Download Vaisala TACMET MAWS201MP Installation manual

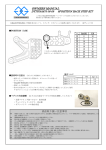

Transcript