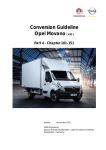

Download Conversions Guidelines (X82)

Transcript