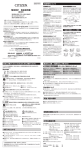

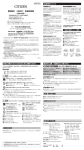

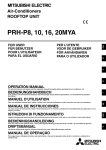

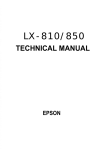

Download Mitsubishi PEH-15MYA Specifications

Transcript