Download The UV Curing System - Multice & Co., Ltd.

Transcript

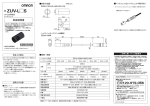

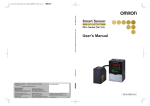

Smart Curing System ZUV Series The UV Curing System Find its value! Never look directly at or allow your skin to be exposed to the ultraviolet light. Ultraviolet light will damage vision and skin if it is viewed directly or the skin is exposed. Workers shall wear protective goggles and equipment to protect from being exposed to light reflection. Never disassemble the Unit. Disassembling the Unit may lead to electric shock or damage from light leakage. This document provides information mainly for selecting suitable models. Please read the document User's Manual (Z257/Z260) carefully for information that the user must understand and accept before purchase, including information on warranty, limitations of liability, and precautions. OMRON Corporation Industrial Automation Company Authorized Distributor: Tokyo, JAPAN Contact: www.ia.omron.com Regional Headquarters OMRON EUROPE B.V. Sensor Business Unit OMRON ELECTRONICS LLC Carl-Benz-Str. 4, D-71154 Nufringen, Germany Tel: (49) 7032-811-0/Fax: (49) 7032-811-199 One Commerce Drive Schaumburg, IL 60173-5302 U.S.A. Tel: (1) 847-843-7900/Fax: (1) 847-843-7787 OMRON ASIA PACIFIC PTE. LTD. OMRON (CHINA) CO., LTD. No. 438A Alexandra Road # 05-05/08 (Lobby 2), Alexandra Technopark, Singapore 119967 Tel: (65) 6835-3011/Fax: (65) 6835-2711 Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road, PuDong New Area, Shanghai, 200120, China Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200 © OMRON Corporation 2009 All Rights Reserved. In the interest of product improvement, specifications are subject to change without notice. Printed in Japan Cat. No. E364-E1-03 @@@@ (@@@@) (@) So, will you keep on using a lamp system ? Cost performance that will overwhelm a lamp system Achieves a low initial cost level believed to be impossible in an LED system up to now. The newly-developed ZUV value model has made sweeping cost reductions possible at an initial cost lower than a lamp system. The cost revolution was made possible because Omron is No.1 in lamp system replacement and LED system introduction in Japan. ThereÕs no mistaking it. ItÕs an LED era from now on. We deliver the features you need, where you need them Two models of controller according to your application Scene 1 Scene 2 For High cost performance For R&D and UV curing trial * Source : 2008 Fuji Chimera Research Institute publication, 2008 General Survey of Image Device Related Markets Value model Multi-function model controller ZUV-C20H controller ZUV-C30H ZUV value model New UV LED Cost-performance Controller NEW Cost-performance Head ZUV-H20MB ZUV-C20H 4-head independent On/Off control Four-head independent On/Off control is available in a single controller. WhatÕs more, weÕve made more efficient illumination possible by achieving Òillumination with a different illumination power and timing at each headÓ which is impossible in a lamp system. Easy operation with an LED display Setup is simple with an LED display. It displays illumination status during operation, allowing for simple, worry-free and reliable UV bonding. ON OFF Setup screen Screen during operation Simple operation in 3 modes Illumination mode Power setup mode Toggle with one push Cumulative illumination time control at every head Time setup mode Cumulative time for every head is stored in the controller. The life of the head can be determined by setting the threshold for this cumulative time. When the cumulative time of the heads exceeds this threshold, an error is issued and the illumination time at every head can be controlled. Because of its ultra compact body thatÕs about 1/8th the size of a conventional lamp system, it lets you build them into small-size devices or install them into the adjusting jig periphery, not to mention integration into cell production lines. Also, we use robot cable instead of quartz glass fiber for connection to the head and controller. It can be reliably used for mounting onto moving elements such as a robot or cylinder. 3CH 4CH Step illumination Illumination time Linear illumination Illumination time Step illumination Illumination time Its usability is top in a class by itself, with multi-connected access link features such as external control using the I/O port or RS-232C connection and data transfers to a PC via USB. I/O and RS-232C connection ports Illumination history can be recorded Illumination power compensation feature 1/8 size 125 mm 125mm Foot switch You can turn illumination On or Off, change illumination patterns, or control various types of alarms externally with the I/O port or the RS-232C connection. 85 mm 4 2CH Terminal/pin (rear) Linear illumination Illumination time Multi-access link Conventional lamp system Ultra compact body 1CH Programmed illumination You can program illumination patterns such as step illumination and linear illumination, and high-precision adhesion to reduce resin shrinkage is possible. Life management with Illumination power is cumulative energy control. adjustable while in Able to adjust illumination operation. power on the fly. rewop noitanimullI Not only letÕs you do constant illumination but patterns as well, such as pulse illumination, to reduce resin shrinkage. Toggle with one push SET button Toggle with one push 2 Easy-to-see menu that can be selectable to English or Japanese. rewop noitanimullI Illumination time and power can be set on the top screen. Illumination power setup rewop noitanimullI Illumination time setup rewop noitanimullI The startup screen at Power On is in illumination mode. Toggle through three modes including Power setup mode, Time setup mode, and Illumination mode with the single push of a button. The setup operation for each mode is simple. With its limited button count, simple operation, and easy-to-read screen, anyone can use it easily. USB You can transfer such cumulative illumination energy and frequency data to a PC via USB. This is useful in QA data storage and failure analysis. 146 mm 5 It comes equipped with a power tuning feature that allows you to correct illumination power based on the output of an illumination meter. Power corrections can be made simply and reliably during startup inspection. Benefit Benefit Initial cost efficiency Beats lamp replacement costs Cost comparison when buying new Comparison of lamp system aging costs and standard model initial costs*1 1 2 Initial cost lower than that for a lamp system Significant cost savings Solve various problems of lamp system Solution 1 Eliminates the manpower, time, and costs of light source replacement Solution 2 High-speed bonding with the highest illumination in the industry of 9,400 mW/cm2 with the Super-light-condensing Lens Industry-best lifetime of 40,000 hours achieved with ultra cooling heads Initial cost for ZUV standard model Initial cost for ZUV standard model Initial cost for least-expensive lamp system main unit Lamp replacement cost *2 *1 Comparing the case in which you keep using a lamp system with the case where you switch to the ZUV standard model *2 Lamp replacement costs after two years have gone by at a replacement frequency of about three times a year If customers who are currently using a lamp system would compare the costs of lamp replacement, which occurs about three times a year, in cases where they would continuously use a lamp system for two years from now on they would find installing the ZUV standard model less expensive. On top of that, running costs are substantially nil. It is characteristic of the LED to have a longer life in comparison with a lamp system. In addition, for a lamp system whose light source is unstable, you have to leave its light source on all the time but an LED system, with its highly stable light source, can be turned off when illumination is not needed. For that reason, extended use over a long period of time is possible and running costs can be said to be substantially nil. Moreover, electricity costs can be reduced by turning the unit off when it is not illuminating. Omron’s unique head technology As for the ultra cooling head, we have expanded the number of heat dissipating ribs in the Smart Canyon Structure from the existing 21 to 40 by making the housing into a long body. Through effective dissipation of heat, we have achieved industry-leading long life and illuminance stability. New structure Optimize structure by widening the ribs. 3 Improvements in tact time due to high-speed bonding can be achieved if you use the ultra light condensing head, with 8,100 mW/cm2 illumination, the best in the industry, which far exceeds the average illumination of a mercury lamp. Reduces tact time by up to 50% compared to a lamp system when used with the ultra light condensing head*1. In addition, when increasing the number of channels in use*2, maximum illumination will decrease as the number of channels increases for a lamp system, but the maximum illumination at each head wonÕt decrease even if the number of channels increases on an LED system and productive UV adhesion is possible. 1 13-fold OFF 1.6-fold 8.3-fold OFF 40,000 hours (approx. 4.6 years)*1 OFF OFF 25,000 hours (approx. 3 years)*1 OFF OFF 3,000 hours (125 days)*1 Illumination comparison between LED system head and lamp system fiber when 4 branches are used (mW/cm2 ) *1 Compared with mercury lamp system *2 When fiber branching is used OFF Lamp-system Standard model Ultra cooling continuously head head continuously lighted continuously lighted lighted CH1 Ultra cooling head lighting control*2 100% 100% 85% 66% 57% 0 LED system (ultra light condensing LED system (Spot Lens (3-mm dia.)) Lamp system 12s 10s Ultra light condensing head 0 5 10 Uses UIT-150 UV Light Integrating Actinometer manufactured by Ushio Inc. When measured at suggested work distance. Lamp system value is an example with a typical fiber. Approx. 45% of previous tact time 15 CH4 100% Lamp system Spot Lens (3-mm dia.) CH3 100% 8000 20s Lighting time 1 *2= = 3 capacity utilization time CH2 100% Tact time comparison Radiation comparison between ultra cooling head and conventional head 20s Tact time (example with a certain type of adhesive) Ultra cooling head (ZUV-H10MB) Highly-exoergic area is extensive Patent pending The Smart Canyon structure has been utilized in all heads in the Conventional structure ZUV Series, but for the sake of achieving low initial cost in the standard model heads we have optimized this Smart Canyon structure even further, enabling it to dissipate heat more efficiently. 120,000 hours (approx. 41 years)* *1 Useful life (no. of years) at 24 hours/day operation It is a UV-LED, whose characteristic is its long life, but there is a chance that its life will be shorter if the heat is not properly dissipated when emitting light. For that reason, it is considered necessary to avoid rises in temperature during illumination. The advance that has fulfilled this requirement in a compact head is OmronÕs unique heat dissipation structure = the Smart Canyon. Optimized “New Smart Canyon Structure” 40-fold Super-light-condensing lens (ZUV-L2H) noitanimulli The basic performance of UV bonding is retained while significant cost savings compared to a conventional LED system is achieved with carefully selected features. ZUV standard model can be purchased at a price below that of the lamp system. The biggest issue for the lamp system is frequent replacement of the lamp light source. LED system has longer life compared to the lamp system. Replacement man hours can also be eliminated if you use the ultra cooling head. The continuously-on lifetime of the ultra cooling head is 40,000 hours, or 13 times that of a lamp system. If you assume Òlighting-on time divided by capacity utilization timeÓ is one-third, a semipermanent usage of 120,000 hours, or 40 times that of a lamp system, is possible. That means light source replacement becomes essentially unnecessary and both the labor hours and running costs of the replacement work can be reduced substantially. Maximum power to greatly reduce tact time Dedicated Jig for ultra cooling heads Its heat dissipation is even better compared to a conventional head, so it can be mounted on the customerÕs existing toolings or on original toolings of new design. It will allow you to trim man-hours of LED system introduction. Mountable on existing fittings No need for heat dissipating fittings 6 Solution 3 Conventional head (ZUV-H20MB/H30MB) Environmentally safe Substantially reduces CO2 emissions in power-saving LED system usage High power consumption and disposal of the mercury lamps that occurs with each replacement are problems at a lamp system site, but they can be resolved by using an LED system. An LED system has lower power consumption than a mercury lamp system, and can also lead to power saving with efficient use of energy through lighting control. In addition, the LED light source doesnÕt use mercury so it is superior in terms of reduced environmental impact. Comparison of annual CO2 discharge amounts when used in 100 units Approx. 64t CO2 Approx. 4.5t Approx. 60t CO2 reduction Conventional lamp system Power consumption Approx. 250W per unit LED system ZUV Power consumption Approx. 53W per unit* * Standard model controller ZUV-C20H Notes ¥ Assumed to be 24 hours and 260 days operation. ¥ Assumes Òon time divided by equipment operation timeÓ to equal one-third. ¥ For CO2 emissions, calculation of 4.1t CO2 reduction with 10,000 kWh reduction in the Nationwide Receiving End Coefficient published by the Federation of Electric Power Companies of Japan ¥ Power consumption may vary according to device conditions 7 Cost performance that will overwhelm a lamp system Achieves a low initial cost level believed to be impossible in an LED system up to now. The newly-developed ZUV value model has made sweeping cost reductions possible at an initial cost lower than a lamp system. The cost revolution was made possible because Omron is No.1 in lamp system replacement and LED system introduction in Japan. ThereÕs no mistaking it. ItÕs an LED era from now on. We deliver the features you need, where you need them Two models of controller according to your application Scene 1 Scene 2 For High cost performance For R&D and UV curing trial * Source : 2008 Fuji Chimera Research Institute publication, 2008 General Survey of Image Device Related Markets Value model Multi-function model controller ZUV-C20H controller ZUV-C30H ZUV value model New UV LED Cost-performance Controller NEW Cost-performance Head ZUV-H20MB ZUV-C20H 4-head independent On/Off control Four-head independent On/Off control is available in a single controller. WhatÕs more, weÕve made more efficient illumination possible by achieving Òillumination with a different illumination power and timing at each headÓ which is impossible in a lamp system. Easy operation with an LED display Setup is simple with an LED display. It displays illumination status during operation, allowing for simple, worry-free and reliable UV bonding. ON OFF Setup screen Screen during operation Simple operation in 3 modes Illumination mode Power setup mode Toggle with one push Cumulative illumination time control at every head Time setup mode Cumulative time for every head is stored in the controller. The life of the head can be determined by setting the threshold for this cumulative time. When the cumulative time of the heads exceeds this threshold, an error is issued and the illumination time at every head can be controlled. Because of its ultra compact body thatÕs about 1/8th the size of a conventional lamp system, it lets you build them into small-size devices or install them into the adjusting jig periphery, not to mention integration into cell production lines. Also, we use robot cable instead of quartz glass fiber for connection to the head and controller. It can be reliably used for mounting onto moving elements such as a robot or cylinder. 3CH 4CH Step illumination Illumination time Linear illumination Illumination time Step illumination Illumination time Its usability is top in a class by itself, with multi-connected access link features such as external control using the I/O port or RS-232C connection and data transfers to a PC via USB. I/O and RS-232C connection ports Illumination history can be recorded Illumination power compensation feature 1/8 size 125 mm 125mm Foot switch You can turn illumination On or Off, change illumination patterns, or control various types of alarms externally with the I/O port or the RS-232C connection. 85 mm 4 2CH Terminal/pin (rear) Linear illumination Illumination time Multi-access link Conventional lamp system Ultra compact body 1CH Programmed illumination You can program illumination patterns such as step illumination and linear illumination, and high-precision adhesion to reduce resin shrinkage is possible. Life management with Illumination power is cumulative energy control. adjustable while in Able to adjust illumination operation. power on the fly. rewop noitanimullI Not only letÕs you do constant illumination but patterns as well, such as pulse illumination, to reduce resin shrinkage. Toggle with one push SET button Toggle with one push 2 Easy-to-see menu that can be selectable to English or Japanese. rewop noitanimullI Illumination time and power can be set on the top screen. Illumination power setup rewop noitanimullI Illumination time setup rewop noitanimullI The startup screen at Power On is in illumination mode. Toggle through three modes including Power setup mode, Time setup mode, and Illumination mode with the single push of a button. The setup operation for each mode is simple. With its limited button count, simple operation, and easy-to-read screen, anyone can use it easily. USB You can transfer such cumulative illumination energy and frequency data to a PC via USB. This is useful in QA data storage and failure analysis. 146 mm 5 It comes equipped with a power tuning feature that allows you to correct illumination power based on the output of an illumination meter. Power corrections can be made simply and reliably during startup inspection. Cost performance that will overwhelm a lamp system Achieves a low initial cost level believed to be impossible in an LED system up to now. The newly-developed ZUV standard model has made sweeping cost reductions possible at an initial cost lower than a lamp system. The cost revolution was made possible because Omron is No.1 in lamp system replacement and LED system introduction in Japan. ThereÕs no mistaking it. ItÕs an LED era from now on. We deliver the features you need, where you need them Two models of controller according to your application Scene 1 Scene 2 For High cost performance For R&D and UV curing trial * Source : 2008 Fuji Chimera Research Institute publication, 2008 General Survey of Image Device Related Markets Standard model Multi-function model controller ZUV-C20H ZUV-C30H ZUV standard model New UV LED Cost-performance Controller NEW Cost-performance Head ZUV-H20MB ZUV-C20H 4-head independent On/Off control Four-head independent On/Off control is available in a single controller. WhatÕs more, weÕve made more efficient illumination possible by achieving Òillumination with a different illumination power and timing at each headÓ which is impossible in a lamp system. Easy operation with an LED display Setup is simple with an LED display. It displays illumination status during operation, allowing for simple, worry-free and reliable UV bonding. ON OFF Setup screen Screen during operation Simple operation in 3 modes Illumination mode Not only letÕs you do constant illumination but patterns as well, such as pulse illumination, to reduce resin shrinkage. Toggle with one push SET button Power setup mode Toggle with one push Toggle with one push Cumulative illumination time control at every head Time setup mode Cumulative time for every head is stored in the controller. The life of the head can be determined by setting the threshold for this cumulative time. When the cumulative time of the heads exceeds this threshold, an error is issued and the illumination time at every head can be controlled. Because of its ultra compact body thatÕs about 1/8th the size of a conventional lamp system, it lets you build them into small-size devices or install them into the adjusting jig periphery, not to mention integration into cell production lines. Also, we use robot cable instead of quartz glass fiber for connection to the head and controller. It can be reliably used for mounting onto moving elements such as a robot or cylinder. 2CH Terminal/pin (rear) 3CH 4CH Linear illumination Illumination time Step illumination Illumination time Linear illumination Illumination time Step illumination Illumination time Its usability is top in a class by itself, with multi-connected access link features such as external control using the I/O port or RS-232C connection and data transfers to a PC via USB. I/O and RS-232C connection ports Illumination history can be recorded Illumination power compensation feature 1/8 size 125 mm 125mm Foot switch You can turn illumination On or Off, change illumination patterns, or control various types of alarms externally with the I/O port or the RS-232C connection. 85 mm 4 1CH Programmed illumination You can program illumination patterns such as step illumination and linear illumination, and high-precision adhesion to reduce resin shrinkage is possible. Life management with Illumination power is cumulative energy control. adjustable while in Able to adjust illumination operation. power on the fly. Multi-access link Conventional lamp system Ultra compact body 2 Easy-to-see menu that can be selectable to English or Japanese. rewop noitanimullI Illumination time and power can be set on the top screen. Illumination power setup rewop noitanimullI Illumination time setup rewop noitanimullI The startup screen at Power On is in illumination mode. Toggle through three modes including Power setup mode, Time setup mode, and Illumination mode with the single push of a button. The setup operation for each mode is simple. With its limited button count, simple operation, and easy-to-read screen, anyone can use it easily. rewop noitanimullI NEW controller USB You can transfer such cumulative illumination energy and frequency data to a PC via USB. This is useful in QA data storage and failure analysis. 146 mm 5 It comes equipped with a power tuning feature that allows you to correct illumination power based on the output of an illumination meter. Power corrections can be made simply and reliably during startup inspection. Benefit Benefit Initial cost efficiency Beats lamp replacement costs Cost comparison when buying new Comparison of lamp system aging costs and standard model initial costs*1 1 2 Initial cost lower than that for a lamp system Significant cost savings Solve various problems of lamp system Ultra cooling head (ZUV-H10MB) Solution 1 Eliminates the manpower, time, and costs of light source replacement Solution 2 High-speed bonding with the highest illumination in the industry of 9,400 mW/cm2 with the Ultra light focus Lens Industry-best lifetime of 40,000 hours achieved with ultra cooling heads Initial cost for ZUV standard model Initial cost for ZUV standard model Initial cost for least-expensive lamp system main unit Lamp replacement cost *2 *1 Comparing the case in which you keep using a lamp system with the case where you switch to the ZUV standard model *2 Lamp replacement costs after two years have gone by at a replacement frequency of about three times a year If customers who are currently using a lamp system would compare the costs of lamp replacement, which occurs about three times a year, in cases where they would continuously use a lamp system for two years from now on they would find installing the ZUV standard model less expensive. On top of that, running costs are substantially nil. It is characteristic of the LED to have a longer life in comparison with a lamp system. In addition, for a lamp system whose light source is unstable, you have to leave its light source on all the time but an LED system, with its highly stable light source, can be turned off when illumination is not needed. For that reason, extended use over a long period of time is possible and running costs can be said to be substantially nil. Moreover, electricity costs can be reduced by turning the unit off when it is not illuminating. Omron’s unique head technology As for the ultra cooling head, we have expanded the number of heat dissipating ribs in the Smart Canyon Structure from the existing 21 to 40 by making the housing into a long body. Through effective dissipation of heat, we have achieved industry-leading long life and illuminance stability. New structure Optimize structure by widening the ribs. 3 Improvements in tact time due to high-speed bonding can be achieved if you use the ultra light focus lens, with 9,400 mW/cm2 illumination, the best in the industry, which far exceeds the average illumination of a mercury lamp. Reduces tact time by up to 55% compared to a lamp system when used with the ultra light focus lens*1. In addition, when increasing the number of channels in use*2, maximum illumination will decrease as the number of channels increases for a lamp system, but the maximum illumination at each head wonÕt decrease even if the number of channels increases on an LED system and productive UV adhesion is possible. 1 13-fold OFF 1.6-fold 8.3-fold OFF 40,000 hours (approx. 4.6 years)*1 OFF OFF 25,000 hours (approx. 3 years)*1 OFF OFF 3,000 hours (125 days)*1 Illumination comparison between LED system head and lamp system fiber when 4 branches are used (mW/cm2 ) *1 Compared with mercury lamp system *2 When fiber branching is used OFF Lamp-system Standard model Ultra cooling continuously head head continuously lighted continuously lighted lighted CH1 Ultra cooling head lighting control*2 100% 100% 85% 66% 57% 0 LED system (Ultra light focus lens) LED system (Spot Lens (3-mm dia.)) Lamp system 12s 9s Ultra light focus lens 0 5 10 Uses UIT-150 UV Light Integrating Actinometer manufactured by Ushio Inc. When measured at suggested work distance. Lamp system value is an example with a typical fiber. Approx. 45% of previous tact time 15 CH4 100% Lamp system Spot Lens (3-mm dia.) CH3 100% 9400 20s Lighting time 1 *2= = 3 capacity utilization time CH2 100% Tact time comparison Radiation comparison between ultra cooling head and conventional head 20s Tact time (example with a certain type of adhesive) Ultra cooling head (ZUV-H10MB) Highly-exoergic area is extensive Patent pending The Smart Canyon structure has been utilized in all heads in the Conventional structure ZUV Series, but for the sake of achieving low initial cost in the standard model heads we have optimized this Smart Canyon structure even further, enabling it to dissipate heat more efficiently. 120,000 hours (approx. 41 years)* *1 Useful life (no. of years) at 24 hours/day operation It is a UV-LED, whose characteristic is its long life, but there is a chance that its life will be shorter if the heat is not properly dissipated when emitting light. For that reason, it is considered necessary to avoid rises in temperature during illumination. The advance that has fulfilled this requirement in a compact head is OmronÕs unique heat dissipation structure = the Smart Canyon. Optimized “New Smart Canyon Structure” 40-fold Ultra light focus lens (ZUV-L2H) noitanimulli The basic performance of UV bonding is retained while significant cost savings compared to a conventional LED system is achieved with carefully selected features. ZUV standard model can be purchased at a price below that of the lamp system. The biggest issue for the lamp system is frequent replacement of the lamp light source. LED system has longer life compared to the lamp system. Replacement man hours can also be eliminated if you use the ultra cooling head. The continuously-on lifetime of the ultra cooling head is 40,000 hours, or 13 times that of a lamp system. If you assume Òlighting-on time divided by capacity utilization timeÓ is one-third, a semipermanent usage of 120,000 hours, or 40 times that of a lamp system, is possible. That means light source replacement becomes essentially unnecessary and both the labor hours and running costs of the replacement work can be reduced substantially. Maximum power to greatly reduce tact time Dedicated Jig for ultra cooling heads Its heat dissipation is even better compared to a conventional head, so it can be mounted on the customerÕs existing toolings or on original toolings of new design. It will allow you to trim man-hours of LED system introduction. Mountable on existing fittings No need for heat dissipating fittings 6 Solution 3 Standard head (ZUV-H20MB/H30MB) Environmentally safe Substantially reduces CO2 emissions in power-saving LED system usage High power consumption and disposal of the mercury lamps that occurs with each replacement are problems at a lamp system site, but they can be resolved by using an LED system. An LED system has lower power consumption than a mercury lamp system, and can also lead to power saving with efficient use of energy through lighting control. In addition, the LED light source doesnÕt use mercury so it is superior in terms of reduced environmental impact. Comparison of annual CO2 discharge amounts when used in 100 units Approx. 64t CO2 Approx. 4.5t Approx. 60t CO2 reduction Conventional lamp system Power consumption Approx. 250W per unit LED system ZUV Power consumption Approx. 53W per unit* * Standard model controller ZUV-C20H Notes ¥ Assumed to be 24 hours and 260 days operation. ¥ Assumes Òon time divided by equipment operation timeÓ to equal one-third. ¥ For CO2 emissions, calculation of 4.1t CO2 reduction with 10,000 kWh reduction in the Nationwide Receiving End Coefficient published by the Federation of Electric Power Companies of Japan ¥ Power consumption may vary according to device conditions 7 Benefit Benefit Initial cost efficiency Beats lamp replacement costs Cost comparison when buying new Comparison of lamp system aging costs and standard model initial costs*1 1 2 Initial cost lower than that for a lamp system Significant cost savings Solve various problems of lamp system Ultra cooling head (ZUV-H10MB) Solution 1 Eliminates the manpower, time, and costs of light source replacement Solution 2 High-speed bonding with the highest illumination in the industry of 9,400 mW/cm2 with the Ultra light focus Lens Industry-best lifetime of 40,000 hours achieved with ultra cooling heads Initial cost for ZUV standard model Initial cost for ZUV standard model Initial cost for least-expensive lamp system main unit Lamp replacement cost *2 *1 Comparing the case in which you keep using a lamp system with the case where you switch to the ZUV standard model *2 Lamp replacement costs after two years have gone by at a replacement frequency of about three times a year If customers who are currently using a lamp system would compare the costs of lamp replacement, which occurs about three times a year, in cases where they would continuously use a lamp system for two years from now on they would find installing the ZUV standard model less expensive. On top of that, running costs are substantially nil. It is characteristic of the LED to have a longer life in comparison with a lamp system. In addition, for a lamp system whose light source is unstable, you have to leave its light source on all the time but an LED system, with its highly stable light source, can be turned off when illumination is not needed. For that reason, extended use over a long period of time is possible and running costs can be said to be substantially nil. Moreover, electricity costs can be reduced by turning the unit off when it is not illuminating. Omron’s unique head technology As for the ultra cooling head, we have expanded the number of heat dissipating ribs in the Smart Canyon Structure from the existing 21 to 40 by making the housing into a long body. Through effective dissipation of heat, we have achieved industry-leading long life and illuminance stability. New structure Optimize structure by widening the ribs. 3 Improvements in tact time due to high-speed bonding can be achieved if you use the ultra light focus lens, with 9,400 mW/cm2 illumination, the best in the industry, which far exceeds the average illumination of a mercury lamp. Reduces tact time by up to 55% compared to a lamp system when used with the ultra light focus lens*1. In addition, when increasing the number of channels in use*2, maximum illumination will decrease as the number of channels increases for a lamp system, but the maximum illumination at each head wonÕt decrease even if the number of channels increases on an LED system and productive UV adhesion is possible. 1 13-fold OFF 1.6-fold 8.3-fold OFF 40,000 hours (approx. 4.6 years)*1 OFF OFF 25,000 hours (approx. 3 years)*1 OFF OFF 3,000 hours (125 days)*1 Illumination comparison between LED system head and lamp system fiber when 4 branches are used (mW/cm2 ) *1 Compared with mercury lamp system *2 When fiber branching is used OFF Lamp-system Standard model Ultra cooling continuously head head continuously lighted continuously lighted lighted CH1 Ultra cooling head lighting control*2 100% 100% 85% 66% 57% 0 LED system (Ultra light focus lens) LED system (Spot Lens (3-mm dia.)) Lamp system 12s 9s Ultra light focus lens 0 5 10 Uses UIT-150 UV Light Integrating Actinometer manufactured by Ushio Inc. When measured at suggested work distance. Lamp system value is an example with a typical fiber. Approx. 45% of previous tact time 15 CH4 100% Lamp system Spot Lens (3-mm dia.) CH3 100% 9400 20s Lighting time 1 *2= = 3 capacity utilization time CH2 100% Tact time comparison Radiation comparison between ultra cooling head and conventional head 20s Tact time (example with a certain type of adhesive) Ultra cooling head (ZUV-H10MB) Highly-exoergic area is extensive Patent pending The Smart Canyon structure has been utilized in all heads in the Conventional structure ZUV Series, but for the sake of achieving low initial cost in the standard model heads we have optimized this Smart Canyon structure even further, enabling it to dissipate heat more efficiently. 120,000 hours (approx. 41 years)* *1 Useful life (no. of years) at 24 hours/day operation It is a UV-LED, whose characteristic is its long life, but there is a chance that its life will be shorter if the heat is not properly dissipated when emitting light. For that reason, it is considered necessary to avoid rises in temperature during illumination. The advance that has fulfilled this requirement in a compact head is OmronÕs unique heat dissipation structure = the Smart Canyon. Optimized “New Smart Canyon Structure” 40-fold Ultra light focus lens (ZUV-L2H) noitanimulli The basic performance of UV bonding is retained while significant cost savings compared to a conventional LED system is achieved with carefully selected features. ZUV standard model can be purchased at a price below that of the lamp system. The biggest issue for the lamp system is frequent replacement of the lamp light source. LED system has longer life compared to the lamp system. Replacement man hours can also be eliminated if you use the ultra cooling head. The continuously-on lifetime of the ultra cooling head is 40,000 hours, or 13 times that of a lamp system. If you assume Òlighting-on time divided by capacity utilization timeÓ is one-third, a semipermanent usage of 120,000 hours, or 40 times that of a lamp system, is possible. That means light source replacement becomes essentially unnecessary and both the labor hours and running costs of the replacement work can be reduced substantially. Maximum power to greatly reduce tact time Dedicated Jig for ultra cooling heads Its heat dissipation is even better compared to a conventional head, so it can be mounted on the customerÕs existing toolings or on original toolings of new design. It will allow you to trim man-hours of LED system introduction. Mountable on existing fittings No need for heat dissipating fittings 6 Solution 3 Standard head (ZUV-H20MB/H30MB) Environmentally safe Substantially reduces CO2 emissions in power-saving LED system usage High power consumption and disposal of the mercury lamps that occurs with each replacement are problems at a lamp system site, but they can be resolved by using an LED system. An LED system has lower power consumption than a mercury lamp system, and can also lead to power saving with efficient use of energy through lighting control. In addition, the LED light source doesnÕt use mercury so it is superior in terms of reduced environmental impact. Comparison of annual CO2 discharge amounts when used in 100 units Approx. 64t CO2 Approx. 4.5t Approx. 60t CO2 reduction Conventional lamp system Power consumption Approx. 250W per unit LED system ZUV Power consumption Approx. 53W per unit* * Standard model controller ZUV-C20H Notes ¥ Assumed to be 24 hours and 260 days operation. ¥ Assumes Òon time divided by equipment operation timeÓ to equal one-third. ¥ For CO2 emissions, calculation of 4.1t CO2 reduction with 10,000 kWh reduction in the Nationwide Receiving End Coefficient published by the Federation of Electric Power Companies of Japan ¥ Power consumption may vary according to device conditions 7 Illumination variation tailored to all UV bonding Illumination Illumination 1 Bonds at once over a wide range Line beam lens with a 12mm beam width 12mm UV adhesion with line beam lens Line beam lens ZUV-L12L Maximum illumination with 4 five spot sizes to choose from Spot lenses with ø3/ø4/ø6/ø8/ø10mm beam diameter With a line beam lens, UV bonding of work which used to be difficult with a single illumination is also possible. A relatively uniform elongated elliptical illumination area is achieved by illuminating with line beam lens with a 12 mm beam width. You can accomplish UV bonding at once without moving the illumination head, so productivity will increase. Easy to change spot size with interchangeable head lenses. Reliable UV bonding can be performed with the selection of a spot in a size appropriate to the work from five lenses. Spot radius Adhesion of a camera module housing and a board ø3mm We shortened tact time by illuminating with a line beam lens. Contributes to improvements in productivity. 11mm ø4mm Illumination Bonds securely even 14mm 2 if separated NEW Achieve 690 mW/cm2 illumination power at a working distance of 30 mm when you use the newly developed diffusion illumination head (ZUV-H35MB/ZUV-H25MB) + diffusing lens (ZUV-L12H). Reliable bonding is realized even at a distance by ensuring illumination power that used to be a problem when illumination couldnÕt be done close to the work. Diffuse illumination head ZUV-H35MB Diffuse illumination head value models ZUV-H25MB Diffusing lens ZUV-L12H ø6mm 690 mW/cm2 illumination power even at a working distance of 30 mm ZUV-L12H Illumination profile* UV illumination power [mW/cm2] 800 700 ø8mm *For WD 30mm 15mm ZUV-H35MB/H25MB+ ZUV-L12H Approx.double ø10mm 600 500 ZUV-H30MB/ H20MB+ ZUV-L10H 400 300 30mm Spot lens ZUV-L3H/L4H/L6H/L8H/L10H 200 100 0 -10 -8 -6 -4 -2 0 4 6 8 10 Horizontal beam (spot) focus movement [mm] UV bonding of a light pickup lens In addition to being able to bond reliably even at a work distance of 30 mm, it contributes to improvements in productivity with diffuse beam illumination. Illumination Effectively save equipment space 5 with a light path that is emitted at 90° Side-view Lens for UV illumination from the side of the lens unit Illumination 3 Bonds firmly for minute objects The light path is illuminated at 90¡ to occupy only about 1/7 the space of previous models. This achieves more flexibility in mounting the Head and enables more flexible usage of space in production equipment. Installation is also possible in small spaces in existing equipment. Narrow radius lenses with ø6/ø8 external lens diameters Narrow radius lenses whose head lens is elongated and extended are most suitable when the head size is too large or head placement is difficult. We made it possible to illuminate tiny components with a number of beams by illuminating with narrow radius lenses. A placement close to the work is also possible. 84mm 12mm Space-saving! About 1/7 space of previous models. UV bonding of a light pickup lens Small diameter lens ZUV-L6T/L8T We achieved high-speed bonding by UV illuminating a tiny optical pickup lens with multiple small lenses. 8 9 Side-view lens ZUV-L3S/L4S/L6S/L8S Illumination variation tailored to all UV bonding Illumination Illumination 1 Bonds at once over a wide range Line beam lens with a 12mm beam width 12mm UV adhesion with line beam lens Line beam lens ZUV-L12L Maximum illumination with 4 five spot sizes to choose from Spot lenses with ø3/ø4/ø6/ø8/ø10mm beam diameter With a line beam lens, UV bonding of work which used to be difficult with a single illumination is also possible. A relatively uniform elongated elliptical illumination area is achieved by illuminating with line beam lens with a 12 mm beam width. You can accomplish UV bonding at once without moving the illumination head, so productivity will increase. Easy to change spot size with interchangeable head lenses. Reliable UV bonding can be performed with the selection of a spot in a size appropriate to the work from five lenses. Spot radius Adhesion of a camera module housing and a board ø3mm We shortened tact time by illuminating with a line beam lens. Contributes to improvements in productivity. 11mm ø4mm Illumination Bonds securely even 14mm 2 if separated NEW Achieve 690 mW/cm2 illumination power at a working distance of 30 mm when you use the newly developed diffusion illumination head (ZUV-H35MB/ZUV-H25MB) + diffusing lens (ZUV-L12H). Reliable bonding is realized even at a distance by ensuring illumination power that used to be a problem when illumination couldnÕt be done close to the work. Diffuse illumination head ZUV-H35MB Diffuse illumination head value models ZUV-H25MB Diffusing lens ZUV-L12H ø6mm 690 mW/cm2 illumination power even at a working distance of 30 mm ZUV-L12H Illumination profile* UV illumination power [mW/cm2] 800 700 ø8mm *For WD 30mm 15mm ZUV-H35MB/H25MB+ ZUV-L12H Approx.double ø10mm 600 500 ZUV-H30MB/ H20MB+ ZUV-L10H 400 300 30mm Spot lens ZUV-L3H/L4H/L6H/L8H/L10H 200 100 0 -10 -8 -6 -4 -2 0 4 6 8 10 Horizontal beam (spot) focus movement [mm] UV bonding of a light pickup lens In addition to being able to bond reliably even at a work distance of 30 mm, it contributes to improvements in productivity with diffuse beam illumination. Illumination Effectively save equipment space 5 with a light path that is emitted at 90° Side-view Lens for UV illumination from the side of the lens unit Illumination 3 Bonds firmly for minute objects The light path is illuminated at 90¡ to occupy only about 1/7 the space of previous models. This achieves more flexibility in mounting the Head and enables more flexible usage of space in production equipment. Installation is also possible in small spaces in existing equipment. Narrow radius lenses with ø6/ø8 external lens diameters Narrow radius lenses whose head lens is elongated and extended are most suitable when the head size is too large or head placement is difficult. We made it possible to illuminate tiny components with a number of beams by illuminating with narrow radius lenses. A placement close to the work is also possible. 84mm 12mm Space-saving! About 1/7 space of previous models. UV bonding of a light pickup lens Small diameter lens ZUV-L6T/L8T We achieved high-speed bonding by UV illuminating a tiny optical pickup lens with multiple small lenses. 8 9 Side-view lens ZUV-L3S/L4S/L6S/L8S Ordering Information Ratings and Characteristics Head Unit Multi-function model ZUV-C30H Value model Model Wavelength Light source Class Vibration tolerance Drop impact resistance Ambient temperature range Ambient humidity range Degree of Protection rellortnoC ZUV-C20H Mega-power head ZUV-H20MB ZUV-H30MB NEW tinU daeH MB Series Value model Material Diffuse illumination head ZUV-H25MB ZUV-H35MB Weight (after packing) Value model Accessories Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) IEC60529 IP40 ZUV-H20MB/25MB:Zinc, aluminum, glass ZUV-H30MB/H10MB/H35MB:Zinc, copper, aluminum, glass ZUV-H20MB/H25MB:Approx. 185g (Main unit: approx. 100g), ZUV-H30MB/H35MB:Approx. 150g (Main unit: approx. 55g), ZUV-H10MB:Approx. 180g (Main unit:approx. 105g) Operation manual, clamp (with M3 thread), warning label (English) * Models are also available with a 385-nm light source wavelength. (ZUV-H21MB/H11MB/H26MB) ¥ Separate Lens Unit required ¥ Separate Lens Unit required ¥ Cable length: 2m ¥ Cable length: 0.3m ¥ Max illumination of ¥ Max illumination of 9400mW/cm2 with 2 beam 9400mW/cm2 with 2 beam dia. dia. Spot lens Ultra light focus lens Line beam lens ZUV-L3H/L4H/L6H/L8H/L10H ZUV-L2H ZUV-L12L NEW tinU sneL Ultra cooling head ZUV-H10MB *1 ZUV-H20MB/H30MB/H10MB/H25MB/H35MB 365nm * Class 3B (JIS C 6802 2005) Class 3B (EN60825-1: 1994 +A1: 2002 +A2: 2001) 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each ¥ Spot dia.: ¿3mm ¥ ZUV-L3H ¿4mm ¥ ZUV-L4H ¿6mm ¥ ZUV-L6H ¿8mm ¥ ZUV-L8H ¿10mm ¥ ZUV-L10H ¥ Spot dia.: ¿2mm ¥ ZUV-L12H ¥ Beam width : 12mm ZUV-L12L ¥ Separate Lens Unit required ¥ Cable length: 0.3m ¥ Max illumination of 9400mW/cm2 with 2 beam dia. Narrow radius lens ZUV-L6T/L8T ¥ Spot dia.: ¿6mm ¥ ZUV-L6T ¿8mm ¥ ZUV-L8T *1 Models are also available with 2-m cables. (ZUV-H10MB 2M) ¥ Separate diffusing lens required ¥ Cable length: 2m ¥ Max illumination of 690mW/cm2 with 12 beam dia. ¥ Separate diffusing lens required ¥ Cable length: 0.3m ¥ Max illumination of 690mW/cm2 with 12 beam dia. Side-view lens *2 Diffusing lens ZUV-L3S/L4S/L6S/L8S ZUV-L12H NEW ¥ Spot dia.: ¿3mm ¥ ZUV-L3S ¿4mm ¥ ZUV-L4S ¿6mm ¥ ZUV-L6S ¿8mm ¥ ZUV-L8S ¥ Spot dia.: ¿12mm ¥ ZUV-L12H Extension Cable ZUV-XC2B/XC5B/XC10B ¥ For extending length between Controller and Heads ¥ Cable length: 2m ZUV-XC2B 5m ZUV-XC5B 10m ZUV-XC10B *2 When using ZUV-H25MB/H35MB diffuse illumination head with side-view lens, we recommend using ZUV-L3S/L4S. Ratings and Characteristics Controller Model Constant Irradiation irradiation method Pattern irradiation No. of settings Cumulative illumination summation Terminalxx Inputs block I/O Outputs ZUV-C20H (Value model) irradiation Illumination power (0% to100%), illumination time (max. 99.9sec/unlimited) Unavailable Illumination power (0% to 100%), irradiation time (999.9 s max.) No bank feature 16 banks ZUV-C30H (Multi-function model) Can be set to step or ramp (linear) 16 points specified per setting) Energy (display unit - J) stop, Start/stop UV illumination (4 channels), Emergency shutdown, UV illumination start/stop (All channels/4-channel) Emergency Select settings (banks) Ready (4 channels), UV illuminating, errors Ready output (all-channels/4-channel), error output, operating Start/stop UV irradiation (4 channels), select settings (banks), RS-232C and USB I/O None get/change settings data, save/read data, power tuning Cooling method Fan air cooling Air cooled (no fan) Select AC or DC power supply AC power only ¥ AC power supply: 100 to 240 V AC±10%, 50/60 Hz (AC adapter included) Power supply voltage 100V-240V AC ± 10%, 50/60 Hz (AC adapter attached) ¥ DC power supply: 24 V DC±10% (supplied from terminal block on back of Unit) ¥ With AC adapter: 2.3 A (55W) Current consumption 1.4A (53W) ¥ With DC power supply: 1.9 A (45W) 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times Vibration tolerance Drop impact resistance 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each Ambient temperature range Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) Ambient humidity range IEC 60529 IP20 Degree of protection Polycarbonate, SECC SUS, aluminum Material Approx. 1,800g (Controller only: approx. 1,200g) Approx. 2,950g (Controller only: approx. 1,900g) Weight (package) Accessories Time (unit: 100 hour display) Instruction sheet, Key, AC adapter Lens Unit Model Vibration tolerance Drop impact resistance Ambient temperature range Ambient humidity range Degree of Protection Material Weight (after packing) ZUV-L2H/L3H/L4H/L6H/L8H/L10H/L12L/L6T/L8T/L3S/L4S/L6S/L8S/L12H 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) IEC60529 IP40 Aluminum, glass Accessories Operation manual Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H20MB/H30MB/H10MB ZUV-L3H ZUV-L2H 2mm dia. 3mm dia. ZUV-L4H 4mm dia. ZUV-L6H 6mm dia. ZUV-L8H 8mm dia. ZUV-L10H 10mm dia. ZUV-L12L 12 ✕ 2mm 10mm 11mm 14mm 15mm 15mm 30mm 15mm 9400mW/cm2 6900mW/cm2 5300mW/cm2 3700mW/cm2 1800mW/cm2 400mW/cm2 460mW/cm2 *2 Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H20MB/H30MB/H10MB ZUV-L8T ZUV-L6T 1.5mm dia. 3mm dia. ZUV-L3S 3mm dia. ZUV-L4S 4mm dia. ZUV-L6S 6mm dia. ZUV-L8S 8mm dia. 6mm 9mm 4mm 5mm 8mm 13mm 5800mW/cm2 4600mW/cm2 6100mW/cm2 5300mW/cm2 3700mW/cm2 2000mW/cm2 Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H25MB/H35MB ZUV-L3S ZUV-L12H 12mm dia. 3mm dia. ZUV-L2H/L3H/L4H/L6H/L8H/L10H:Approx. 10g (Main unit: approx. 5g), ZUV-L12L:Approx. 30g (Main unit: approx. 5g), ZUV-L6T:Approx. 35g (Main unit: approx. 7g), ZUV-L8T:Approx. 40g (Main unit: approx. 10g), ZUV-L3S/L4S/L6S/L8S:Approx. 35g (Main unit: approx. 5g), ZUV-L12H:Approx. 30g (Main unit: approx. 5g) 30mm 690mW/cm ZUV-L4S 4mm dia. 8mm 2 3300mW/cm 13mm 2 1500mW/cm2 *1 Under the following conditions: 100% irradiation, 25¡C room temperature and with heat sink. Values for reference only. *2 Illumination is the value at a 15-mm working distance and in a 12 ✕ 2-mm beam shape range. Instruction sheet, Key, AC adapter, CD-ROM (USB driver, user's manual PDF) 10 11 Ordering Information Ratings and Characteristics Head Unit Multi-function model ZUV-C30H Value model Model Wavelength Light source Class Vibration tolerance Drop impact resistance Ambient temperature range Ambient humidity range Degree of Protection rellortnoC ZUV-C20H Mega-power head ZUV-H20MB ZUV-H30MB NEW tinU daeH MB Series Value model Material Diffuse illumination head ZUV-H25MB ZUV-H35MB Weight (after packing) Value model Accessories Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) IEC60529 IP40 ZUV-H20MB/25MB:Zinc, aluminum, glass ZUV-H30MB/H10MB/H35MB:Zinc, copper, aluminum, glass ZUV-H20MB/H25MB:Approx. 185g (Main unit: approx. 100g), ZUV-H30MB/H35MB:Approx. 150g (Main unit: approx. 55g), ZUV-H10MB:Approx. 180g (Main unit:approx. 105g) Operation manual, clamp (with M3 thread), warning label (English) * Models are also available with a 385-nm light source wavelength. (ZUV-H21MB/H11MB/H26MB) ¥ Separate Lens Unit required ¥ Separate Lens Unit required ¥ Cable length: 2m ¥ Cable length: 0.3m ¥ Max illumination of ¥ Max illumination of 9400mW/cm2 with 2 beam 9400mW/cm2 with 2 beam dia. dia. Spot lens Ultra light focus lens Line beam lens ZUV-L3H/L4H/L6H/L8H/L10H ZUV-L2H ZUV-L12L NEW tinU sneL Ultra cooling head ZUV-H10MB *1 ZUV-H20MB/H30MB/H10MB/H25MB/H35MB 365nm * Class 3B (JIS C 6802 2005) Class 3B (EN60825-1: 1994 +A1: 2002 +A2: 2001) 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each ¥ Spot dia.: ¿3mm ¥ ZUV-L3H ¿4mm ¥ ZUV-L4H ¿6mm ¥ ZUV-L6H ¿8mm ¥ ZUV-L8H ¿10mm ¥ ZUV-L10H ¥ Spot dia.: ¿2mm ¥ ZUV-L12H ¥ Beam width : 12mm ZUV-L12L ¥ Separate Lens Unit required ¥ Cable length: 0.3m ¥ Max illumination of 9400mW/cm2 with 2 beam dia. Narrow radius lens ZUV-L6T/L8T ¥ Spot dia.: ¿6mm ¥ ZUV-L6T ¿8mm ¥ ZUV-L8T *1 Models are also available with 2-m cables. (ZUV-H10MB 2M) ¥ Separate diffusing lens required ¥ Cable length: 2m ¥ Max illumination of 690mW/cm2 with 12 beam dia. ¥ Separate diffusing lens required ¥ Cable length: 0.3m ¥ Max illumination of 690mW/cm2 with 12 beam dia. Side-view lens *2 Diffusing lens ZUV-L3S/L4S/L6S/L8S ZUV-L12H NEW ¥ Spot dia.: ¿3mm ¥ ZUV-L3S ¿4mm ¥ ZUV-L4S ¿6mm ¥ ZUV-L6S ¿8mm ¥ ZUV-L8S ¥ Spot dia.: ¿12mm ¥ ZUV-L12H Extension Cable ZUV-XC2B/XC5B/XC10B ¥ For extending length between Controller and Heads ¥ Cable length: 2m ZUV-XC2B 5m ZUV-XC5B 10m ZUV-XC10B *2 When using ZUV-H25MB/H35MB diffuse illumination head with side-view lens, we recommend using ZUV-L3S/L4S. Ratings and Characteristics Controller Model Constant Irradiation irradiation method Pattern irradiation No. of settings Cumulative illumination summation Terminalxx Inputs block I/O Outputs ZUV-C20H (Value model) irradiation Illumination power (0% to100%), illumination time (max. 99.9sec/unlimited) Unavailable Illumination power (0% to 100%), irradiation time (999.9 s max.) No bank feature 16 banks ZUV-C30H (Multi-function model) Can be set to step or ramp (linear) 16 points specified per setting) Energy (display unit - J) stop, Start/stop UV illumination (4 channels), Emergency shutdown, UV illumination start/stop (All channels/4-channel) Emergency Select settings (banks) Ready (4 channels), UV illuminating, errors Ready output (all-channels/4-channel), error output, operating Start/stop UV irradiation (4 channels), select settings (banks), RS-232C and USB I/O None get/change settings data, save/read data, power tuning Cooling method Fan air cooling Air cooled (no fan) Select AC or DC power supply AC power only ¥ AC power supply: 100 to 240 V AC±10%, 50/60 Hz (AC adapter included) Power supply voltage 100V-240V AC ± 10%, 50/60 Hz (AC adapter attached) ¥ DC power supply: 24 V DC±10% (supplied from terminal block on back of Unit) ¥ With AC adapter: 2.3 A (55W) Current consumption 1.4A (53W) ¥ With DC power supply: 1.9 A (45W) 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times Vibration tolerance Drop impact resistance 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each Ambient temperature range Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) Ambient humidity range IEC 60529 IP20 Degree of protection Polycarbonate, SECC SUS, aluminum Material Approx. 1,800g (Controller only: approx. 1,200g) Approx. 2,950g (Controller only: approx. 1,900g) Weight (package) Accessories Time (unit: 100 hour display) Instruction sheet, Key, AC adapter Lens Unit Model Vibration tolerance Drop impact resistance Ambient temperature range Ambient humidity range Degree of Protection Material Weight (after packing) ZUV-L2H/L3H/L4H/L6H/L8H/L10H/L12L/L6T/L8T/L3S/L4S/L6S/L8S/L12H 10 to 150 Hz acceleration 50 m/s2, half amplitude 0.35 mm, X/Y/Z direction 8 minutes each 10 times 150 m/s2, 6 directions (up/down, right/left, front/back) 3 times each Operating: 5 to 35¡C; Storage: -10 to +60¡C (with no condensation or icing) Operating/storage: 30% to 85% (with no condensation or icing) IEC60529 IP40 Aluminum, glass Accessories Operation manual Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H20MB/H30MB/H10MB ZUV-L3H ZUV-L2H 2mm dia. 3mm dia. ZUV-L4H 4mm dia. ZUV-L6H 6mm dia. ZUV-L8H 8mm dia. ZUV-L10H 10mm dia. ZUV-L12L 12 ✕ 2mm 10mm 11mm 14mm 15mm 15mm 30mm 15mm 9400mW/cm2 6900mW/cm2 5300mW/cm2 3700mW/cm2 1800mW/cm2 400mW/cm2 460mW/cm2 *2 Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H20MB/H30MB/H10MB ZUV-L8T ZUV-L6T 1.5mm dia. 3mm dia. ZUV-L3S 3mm dia. ZUV-L4S 4mm dia. ZUV-L6S 6mm dia. ZUV-L8S 8mm dia. 6mm 9mm 4mm 5mm 8mm 13mm 5800mW/cm2 4600mW/cm2 6100mW/cm2 5300mW/cm2 3700mW/cm2 2000mW/cm2 Head Unit model Lens Unit model Spot diameter/Beam shape Recommended working distance Peak illumination *1 ZUV-H25MB/H35MB ZUV-L3S ZUV-L12H 12mm dia. 3mm dia. ZUV-L2H/L3H/L4H/L6H/L8H/L10H:Approx. 10g (Main unit: approx. 5g), ZUV-L12L:Approx. 30g (Main unit: approx. 5g), ZUV-L6T:Approx. 35g (Main unit: approx. 7g), ZUV-L8T:Approx. 40g (Main unit: approx. 10g), ZUV-L3S/L4S/L6S/L8S:Approx. 35g (Main unit: approx. 5g), ZUV-L12H:Approx. 30g (Main unit: approx. 5g) 30mm 690mW/cm ZUV-L4S 4mm dia. 8mm 2 3300mW/cm 13mm 2 1500mW/cm2 *1 Under the following conditions: 100% irradiation, 25¡C room temperature and with heat sink. Values for reference only. *2 Illumination is the value at a 15-mm working distance and in a 12 ✕ 2-mm beam shape range. Instruction sheet, Key, AC adapter, CD-ROM (USB driver, user's manual PDF) 10 11 External Dimensions (Unit: mm) Beam Spot Profile (Typical Examples) Mega-power head /ultra-cooling head ZUV-H20MB/H30MB/H10MB • Controller (Controller ZUV-C20H/C30H, 100% power when illuminated) Multi-function model ZUV-C30H Value model ZUV-C20H 4- 14 12.7 26 6 12.7 49 12.7 10 12 14 16 20 11000 10000 9000 8000 5000 WD= 8 WD=11 WD=14 WD=16 WD=20 6000 5000 4000 3500 3000 3000 5000 4000 2000 1500 2000 3000 1000 2000 1000 500 1000 2-M4 x valid depth 6 1 2500 20 40 2 .aid 7.41 .aid 5 Lens Unit 300 -1 0 1 2 3 4 ZUV-L8H Illumination profile 600 WD=10 WD=15 WD=20 WD=25 WD=30 .aid 7.41 .aid 5 0 -5 -4 -3 -2 -1 0 1 2 3 4 -4 -3 -2 -1 0 1 2 3 4 5000 WD=3 WD=5 WD=6 WD=7 WD=10 WD=15 5000 4000 4.4 3.5 2.6 Note: The model number is printed on the side of the Lens Unit. 11.1 12 dia. 4500 11.1 1.7 3500 12 dia. .aid 21 43 .aid 7.41 .aid 5 .aid 7.41 .aid 5 Lens Unit 5 -4 -3 -2 -1 0 1 2 3 4 5 Position (mm) Side-view lens ZUV-L4S Illumination profile 8 10 Position (mm) 4000 Position (mm) Side-view lens ZUV-L6S Illumination profile ZUV-L8S Illumination profile 2200 2000 3500 1800 3000 1600 1400 2500 1200 2000 1000 800 1500 2000 1500 600 1000 400 1000 500 200 Position (mm) Position (mm) Position (mm) Diffuse illumination head ZUV-H25MB/H35MB Line beam lens 1100 WD=10 WD=15 WD=20 WD=30 1000 900 800 700 1100 800 500 400 400 300 300 200 200 100 100 -2 0 2 4 6 8 10 Position (mm) 800 0 -5 ZUV-L12H illumination profile WD=10 WD=15 WD=20 WD=25 WD=30 WD=50 700 600 700 600 -4 Diffusing lens WD=10 WD=15 WD=20 WD=30 900 500 -6 ZUV-L12L illumination profile (width direction) 1000 600 -8 (Controller ZUV-C20H/C30H, 100% power when illuminated) Line beam lens ZUV-L12L illumination profile (length direction) 0 -10 12 4 )2mc/Wm( noitanimullI 2000 56.7 Note: When attached to ZUV-H20MB (Standard head value model) 3 Position (mm) )2mc/Wm( noitanimullI ZUV-L8T 6 1000 3000 )2mc/Wm( noitanimullI 13.7 1.7 .aid 21 99.6 43 2 .aid 7.41 .aid 5 2000 .aid 8 .aid 8 ZUV-L6T 1 43 Note: When attached to ZUV-H20MB (Mega-power head standard model) 12 dia. 13.2 56.2 Lens Unit Lens Unit 56.7 .aid 21 .aid 6 .aid 6 99.1 56.2 12 dia. 2000 22.7 .aid 7.41 Lens Unit 0 500 66 .aid 5 12 dia. 43 2000 Note: When attached to ZUV-H25MB (Diffuse illumination head standard model) Note: When attached to ZUV-H20MB (Mega-power head standard model) Narrow radius lens ZUV-L6T/L8T 7 0.8 7.7 .aid 7.41 .aid 5 Lens Unit 51 43 -1 3500 Note: The model number is printed on the side of the Lens Unit. 4 2000 0 -5 2500 12 dia. 0.8 -2 5000 22.7 7.7 -3 4000 Side-view lens ZUV-L S NEW 2 ZUV-L3S Illumination profile )2mc/Wm( noitanimullI Diffusing lens ZUV-L12H -4 4500 Note: When attached to ZUV-H20MB (Mega-power head standard model) 0 1000 )2mc/Wm( noitanimullI Lens Unit 5500 -2 3000 1500 Side-view lens .aid 7.41 ZUV-L10H 43 2000 -4 4000 500 )2mc/Wm( noitanimullI 62.5 19.1 -6 5000 2500 0 -5 .aid 5 ZUV-L3H/L4H/L6H/L8H 19.1 -8 6000 3000 1000 .aid 21 Spot lens ZUV-L3H/L4H/L6H/L8H/L10H 2000 WD=10 WD=15 WD=20 WD=25 WD=30 WD=50 7000 WD=5 WD=8 WD=9 WD=10 WD=15 4000 2000 Ultra light focus lens ZUV-L2H NEW • Lens unit 58 15.1 5 Side-view lens ZUV-L8T Illumination profile 2000 12 dia. 4 Position (mm) ZUV-L10H Illumination profile 0 -10 5 Position (mm) )2mc/Wm( noitanimullI 300 7.7 Lens Unit 15.1 1 1.5 3 400 Narrow radius lens ZUV-L6T Illumination profile )2mc/Wm( noitanimullI 43 .aid 5 .aid 5 .aid 7.41 .aid 7.41 51 12 dia. )2mc/Wm( noitanimullI 6000 43 Line beam lens ZUV-L12L 2 100 0 -5 5 Position (mm) 3000 12 dia. 1 1000 Narrow radius lens Lens Unit 0 200 ZUV-H35MB 7.7 -1 1000 NEW Value model ZUV-H25MB 12 dia. -2 300 43 Diffuse illumination head 2000 -3 500 500 51 -4 Spot lens 500 Lens Unit 0 -5 5 Position (mm) 1500 1500 126.6 11.1 -2 2000 2000 Ultra cooling head ZUV-H10MB 12 dia. 2500 WD=10 WD=15 WD=20 WD=25 WD=30 3000 5.12 ia 2d -3 )2mc/Wm( noitanimullI . 20 62 .aid 7.41 12 dia. 43 -4 Spot lens ZUV-L6H Illumination profile )2mc/Wm( noitanimullI 300 54 11.1 43 .aid 5 Lens Unit Spot lens 3500 31 12 dia. 20 ZUV-H30MB 2000 54 11.1 Position (mm) )2mc/Wm( noitanimullI NEW Value model ZUV-H20MB NEW 0 -5 Clamp Standard head WD=10 WD=14 WD=20 WD=25 WD=30 2500 6000 • Head unit ZUV-L4H Illumination profile 4500 4000 7000 12.7 ZUV-L3H Illumination profile 7000 12000 4.75 6.21 6.13 6.65 6.18 6.601 12 3 6.1 9.7 521 18.6 146 63 8.03 4.82 18.6 61 1.4 15.7 03 5 .2 72 6.6 18.6 37.4 55 08 501 521 18.6 3.5 85 Spot lens Spot lens ZUV-L2H Illumination profile )2mc/Wm( noitanimullI 4- 14 85 13000 )2mc/Wm( noitanimullI 146 )2mc/Wm( noitanimullI 2.5 Ultra light focus lens 21.5 30.8 13.1 1.01 85 24.5 23.6 15.45 500 400 300 200 100 -4 -3 -2 -1 0 13 1 2 3 4 5 Position (mm) 0 -10 -8 -6 -4 -2 0 2 4 6 8 10 Position (mm) External Dimensions (Unit: mm) Beam Spot Profile (Typical Examples) Mega-power head /ultra-cooling head ZUV-H20MB/H30MB/H10MB • Controller (Controller ZUV-C20H/C30H, 100% power when illuminated) Multi-function model ZUV-C30H Value model ZUV-C20H 4- 14 12.7 26 6 12.7 49 12.7 10 12 14 16 20 11000 10000 9000 8000 5000 WD= 8 WD=11 WD=14 WD=16 WD=20 6000 5000 4000 3500 3000 3000 5000 4000 2000 1500 2000 3000 1000 2000 1000 500 1000 2-M4 x valid depth 6 1 2500 20 40 2 .aid 7.41 .aid 5 Lens Unit 300 -1 0 1 2 3 4 ZUV-L8H Illumination profile 600 WD=10 WD=15 WD=20 WD=25 WD=30 .aid 7.41 .aid 5 0 -5 -4 -3 -2 -1 0 1 2 3 4 -4 -3 -2 -1 0 1 2 3 4 5000 WD=3 WD=5 WD=6 WD=7 WD=10 WD=15 5000 4000 4.4 3.5 2.6 Note: The model number is printed on the side of the Lens Unit. 11.1 12 dia. 4500 11.1 1.7 3500 12 dia. .aid 21 43 .aid 7.41 .aid 5 .aid 7.41 .aid 5 Lens Unit 5 -4 -3 -2 -1 0 1 2 3 4 5 Position (mm) Side-view lens ZUV-L4S Illumination profile 8 10 Position (mm) 4000 Position (mm) Side-view lens ZUV-L6S Illumination profile ZUV-L8S Illumination profile 2200 2000 3500 1800 3000 1600 1400 2500 1200 2000 1000 800 1500 2000 1500 600 1000 400 1000 500 200 Position (mm) Position (mm) Position (mm) Diffuse illumination head ZUV-H25MB/H35MB Line beam lens 1100 WD=10 WD=15 WD=20 WD=30 1000 900 800 700 1100 800 500 400 400 300 300 200 200 100 100 -2 0 2 4 6 8 10 Position (mm) 800 0 -5 ZUV-L12H illumination profile WD=10 WD=15 WD=20 WD=25 WD=30 WD=50 700 600 700 600 -4 Diffusing lens WD=10 WD=15 WD=20 WD=30 900 500 -6 ZUV-L12L illumination profile (width direction) 1000 600 -8 (Controller ZUV-C20H/C30H, 100% power when illuminated) Line beam lens ZUV-L12L illumination profile (length direction) 0 -10 12 4 )2mc/Wm( noitanimullI 2000 56.7 Note: When attached to ZUV-H20MB (Standard head value model) 3 Position (mm) )2mc/Wm( noitanimullI ZUV-L8T 6 1000 3000 )2mc/Wm( noitanimullI 13.7 1.7 .aid 21 99.6 43 2 .aid 7.41 .aid 5 2000 .aid 8 .aid 8 ZUV-L6T 1 43 Note: When attached to ZUV-H20MB (Mega-power head standard model) 12 dia. 13.2 56.2 Lens Unit Lens Unit 56.7 .aid 21 .aid 6 .aid 6 99.1 56.2 12 dia. 2000 22.7 .aid 7.41 Lens Unit 0 500 66 .aid 5 12 dia. 43 2000 Note: When attached to ZUV-H25MB (Diffuse illumination head standard model) Note: When attached to ZUV-H20MB (Mega-power head standard model) Narrow radius lens ZUV-L6T/L8T 7 0.8 7.7 .aid 7.41 .aid 5 Lens Unit 51 43 -1 3500 Note: The model number is printed on the side of the Lens Unit. 4 2000 0 -5 2500 12 dia. 0.8 -2 5000 22.7 7.7 -3 4000 Side-view lens ZUV-L S NEW 2 ZUV-L3S Illumination profile )2mc/Wm( noitanimullI Diffusing lens ZUV-L12H -4 4500 Note: When attached to ZUV-H20MB (Mega-power head standard model) 0 1000 )2mc/Wm( noitanimullI Lens Unit 5500 -2 3000 1500 Side-view lens .aid 7.41 ZUV-L10H 43 2000 -4 4000 500 )2mc/Wm( noitanimullI 62.5 19.1 -6 5000 2500 0 -5 .aid 5 ZUV-L3H/L4H/L6H/L8H 19.1 -8 6000 3000 1000 .aid 21 Spot lens ZUV-L3H/L4H/L6H/L8H/L10H 2000 WD=10 WD=15 WD=20 WD=25 WD=30 WD=50 7000 WD=5 WD=8 WD=9 WD=10 WD=15 4000 2000 Ultra light focus lens ZUV-L2H NEW • Lens unit 58 15.1 5 Side-view lens ZUV-L8T Illumination profile 2000 12 dia. 4 Position (mm) ZUV-L10H Illumination profile 0 -10 5 Position (mm) )2mc/Wm( noitanimullI 300 7.7 Lens Unit 15.1 1 1.5 3 400 Narrow radius lens ZUV-L6T Illumination profile )2mc/Wm( noitanimullI 43 .aid 5 .aid 5 .aid 7.41 .aid 7.41 51 12 dia. )2mc/Wm( noitanimullI 6000 43 Line beam lens ZUV-L12L 2 100 0 -5 5 Position (mm) 3000 12 dia. 1 1000 Narrow radius lens Lens Unit 0 200 ZUV-H35MB 7.7 -1 1000 NEW Value model ZUV-H25MB 12 dia. -2 300 43 Diffuse illumination head 2000 -3 500 500 51 -4 Spot lens 500 Lens Unit 0 -5 5 Position (mm) 1500 1500 126.6 11.1 -2 2000 2000 Ultra cooling head ZUV-H10MB 12 dia. 2500 WD=10 WD=15 WD=20 WD=25 WD=30 3000 5.12 ia 2d -3 )2mc/Wm( noitanimullI . 20 62 .aid 7.41 12 dia. 43 -4 Spot lens ZUV-L6H Illumination profile )2mc/Wm( noitanimullI 300 54 11.1 43 .aid 5 Lens Unit Spot lens 3500 31 12 dia. 20 ZUV-H30MB 2000 54 11.1 Position (mm) )2mc/Wm( noitanimullI NEW Value model ZUV-H20MB NEW 0 -5 Clamp Standard head WD=10 WD=14 WD=20 WD=25 WD=30 2500 6000 • Head unit ZUV-L4H Illumination profile 4500 4000 7000 12.7 ZUV-L3H Illumination profile 7000 12000 4.75 6.21 6.13 6.65 6.18 6.601 12 3 6.1 9.7 521 18.6 146 63 8.03 4.82 18.6 61 1.4 15.7 03 5 .2 72 6.6 18.6 37.4 55 08 501 521 18.6 3.5 85 Spot lens Spot lens ZUV-L2H Illumination profile )2mc/Wm( noitanimullI 4- 14 85 13000 )2mc/Wm( noitanimullI 146 )2mc/Wm( noitanimullI 2.5 Ultra light focus lens 21.5 30.8 13.1 1.01 85 24.5 23.6 15.45 500 400 300 200 100 -4 -3 -2 -1 0 13 1 2 3 4 5 Position (mm) 0 -10 -8 -6 -4 -2 0 2 4 6 8 10 Position (mm) Never look directly at or allow your skin to be exposed to the ultraviolet light. Ultraviolet light will damage vision and skin if it is viewed directly or the skin is exposed. Workers shall wear protective goggles and equipment to protect from being exposed to light reflection. Never disassemble the Unit. Disassembling the Unit may lead to electric shock or damage from light leakage. This document provides information mainly for selecting suitable models. Please read the document User's Manual (Z257/Z260) carefully for information that the user must understand and accept before purchase, including information on warranty, limitations of liability, and precautions. OMRON Corporation Industrial Automation Company Authorized Distributor: Tokyo, JAPAN Contact: www.ia.omron.com Regional Headquarters OMRON EUROPE B.V. Sensor Business Unit OMRON ELECTRONICS LLC Carl-Benz-Str. 4, D-71154 Nufringen, Germany Tel: (49) 7032-811-0/Fax: (49) 7032-811-199 One Commerce Drive Schaumburg, IL 60173-5302 U.S.A. Tel: (1) 847-843-7900/Fax: (1) 847-843-7787 OMRON ASIA PACIFIC PTE. LTD. OMRON (CHINA) CO., LTD. No. 438A Alexandra Road # 05-05/08 (Lobby 2), Alexandra Technopark, Singapore 119967 Tel: (65) 6835-3011/Fax: (65) 6835-2711 Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road, PuDong New Area, Shanghai, 200120, China Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200 © OMRON Corporation 2009 All Rights Reserved. In the interest of product improvement, specifications are subject to change without notice. CSM_1_2_0512 Printed in Japan Cat. No. E364-E1-03 0512 (0212)