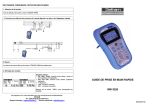

Download C.A 6030 - Chauvin Arnoux

Transcript