole will correct this adjustnient. However, in

same cases it may be necessary to rotate it two holes.

8. Make sure the hole in yoke clamp assembly (2, figure

24) lines up with lock screw hole and install and tighten

lock screw (3, figure 26)

.

.---

;d'

9. Slide motor and carriage assembly on radial arm. (See

.

CARRIAGE BEARING ADJUSTMENT

!

(1, figure 14).

2. Loosen nuts (3 and 4, figure 30) just enough to permit

eccentrics to turn. (See figure 29.)

3. Turn adjusting screws (1 and 2, figure 30) a partial turn

left or right as required to take up looseness.

4. Hold head of screws (1 and 2, figure 30) in position

established in preceding step and tighten nuts (3 and

4) on underside of carriage.

5. Correct adjustment exists when there i s no play between

thecarriage ond radial arm, and yet the cdrritige moves

freely.

6. Install carriage cover (1, figure 14).

NOTE: It will probabl y be necessary to recheck steps "THREE, FOUR and FIVE" under

"ASSEMBLING AND ADJUSTING YOUR

SAW," after adjusting carriage bearings.

Your saw i s a fine machine and should be given the best

of care. If kept clean and properly lubricated, it will give

many years of trouble-free service. Before describing the

various points which may periodically require lubrication,

IT IS MORE IMPORTANT TO FIRST MENTION THE VARIOUS SPOTS WHICH SHOLILD NOT BE LUBRICATED.

..

,

.

.'.

-1:: L: k.9 ?

To test for looseness in carriage ball bearings (bedit%"bearings and tracks on radio1arm), lock yoke clamp handle,

grasp the motor and carriage assembly firmly and apply a

firm rocking motion. If looseness exists, the two bearings

on left-hand side of radial arm must be adjusted. The

two bearings on right-hand side of arm are attached to the

carriage with regular hex-head screws and ore not adjustable. The two bearings on left-hand side of arm are

attached to corriage with. eccentric screws. (See figure 29.)

1. Remove left-hand carriage cover

---" $3

!,. .I.

":

'

.

"CAUTION" under. preceding step 4.)

.

N O LUBRICATION REQUIRED:

Do not lubricate carriage b a l l bearings.

Do not lubricate the motor bearings. These a r e sealed

b a l l bearings a n d require n o a d d e d lubrication.

Do not lubricate between r b d i a l a r m c a p a n d r a d i a l

arm.

PERIODICALLY LUBRICATE THESE POINTS

Use SAE No. 10-30 auto engine oil and refer to Parts List

for locations.

Apply o few drops of oil along the swivel latch pin only

if the pin has o tendency l o slick. Remove the left-hand

carriage cover and use oil sparingly to prevent it from

getting on the ball bearings or races.

A light film of oil can be wiped on the face of the column

tube and keyway to lubricate the fit between this part and

the key and column support.

1

I

OIL HOLE

:

Apply a few drops of oil to the bearing surfaces of the

elevation crank shaft assembly. An oiling hole i s provided

in the elevation shaft bearing bracket to facilitate the

lubrication of the bearing support. (See figure 31.)

The thread on the elevation shaft assembly can be lubricoted through the oiling hole in the center of the radial

arm cap.

CAUTION: Excessive oil a t any location will

attract dust particles and sawdust.

PRELIMINARY CROSS-CUT AT

THE O0 POSITION

. ..

NOTE: The bevel index handle must be positioned at 0°, as indicated on the bevel index

scale, and locked.

1. Pull motor forward of fence so that blade i s free to

rotate.

2. Lower radial arm until saw blade just clears the table top.

3. Tighten carriage lock knob (figure 20).

CAUTION: Before cutting, always be sure that

the arm latch handle i s locked.

4. Plug power cord into receptacle.

5. Insert switch key; turn the key and press the switch "ON''.

6. Lower radial arm until blade cuts into table fop approxi..-

'.

mately 1/32".

7. Hold the bevel index handle with the left hand and loosen

the carriage lock knob with the right hand. Slowly pull

the motor out to the extreme end of travel. Then push

the motor back through the fence to the extreme rear

position. Push the switch "OFF".

-

CROSS-CUTTI NG

Cross-cutting is the sawing of wood across the grain. Lumber

i s milled with the grain running the length of the board. If

a straight cross-cut is desired, the board is placed on the

anti-kickback pawl assembly so i t clears the board to be cut.

Turn key and press the switch "On" to start the saw motor.

Hold the board firmly against the rip fence with the left hand

a n d grasp the bevel index handle with the right hand. The

cut i s then made b y pulling the carriage forward until the

saw blade cuts through the work. When the cut i s complete,

the saw should be returned to the back of the radial arm and

the switch turned "Off". When m o r e experience is gained

by using the saw, i t will b e noticed that w h e n p u l l i n g

t h e s a w t o w a r d you d u r i n g cross-cutting, the saw

b l a d e tends t o feed itself t h r o u g h the w o r k d u e t o the

r o t a t i o n o f the b l a d e a n d the direction o f feed. Therefore, the operator should d e v e l o p the h a b i t o f holding his right a r m straight f r o m the shoulder t o the

wrist. After this method is used a few times the operator

will find that i t i s necessary to roll or rotate the body from

the waist up. Thus, it will become apparent that very little

effort i s required on the port of the operator to move the

saw blade through the work, and in most cases, the right

arm i s used merely to control the rate of feed of the saw

through the board. It will also be found that when crosscutting a thick board it will be necessary to retard rnovernent of the saw through the work. By holding the right

arm (right hand normall y grips the saw handle) straight,

the operator can easily control the rate of feed, thus preventing the saw blade from overfeeding and stalling the

saw motor. This must be avoided whenever possible.

saw table against the fence so that -the grain i s parallel

to the fence. (See figure 32.)

NOTE: When cross-cutting normal pieces of

lumber, the long end of the board should b e

placed to the left of the saw blade as the board

i s normally held by the left hand during operation. The saw i s pulled through the stock - not

pushed through.

The radial arm must be positioned at O0 as indicated by

the radial arm position indicator. The arm latch lever must

be indexed and arm latch handle tightened.

tf

s

\

The yoke must be indexed at the O0 position, making the

saw blade perpendicular to the rip fence, and the yoke

clamp handle placed in the locked position. The bevel

index handle must b e positioned a t 0°, as indicated by

the bevel scale, and locked. Turn the elevation crank to

lower the saw until the blade teeth are approximately

1/32-inch below the table surface and ride in the saw slot

made when performing the "PRELIMINARY CROSS-CUT

AT 'THE O0 POSITION".

Push the saw carriage to the rear of the radial arm so the

blade is behind the rip fence. Adjust the saw guard so

the bottom is porallel to the table and remove or set the

Figure 32

3. Screw or nail the cross members on the 2 x 4's as shown

in figure 34. Make sure the support is square.

----___

"?

4. A right-hand configuration can be made b y extedding . - . .

the top cross piece toward the opposite side as sIj0b.n .

. .

in figure 35. I f only o single support i s required, tj, -bk . .. :,.

rnovcd from the right or left-hand side as nceddd;:$

(,

duo1 purpose unit may be m a d e b y allowing a 10-k/8"

extension of the upper cross member as shown?----'

figure 36.

:;;;

..

I

/

.--

... !

'

&

+

r

I

5. Insert two standard 2 x 4's through the clamps on the

Figure

legs of the saw table and ti g hten the clamps securely.

These 2 x 4's may be as long as desired t o handle the

boards to be ripped.

33

8

6. Place the support stand in position with the upright

members on the stand inside the 2 x 4's attached to

saw table legs. (See figure 37.)

In some cases it may become necessary to. cross-cut long

boards which extend over the saw table on one, or both

sides. 'This can cause buckling of the board and bind the

saw during the cut. To eliminate this condition the ends

of the board should be supported. Figure 33 illustrates a

typical support which can be mode and used to facilituIe

cross-cutting of long lumber.

7. Position the lower ends' of stand uprights outward until

the cut angles fit the floor and secure the stand uprights to the 2 x 4's on the saw with two "C" clamps

as shown in figure 37.

8. Lay a board on stand and saw table in ripping position

as shown in figure 37, and adjust the angle of the stand

Another type of work support for ripping long boards with

the 12-inch radial saw can be constructed as follows:

I.

'.

r

until the board to be ripped i s level with saw table.

9. If two stands are to be used, install the right-hand

Cut and assemble boards for the end support according

to the dimensions shown in figure 34, which is designed

specifically for use on the left-hand side of the saw table.

The uprights are cut from standard size 2" x 4" stock and

the cross pieces may be standard 1" x 6" or 2" x 6"

stock. Scrap boards may be sawed to the dimensions

shown, i f standard 1" x 6'' or 2" x 6" stock i s not available.

stand at right of saw in the same manner.

The clamp attached to each leg is for clamping one 2" x 4"

board on the two front legs and another-on the two reor

legs. (See figure 38.) These 2" x 4" extensions may be used

to attach outboard supports to assist in supporting long

boards, or may be used to pick up the saw (one man at

each side) ond move it. They are also effective for supporting the saw in the bed of a pick-up truck when moving

from one job to another.

Cut a corner of each upright 2 x 4 according to dimensions shown in figure 34, to fit the floor.

,)

,.J'

g

-T===r

I' I

I1

I-&

WOOD SCREWS

(OR NAILS)

10-3/8"

RIGHT-HAND CONFIGURATION

20-3,4

--Figure

35

*

I

I

I

DUAL PURPOSE

(BOTH R .H. A N D L .H .)

-

F i g u r e 36

Figure 34

1

t

14

*

Figure 38

Holes are located in the saw base that permit legs to be

extended outward horizontally if desired. This i s accomplished by removing three attaching screws in each leg,

rotating the leg to a horizontal position a n d re-installing

the three screws. (See figure 39.) The lower inside screw at

each location need not be removed, but should b e loosened

just enough to permit the leg to rotate on i t as a n axis.

'.

Ripping i s the sawing of wood with the grain. I t is always

done with the help of the fence as a guide t o position and

rnointain the work at the correct width for the cut. Because

the work i s pushed along the fence, i t must have a reosonably straight edge to make sliding contact with the fence.

Also, the work must make solid contact with the toble so

that it will not wobble or rock. Provide a straight edge,

even i f this means temporary nailing or clamping an

auxiliary straight edge board to the work. If work piece

is warped, turn the hollow side up.

Use of the saw guard is always recommended; and the

anti-kickback pawl assembly should always be used i n

both ripping operations.

Before ripping and after the saw has been positioned prior

to cutting, the saw guard a n d anti-kickback p a w l assembly

must be properl y adjusted. Loosen the guard clamp screw

holding the guard to the motor a n d lower the nose o f the

guard fo within 7/8" above the fop surface of the b o a r d

to be cut. Retighten fhe guard clamp screw securely.

CAUTION: The nose o f the guard refers ta that

end of the guard which i s opposite to the end

which mounts the anti-kickback pawl assembly.

Always r i p from the nose o f the guard. See

Warning Label on guard.

At the opposite end of the guard, loosen the wing screw

holding the anti-kickback p a w l assembly a n d lower the

assembly until the tips o f the pawls are 7/8" below the t o p

surfoce of fhe b o a r d t o be cuf. Retighten the wing screw

securely.

The anti-kickback pow1 assembly i s equipped with a "splitter" on its lower end t o prevent the saw slot from closing

and binding the saw blade. (See figure 40.) Therefore, the

anti-kickback pawl must be adjusted so the splitter i s

aligned with the saw blade. This is accomplished by adjusting the two socket-head, set-screws in the guard assembly.

Use a straight edge agoinst the splitter and saw blade a n d

adjust the socket-head set-screws so the splitter is aligned

with the blade when the wing screw i s tightened.

I

LEG IN HORIZONTAL

POSITION

SOCKET - HEA

LEG ROTATES

ORIGINAL

OF LEG

A L I G N SPLITTER

W I T H SAW

\\

-b

Figure 39

1

\\

\\

!\,

-

LADE

IN-RIPPING - refers to a

- , ~ o- s i t i o nwhen the blade is

between the motor and the fence and p arallel to ~ h fence.

e

(See figure 121 ) To place the saw in this position, unlock

c swivel latch pin and rotate the

the yoke, d i s e ~ ~ g a gthe

yoke 90' clockwise (viewing it from t ! ~ ecarl.iage) until

,e swivel larch pin automatically indexes the yoke 90'.

.,clock the yoke. Position the motor on the radial arm until

the pointer on the "In-Rip" scale indicates the desired width

of the finished cut board. Tighten the carriage lock knob

securely. Turn the saw "On" and lower the radial arm until

the saw blade cuts into the table top a p proximately 1/32inch. Turn the saw "Off". Now adjust the saw guard and

anti-kick pawl cssembly as described in the paragraph "Ripping". The board to be ripped must be fed into the saw

blade from the right-hand side of the table, therefore, the

normal position for the operator i s also at the right side

of the table. With left hand safely clear of the blade and

holding the board to be ripped down against the table

and against thtt face of the fence as a guide, use the right

hand to feed the board into the saw. The left hand should

remain stationary, serving as a guide only. As the right

hand opprclches the left hand, hold a push stick with

the rigth hand to complete the cut. Do not leave a long

board unsupported so that the spring of the board causes

it to shift on the table. A support (described in "Crosscutting") may be used to support the board behind the

blade; and if the board is very long, use another support

in front of the saw. Ripped boards up to 16-inches wide

can be cut in the In-Rip position.

0

OUT-RIPPING -- refers to a position when the motor i s

between the biode and the fence. Normally, this position

is only used w l ~ e nthe width of the required ripped board

cannot be cut from the in-rip position. Ripped boards up to

17-1 /2-inches wide can be cut in the out-rip position when

.he fence i s agoinst the front table. If the fence is moved to

rre extreme rear position against the table clamps, ripped

boards up to 36-1/2-inches wide can be cut. To place the

saw in the out-rip position, the yoke must be rotated and

indexed 90° counterclockwise from the cross-cut position

and locked. The some procedure for pre-cutting the table

top (see "In-Ripping") ond adiusting the anti-kickback

pawl assembly should be followed. The same procedure

for sawing i s used except that the operator stands at the

left-hand side of the table and a push stick is normally

not required.

Resowing i s cutting thick boards into thinner ones with

a ripping operation. (See figure 42.) Small boards, up to

4-inches maxinlum width can be resawed in one pass;

but larger boards require two passes, one pass along each

edge of the board. When two cuts from opposite edges are

required, these should be made to overlap 1 /2-inch from

the opproximatc center of the board. If the first cut i s too

deep, the kerf may close and bind the saw on the second

cut, with dangcr of kickback. Also, when the kerf closes,

the two sides cf the cut are no longer parallel to the sow

blade, and the saw will cut into them to spoil their appearance. Keep the same face of thc board against the fence

when making both cuts. When cutting boards thicker than

4 inches, a fence should be used which extends 3-1/?-inches

above the table top.

BEVEL A N D MITER CUTS

t3evcl cuts may be made from either a cross-cutting or ripping position b y tilting the blade to the desired angle.

Miter cuts can be made only from a cross-cutting position

when the blade and radial orrn are at some angle other

Figure 41

0

Figure 42

I

Figure 43

than 90' to the fence. A bevel miter cut i s a cut which is

both beveled and mitcred. This cut i s made w i ~ hthe blade

and radial arm sct at the desired miter angle to the fcnce;

then the blade only i s tilted ta the desired bevel angle.

This cut i s also referred to as a conipound miter. (See figure 43.)

I

USE OF THE DADO HEAD

The dado saw (or head) i s a special set of blodes for cutting grooves and dodos. Craftsnian 8-inch Kromedge Dado

set may be purchased at any Sears Retail Store or Mail

Order House. The head consists of two outside blades

1/8-inch thick, six 1/8-inch thick chipper blades and paper

washers for 1/16-inch width adiustments. With these blades,

grooves of 118-inch, l/4-inch and, additional widths increased in steps of 1 /16-inch up to a maximum of 1-inch

wide, can be cut. Outside blades may be used alone, chippers cannot be used alone.

When using the maximum width of dado of I-inch on the

motor shaft, the loose collars must not be used. The width

of the dado may be reduced while using the loose collar

and two or more passes made with the work to obtain the

desired width of cut. Whenever two or more chippers are

used, stagger the cutting ends as evenly as possible around

the circumference.

Fractional adjustments in thickness of the head may be

made by using paper washers between outside blades nnd

chippers. Dado head operations are essentially the same

as those with a standard blade. However, the dado head

takes a bigger bite, so the work-piece should be held more

firmly. When a groove wider than the dado head is needed,

make two or more passes. Space the cuts so they overlap a

trifle. Dado work i s performed in the crosscut position.

Ploughing is done in the ripping position. If the rip (or

plough) position is used, the anti-kickback pawl assembly

should be adjusted as described in the paragraph entitled

"Ripping". Rabbeting i s performed in the vertical position.

(See figure 44). When rabbeting, the motor i s indexed 90°

to the vertical position so the blades ore between the table

top and the motor and yoke i s indexed 90° clockwise and

locked. The saw i s moved back on,the radial arm and

locked to the arm when the amount of blade extending

forward of the fence i s equal to the depth of the rabbet

desired. If the depth of the rabbet i s large, do not attempt

to cut i t in one operation. Lower the radial arm until the

blades are in a position to cut the desired width of rabbet

in the edge of the board.

I

f i g u r e 44

I

Figure 45

-

MOLDiNG OR SHAPING

This work is done with the Craftsman Moldin g Cutter Head

and a set of cutters, depending upon the type of molding

cut desired, with the saw in the same position as that described for robbeting. (See figure 45.) Since the position

of the cutters with respect to the fence and table top can

be adjusted, any (or all) of the cutter shapes may be used.

ROUTING AND DOVETAII-ING

Routing and dovetailing are accomplished with the motor

indexed and locked 90° from horizontal, except the externally threaded stub end (opposite the normal blade end)

is between the motor and table top. The following chucks

will mate with this external 1/2-20 thread. (See figure 46.)

0-inch to 1 /4-inch Key Chuck

5/64-inch to 1/2-inch Key Chuck

The following routers and dovetails ore recommended:

1 /8-inch router

1 /4-inch router

3/8-inch dovetail

1 /2-inch dovetail

3/8-inch router

1 /2-inch router

5/8-inch router

Routing may be performed by either moving the work with

a stotionury router or b y clanlping tire work to the table

and moving the router. Always approach the router b i t

from the lefi-hand side of the saw.

I

I

Figure 47

BORING

The saw may be converted to a horizontal drill f o r

by using one of the recommended chucks a n d the

drill. For drilling holes o n a n angle, the radial arm

be positioned to the desired angle while the work

parallel t o the fence. (See figure 47.)

boring

proper

should

i s held

SANDING

Using the 10-inch sanding disc mounted on the saw end o f

the motor, the saw c a n be converted into a sander a n d

operated in any position. One loose collar should b e used

Jn each side of the sanding disc. (Sce figure 48.)

FENCE LOCATIONS

Tlicre are three positions in which the fence can b e located.

(See figure 49.)

1. Normal position.

2. Position used for maximum crosscut o n one-inch material

a n d for greater bevel and miter capacity.

CAUTION: Rip scales cannot b e used in this

position.

3. Position used for maximum out-rip capacity.

STABILIZING WASHERS FOR THIN BLADES

shoe i s instantly pulled away from the brake lining so the

motor does not start under load. When the motor is turned

off, braking action takes place automatically. This brake

is designed to stop a free running saw blade in 20 t o 25

seconds. DO NOT attempt to alter either the brake disc

or the lining to obtain o faster stopping time. Stopping

the blade too suddenly could possibly unscrew the shaft nut.

-

HELPFUL HINTS

1. The life of the laminated saw table can b e greatly

lengthened by tacking a piece o f l / d i n c h thick plywood to the table top.

2 . There is a possibility that after tacking a piece o f plywood to the table top, the plywood surface may not

b e smooth or may be uneven. Lay a,straightedge across

the surface of the table a n d check for gaps or high spots

on the table. Any portions of the table that are not

flat may be sanded until flat. Sanding can b e accomplished in the manner shown i n figure 48.

3. When sanding on the table top, or routing with fhe

work stationary, the arm lock pin can be prevented

from automaticoily indexing a t O0 and 45' by rotating

the arm latch handle approximately six turns counterclockwise from the locked position.

Stabilizing washers should be used with blades for improved appearance of the finished cub.

4. A scale may b e provided to a i d the operator when

measuring lengths during cross-cut. operations, by tacking or gluing a yard-stick or wood scale to the fence as

..

shown. (See figure 50.)

BRAKE

5. In the event o f a warped fence that cannot b e straight-

The motor o f this saw i s equipped with a built-in electromechanical brake t o eliminote a lengthy "coast" time after

the saw is turned off. W h e n the motor is started, the brake

.

ened b y tightening the table clamps, remove the fence

and install a new fence cut t o the same size from a

piece of straight stock.

SAW KERF IN

Figure 49

.A,

u

6. Keep c ~ l cutting

l

tools sucl) as saw blades, drills, rnold~rlg

cutters, dodos, etc., sharp a n d d o not force fecd the

work t o tile point where the motor speed is drasticnlly

reduced. This will minimize e f f o r t , nlovidrt snloother and

more accurate cuts, resist overl~eatinga n d pos:ib!c.

out couscd b y obuse due to overloading.

7.

burn

W h e n using the planer, molding, or dado blades, repea+edlight cuts will producc best results. Deep cuts

reducc the quality o f the finish.

BENCH POWER TOOL GUARANTEE

W c guaruntce a l l Craftsman Radial Saws lo bc free from

material a n d workmanship: w h e n properly used,

defects

cared for a n d maintained, we will re p lace or repair ot our

option and install without cost to you, f o r a period of onc (1)

year from date o f sale, any port which proves, upor1 our

examinations, to b e defective under normal use. This guarantee doesn't a p p l y to Radial Saws used i n rental service.

F O R PARTS LISTS

SEE PAGES 20 0

28

FOR TROUBLE-SHOQTiNG CHikRVS

SEE PAGES 29 A N D 30

PARTS

;;

CRAFTSMAN, 12- INCH RADIAL SAW, MODEL NO. 1 13.29501

,;,' i:.,

:

,\ ,.-,.,

'.d

0

-'<

!$

w \

-+y

,I1 parts illustrated in Figures 51 through 56 and listed under part numbers may be ordered through any &arc retadstore or Catalog order store. Order parts by mail from the Cotalog order house which serves the territory in which you

live. In several instances, part numbers are listed for COMPLETE ASSEMBLIES. All parts are shipped prepaid within the

limits of the Continental United States.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN

ON THIS LIST:

1. THE PART NUMBER

3. THE MODEL NUMBER 113.29501

4. THE NAME OF ITEM - RADIAL SAW

2. THE PART NAME

Always order by Part Number - not by Key Number

FIGURE 5 1 PARTS

Key

No.

1

2

3

4

5

6

7

8

I

10

11

12

13

14

15

16

17

18

19

20

21

22

Part

No.

Description

Screw, Mach., No. 10-32 x 318,

Type 23 C.I., Pan Hd. Slotted

Plate, Cover

63098

Cap, Radial Arm

63097

*Washer, Lock 114 x .I09x .062

1 1 51 09

226310 *Screw, Mach., 1/4-28 x 1-3/4,

Fil. Hd.

Washer, Fibre .I40x .250x 1/32

37935

Screw, Mach., NO. 6-32 x 5/16,

9404351

Type 23 C.I., Pan Hd.

Indicator No. 1

30474

63085

Clamp, Cord

Screw, Mach., No. 8-32 x 318,

44801 1

Type 23 C.I., Pan Hd.

30662

Screw, Arm Lock

30482

Pin, Arm Lock

60021

*Screw, Mach., 1 /4-20 x 7/16,

Hex. Hd. Ind.

Support Assy., Motor

63102

Washer, Index Handle

30606

9421626 *Screw, Socket Hex. Hd.,

Cap, 5/16-18 x 1-112

*Wrench, Hex. "L", 1 /4 Across Flats

37435

37861

Key, Safety Lock

Shaft Assembly, Latch Arm

37370

30655

Ring, Retaining

30489

Washer, Spring Support

4431 51

Pin, Groove

448033

'Standard

LIST

Part

Key

No.

No.

23

24

25

30490

63096

436753

26

27

28

29

30

31

32

60076

37372

37373

60030

37374

63111

60077

-

33

34

35

36

37

38

39

40

41

42

63139

63141

63142

30495

30494

60177

631 49

30661

30479

9415837

43

44

131 202

63160

63161

Not

Shown

Description

Spring, Arm Latch

Cap, Trim

Screw, Mach., No. 10-32 x 3/4,

Type 23 C.I., Pan Hd.

Washer, Plain, 505 x 1-1 /8 x 1 /16

Lever, Arm Latch

Washer, Spring

Washer, Plain, 505 x 1 x 1 /32,Steel

Handle

Disc, Color (Ring)

Screw, Mach., 1 /4-20 x 1 -3/8,Truss

Hd., w/L/washer

Clamp, Cord

Wrench, Shaft

Wrench, Arbor

Nut, Shaft

Collar

Blade, Saw, 12"

Motor Assembly (See figure 54)

Shoe, Brake

Latch, Arm

*Screw. Mach., 3/8-16 x 314,

Hex Hd.

Washer, Lock, 3/8 5:A.E. Stl:

Trim, Radial Arm

Operating Instructions and Parts List

For Craftsman 12" Radial Arm Saw

Model 1 13.29501

Hardware Item - May be Purchased Locally.

NOTE: Shipping and handlin g charges for standard hardware items (identified by*) such as nuts, screws, washers,

etc., make buying these items by mail uneconomical. TOavoid shipping and handling charges, you may obtain

most of these locally.

.-A

-

.

,

U

CRAFTSMAN,

12- INCH RADIAL SAW, MODEL NO. 1 13.29501

.

S i f f ICUBE 52

FOP : XPLODLD V l t Y /

SEE FIGl)RE 55

FOP E > PtODfD 1,IEW

SEE i l G V P E

FOR EXPLODED

Figure 51

53

VlEVf

CRAFTSMAN,

12-INCH RADIAL SAW, MODEL NO. 1 13.29501

FIGURE 5 2 PARTS LIST

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

1 : 1

Part

No.

Key

No.

Description

63126

63129

60004

63128

63130

436664

Arm, Radial

Pin, Spring

Ring, Retaining

Stop, Carriage

Spring, Carriage Stop

*Screw, Mach., No. 6-32 x 7/16,

Pan Hd., Cad.

63087

Indicator, Rip Scale

63120

Shoe, Carriage Lock

63147

Pin, Carriage Lock

63099

Cover, Carriage R.H.

63101

Knob, Carriage Lock

63072

Disc, Color (4)

436751

*Screw, Mach., No. 10-32 x 5/8,

Pan Hd., Cad.

30530

Nut, Twin

6 0 0 8 8 , *Screw, Mach., 5/16-18 x 1-1 /2,

Hex. Hd. Ind., Steel

37388

Sleeve, Bearing

37936

Washer, Plain, .328 x 3/4 x 1 /16

63117

Bearing, Carriage

,

* Standard Hardware Item - May be Purchased locally.

Part

No.

19

30566

30567

20

456299

21

63148

22

23

120214

124824

24

37403

25

63071

26

37816

27

28

30558

29

63118

30

30565

63100

31

37494

32

37387

33

30521

34

63119

35

63138

36

37

38 7; : : : !

-

1 1

Description

~ l o m

Assembly,

~

Yoke

Bumper

Pin, Roll

Carriage

*Washer, Lock 5/16 x .I25 x .078

*Nut, Hex., 5/16-18 x 1 /2 x 3/16, Stl.

Handle, Yoke Clamp

Disc, Color (3)

Washer, Flat, -630 x 1-1/8 x .093

Screw, Lock

Housing, Latch Pin

Bumper

Cover, Carriage L.H.

Pin, Swivel Latch

Screw, Eccentric

Spring, Swivel latch

Retainer, Spring

Handle, Swivel Latch Pin

Track

Screw, Mach., No. 10-32 x 518,

Type 23 C.I., Rd. Hd., Cad.

CRAFTSMAN, 12-INCH RADIAL S A W , MODEL NO. 1 13.29501

?

-.c-

SEE FIGURE 56

FOP EXPLODED VIEW

Figure 52

CRAFTSMAN, 12-INCH RADIAL SAW, MODEL NO. 1 13.29501

P A R T S LIST

FIGURE 53

Key

...

No.

1

2

63146

139416

3

4

63114

60020

5

6

63108

60056

7

8

9

10

11

12

37937

63109

631 10

63107

131 202

60022

13

14

15

16

125525

63094

60087

9415838

17

18

19

21

22

63105

115109

115120

11e615

120217

448035

23

24

30505

102570

25

26

63084

63091

20

1

Part

No.

Description

Tube Assembly, Column

*Screw, Set, 3/8-16 x 5/8,

Socket Hd., Cone Pt.

Support, Column

*Screw, Mach., 3/8-16 x 1-1 /8,

Hex. Hd. Ind.

Table, Rear

*Screw, Mach., 1/4-20 x 1,

Pan Hd., Slotted

*Washer, Plain, 17/64 x 5/8 x 1/32

Spacer, Table

Fence, Rip

Table, Front

Washer, Lock, 3/8 S.A.E. Stl.

*Screw, Mach., 3/8-16 x 5/8,

Hex. Hd., Steel

*Nut, Square, 3/8-16 x 5 / 8 x 21 /64

Base

*Washer, Plain, 13/32 x 7/8 x 1/16

'Screw, Mach., 3/8-16 x 1,

Hex. Hd. Ind.

Support, Table R.H.

*Washer,Lock,1/4~.109~.062

*Nut, Hex., 1/4-20x 7 / 1 6 x 3/16, St!.

*Nut, Hex., 3/8-16x 9/16 x 21/64, Stl.

'Washer, Lock, No. 10 x .062 x .047

*Screw, No. 10-32 x 1 /2,

Pan Hd.

*Wrench, Hex. "L", 1/8 Across Flats

*Screw, Set, 1/4-20 x 3/8, Socket Hd.,

Cup Pt.

Crank Assembly, Elevation

Leg

Standard Hardware Item - May be Purchased Locally.

Key

No.

27

28

29

Part

No.

30

63116

30509

30510

448649

31

32

33

34

35

36

37

38

39

3051 2

60079

30604

3051 1

63115

37428

60080

30516

423561

4041

42

63086

63104

9415813

43

60013

44

45

46

47

48

49

219463

116120

63106

37862

37911

102718

50

51

52

53

63078 .

63077

63079

37530

Description

Shaft Assembly, Elevating Crank

Washer, End Play, No. 8 (As Required)

Bracket, Elevating Shaft Bearing

Screw, Mach.. 1 /4-20 x 3/4,

Type 23 C.I., Hex. Hd.

Bracket, Bearing

Washer, Plain, .203 x 7/16 x 1/16

Washer, Oil Sling

Pin, Pivot

Shaft Assembly, Elevation

Plate, Retaining

Washer, Plain, .515 x 7/8 x 1/32, St!.

Ring, Retaining

*Screw, Moch., 5/16-18 x 7/8,

Hex. Hd. Ind. w/L/washer

Clamp

Support, Table L.H.

*Screw, Moch., 5/16-18 x 3/4,

Hex. Hd. Ind.

*Washer, Plain, 11 /32 x 7/8 x 1/16,

Steel

*Nut, Hex., 5/16-18 x 1/2x21/64, Stl.

*Washer, Lock, 5/16x .I25 x .078

Support, $2 Table

Clamp, Table

*Wrench, Hex. "L", 3/16 Across Flats

*Screw,Set,5/16-18x1/2,

Slotted, Cup Pt.

Plug, Back up (Steel)

Plug, Friction (Nylon)

Key, Column Tube

Nut, "U" Clip, 1./4-20

CRAFTSMAN, 1 2-INCH RADIAL SAW, MODEL NO. 1 13.29501

, ....,

CRAFTSMAN, 12-INCH RADIAL SAW, MODEL NO. 1 13.29501

F I G U R E 5 4 P A R T S LIST

Description

1

448001

2

3

4

5

6

63103

63065

63132

37409

44801 1

7

8

9

10

11

12

13

30700

30573

63136

30586

63135

63068

63131

+

Screw, No. 6-32 x 1 /4, Type 23 C.I.,

Pan Hd., Slotted, Steel

Cover and Nameplate

Lead, Assembly, Block

Relay

Lead Assembly, Red

Screw, No. 8-32 x 3/8,Type 23 C.I.,

Pan Hd., Slotted, Steel

Clamp, Capacitor

*Connector, Wire

Lead, White, No. 16, 4"

Capacitor

Lead, Brown, No. 16, 4"

Lead, Black, No. 16, 4"

Protector

Key

No.

Part

No.

14

9404353

15

16

17

18

19

20

21

22

23

24

25

26

27

28

30783

37942

37415

37908

63133

63134

63137

37884

63140

30582

37886

37412

37875

63149

Description

Screw, No. 6-32 x 7/16, Type 23 C.I.,

Pan Hd., Slotted

Ring, Retaining

Washers, Spacer (As Required)

Spring

Housing, Brake c o i l

Coil, Brake

.. .

Shoe, Brake

Lining, Brake

Disk, Brake

Cover, Brake

Cap, Shaft

Washer, Spring

Cleat

Relief, Strain

Complete motor assembly

Standard Hardware Item - May be Purchased Locally.

For Complete Motor Assembly Refer t o Figure 51, Key No. 39, Page 21

CRAFTSMAN, 12-INCH RADIAL SAW, MODEL NO. 1 13.29501

I

10

Figure 55

FIGURE 55

PARTS LIST

1

Key

No.

Port

1

2

63144

448035

3

4

5

6

7

63145

63143

63039

30540

63090

No.

Description

Guard Assembly

Screw, No. 10-32x 1/2,Type 23 C.I.,

Pan Hd., Cad.

Plate, Guard Cover

Guard Assembly, Partial

Screw, Guard Clamp

Screw, Wing

Tube, Exhaust

* Standard Hardware Item - M a y be Purchased Locally.

Key

Port

No.

No.

8

9

10

11

12

13

14

30505

222407

63088

30542

30543

63150

37400

Description

*Wrench, Hex. "L", 1 /8 Across Flats

*Screw, Set, 1 /4-20x 1 /2,

Hex. Socket, Flat Pt.

Pawl Assembly, Anti-Kickback

Washer, "X"

Pawl, Anti-Kickback

Rod Assembly

Pin, Cross

CRAFTSMAN, 1 2 - I N C H RADIAL SAW, MODEL NO. 1 13.29501

:

... .

\-

I

24

23 22

e

Figure 56

FIGURE 56 PARTS LIST

Key

NO.

Part

1

2

3

4

5

6

7

8

305-17

30548

30690

30689

30574

60055

30472

63162

63163

37568

453676

30693

448001

9

10

11