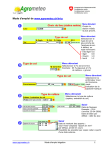

Download 3.2 NMC Pro and NMC Junior - Irrigation

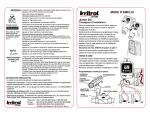

Transcript