Download User Manual - All Floor Supplies

Transcript

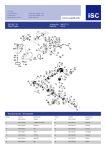

Operating manual EXTRO-STRIPPER 230 V /50 Hz English Item-No. 038588 EXTRO-STRIPPER 115 V /50-60 Hz Item-No. 039121 Read before use and keep safe Contents Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11 Information about various floorings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13 Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 13 Spare Parts / drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .appendix 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 8 1.0 Technical Data Comes with Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . .230 V / 115 V Power consumption . . . . . . . . . . . . . . . . . . .2500 W / 2300 W Number of strokes . . . . . . . . . . . . . . . . . . . .5000 strokes/min Sound pressure level . . . . . . . . . . . . . . . . . . . . . . . . .92 dB(A) Sound energy level . . . . . . . . . . . . . . . . . . . . . . . . .105 dB(A) Hand/Arm-Vibration . . . . . . . . . . . . . . . . . . . . . . . . . .10 m/s2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122 kg EXTRO-STRIPPER Spare blade Ear protectors Thread Plug Tools Operating manual Safety gloves 2.0 Declaration of conformity We declare under our sole responsibility that this product is in conformity with the following standards of standardization documents: EN 50 144, according to the provisions of the Directives 73/23/EWG, 89/336/EWG 98/37 EG 05 Dipl.-Ing. (FH) Dieter Hammel Konstruktionsleitung i.V. WOLFF | Eine Marke der Uzin Utz Gruppe | D-71665 Vaihingen/Enz | Dieselstraße 19 3.0 Safety instructions Disconnect the power supply before any maintenance is carried out. Use only recommended blades and ensure it is sharp before starting. Maintenance should be undertaken only by qualified personnel. Use only genuine Wolff spare parts. Transport To avoid harm or danger, always remove the blade before transporting the machine. Disconnect the power supply and the plug of the motor before removing the handle. Always wear ear protectors! The user and any person not far off should always use ear protectors! See supplementary sheet "General safety instructions" 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 9 3.1 Introduction This operating manual should be used to get the most benefit from your EXTRO-STRIPPER. Following these instructions will both extend the life of your machine and reduce repair costs. Please ensure any user of the machine is fully familiar with the instructions for use before allowing work to start. 3.2 Danger while working with the machine Use this machine only as instructed in this operating manual with the machine in perfect working order. The EXTRO-STRIPPER is designed to the highest technical standards. Incorrect use can be dangerous! Disturbances that could impair safety, have to be eliminated at once. 3.3 Restriction of use WOLFF cannot be held responsible for any damage or loss caused by incorrect use Correct use also includes to take care of all directions from the operating manual and the execution of maintenance and service. The EXTRO-STRIPPER is exclusively for removing bonded floor coverings in dry environments. It should not be used for any other purpose. Wolff cannot be held responsible for any damage or loss caused by incorrect use. 3.4 Genuine Spare Parts Spare parts and accessories are manufactured uniquely for the Turbo- Stripper. It must be emphasized that parts obtained from unauthorized sources must not be used. Wolff cannot be held responsible for the performance of or any damage arising from the use of machines in which genuine spare parts have not been used. This is particularly important with replacement blades. 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 10 4.0 Maintenance The EXTRO-STRIPPER is virtually maintenance-free. Have the guides of the swing bolts lubricated from time to time (after approx. 500 square meters). Lubricator nipples The lubricator nipples are located collateral on the front side (see picture). The used grease will flush dirt out of the machine. Press maximum 3 to 4 times with the grease gun. Never press too much grease into the machine. Otherwise the mechanism will be blocked. Changing the blade Disconnect the power supply before changing the blade. Use work gloves for your own safety. tip the machine put on the blade protection (enclosed in the tools set) Warning! Very sharp blade! You may cause injury without using the blade protection! secure the tipped machine from tilting over clean and loosen the screws of the blade mounting, Attention! Set the wrench at a position opposite to the blade to avoid injury. replace the blade. 2 Make sure that the blade fits in exactly into the support. On normal and hard subfloors the bevel of the blade should show upwards (1), on soft subfloors (e.g. chipboards) the bevel should show downwards (2). 1 Changing the driving wheels Remove the splint-pins and pull the wheels from the axle. Do not loose the springs (Pos. 53) under any circumstances! 52 53 32 30 5.0 Use The EXTRO-STRIPPER removes any bonded floor coverings in strips. This procedure corresponds with the customary method of using a hand floor scraper. The stripper works with a thin steel blade at very high frequency, minimizing vibration and noise. The EXTRO-STRIPPER is self propelled. The motor actuates both the blade and the machine movement. The blade drive starts as soon as the machine is switched on. The hand clutch will engage the drive. 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 11 Preparations Before starting work, cut the floor covering into strips of about 35 cm. You cannot work faster if you cut wider strips. blade`s width Messerbreite 1 6 5 4 3 2 To begin, cut one strip crosswise. Then lift the floor slightly in order to get the blade underneath it. We recommend to cut the first strip at right angles to the main working direction. By so doing access to the adjacent strips is made easier. Cut the strips smaller if the floor covering is bonded very securely, e.g. with an epoxy adhesive. The blades are sharpened by the floor pavement. Therefore the blade only has to be changed if it is twisted or becomes worn. (Pic. 1) The driving wheels are subjected to wear. They have to be changed after approximately 16 mm (0.6 inch) of the surface has been worn away. Otherwise the working angle of the striking apparatus will not be correct especially critical with cork or foam backed carpets. 5.1 Pull Back (Pic. 2) The patented Pull Back system was developed to allow for an easy pulling back of the Extro Stripper. (Pic. 2) When you have reached a wall or another obstacle during your work, simpy pull the handle to lift the driving wheels. The machine comes to a standstill although the wheels continue to rotate. If you pull the handle more powerfully, you can pull back the machine to the place where the next lane is to be stripped off. If the handle is moved forward again, the driving wheels reach the floor again and the machine moves forward. (Pic. 3) When working, make sure the handle is pressed gently to the front so that the small transportation rollers are lifted. 5.1.1Locking the Pull Back system For certain floors, it may be required to lock the Pull Back system. Use the two screws in the lifting brackets. (Pic. 2) Unscrew the screws, press the handle to the front and tighten the screws through the lifting brackets to the angled clips. Screw 01/2006 If you pull the handle, the blade is lifted from the floor immediately without stopping the drive. EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 12 5.2 Switching on the machine The EXTRO-STRIPPER is equipped with a power-on indicator lamp and red lever located at the top of the switch housing. The switch has a restart protection for low-voltage failures. If the lamp does not indicate power-on, use another power socket or check power supply. The machine is switched on by pulling the red lever. The drive and the impact system start at the same time. When the red lever is released, the machine is switched off. Note the after-running of the machine. 6.0 Information about certain floor coverings Needlepunch felt and tufted carpets on jute hessian backings Cut into strips of approx. 35 cm (14 inch) width. If the flooring is bonded very tight, cut strips smaller. The machine should remove the flooring without slipping wheels. Carpets with foam backing A sharp blade is essential in order to ensure the floor covering is removed together with the foam backing. Remove floorings across the width, particularly if you have an uneven sub-floor. Tiles Use blade of the same width as the tiles and use a new blade. Tiles above size 30 x 30cm (12 x 12inch) have to be cut into half. If the sub-floor is uneven, use smaller blades. In all cases, check from time to time to ensure the blade is still sharp. If it is not or any distortion has occurred, replace it immediately. 7.0 Trouble Shooting Trouble Machine does not run Eventual cause Power supply disconnected blown fuse defective cable or plug Elimination Have machine repaired by a qualified electrician, respective change parts Undue force necessary or excessive vibration Blade is blunt Change blade Excessive vibration Expendable parts are worn out Return machine for service and/or repair 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 13 Ersatzteilliste / Spare parts list / Liste des pièces de rechange Pos 1 4 5 6 8 12 13 20 21 22 23 25 26 27 28 30 32 33 34 35 36 37 38 39 40 41 42 46 48 49 52 53 54 57 58 61 62 63 64 65 66 67 68 69 70 71 72 73 75 76 77 77 77 78 79 Pcs 1 2 14 20 1 1 2 1 1 9 4 2 6 2 2 2 2 1 4 6 1 1 1 1 1 2 2 2 1 1 1 2 1 2 2 1 1 1 2 2 1 2 2 1 1 1 1 2 4 8 1 1 1 1 1 01/2006 Art.No 015106 016228 014736 014860 014914 038533 014735 038536 015127 014734 014763 015132 014833 014744 015417 014888 015135 021505 014741 014861 021599 032752 032743 032741 032747 032746 014703 014859 015140 014938 015142 014902 015036 033399 014886 014904 015144 014875 014710 014856 014850 014712 014853 015145 014901 014903 014852 017079 014742 014876 015057 015056 019910 015129 014973 Bezeichnung Rahmenplatte Führungshülse 4kt Zylinderschraube M8x30 Schnorrscheibe 8 mm Schmiernippel Haube Zylinderschraube M8x25 Abweiser Schwingerkopf Zylinderschraube M8x20 Senkschraube M10x25 Führungshülse U-Scheibe, 13 mm Zylinderschraube M12x30 Pleuellager Klappsplint Antriebsrad B16, glatt Getriebehalterung, rechts compl. Zylinderschraube M10x45 Schnorrscheibe 10 mm T-Schraube Gummipuffer Extro Anhebewinkel rechts Extro Anhebewinkel links Extro-Str. Transportachs Extro Klemmlasche Extro-Str Kugellager 6004 Schnorrscheibe, 6 mm Getriebe Zahnriemen Antriebsachse Passfeder 5x5x32 Getriebehalterung, links compl. Transportrad Splint 3,2x32 Paßfeder 6x6x32 Pleuel Pleuelbolzen Kugellager 6206 Seegerring I62 Seegerring A17 Kugellager 6305 Seegerring A 30 Exzenterwelle Paßfeder 4x4x20 Paßfeder 6x6x25 Seegerring A25 Lagerbock, re/li Zylinderschraube M10x70 Zylinderstift 8x40 Motor, 230V Motor, 115V Motor, 100V Zahnscheibe Zuleitung, kurz, Schuko WOLFF EXTRO-STRIPPER 2 02/2006 Description Chassis Piston block Screw M 8x30 Washer, 8 mm Lubricating nippel Cover Screw M8x25 Blade holder Striking foot Turbo Cyl. screw M8x20 Screw M10x25 Piston rods Washer, 13 mm Screw M12x30 Connecting block Wheel pin Drive wheel B16 Gear mounting block, right compl. Screw M10x45 Safety washer, 10 mm T-Screw short Rubber stop Lift bracket right Lift bracket left Transport axle Bracket Ball bearing 6004 Washer, 6 mm Gear block Drive belt Drive shaft axle Key 5x5x32 Gear mounting block, left compl. Nylon wheel Split-pin 3,2x32 Nut key 6x6x32 Connecting rod Connecting rod pin Ball bearing 6206 Circlip I62 Circlip A17 Ball bearing 6305 Circlip A 30 Excenter shaft Turbo Nut key 4x4x20 Key 6x6x25 Circlip A 25 Bearing block, right/left Screw M10x70 Cyl. pin 8x40 Motor, 230V Motor, 115V Motor, 100V Drive sprocket Electrical cord with plug EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM Dénomination Plaque à cadre Douille de guidage, carrée Vis à tête cylindrique M8x30 Disque Schnorr 8 mm Graisseur Capot Vis à tête cylindrique M8x25 Déflecteur Tête porte-lame oscillante Vis à tête cylindrique M8x20 Vis à tête conique M10x25 Douille de guidage Rondelle, 13 mm Vis à tête cylindrique M12x30 Coussinet de bielle Goupille fendue à charnière Roue d'entraînement B 16, lisse Porte-engrenage à droite compl. Vis à tête cylindrique M10x45 Disque Schnorr 10 mm Vis T, court Manchette en caoutchouc coin à droite coin à gauche Arbre de transport Couvre-joint Roulement à billes 6004 Disque Schnorr, 6 mm Engrenage Courroie dentée Arbre de transmission Ressort d'ajustage 5x5x32 Porte-engrenage à gauche compl. Roue de transport Goupille 3,2x32 Ressort d'ajustage 6x6x32 Bielle Boulon de bielle Roulement à billes 6206 Anneau Truarc I62 Anneau Truarc A17 Roulement à billes 6305 Anneau Truarc A 30 Arbre excentrique Ressort d'ajustage 4x4x20 Ressort d'ajustage 6x6x25 Anneau Truarc A 25 Palier à droite/ gauche Vis à tête cylindrique M 10x70 Goupille cylindrique 8x40 Moteur, 230V Moteur, 115V Moteur, 100V Disque denté Alimentation, courte, contact sécurité 20 Pos 80 81 82 84 85 86 87 88 89 90 91 92 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 113 115 117 118 119 121 122 123 125 126 127 128 129 130 130 133 137 139 140 141 142 146 146 147 148 149 150 151 Pcs 1 4 4 1 1 1 1 1 1 2 2 2 1 1 5 1 1 1 4 1 2 1 2 1 1 1 1 2 1 1 1 1 4 1 4 2 1 2 1 2 1 1 1 1 2 2 2 2 1 1 1 1 1 2 2 1 1 01/2006 Art.No 016860 014721 014858 014937 038531 038508 038509 014974 038567 037953 018800 014735 015154 039202 014799 014970 015155 015156 014828 014845 018153 038606 014862 015164 038633 038506 038505 038566 039234 015130 014724 014910 014835 014984 118141 014737 039188 018284 032751 014992 015125 017559 013978 013979 015107 017452 018259 038585 014816 014848 017439 021237 020969 038284 038568 017473 038584 Bezeichnung Motorwinkel universal Zylinderschraube M5x25 Schnorrscheibe 5 mm Zahnriemen SG-Stielhalterung Aussenrohr Innenrohr Zuleitung m Kupplung Klemmhebel M10x16 Arretierbolzen Stopfen Zylinderschraube DIN 912 M8x25 Abdeckung Griffrohr Linsenflansch-Kopfschraube Zuleitung, lang Zahnriemenscheibe Z 24 Zahnriemenscheibe Z 12 U-Scheibe Ø 8,4 Kompaktnutring Sechskantschraube DIN 933 M8x22 Halter für Bügel Schnorrscheibe 12 mm Anlaufscheibe Bügel Schaltergehäuse Deckel Klemmhebel M10x50 Dreisternschraube M10x80 Motordeckel, neu Zylinderschraube M5x90 Buchse 20x26x30 Scheibe Signalleuchte 230V Etikett Zylinderschraube M8x35/912 Kabelkanal Zylinderschraube M4x12/912 Totmanngriff Verschraubung PG 11 Fuß-Stütze Zugentlastung Ersatzmesser 1,0 Ersatzmesser 1,5 Lasche U-Scheibe Ø 4,3 Zylinderschraube 912/M6x60 Verschr. m. Biegeschutz M16x1,5 Stopmutter DIN 985 M8 Zahnscheibe DIN 6797-A4.3 Schütz 115V Schütz 230V Hutschiene Zylinderschraube M6x105 Griffbezug Messingschraube 84/M4x8 Verschr. m. Biegeschutz M12x1,5 Description Motor plate, new Screw M 5x25 Washer, 5 mm Drive belt Handle bracket Outer tube Inner tube Electrical cord Clamping lever Arresting bolt Stopper Cylindrical screw Cover Handle complete Screw Electrical cord, long Belt pulley Z 24 Belt pulley Z 12 Washer Ø 8,4 Groove ring Hexagon bolt Bracket Washer, 12 mm Starter disc Rod Switch housing Cover Clamping lever Screw Motor cover, new Screw M 5x90 Bush 20x26x30 Washer Indicator 230V Etikett Cyl. screw M8x35 Cable pit Cyl. screw M4x12/912 Dead man grip Protective cut-out switch Tilt support Strain relief Replacement blade 1,0 Replacement blade 1,5 Bracket Washer Ø 4,3 Cylincrical screw Fitting Stop nut Washer Contactor 115V Contactor 230V Top hat rail Cylincrical screw Grip covering Screw 84/M4x8 Fitting EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM Dénomination Equerre moteur Vis à tête cylindrique M5x25 Disque Schnorr, 5 mm Courroie dentée Porte-manche Tube extérieur Tube intérieur Alimentation, courte, Levier de serrage Axe d'arrêttage Bouchon Vis à tête cylindrique Recouvrement Tube d` poignée Bride bombée, vis à tête goutte-de-suif Alimentation, longue Disque de courroie dentée Z 24 Disque de courroie dentée Z 12 Rondelle Ø 8,4 Joint en U à lèvres Vis à tête hexagonale Fixation Disque Schnorr 12 mm Disque de démarrage Etrier Couvercle de levier Couvercle Levier de serrage Vis Spax Couvercle de moteur Vis à tête cylindrique M5x90 Douille 20x26x30 Disque Indicateur 230V Etiquette Vis à tête cylindrique M8x35 Conduite de câbles Vis à tête cylindrique M4x12/912 Homme mort prise Disjoncteur de protection Manche de sécurité Décharge de traction Lame de rechange 1,0 Lame de rechange 1,5 Couvre-joint Disque Ø 4,3 Vis cylindrique Fermeture Ecrou d´arrêt Rondelle Contacteur 115V Contacteur 230V Barre Vis cylindrique Coussinets pour poignée Vis 84/M4x8 Fermeture 21 Pos 153 154 155 156 158 157 Pcs 2 1 2 1 1 1 Art.No 038581 014696 018280 039636 021232 014844 Bezeichnung Schalter f. Totmanngriff Sanftanlauf Zylinderschraube 912/M4x8 Abkippstütze Flanschkopfschraube Federring Description Switch Current limitor Cylincrical screw Column Counter sink screw Split washer Zubehör / accessories / accessoires Extro Stripper 1 1 38590 Anleitung Extro 3-sprachig 2 2 015161 Tragegriff m.Kette 3 1 015162 Werkzeugsatz TURBO 4 1 015315 Gehörschützer 5 1 015809 Schutzhandschuhe, 1 Paar 6 1 017661 Kontrollnachweis 7 1 107287 Einlage Systemstiel 8 1 107291 Holzkiste 9 1 107299 Karton Systemstiel 11 1 Messerschutz Dénomination Interrupteur Limiteur de courant Vis cylindrique Pilier Vis à tête conique Rondelle éalstique bombée Operating manual Grip with chain Tool kit Ear protector gloves Certificate Stiffening handle Wooden box Board handle Thread Plug Mode d‘emploi Poignée de manutention avec chaîne Jeu d'outils protection de l’ouïe gants Preuve Apport manche Caisse en bois carton manche Bouchon filetée 108 Explosion Stiel EXTRO-Stripper 20.01.06 121 146 155 155 154 137 150 141 147 142 107 100 125 149 126 140 119 151 129 139 102 100 123 153 140 86 148 6 92 91 87 157 90 122 95 149 158 156 89 90 97 88 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM 22 M braun braun Schaltplan EXTRO-Stripper 230 V 24.01.2006 Motor Pos:77 T3 A2 A2 Signalleuchte Pos:116 schwarz Schütz Pos:146 schwarz Sanftanlauf Pos:154 T2 L3 A1 T1 L2 L1 L N PE Gehäuse Pos:107 Schalter Pos:153 T3 A2 A2 A1 Motor Pos:77 T2 L3 Signalleuchte Pos:116 Schaltplan EXTRO-Stripper 100/115 V 24.01.2006 Schütz Pos:146 M T1 L2 L1 L N PE Schalter Pos:153 01/2006 EXTRO-STRIPPER 2, 230 V Artikel. Nr 038588, 115 V Item-No. 039121,RÄSM Gehäuse Pos:107 23 32 49 75 35 73 130 22 23 66 99 46 35 96 34 EXTRO-Stripper Art. Nr. 038588 24.01.2006 20 30 42 25 80 76 26 81 67 27 21 104 82 105 33 117 28 5 6 1 76 78 22 6 63 84 77 115 79 113 92 103 92 28 92 94 68 96 118 4 8 62 133 22 41 64 106 92 64 22 41 65 70 48 76 73 35 75 69 57 22 67 61 101 52 71 68 53 38 39 37 58 26 110 53 34 12 46 96 117 42 98 72 54 90 22 32 85 6 30 57 22 26 40 58 6 109 22 128 WOLFF | Eine Marke der Uzin Utz Gruppe WOLFF | Eine Marke der Uzin Utz Gruppe | D-71665 Vaihingen/Enz | Dieselstraße 19 | Tel. +49 (0)70 42 95 11- 0 | Fax +49 (0)70 42 95 11- 44 | E-Mail [email protected] | Internet www.uzin-utz.com 24