Download STM3210C-EVAL evaluation board

Transcript

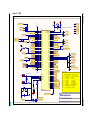

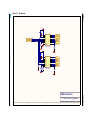

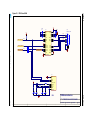

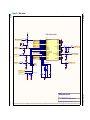

UM0600 User manual STM3210C-EVAL evaluation board Introduction The STM32F107VCT evaluation board STM3210C-EVAL is designed as a complete development platform for STMicroelectronic's ARM Cortex-M3 core-based STM32F107VCT microcontroller with full speed USB-OTG, ethernet MAC, two channels of CAN2.0A/B compliant interface, 2 channels I2S, 2 channels I2C, 5 channels USART with smartcard support, 3 channels SPI, internal 64 KB SRAM and 256 KB Flash, JTAG and SWD debugging support. The full range of hardware features on the board help you evaluate all peripherals (USBOTG FS, ethernet, motor control, CAN, microSD CardTM, smartcard, USART, audio DAC, MEMS, EEPROM… etc.) and develop your own applications. Extension headers make it easy to connect a daughterboard or wrapping board for your specific application. Figure 1. February 2011 STM3210C-EVAL evaluation board Doc ID 15082 Rev 4 1/52 www.st.com Contents UM0600 Contents 1 2 3 2/52 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 Demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.3 Order code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Hardware layout and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.2 Boot option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.3 Clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.4 Reset source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.5 Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.6 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.7 CAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.8 RS-232 and IrDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.9 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 2.10 Smartcard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 2.11 MicroSD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 2.12 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 2.13 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 2.14 USB-OTG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 2.15 MEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.16 Development and debug support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.17 Display and input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 2.18 IDD measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3.1 Motor control connector CN17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3.2 Analog input connector CN10 and CN11 . . . . . . . . . . . . . . . . . . . . . . . . . 20 3.3 CAN D-type 9-pin male connector CN3 and CN4 . . . . . . . . . . . . . . . . . . 20 3.4 Ethernet RJ45 connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.5 Trace debugging connector CN12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Doc ID 15082 Rev 4 UM0600 4 Contents 3.6 RS-232 connector CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.7 JTAG debugging connector CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.8 Daughterboard extension connector CN8 and CN9 . . . . . . . . . . . . . . . . . 23 3.9 Audio jack CN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 3.10 TFT LCD connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 3.11 MicroSD card connector CN16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.12 USB MicroAB connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.13 Power connector CN18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 3.14 Smartcard connector CN5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Appendix A STM3210C-EVAL I/O assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Doc ID 15082 Rev 4 3/52 Overview UM0600 1 Overview 1.1 Features 1.2 ● Three 5 V power supply options: Power jack, USB connector or daughterboard. ● Boot from user Flash, system memory or SRAM. ● I2S audio DAC, stereo audio jack. ● 2 GByte (or more) microSD CardTM. ● Both type A and B smartcard support. ● I2C compatible serial interface 64 Kbit EEPROM, MEMS and I/O expander. ● RS-232 communication. ● IrDA transceiver. ● USB-OTG full speed, USB microAB connector. ● IEEE-802.3-2002 compliant ethernet connector. ● Two channels of CAN2.0A/B compliant connection. ● Inductor motor control connector. ● JTAG and trace debug support. ● 3.2" 240x320 TFT color LCD with touch screen. ● Joystick with 4-direction control and selector. ● Reset, Wakeup, Tamper and User button. ● 4 color LEDs. ● RTC with backup battery. ● MCU consumption measurement circuit. ● Extension connector for daughterboard or wrapping board. Demonstration software Demonstration software is preloaded in the board’s Flash memory for easy demonstration of device peripherals in stand-alone mode. For more information and to download the latest version available, please refer to STM3210C-EVAL demonstration firmware available on the web: www.st.com/mcu. 1.3 Order code To order the STM32F107VCT evaluation board, use the order code STM3210C-EVAL. 4/52 Doc ID 15082 Rev 4 UM0600 Hardware layout and configuration 2 Hardware layout and configuration The STM3210C-EVAL evaluation board is designed around the STM32F107VCT in a 100pin LQFP package. The hardware block diagram Figure 2 illustrates the connection between the STM32F107VCT and peripherals (LCD, EEPROM, MEMS, USART, IrDA, USB-OTG, ethernet, audio, CAN bus, smartcard, microSD card and motor control) and Figure 3 helps you locate these features on the actual evaluation board. Figure 2. Hardware block diagram I2S2 3.3V regulator MCU consumption measurement LEDs,Key Audio DAC I2C1 MEMS EEPROM GPIO Joystick Extension connector for GPIOs I/O expander Touchscreen TFT LCD USB microAB connector OTG MicroSD Card SPI3 MC control connector MC JTAG USB power switch STM32F107VCT MII/RMII 2 BNC connector CAN transceiver CAN DB9 connector CAN2 CAN transceiver CAN DB9 connector RS-232 transceiver USART 2 DB9 connector ADC USART2 IrDA transceiver Potentiometer Battery voltage measurement Integrated RJ45 connector CAN1 Debug Trace PHY USART3 Doc ID 15082 Rev 4 Smartcard interface Smartcard connector 5/52 Hardware layout and configuration Figure 3. UM0600 STM3210C-EVAL evaluation board layout CN10, CN11 BNC CN8, CN9 Extension header CN17 Motor control CN1 RJ45 connector CN4 CAN2 CN6 RS-232 U9 STM32F107VCT CN3 CAN1 CN2 USB microAB connector CN12 Trace CN18 5V power CN13 JTAG CN7 Audio jack CN14 Color LCD CN16 MicroSD card U12 IrDA CN5 Smartcard RV1 Potentiometer B1 Reset B3 User key B2 Wakeup 6/52 B4 Tamper Doc ID 15082 Rev 4 U15 Joystick UM0600 2.1 Hardware layout and configuration Power supply The STM3210C-EVAL evaluation board is designed to be powered by a 5 V DC power supply and to be protected by PolyZen from a wrong power plug-in event. It is possible to configure the evaluation board to use any of following three sources for the power supply. ● 5 V DC power adapter connected to CN18, the power jack on the board (PSU on silk screen for power supply unit). ● 5 V DC power with 500 mA limitation from CN2, the USB MicroAB connector (USB on silkscreen). ● 5 V DC power from both CN8 and CN9, the extension connector for daughterboard (DTB for daughterboard on silkscreen). The power supply is configured by jumpers JP24 and JP25 as described in Table 1. To enable MCU power consumption measurement, JP1, JP14 and JP23 should be reconfigured as described in Table 2. Table 1. Power related jumpers Jumper Description PSU DTB USB For power supply from the daughterboard connectors (CN8 and CN9) to STM3210C-EVAL only, JP25 is set as shown: PSU DTB USB JP25 selects one of the three possible power supply resources. For power supply jack (CN18) to the STM3210C-EVAL only, JP25 is set as shown: (Default) Configuration JP25 Vbat is connected to 3.3 V power when JP24 is set as shown: (Default) PSU DTB USB For power supply from power supply jack (CN18) to both STM3210CEVAL and daughterboard connected on CN8 and CN9, JP25 is set as shown to the right (the daughterboard must not have its own power supply connected): PSU DTB USB For power supply from USB (CN2) to STM3210C-EVAL only, JP25 is set as shown: 1 2 3 JP24 Vbat is connected to battery when JP24 is set as shown: Warning: 1 2 3 When the board is connected to a USB host via CN2 and powered by an external power supply (JP25 in position PSU) it is mandatory to remove the USB cable when the external power supply is OFF, else an unexpected current is provided by USB VBUS which maintains a residual voltage on the board. Doc ID 15082 Rev 4 7/52 Hardware layout and configuration UM0600 Table 2. MCU power consumption measurement related jumpers Jumper Description PC13 is connected to anti-tamper button when JP1 is set as shown: (Default) JP1 PC13 is connected to MCU consumption measurement circuit as IDD_CNT_EN signal when JP1 is set as shown. In this position PC13 is reserved to enable or clear the counter U24 used to measure IDD when the MCU is in low power mode. Configuration 1 2 3 1 2 3 PA0 is connected to WUKP button and MCU power consumption measurement circuit as LP_WAKEUP when JP14 is set as shown: 1 2 3 PA0 is connected to ethernet PHY as signal MII_CRS when JP14 is set as shown: (Default) 1 2 3 JP14 Connect +3.3V power to MCU directly when JP23 is set as shown: The MCU current consumption measurement can be done manually by an ammeter connected on PJ23 pin 1 & 2. (Default) JP23 Connect +3.3 V power to MCU with MCU current-sampling resister (1 ohm or 1 Kohm) in series and IDD current measurement circuit in parallel when JP23 is set as shown to the right. MCU power consumption measurement is enabled. 1 2 3 1 2 3 The LED LD7 is lit when the STM3210C-EVAL board is powered by the 5 V correctly. 8/52 Doc ID 15082 Rev 4 UM0600 2.2 Hardware layout and configuration Boot option The STM3210C-EVAL board is able to boot from: ● Embedded user Flash ● System memory with boot loader for ISP ● Embedded SRAM for debugging The boot option is configured by setting switches SW1 (BOOT1) and SW2 (BOOT0). The BOOT0 can be configured also via the RS-232 connector CN6 when JP18 is fitted. Table 3. Boot related switches Switch Boot from Configuration STM3210C-EVAL boots from User Flash when SW2 is set as shown to the right. SW1 setting does not matter in this configuration. (Default) SW1 and SW2 SW2 0< >1 SW1 STM3210C-EVAL boots from System Memory when SW1 and SW2 are set as shown: SW2 0< >1 SW1 STM3210C-EVAL boots from Embedded SRAM when SW1 and SW2 are set as shown: SW2 0< 2.3 >1 Clock source Two clock sources are available on the STM3210C-EVAL evaluation board for STM32F107VCT and RTC is embedded. 2.4 ● X2, 32 kHz crystal for embedded RTC. ● X3, 25 MHz crystal with socket for an STM32F107VCT microcontroller, it can be removed from the socket when an internal RC clock is used. Reset source The reset signal of the STM3210C-EVAL board is active low and the reset sources include: ● Reset button, B1 ● Debugging tools from JTAG connector CN13 and trace connector CN12 ● Daughterboard from CN9 ● RS-232 connector CN6 for ISP when JP19 is fitted. Table 4. Jumper JP20 Reset related jumper Description Enables reset of the STM32F107VCT embedded JTAG TAP controller each time a system reset occurs. JP20 connects the TRST signal from the JTAG connection with the system reset signal RESET#. Default setting: Not fitted. Doc ID 15082 Rev 4 9/52 Hardware layout and configuration 2.5 UM0600 Audio The STM3210C-EVAL evaluation board supports stereo audio play by using an audio DAC CS43L22 connected to both an I2S2 port and one channel of the DAC of microcontroller STM32F107VCT. The CS43L22 can be configured via the I2C1 bus when JP9 is fitted (default setting). The automatic switch between the speaker and headphone is performed by both CS43L22 and the audio jack with plug detection pin. 2.6 EEPROM A 64 Kbit EEPROM connected to the I2C1 bus of STM32F107VCT. Table 5. EEPROM related jumper Jumper JP17 2.7 Description The EEPROM is in Write protection mode when JP17 is open. Default setting: Fitted. CAN The STM3210C-EVAL evaluation board supports two channels of CAN2.0A/B compliant CAN bus communication based on a 3.3 V CAN transceiver. High-speed mode, standby mode and slope control mode are available and can be selected by setting JP7 for CAN1 and JP8 for CAN2. Note: JP9 should be kept open for CAN2 to avoid any impact from pull-up on I2C1 bus. Table 6. CAN1 related jumpers Jumper Description CAN1 transceiver works in standby mode when JP7 is set as shown: JP7 CAN1 transceiver works in high-speed mode when JP7 is set as shown: (Default) Configuration 1 2 3 1 2 3 CAN1 transceiver works in slope control mode when JP7 is open. JP5 Table 7. Jumper CAN1 terminal resistor is enabled when JP5 is fitted. Default setting: Not fitted CAN2 related jumpers Description CAN2 transceiver works in standby mode when JP8 is set as shown: JP8 CAN2 transceiver works in high-speed mode when JP8 is set as shown: (Default) CAN2 transceiver works in slope control mode when JP8 is open. JP6 10/52 CAN2 terminal resistor is enabled when JP6 is fitted. Default setting: Not fitted Doc ID 15082 Rev 4 Configuration 1 2 3 1 2 3 UM0600 2.8 Hardware layout and configuration RS-232 and IrDA Both RS-232 and IrDA communications are supported by D-type 9-pin RS-232 connectors CN6 and IrDA transceiver U12 which connect to USART2 of the STM32F107VCT on the STM3210C-EVAL evaluation board. Two signals, Bootloader_BOOT0 and Bootloader_RESET, are added on the RS-232 connector for ISP support. RS-232 or IrDA are selected by setting JP16. Table 8. RS-232 and IrDA related jumpers Jumper Description Configuration USART2_RX is connected to RS-232 transceiver and RS-232 communication is enabled when JP16 is set as shown: (Default) 1 2 3 USART2_RX is connected to IrDA transceiver and IrDA communication is enabled when JP16 is set as shown: 1 2 3 JP16 Note: JP18 Bootloader_BOOT0 is disconnected from CN6 when JP18 is open. Default setting: Not fitted JP19 Bootloader_RESET is disconnected from CN6 when JP19 is open. Default setting: Not fitted To communicate with an RS-232 port on a PC, a 9-pin straight RS-232 cable (direct pin to pin connection) is needed since: ● On CN6 the RX signal is connected on pin 2 and the TX data on pin 3, ● On the PC side the RX signal is generally on pin 3 and the TX signal on pin 2. This standard 9-pin straight RS-232 cable is not provided with the board. Refer to Section 3.6 for details on RS-232 connector pinout. Doc ID 15082 Rev 4 11/52 Hardware layout and configuration 2.9 UM0600 Motor control The STM3210C-EVAL evaluation board supports a three-phase brushless motor control via a 34-pin connector CN17, which provides all required control and feedback signals to and from a motor power-driving board. Available signals on this connector include emergency stop, motor speed, 3 phase motor current, bus voltage, heat sink temperature from the motor driving board and 6 channels of PWM control signal going to the motor driving circuit. JP 22 selects one of two kinds of synchronization methods for PFCs (power factor correction). The I/O pins used on the motor control connector CN17 are multiplexed with some peripherals on the board; either motor control connector or multiplexed peripherals can be enabled by setting jumpers JP10, JP21, JP22 and JP26. Table 9. Jumper Motor control related jumpers Description Configuration peripherals JP22 JP22 allows a PFC synchronization signal to be redirected to the timer 4 input capture 3 pin, additionally to the timer 4 external trigger input. Default setting: Not fitted. JP21 JP21 should be kept open when encoder signal is input from pin31 of CN17 while it should be kept on close when analog signal is from pin31 of CN17 for special motor. Default setting: Not fitted. MC_EnA is enabled when JP10 is set as shown: 1 2 3 JP10 Audio I2S_MCK is enabled when JP10 is set as shown: (Default) JP26 12/52 Multiplexed PE0 is connected to SD card detection when JP26 is fitted. JP26 should be kept open when PE0 is used as MC_PFCsync2. Default setting: Fitted Doc ID 15082 Rev 4 1 2 3 MicroSD card UM0600 2.10 Hardware layout and configuration Smartcard STMicroelectronic’s smartcard interface chip ST8024 is used on the STM3210C-EVAL board for asynchronous 3 V and 5 V smartcards. It performs all supply protection and control functions based on the connections with the STM32F107VCT listed in Table 10: Table 10. Connection between the ST8024 and STM32F107VCT Signals of ST8024 Description Connect to STM32F107VCT 5V/3V Smartcard power supply selection pin PC0 I/OUC MCU data I/O line PD8 XTAL1 Crystal or external clock input PD10 OFF Detect presence of a card, interrupt to MCU PE7 RSTIN Card reset input from MCU PD9 CMDVCC Start activation sequence input (active low) PE14 Some jumpers must be re-configured to enable smartcard. Note: Two test points TP2 and TP3 are available on the board for AUX2 (auxiliary line to and from card C8) and AUX1 (auxiliary line to and from card C4). Table 11. Jumper Smartcard related jumpers Description Configuration PD10 is connected to ethernet PHY as signal MII_RXD1 when JP11 is set as shown: (Default) 1 2 3 PD10 is connected to smartcard interface chip as signal smartcard_CLK when JP11 is set as shown: 1 2 3 PD9 is connected to ethernet PHY as signal MII_RXD0 when JP12 is set as shown: (Default) 1 2 3 PD9 is connected to smartcard interface chip as signal smartcard_RST when JP12 is set as shown: 1 2 3 PD8 is connected to ethernet PHY as signal MII_RX_DV/RMII_CRSDV when JP13 is set as shown: (Default) 1 2 3 PD8 is connected to smartcard interface chip as signal smartcard_IO when JP13 is set as shown: 1 2 3 JP11 JP12 JP13 Doc ID 15082 Rev 4 13/52 Hardware layout and configuration 2.11 UM0600 MicroSD card The 2 GByte (or more) microSD card connected to SPI3 of STM32F107VCT is available on the board. MicroSD card detection is managed by the standard I/O port PE0. JP15 must remain fitted to enable microSD card chip select. Table 12. MicroSD card related jumper Description Jumper 2.12 JP15 JP15 enables microSD card chip select line. MicroSD card chip select is enabled when JP15 is fitted. JP15 should be kept open when PA4 is configured as a DAC output for audio DAC. Default setting: Fitted. JP26 PE0 is connected to SD card detection when JP26 is fitted. JP26 should be kept on open when PE0 is used as MC_PFCsync2. Default setting: Fitted. Analog input Two BNC connectors CN10 and CN11 are connected to PB0 and PA7 of the STM32F107VCT as external analog input when a motor control connector is not used. The 50 ohm terminal resister can be enabled by closing solder bridge SB3 and SB4 for each BNC connector. The test point TP7 and TP8 can be used for ADC precision measurement with BNC1 connector disconnected from PA7 by open SB5. A low pass filter can be implemented for each BNC connector by replacing R141 and C64, R143 and C65 with the value of resister and capacitor as requested by the end user’s application. There are also 3 analog signals available on the board: 14/52 1. 10 Kohm potentiometer RV1 connected to PC4. 2. IDD measurement output signal connected to PA6 for power consumption test in RUN, SLEEP and STOP mode. 3. Battery voltage measurement output signal connected to PC5. For battery voltage measurement VBAT is connected to ADC input using resistor divider since this voltage may be higher than MCU_VDD when the battery is new. The resistor divider 2/3 needs to be pulled low by an I/O expander (VBAT_DIV on EXP_IO12) in order to avoid permanent current on this bridge. Doc ID 15082 Rev 4 UM0600 2.13 Hardware layout and configuration Ethernet The STM3210C-EVAL evaluation board supports 10M/100M ethernet communication by a PHY DP83848CVV (U1) and integrated RJ45 connector (CN1). Both MII and RMII interface modes are supported and can be selected by setting jumpers JP2, JP3 and JP4. Table 13. Ethernet related jumpers Jumper JP2 Description Configuration JP2 selects MII or RMII interface mode. MII is enabled when JP2 is open while RMII interface mode is enabled when JP2 is fitted. Default setting: Not fitted. JP3 should be set as shown when MII interface mode is enabled. (Default) 1 2 3 JP3 JP3 should be set as shown when RMII interface mode is enabled. JP4 1 2 3 25 MHz clock for MII or 50 MHz clock for RMII is provided by MCO at PA8 when JP4 is set as shown: (Default) 1 2 3 25 MHz clock is provided by external crystal X1 (for MII interface mode only) when JP4 is set as shown: 1 2 3 JP4 has to be kept open when the clock is provided by external oscillator U2 (not fitted by default). Note: JP11, JP12, JP13 and JP14 are set to support ethernet by default, please verify the jumper configuration before ethernet demonstration. Note2: Test point TP1 is connected to 25MHz clock output pin of Ethernet PHY U1 which provide 25MHz or 50MHz clock for system in MII or RMII mode. Note3: Test point TP4 can be used for PTP_PPS feature only when R45 is removed. 2.14 USB-OTG The STM3210C-EVAL evaluation board supports USB-OTG full speed communication via a USB MicroAB connector (CN2) and a USB power switch (U3) connected to VBUS. The evaluation board can be powered by this USB connection at 5 V DC with a 500 mA current limitation. LED LD6 is lit: ● in Host mode when the power switch (U3) is ON (STM3210C-EVAL is acting as a USB host), ● in Device mode when a cable is connected to a PC (STM3210C-EVAL is acting as a USB device and VBUS is powered by another USB host). LD5 is lit when over-current occurs in Host mode. Doc ID 15082 Rev 4 15/52 Hardware layout and configuration 2.15 UM0600 MEMS An ST MEMS device LIS302DL is connected to the I2C1 bus of STM32F107VCT. 2.16 Development and debug support The two debug connectors available on STM3210C-EVAL evaluation board are: 16/52 1. CN13, standard 20-pin JTAG interface connector that is compliant with the debug tools of ARM7 and ARM9 and cortex M3. 2. CN12, SAMTEC 20-pin connector FTSH-110-01-L-DV for both SWD and trace that is compliant with ARM CoreSightTM debug tools. Doc ID 15082 Rev 4 UM0600 2.17 Hardware layout and configuration Display and input devices The 3.2” TFT color LCD connected to SPI3 and 4 general purpose color LED’s (LD 1,2,3,4) are available as display devices. A touch screen connected to an I/O expander (U7), 4-direction joystick with selection key, general purpose button (B3), wakeup button (B2) and tamper detection button (B4) are available as input devices. JP14 should be re-configured to enable wakeup button B2 which shares the same I/O as MII_CRS of the ethernet. You may refer to Table 2 for details. The STM3210C-EVAL board also supports a second optional 2.4” TFT LCD without touch screen that can be mounted on CN15 connector. The 2.4” TFT LCD is not populated by default. Table 14 shows both the LCD modules pin connections. Table 14. LCD modules 3.2" TFT LCD with touch screen CN14 (default) Pin on CN14 Description Pin connection 2.4" TFT LCD CN15 (optional) Pin on CN15 Description Pin connection 1 CS PB2 1 CS PB2 2 RS - 2 SCL PC10 3 WR/SCL PC10 3 SDI PC12 4 RD - 4 RS - 5 RESET RESET# 5 WR - 22 BL_GND GND 6 RD - 23 BL_control +5V 7 SDO PC11 24 VDD 3.3V 8 RESET RESET# 25 VCI 3.3V 9 VDD 3.3V 26 GND GND 10 VCI 3.3V 27 GND GND 11 GND GND 28 BL_VDD +5V 12 GND GND 29 SDO PC11 13 BL_VDD 3.3V 30 SDI PC12 14 BL_Control 3.3V 31 XL IO Expander 15 BL_GND GND 32 XR IO Expander 16 BL_GND GND 33 YD IO Expander 34 YU IO Expander Doc ID 15082 Rev 4 17/52 Hardware layout and configuration 2.18 UM0600 IDD measurement Figure 4. STM3210C-EVAL IDD measurement circuit The circuit above is implemented on STM3210C-EVAL for IDD measurement. In Run mode, IDD current is measured using MAX9938FEUK+ (U21) connected to the 1ohm shunt resistor. In this case IDD_CNT_EN remains high during measurement and JP23 jumper must be set to 2<->3. In Stop or Standby mode, the operational amplifier MAX9938FEUK+ (U21) is connected on the 1 Kohm shunt resistor. To measure a current corresponding to the Stop or Standby modes the procedure is: 1. Configure ADC to measure voltage on IDD_measurement pin. 2. Configure PA0 as interrupt input on falling edge. 3. Enter in Stop or Standby modes with IDD_CNT_EN Low. 4. LP_WAKEUP falling edge wakeup the MCU after 100 ms. 5. Start ADC conversion as soon as possible after wakeup in order to measure the voltage corresponding to Low power mode on 1 uF capacitor. 6. Reset the counter by programming IDD_CNT_EN High in less than 50 mS after the wakeup to avoid 1 Kohm to be connected later on VDD_MCU. In Stop or Standby modes, the 1K resistor is connected when T2 goes off after entering the Stop or Standby mode. Q13 output of the counter allows connection of the 1K resistor when the current IDD becomes very low. Figure 5 shows the measurement timing. 18/52 Doc ID 15082 Rev 4 UM0600 Figure 5. Hardware layout and configuration STM3210C-EVAL IDD Low power mode measurement timing diagram IDD measure Run Stop or Standby Wake-up Clear CNT MCU mode 0 150ms 300ms 450ms IDD_CNT_EN Q13=LOW_POWER_EN (T2 pin 3) Q14=LP_WAKEUP Q14n=Switch control (U22 pin 4) The Low power mode measurement procedure can be used in Stop or Standby modes if the IDD current does not exceed 60 uA, otherwise the Run mode measurement procedure should be used up to 60 mA. Doc ID 15082 Rev 4 19/52 Connectors UM0600 3 Connectors 3.1 Motor control connector CN17 Figure 6. Motor control connector CN17 viewed from above the PCB Table 15. Motor control connector CN17 Description 20/52 Pin of Pin number STM32F107VCT of CN17 Pin number Pin of Description of CN17 STM32F107VCT Emergency stop PE15 1 2 GND PWM-UH PE9 3 4 GND PWM-UL PE8 5 6 GND PWM-VH PE11 7 8 GND PWM-VL PE10 9 10 GND PWM-WH PE13 11 12 GND PWM-WL PE12 13 14 PHASE A current PA7 15 16 GND PHASE B current PB0 17 18 GND PHASE C current PB1 19 20 GND NTC bypass relay PD2 21 22 GND Dissipative brake PWM PA0 23 24 GND +5V power +5V 25 26 PFC SYNC PE0 and PD14 27 28 VDD_Micro PFC PWM PD15 29 30 GND Encoder A PC6 via JP10 31 32 GND Encoder B PC7 33 34 Doc ID 15082 Rev 4 PA5 PC0 PC8 Bus voltage Heat sink temperature Encoder index UM0600 3.2 Connectors Analog input connector CN10 and CN11 Figure 7. Analog input connector CN10 and CN11 viewed from the bottom Table 16. Analog input connector CN10 and CN11 Pin number 3.3 Description Pin number Description 1 GND 4 GND 2 GND 5 Analog input PB0 and PA7 for CN10 and CN11 respectively 3 GND CAN D-type 9-pin male connector CN3 and CN4 Figure 8. CAN D-type 9-pin male connector CN3 and CN4 viewed from the front Table 17. CAN D-type 9-pin male connector CN3 and CN4 Pin number 1,4,8,9 2 Description NC Pin number 7 CANL 3,5,6 Doc ID 15082 Rev 4 Description CANH GND 21/52 Connectors 3.4 UM0600 Ethernet RJ45 connector CN1 Figure 9. Ethernet RJ45 connector CN1 viewed from the front Table 18. RJ45 connector CN1 Pin number 3.5 Description Pin number Description 1 TxData+ 2 TxData- 3 RxData+ 4 Shield 5 Shield 6 RxData- 7 Shield 8 Shield Trace debugging connector CN12 Figure 10. Trace debugging connector CN12 viewed from above the PCB Table 19. 1 20 18 16 14 12 10 8 6 4 2 Trace debugging connector CN12 Pin number 22/52 19 17 15 13 11 9 7 5 3 Description Pin number Description 1 3.3V power 2 TMS/PA13 3 GND 4 TCK/PA14 5 GND 6 TDO/PB3 7 KEY 8 TDI/PA15 9 GND 10 RESET# 11 GND 12 TraceCLK/PE2 13 GND 14 TraceD0/PE3 or SWO/PB3 15 GND 16 TraceD1/PE4 or nTRST/PB4 17 GND 18 TraceD2/PE5 19 GND 20 TraceD3/PE6 Doc ID 15082 Rev 4 UM0600 3.6 Connectors RS-232 connector CN6 Figure 11. RS-232 connector CN6 with ISP support viewed from the front Table 20. RS-232 connector CN6 with ISP support Pin number 3.7 Description Pin number Description 1 Bootloader_RESET 6 NC 2 RS232_RX (PD6) 7 NC 3 RS232_TX (PD5) 8 Bootloader_BOOT0 4 NC 9 NC 5 GND JTAG debugging connector CN13 Figure 12. JTAG debugging connector CN13 viewed from above the PCB Table 21. 19 17 15 13 11 9 7 5 3 1 20 18 16 14 12 10 8 6 4 2 JTAG debugging connector CN13 Pin number Description Pin number Description 1 3.3V power 2 3.3V power 3 PB4 4 GND 5 PA15 6 GND 7 PA13 8 GND 9 PA14 10 GND 11 RTCK 12 GND 13 PB3 14 GND 15 RESET# 16 GND 17 DBGRQ 18 GND 19 DBGACK 20 GND Doc ID 15082 Rev 4 23/52 Connectors 3.8 UM0600 Daughterboard extension connector CN8 and CN9 Two 50-pin male headers CN8 and CN9 can be used to connect a daughterboard or standard wrapping board to the STM3210C-EVAL evaluation board. All 80 GPI/Os are available on it. The space between these two connectors and power position, GND and RESET pin are defined as a standard, which allows to develop common daughterboards for several evaluation boards. The standard width between CN8 pin1 and CN9 pin1 is 2700 mils (68.58mm). This standard is implemented on the majority of evaluation boards. Each pin on CN8 and CN9 can be used by a daughterboard after disconnecting it from the corresponding function block on the STM3210C-EVAL evaluation board. Please refer to Table 22 and Table 23 for details. Table 22. Pin Daughterboard extension connector CN8 Description Alternative function How to disconnect with function block on STM3210C-EVAL 1 GND - 3 PC7 MC Disconnect STM3210C-EVAL board from motor power drive board 5 PC9 USB power switch On Remove R36 7 PA9 USB VBUS Remove R78 9 PA0 MC/Ethernet/WKUP Keep JP14 open. Disconnect STM3210C-EVAL board from motor power drive board. 11 PC14 via SB1 32kHz oscillator Remove R161, close SB1 13 PA12 Remove R43 or disconnect USB cable 15 PC15 via SB2 32kHz oscillator 17 PC10 SPI1_CLK 19 GND - 21 PC12 SPI1_MOSI 23 PD1 CAN1_TX 25 PD3 LD3 27 PD5 USART2_TX 29 PD7 LD1 33 PB3 TDO/SWO 35 PB5 CAN2_RX Remove R45 37 PB7 I2C1_SDA Remove R132 39 GND - 41 PE2 Trace_CK 43 PE4 Trace_D1 45 PB8 MC USB_DP Remove R59, close SB2 Remove R96 Remove R94 31 24/52 Disconnect STM3210C-EVAL board from motor power drive board Doc ID 15082 Rev 4 UM0600 Table 22. Pin Connectors Daughterboard extension connector CN8 (continued) Description Alternative function How to disconnect with function block on STM3210C-EVAL 47 PE6 Trace_D3 49 D5V 2 PC6 I2S_MCK/MC JP10 open 4 PC8 MC Disconnect STM3210C-EVAL board from motor power drive board 6 PA8 MCO JP4 open 8 PA10 USB_ID Remove R38 or disconnect USB cable 10 GND 12 PA11 USB_DM Remove R42 or disconnect USB cable 14 PA13 TMS/SWDIO 16 PA14 TCK/SWCLK 18 PC11 SPI1_MISO 20 PA15 TDI 22 PD0 CAN1_RX Remove R44 24 PD2 MC Disconnect STM3210C-EVAL board from motor power drive board. 26 PD4 LD4 Remove R97 28 PD6 USART2_RX Keep JP16 open 30 GND Remove R135 and LCD 32 34 PB4 TRST Keep JP20 open 36 PB6 CAN2_TX/ I2C1_SCK Keep JP9 open 38 PE0 MC/MicroSD card detection Remove MicroSD card. Disconnect STM3210C-EVAL board from motor power drive board. 40 PE1 USB_Ove-current Remove R35 42 PE3 Trace_D0 44 PE5 Trace_D2 46 PB9 User Button 48 3V3 50 GND Remove R104 Doc ID 15082 Rev 4 25/52 Connectors Table 23. Pin UM0600 daughterboard extension connector CN9 Description Alternative function How to disconnect with component on STM3210C-EVAL board 1 GND - 3 PD14 MC Keep JP22 open. Disconnect STM3210C-EVAL board from motor power drive board. 5 PD12 Ethernet Remove RS2 7 PD10 Ethernet/Smartcard Keep JP11 open 9 PC13 button B3 IDD_CNT_EN / Anti-tamper button B4 Keep JP1 open 11 RESET# - 13 PB15 I2S_DIN 15 PB13 I2S_CK / Ethernet Remove RS3 17 PB11 Ethernet Remove RS3 19 D5V - 21 PE14 Smartcard_CMDVCC 25 PE12 MC 27 PE10 MC 29 PE8 MC 31 PE7 Smartcard_OFF Remove R69 33 PB1 MC Remove R168 35 PC5 VBAT_voltage Remove R154 37 PA7 MC Remove R169 39 GND 41 PA4 MicroSD card / Audio_DAC Keep JP15 open 43 PA2 Ethernet Remove R162 45 PC3 Ethernet Remove RS1 47 PC1 Ethernet 49 PC13 IDD_CNT_EN / Anti-tamper button B4 Keep JP1 open 2 PD15 MC Disconnect STM3210C-EVAL board from motor power drive board 4 PD13 LD2 Remove R95 6 PD11 Ethernet Remove RS1 8 PD9 Ethernet / Smartcard Keep JP12 open 10 GND 12 PD8 Ethernet / Smartcard Keep JP13 open 14 PB14 IO_Expandor_INT Remove R159 Remove R166 23 26/52 Disconnect STM3210C-EVAL board from motor power drive board Doc ID 15082 Rev 4 UM0600 Table 23. Connectors daughterboard extension connector CN9 (continued) Pin Description Alternative function How to disconnect with component on STM3210C-EVAL board 16 PB12 Ethernet / Audio Remove RS3 18 PB10 Ethernet Remove RS2 20 PE15 MC Remove R139 22 PE13 MC Disconnect STM3210C-EVAL board from motor power drive board 26 PE11 MC 28 PE9 MC 30 GND 32 PB2 MC Remove R168 34 PB0 MC Remove R167 36 PC4 Potentiometer Remove R103 38 PA6 IDD_Measurement Remove R79 40 PA5 MC Remove R84 42 PA3 MC / Ethernet Keep JP10 open 44 PA1 Ethernet Keep JP3 open 46 PC2 Ethernet Remove RS1 48 PC0 MC / Smartcard Remove R165 50 GND 24 Disconnect STM3210C-EVAL board from motor power drive board 3.9 Audio jack CN7 A 3.5 mm stereo audio jack CN7 connected to audio DAC is available on the STM3210C-EVAL board. 3.10 TFT LCD connector CN14 One 34-pin male header CN14 is available on the board to connect LCD module board MB785. Please refer to Chapter 2.17 for detail. Doc ID 15082 Rev 4 27/52 Connectors 3.11 UM0600 MicroSD card connector CN16 Figure 13. MicroSD card connector CN16 viewed from the front Table 24. MicroSD card connector CN16 Pin number Description Pin number 1 3.12 Description 6 Vss/GND MicroSDcard_DOUT(PC11) 2 MicroSDcard_CS (PA4) 7 3 MicroSDcard_DIN(PC12) 8 4 +3V3 9 GND 5 MicroSDcard_CLK (PC10) 10 MicroSDcard_detect (PE0) USB MicroAB connector CN2 Figure 14. USB MicroAB connector CN2 viewed from the front Table 25. USB MicroAB connector CN2 Pin number 28/52 Description Pin number Description 1 VBUS (PA9) 4 ID (PA10) 2 D- (PA11) 5 GND 3 D+ (PA12) Doc ID 15082 Rev 4 UM0600 3.13 Connectors Power connector CN18 Your STM3210C-EVAL evaluation board can be powered from a DC 5 V power supply via the external power supply jack (CN18) shown in Figure 15. The central pin of CN18 must be positive. Figure 15. Power supply connector CN18 viewed from the front DC +5V GND 3.14 Smartcard connector CN5 Figure 16. Smartcard connector CN5 1234 17 18 5678 Table 26. Smartcard connector CN5 Pin number Description Pin number Description 1 VCC 5 GND 2 RST 6 NC 3 CLK 7 I/O 4 NC 8 NC 17 Detection pin of card presence 18 Detection pin of card presence Doc ID 15082 Rev 4 29/52 Schematics 4 UM0600 Schematics This section provides the following schematics: 30/52 ● Figure 17: STM3210C on page 31 ● Figure 18: MCU on page 32 ● Figure 19: Ethernet on page 33 ● Figure 20: Full speed USB-OTG on page 34 ● Figure 21: Audio on page 35 ● Figure 22: LCD on page 36 ● Figure 23: I/O expander on page 37 ● Figure 24: CAN on page 38 ● Figure 25: RS-232 and IrDA on page 39 ● Figure 26: Smartcard on page 40 ● Figure 27: Motor control on page 41 ● Figure 28: I/O peripherals on page 42 ● Figure 29: Extension connector on page 43 ● Figure 30: JTAG and trace on page 44 ● Figure 31: MicroSD card on page 45 ● Figure 32: Power on page 46 ● Figure 33: 3.2” LCD module with SPI and 16-bit interface on page 47 Doc ID 15082 Rev 4 UM0600 Figure 17. STM3210C U_Audio Audio.SchDoc U_MCU MCU.SchDoc Audio_RST Audio_DAC_OUT Audio_SDA Audio_SCK I2S_CK I2S_DIN I2S_CMD I2S_MCK Audio_DAC_OUT I2S_CK I2S_DIN I2S_CMD I2S_MCK U_CAN CAN.SchDoc CAN1_RX CAN1_TX CAN2_RX CAN2_TX CAN1_RX CAN1_TX CAN2_RX CAN2_TX U_MicroSDCard MicroSDCard.SchDoc MicroSDCard_MISO MicroSDCard_Detection MicroSDCard_CS MicroSDCard_MOSI MicroSDCard_SCK MicroSDCard_Detection MicroSDCard_CS U_MotorControl MotorControl.SchDoc MC_PFCsync1 MC_PFCsync2 MC_WL MC_VH MC_VL MC_UH MC_UL MC_WH MC_NTC MC_DissipativeBrake MC_PFCpwm MC_EnIndex MC_BusVoltage MC_HeatsinkTemperature MC_EnB MC_EnA MC_CurrentC MC_CurrentB MC_CurrentA MC_EmergencySTOP U_JTAG&Trace JTAG&Trace.SchDoc Doc ID 15082 Rev 4 TDI RESET# TRST TMS/SWDIO TCK/SWCLK TDO/SWO TRACE_CK TRACE_D0 TRACE_D1 TRACE_D2 TRACE_D3 TDI RESET# TRST TMS/SWDIO TCK/SWCLK TDO/SWO TRACE_CK TRACE_D0 TRACE_D1 TRACE_D2 TRACE_D3 U_Ethernet Ethernet.SchDoc MII_TX_CLK MII_TXD0 MII_TXD1 MII_TXD2 MII_TXD3 MII_INT MII_TX_EN MII_RX_ER MII_RX_DV/RMII_CRSDV MII_RX_CLK/RMII_REF_CLK MII_RXD0 MII_RXD1 MII_RXD2 MII_RXD3 MII_COL MII_CRS MII_MDIO MII_MDC MCO PHY_RESET# MII_TX_CLK MII_TXD0 MII_TXD1 MII_TXD2 MII_TXD3 MII_TX_EN MII_RX_ER MII_RX_DV/RMII_CRSDV MII_RX_CLK/RMII_REF_CLK MII_RXD0 MII_RXD1 MII_RXD2 MII_RXD3 MII_COL MII_CRS MII_MDIO MII_MDC MCO SmartCard_CMDVCC SmartCard_CLK SmartCard_RST SmartCard_IO SmartCard_3/5V SmartCard_OFF SmartCard_CMDVCC SmartCard_CLK SmartCard_RST SmartCard_IO SmartCard_3/5V SmartCard_OFF U_Power Power.SchDoc IDD_Measurement VBAT_Voltage LP_WAKEUP VBAT_DIV IDD_CNT_EN IDD_CNT_EN U_USART&IrDA USART&IrDA.SchDoc BNC1 BNC2 JOY_SEL JOY_DOWN JOY_LEFT JOY_RIGHT JOY_UP MEMS_INT1 MEMS_INT2 U_IO_Expandor IO_Expandor.SchDoc I2C1_SCK I2C1_SDA IO_Expandor_INT R131 R132 0 0 IO_Expandor_SCK IO_Expandor_SDA IO_Expandor_INT EXP_IO12 EXP_IO11 EXP_IO10 EXP_IO9 EXP_IO8 EXP_IO7 EXP_IO6 EXP_IO5 EXP_IO4 EXP_IO3 EXP_IO2 EXP_IO1 TouchScreen_YTouchScreen_Y+ TouchScreen_XTouchScreen_X+ R133 R134 4K7 4K7 +3V3 U_LCD LCD.SchDoc LCD_CS SPI3_SCK SPI3_MOSI LCD_CS LCD_CLK LCD_DI RESET# LCD_DO TouchScreen_YTouchScreen_Y+ TouchScreen_XTouchScreen_X+ U_ExtensionConnector ExtensionConnector.SchDoc PA[0..15] PB[0..15] PC[0..15] PD[0..15] PE[0..15] PA[0..15] PB[0..15] PC[0..15] PD[0..15] PE[0..15] RESET# U_USB_OTG_FS USB_OTG_FS.SchDoc USB_PowerSwitchOn USB_DM USB_DP USB_ID USB_VBUS USB_OverCurrent USB_PowerSwitchOn USB_DM USB_DP USB_ID USB_VBUS USB_OverCurrent Note1: only decoupling capacitors value was updated from Versioin B.1 to B.2. Note2: only assembly request of R42 and R43 was updated from Versioin B.2 to B.3. 31/52 STMicroelectronics Title: STM3210C-EVAL Number:MB784 Rev: B.3(PCB.SCH) Date: 9/18/2009 Sheet 1 of 16 Schematics USART2_RX USART2_TX Bootloader_RESET Bootloader_BOOT0 LED4 LED3 LED2 LED1 EEPROM_SCK EEPROM_SDA MEMS_SCK MEMS_SDA Potentiometer Anti_Tamper WAKEUP User_Button Potentiometer Anti_Tamper WAKEUP User_Button IDD_Measurement VBAT_Voltage_OUT USB_VBUS RS232/IrDA_RX RS232/IrDA_TX Bootloader_RESET Bootloader_BOOT0 U_IO Peripherals IO Peripherals.SchDoc LED4 LED3 LED2 LED1 SPI3_MISO U_SmartCard SmartCard.SchDoc MC_PFCsync1 MC_PFCsync2 BNC2 MC_WL BNC1 MC_VH MC_VL MC_UH MC_UL MC_WH MC_NTC MC_DissipativeBrake MC_PFCpwm MC_EnIndex MC_BusVoltage MC_HeatsinkTemperature MC_EnB MC_EnA MC_CurrentC MC_CurrentB MC_CurrentA MC_EmergencySTOP 1 2 TP6 MCO MC_DissipativeBrake C17 10pF 2 1 MII_CRS 3 2 4 1 R59 0 U9A JP14 MII_RX_CLK/RMII_REF_CLK MII_MDIO MII_COL JP15 MicroSDCard_CS Audio_DAC_OUT R78 USB_VBUS 0 +3V3 1 SW1 2 R60 09.03290.01 10K MC_BusVoltage IDD_Measurement MC_CurrentA MCO USB_ID USB_DM USB_DP TMS/SWDIO TCK/SWCLK TDI Doc ID 15082 Rev 4 MC_CurrentB MC_CurrentC LCD_CS TDO/SWO TRST CAN2_RX CAN2_TX JP9 I2C1_SDA MII_TXD3 User_Button MII_RX_ER MII_TX_EN I2C1_SCK MII_TXD0 I2S_CMD I2S_CK MII_TXD1 IO_Expandor_INT I2S_DIN PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 PA8 PA9 PA10 PA11 PA12 PA13 PA14 PA15 23 24 25 26 29 30 31 32 67 68 69 70 71 72 76 77 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12 PB13 PB14 PB15 35 36 37 89 90 91 92 93 95 96 47 48 51 52 53 54 12 13 14 73 94 C18 20pF C19 R63 R61 10K 220 PC15-OSC32_OUT PC14-OSC32_IN PC13-ANTI_TAMP PC12 PC11 PC10 PC9 PC8 PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12 PB13 PB14 PB15 PD15 PD14 PD13 PD12 PD11 PD10 PD9 PD8 PD7 PD6 PD5 PD4 PD3 PD2 PD1 PD0 PE15 PE14 PE13 PE12 PE11 PE10 PE9 PE8 PE7 PE6 PE5 PE4 PE3 PE2 PE1 PE0 OSC_IN OSC_OUT NRST NC BOOT0 D1 1N4148 2 20pF PA0-WKUP PA1 PA2 PA3 PA4 PA5 PA6 PA7 PA8 PA9 PA10 PA11 PA12 PA13 PA14 PA15 TP4 PTP_PPS X3 25MHz (with socket) B1 3 SW2 09.03290.01 JP18 PA[0..15] C16 10pF PC15 PC14 PC13 PC12 PC11 PC10 PC9 PC8 PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0 62 61 60 59 58 57 56 55 88 87 86 85 84 83 82 81 PD15 PD14 PD13 PD12 PD11 PD10 PD9 PD8 PD7 PD6 PD5 PD4 PD3 PD2 PD1 PD0 46 45 44 43 42 41 40 39 38 5 4 3 2 1 98 97 PE15 PE14 PE13 PE12 PE11 PE10 PE9 PE8 PE7 PE6 PE5 PE4 PE3 PE2 PE1 PE0 C15 100nF R62 +3V3 X2 MC306-G-06Q-32.768 (manufacturer JFVNY) PC[0..15] PD[0..15] 1 IDD_CNT_EN 2 3 SPI3_MOSI SPI3_MISO SPI3_SCK USB_PowerSwitchOn MC_EnIndex MC_EnB VBAT_Voltage_OUT Potentiometer MII_TX_CLK MII_TXD2 MII_MDC PE[0..15] PA[0..15] PB[0..15] PC[0..15] PD[0..15] PE[0..15] Anti_Tamper JP1 1 I2S_MCK 2 3 MC_EnA JP10 SmartCard_3/5V R165 MC_HeatsinkTemperature 0 MC_PFCpwm MC_PFCsync1 LED2 MII_RXD3 MII_RXD2 1 SmartCard_CLK 2 3 MII_RXD1 JP11 1 LED1 USART2_RX USART2_TX LED4 LED3 MC_NTC CAN1_TX CAN1_RX 2 3 SmartCard_RST MII_RXD0 JP12 1 2 3 SmartCard_IO MII_RX_DV/RMII_CRSDV JP13 MC_EmergencySTOP SmartCard_CMDVCC MC_WH MC_WL MC_VH MC_VL MC_UH MC_UL SmartCard_OFF TRACE_D3 TRACE_D2 TRACE_D1 TRACE_D0 TRACE_CK USB_OverCurrent MC_PFCsync2 Jumper configuration: default set/ feature enabled another set/ feature enabled ================================================== JP1: 2<->3 / Anti_Temper 1<->2 / MCU current measurement JP9: close / I2C device open / CAN2 JP10: 1<->2 / I2S Audio 2<->3 / MC JP11: 2<->3 / Ethernet 1<->2 / Smartcard JP12: 2<->3 / Ethernet 1<->2 / Smartcard JP13: 2<->3 / Ethernet 1<->2 / Smartcard JP14: 1<->2 / Ethernet 2<->3 / WKUP & MC JP15: close / SDcard CS open / output for audio DAC JP18: open/ BL_Boot0 disabled close / BL_Boot0 JP19: open/ BL_Reset disabled close / BL_Reset JP26 +3V3 MicroSDCard_Detection STMicroelectronics [N/A] Bootloader_BOOT0 Title: JP19 RESET# Bootloader_RESET STM3210C-EVAL MCU Number:MB784 1N4148 2 3 Rev: B.3(PCB.SCH) Date: 10/10/2009 4 Sheet 2 of 16 UM0600 D2 R161 0 PB[0..15] STM32F107VCT 3 2 4 1 1 9 8 7 80 79 78 66 65 64 63 34 33 18 17 16 15 RESET 1 4 3 WAKEUP 3 3 Schematics 32/52 Figure 18. MCU UM0600 Figure 19. Ethernet PA0 PB10 PA3 PD12 PD11 PB8 PC2 PC3 MII_CRS MII_RX_ER MII_COL MII_RXD3 MII_RXD2 MII_TXD3 MII_TXD2 MII_TX_CLK +3V3 +3V3 R8 1K5 RS1 33 Unused in RMII mode C1 100nF RS2 33 1 2 3 4 5 6 33 RS4 PD10 PD9 PD8 MII_RXD1 MII_RXD0 MII_RX_DV/RMII_CRSDV +3V3 R2 JP2 43 44 45 46 41 39 38 33 Doc ID 15082 Rev 4 2K2 42 40 PC1 PA2 MII_MDC MII_MDIO PHY_RESET# R162 3 PA1 MII_RX_CLK/RMII_REF_CLK 0 MII_INT 1 R1 CN1 JP3 33 34 25 TP1 25MHz JP4 1 2 PA8 TX_CLK TX_EN TXD_0 TXD_1 TXD_2 TXD_3/SNI_MODE TD+ TDRD+ RDNC NC NC NC NC RXD_0/PHYAD1 RXD_1/PHYAD2 RXD_2/PHYAD3 RXD_3/PHYAD4 RX_ER/MDIX_EN RX_DV/MII_MODE RX_CLK 3 R31 4.87K 24 37 18 23 17 16 14 13 12 11 10 9 8 1 4 2 3 5 6 9 10 12 11 COL/PHYAD0 CRS/CRS_DV/LED_CFG MDC MDIO RS6 LED_LINK/AN0 LED_SPEED/AN1 LED_ACT/COL/AN_EN RESET_N PWR_DOWN/INT NC NC To IO expandor X1 25MHz (with socket) MCO 29 7 2K2 R41 0 0 C10 22pF AVDD33 IOVDD33 IOVDD33 X2 X1 25MHz_OUT AGND AGND IOGND IOGND DGND RBIAS PFBIN2 PFBIN1 PFBOUT 7 8 13 14 +3V3 RD+ RCT RDLED(green)_A LED(green)_K LED(Yellow)_A LED(Yellow)_K NC CHS GND Shield Shield J0011D21B Second source: SI-60116-F 28 27 26 21 R6 20 R7 22 48 32 TD+ TCT TD- 2K2 2K2 2K2 +3V3 +3V3 19 15 47 35 36 MII RMII ==================== JP2 open close JP3 2<->3 1<->2 JP4 2<->3 2<->3 DP83848CVV +3V3 U2 +3V3 4 1 R32 10K 31 30 +3V3 2 R30 C9 22pF R13 R14 240 240 U1 RS3 PB11 PB12 PB13 MII_TX_EN MII_TXD0 MII_TXD1 C2 100nF RS5 50 VCC OUT EN GND 3 2 C3 100nF C4 100nF C5 100nF C11 10uF C6 100nF C7 100nF External 25MHz crystal mode ===================== JP4 1<->2 (MCO pin free for another application) C8 100nF SM7745HEV-50.0M (do not fit) Title: 33/52 STM3210C-EVAL Ethernet Number:MB784 Rev: B.3(PCB.SCH) Date: 9/18/2009 Sheet 3 Schematics STMicroelectronics 1 2 3 Schematics 34/52 Figure 20. Full speed USB-OTG 4 A A +3V3 R33 680 R36 0 2 5 4 +5V B GND FAULT IN OUT EN STMPS2141STR 3 1 LD5 Red R35 0 PE1 CN2 1 2 3 4 5 C12 4.7uF VBUS DM DP ID GND Shield B 475900001 PA9 PA11 PA12 PA10 +3V3 R42 R43 R38 22 22 0 R39 330 1 USB_VBUS USB_DM USB_DP USB_ID C ID D+in D-in Pd1 Pd2 GND A3 C1 D1 B1 C2 C LD6 Green 3 Vbus D+out D-out Dz Pup 2 U4 B3 C3 D3 A2 B2 R4 T3 9013 2 47K 1 Doc ID 15082 Rev 4 0 USB_Micro-AB receptacle PC9 R34 47K U3 2 R40 10K USB_PowerSwitchOn USB_OverCurrent 1 +3V3 D2 R5 [N/A] EMIF02-USB03F2 D D STMicroelectronics Title: STM3210C-EVAL USB_OTG_FS Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/17/2010 Sheet 4 of 16 4 UM0600 UM0600 Figure 21. Audio R72 51 C43 0.022uF U13 Audio_SDA Audio_SCK I2S_MCK I2S_CK I2S_DIN I2S_CMD R74 Audio_RST 10K R82 0 1 2 3 PB7 PB6 PC6 PB13 PB15 PB12 37 38 39 40 32 From IO expandor 10 11 Doc ID 15082 Rev 4 C45 1uF C46 1uF 12 SDA SCL A0 HP/LINE_OUTA HP/LINE_OUTB SPKR/HP MCLK SCLK SDIN LRCK RESET -VHPFILT FLYN FLYP +2V5 C39 100nF C40 100nF C41 100nF 13 16 34 C47 1uF +3V3 C42 100nF 20 36 33 35 0 +VHP VA VD TSTO TSTO VL DGND GND/Thermal Pad CS43L22 I2C address 0x94 R73 51 +2V5 C44 0.022uF R75 47K 2 CN7 15 14 31 3 1 4 U25 SPKR_OUTA+ SPKR_OUTASPKR_OUTB+ SPKR_OUTBVP VP AIN1B AIN1A AIN2B AIN2A AIN3B AIN3A AIN4B AIN4A VQ AFILTB AFILTA FILT+ AGND 4 6 7 9 8 5 30 29 26 25 24 23 22 21 1 2 6 5 KSS-1508 or KSSG1708 ST-212-02V +5V C37 100nF C38 100nF R80 100 C95 1uF R83 R81 100K 0 Audio_DAC_OUT 19 28 27 18 17 C49 1uF C50 1uF C93 150pF(COG) C94 150pF(COG) Title: STM3210C-EVAL Audio 35/52 Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 5 of 16 Schematics STMicroelectronics Schematics 36/52 Figure 22. LCD CN14 PB2 LCD_CS 1 2 3 4 5 PC10 LCD_CLK RESET# +5V +3V3 Doc ID 15082 Rev 4 LCD_DO LCD_DI +5V PC11 PC12 22 23 24 25 26 27 28 29 30 CS RS WR/SCL RD RESET BL_GND BL_Control VDD VCI GND GND BL_VDD SDO SDI PD1 PD2 PD3 PD4 PD5 PD6 PD7 PD8 PD10 PD11 PD12 PD13 PD14 PD15 PD16 PD17 XL XR YD YU 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 To IO expandor TouchScreen_XTouchScreen_X+ TouchScreen_YTouchScreen_Y+ 31 32 33 34 3.2" LCD_connector (MB785 with AM-240320D4TOQW-T00H(R)) CN15 1 2 3 4 5 6 7 8 +3V3 +3V3 9 10 11 12 13 14 15 16 CS SCL SDI RS WR RD SDO RESET VDD VCI GND GND BL_VDD BL_Control BL_GND BL_GND 2.4" LCD connector (MB542 with AM240320L8TNQW-00H) STMicroelectronics STM3210C-EVAL LCD Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 6 of UM0600 Title: UM0600 Figure 23. I/O expander +3V3 C89 100nF IO_Expandor_SCK IO_Expandor_SDA IO_Expandor_INT PB6 PB7 PB14 R159 U7 6 14 10 4 5 2 7 3 0 R37 10K VCC Vio GND SCLK SDAT INT Data in A0/Data Out YXY+ X+ IN3 IN2 IN1 IN0 1 16 15 13 12 11 9 8 STMPE811 I2C device address:0x82 TouchScreen_YTouchScreen_XTouchScreen_Y+ TouchScreen_X+ EXP_IO9 EXP_IO10 EXP_IO11 EXP_IO12 R57 100K +3V3 +3V3 Doc ID 15082 Rev 4 C90 100nF U8 6 14 10 4 5 2 7 3 R160 10K R164 10K +3V3 R56 10K VCC Vio GND SCLK SDAT INT Data in A0/Data Out YXY+ X+ IN3 IN2 IN1 IN0 STMPE811 I2C device address:0x88 1 16 15 13 12 11 9 8 EXP_IO1 EXP_IO2 EXP_IO3 EXP_IO4 EXP_IO5 EXP_IO6 EXP_IO7 EXP_IO8 R58 100K +3V3 Title: STM3210C-EVAL IO_Expandor 37/52 Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 7 of Schematics STMicroelectronics Schematics +3V3 R48 10K 0 Default setting: 1<->2 3 R46 2 +3V3 C13 1 38/52 Figure 24. CAN JP7 100nF CN3 DB9-male CAN connector Default setting: Open 1 6 2 7 3 8 4 9 5 U5 CAN1_TX CAN1_RX PD1 PD0 1 2 3 4 R44 0 D GND VCC R RS CANH CANL Vref JP5 8 7 6 5 R52 120 SN65HVD230 R54 [N/A] R49 0 +3V3 +3V3 R50 10K 0 Default setting: 1<->2 2 3 R47 1 Doc ID 15082 Rev 4 +3V3 C14 100nF JP8 CN4 DB9-male CAN connector Default setting: Open 1 6 2 7 3 8 4 9 5 U6 CAN2_TX CAN2_RX PB6 PB5 R45 0 1 2 3 4 D GND VCC R RS CANH CANL Vref SN65HVD230 8 7 6 5 JP6 R53 120 R55 [N/A] R51 0 +3V3 STMicroelectronics STM3210C-EVAL CAN Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 8 of UM0600 Title: UM0600 Figure 25. RS-232 and IrDA +3V3 100nF C30 +3V3 C31 100nF R3 10K RS232/IrDA_TX 3 PD6 C1+ C1C2+ C2- 2 Bootloader_BOOT0 1 T1IN T2IN T3IN 21 20 19 18 17 16 15 Bootloader_RESET RS232/IrDA_RX 28 24 1 2 14 13 12 PD5 21 20 R1OUT R2OUT R3OUT R4OUT R5OUT Doc ID 15082 Rev 4 23 JP16 C34 100nF U11 nEN VCC GND V+ VT1OUT T2OUT T3OUT R1IN R2IN R3IN R4IN R5IN nSHDN 26 25 27 3 CN6 DB9-male UART4 C32 100nF C33 100nF 9 10 11 DCD RXD TXD CTS 1 6 2 7 3 8 4 9 5 4 5 6 7 8 +3V3 22 ST3241EBPR U12 5 3 4 +3V3 R76 5 R77 47 1 2 6 7 8 SD TxD RxD Anode (VCC2) Cathode VCC1 Vlogic GND TFDU4300 C35 4.7uF C28 100nF C36 4.7uF C29 100nF Title: STM3210C-EVAL RS232&IrDA 39/52 Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 9 of Schematics STMicroelectronics IrDA Schematics 40/52 Figure 26. Smartcard +3V3 +3V3 R64 R65 10K 10K R71 4K7 PC0 TP2 AUX2 TP3 AUX1 U10 +5V C20 Doc ID 15082 Rev 4 C21 100nF C25 10uF C22 1 2 3 4 100nF 5 6 7 100nF 8 9 10 11 12 13 14 28 27 26 25 24 23 22 21 20 19 18 17 16 15 CLKDIV1 AUX2UC CLKDIV2 AUX1UC 5V/3V I/OUC PGND XTAL2 C1+ XTAL1 Vddp OFF C1GND Vup Vdd PRES RSTIN PRES CMDVCC I/O PORADJ AUX2 Vcc AUX1 RST CGND CLK R68 0 R69 0 R166 0 PD8 PD10 PE7 C23 100nF SmartCard_3/5V SmartCard_IO SmartCard_CLK SmartCard_OFF +3V3 C26 10uF +3V3 ST8024CDR C24 PD9 PE14 R66 10K SmartCard_RST SmartCard_CMDVCC 100nF R67 10K 5 6 7 8 GND VCC NC RST I/O CLK NC NC CN5 C816 1 2 3 4 17 18 R70 100K +3V3 STMicroelectronics STM3210C-EVAL Smart card Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 10 of UM0600 Title: UM0600 Figure 27. Motor control +3V3 MC_EmergencySTOP PE15 0 TP7 TP8 AIN- AIN+ PA7 R169 0 MC_CurrentA R139 MC_UH MC_UL MC_VH MC_VL MC_WH MC_WL C61 1nF SB5 Doc ID 15082 Rev 4 MC_NTC MC_DissipativeBrake 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 PE9 PE8 PE11 PE10 PE13 PE12 PD2 PA0 +5V R143 0 C65 [N/A] MC_PFCpwm MC_EnA MC_EnB PD15 PC6 PC7 EMERGENCY STOP MC-UH MC_UL MC_VH MC_VL MC_WH MC_WL CURRENT A CURRENT B CURRENT C NTC BYPASS RELAY DISSIPATIVE BRAKE +5V POWER PFC SYNC PFC PWM Encoder A Encoder B GND GND GND GND GND GND BUS VOLTAGE GND GND GND GND GND Heatsink Temperature Vdd_Micro GND GND Encoder Index 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 R140 0 C62 100nF R142 +3V3 0 C63 100nF R145 100K R84 PA5 0 R85 PC0 0 MC_BusVoltage MC_HeatsinkTemperature MC_connector PB1 R168 0 MC_CurrentC CN17 R141 0 C64 [N/A] PB0 R167 0 MC_CurrentB Motor control connector R146 3K3 PC8 R144 0 C66 [N/A] Default setting: Open BNC2 BNC1 MC_EnIndex C67 [N/A] JP21 MC_PFCsync2 MC_PFCsync1 C68 [N/A] PE0 JP22 PD14 C71 [N/A] Default setting: Open C69 [N/A] C72 [N/A] C73 10nF C70 [N/A] Title: STM3210C-EVAL Motor control 41/52 Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 11 of 16 Schematics STMicroelectronics 1 2 R108 R89 10K R90 10K R91 10K R92 10K R93 10K 2 COMMON Selection 100nF 100nF 100nF 100nF 100nF C54 C55 C56 3 1 4 6 DWON LEFT RIGHT UP R94 PD7 LED1 LD1 Green 1 2 330 PD13 LED2 0 0 0 0 0 C53 R98 R99 R100 R101 R102 C52 To IO expandor JOY_SEL JOY_DOWN JOY_LEFT JOY_RIGHT JOY_UP 4 U15 5 100 +3V3 3 Schematics 42/52 Figure 28. I/O peripherals PD3 LED3 MT008-A PD4 LED4 LD2 Orange R95 1 680 LD3 Red R96 1 680 LD4 Blue R97 1 680 2 2 2 Joystick SB4 +3V3 R112 50 R113 50 C91 +3V3 U17 1 2 3 4 E0 E1 E2 VSS VCC WC SCL SDA 100nF 8 7 6 PB6 5 PB7 R107 10K JP17 MEMS_SDA MEMS_SCK MEMS_INT1 MEMS_INT2 EEPROM_SCK EEPROM_SDA 5 4 3 2 1 5 4 3 2 1 BNC1 BNC2 M24C64-WMN6 +3V3 U16 1 VDD_IO CS 6 VDD SDO 100nF 3 Reserved GND PB7 13 SDA GND PB6 14 SCL GND 8 INT1 GND 9 INT2 Reserved R106 10K C92 PA7 PB0 To IO expandor CN11 VB334 BNC LIS302DL EEPROM +3V3 +3V3 MEMS +3V3 +3V3 R109 B2 WKUP R111 100 100 3 3 4 R110 C58 100nF WAKEUP PA0 R116 330 PC4 1 4 Potentiometer C59 [N/A] B4 Tamper C57 100nF 1 4 B3 USER 100 R105 0 2 0 PC13 1K C60 10nF 2 RV1 10K STMicroelectronics R117 220K STM3210C-EVAL IO Peripherals 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 12 of 16 UM0600 Title: Number:MB784 2 R86 0 Potentiometer BUTTON 1 R103 1 R115 4K7 Anti_Tamper 2 R114 4K7 R104 3 PB9 2 User_Button 7 12 2 10 5 4 11 3 CN10 VB334 1 Doc ID 15082 Rev 4 SB3 LEDs UM0600 Figure 29. Extension connector Pin assignment fixed Pin assignment fixed Pin assignment fixed Pin assignment fixed Left Right CN8 PC14 Doc ID 15082 Rev 4 PC15 PC7 PC9 PA9 PA0 SB1 PA12 SB2 PC10 Open by default PC12 PD1 PD3 PD5 PD7 PB3 PB5 PB7 PE2 PE4 PB8 PE6 D5V 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 CN9 PC6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 PC8 PA8 PA10 PC13 RESET# PA11 PA13 PA14 PC11 PA15 PD0 PD2 PD4 PD6 D5V PD14 PD12 PD10 R87 R88 PB15 PB13 PB11 PE14 PE12 PE10 PE8 PE7 PB1 PC5 PA7 PB4 PB6 PE0 PE1 PE3 PE5 PB9 +3V3 PA4 PA2 PC3 PC1 PC13 Header 25X2 820 820 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 PD15 PD13 PD11 PD9 PD8 PB14 PB12 PB10 PE15 PE13 PE11 PE9 PB2 PB0 PC4 PA6 PA5 PA3 PA1 PC2 PC0 Header 25X2 PA[0..15] PB[0..15] PC[0..15] PD[0..15] PE[0..15] RESET# PA[0..15] PB[0..15] PC[0..15] PD[0..15] PE[0..15] RESET# Title: STM3210C-EVAL Extension connector 43/52 Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 13 of 16 Schematics STMicroelectronics +3V3 Schematics 44/52 Figure 30. JTAG and trace JP20 R121 R122 R123 10K 10K 10K R124 10K PA13 PA14 PB3 PA15 PB4 TMS/SWDIO TCK/SWCLK TDO/SWO TDI TRST RESET# R125 10K Doc ID 15082 Rev 4 CN12 FTSH-110-01-L-DV +3V3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 TRACE_D3 TRACE_D2 TRACE_D1 TRACE_D0 TRACE_CK CN13 JTAG +3V3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 KEY R129 0 R119 [N/A] R130 0 R120 [N/A] +3V3 R118 [N/A] R126 10K R127 10K R128 10K JTAG connector PE6 PE5 PE4 PE3 PE2 Trace connector STMicroelectronics STM3210C-EVAL JTAG & Trace Number:MB784 1 2 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 14 of UM0600 Title: UM0600 Figure 31. MicroSD card +3V3 R138 4K7 MicroSDCard_SCK MicroSDCard_MOSI MicroSDCard_CS PC11 R135 0 R136 0 PC10 PC12 PA4 +3V3 9 10 SW2 SW1 Doc ID 15082 Rev 4 CN16 PJS008-2000 SMS064FF or SMS128FF 1 2 3 4 5 6 7 8 MicroSDCard_MISO MicroSDCard_Detection PE0 R137 0 MicroSD card Title: 45/52 STM3210C-EVAL MicroSD card Number:MB784 Rev: B.3(PCB.SCH) Date: 9/18/2009 Sheet 15 of Schematics STMicroelectronics 1 2 3 Schematics 46/52 Figure 32. Power 4 U21 MAX9938FEUK+ U22 5 3 1 4 3 4 R157 1K(1%) R79 4K7 5 C78 0.47uF +3V3 3 G 4 T2 STT5PF20V D 5 +3V3 3 U23 74LX1G04CTR +3V3 C48 100nF U24 2 3 PA6 4 IDD_Measurement +3V3 5 1 2 6 STT5PF20V 5 1 2 6 S 0 T1 74H1G66STR 1(1%) 4 R149 2 Doc ID 15082 Rev 4 1 2 3 4 5 6 7 8 16 15 14 13 12 11 10 9 Q12 VCC Q13 Q10 Q14 Q8 Q6 Q9 Q5 CLR Q7 CI Q4 CO GND CO G +3V3 2 R156 I/O O/I C GND VCC D JP23 S 1 3 1 2 VDD_MCU PA0 R152 10K PC13 M74HC4060TTR C88 1nF LP_WAKEUP +3V3 R158 15K IDD_CNT_EN R153 30K Oscillator frequency 30KHz C27 U18 ZEN056V130A24LS TP13 VREF 47 100nF 21 22 50 C76 C87 75 1uF 100nF 100 28 11 VDD_MCU 6 L1 VDD_MCU BEAD VREF+ VDDA VDD_1 VDD_2 VDD_3 VDD_4 VDD_5 VBAT VREFVSSA VSS_1 VSS_2 VSS_3 VSS_4 VSS_5 20 19 49 74 99 27 10 1 3 1 2 Z1 SMAJ5.0A-TR C77 100nF SV TP10 3V3 U19 LD1086D2M33 +5V 3 C79 220uF SG CG1 CG2 CG3 Vin C79_1 220uF 3 2 C81 100nF JP24 BT1 CR1220 holder 0 R151 20K(1%) R163 C84 100nF D5V Vout JP25 2 C75 10uF C80 100nF Vin Vout LD7 2 1 TP12 Ground R148 red 2 STMicroelectronics C51 10uF Title: VBAT_DIV STM3210C-EVAL Power Number:MB784 2 5 3 1 1K5 +2V5 From IO expandor 1 6 4 2 USB_VBUS TP5 2V5 U27 LD1117S25TR 3 VBAT_Voltage TP11 5V +5V E5V +3V3 C85 100nF +5V PC5 C74 10uF 4 5 6 3 Rev: B.3(PCB.SCH) Date: 9/18/2009 4 Sheet 16 of 16 UM0600 0 C83 100nF 1 R150 10K(1%) R154 C82 100nF 3 BNX002-01 1 VDD_MCU 1 CV R147 0 BARRACUDA_256K +3V3 1 2 3 DC-10B VREF- U9B E5V U20 CN18 GND VDDA R155 1uF C86 2 VREF+ UM0600 Figure 33. 3.2” LCD module with SPI and 16-bit interface CN1 CS RS WR RD #RESET 1 2 3 4 5 CS RS WR/SCL RD RESET PD1 PD2 PD3 PD4 PD5 PD6 PD7 PD8 BLGND BL_Control VDD BLVDD SDO SDI 22 23 24 25 26 27 28 29 30 PD10 PD11 PD12 PD13 PD14 PD15 PD16 PD17 BL_GND BL_Control VDD VCI GND GND BL_VDD SDO SDI XL XR YD YU 6 7 8 9 10 11 12 13 PD1 PD2 PD3 PD4 PD5 PD6 PD7 PD8 14 15 16 17 18 19 20 21 PD10 PD11 PD12 PD13 PD14 PD15 PD16 PD17 31 32 33 34 XL XR YD YU Soldered for i80-system 16-bit interface SDO SDI Doc ID 15082 Rev 4 CS WR RD RS 31 34 35 33 SDO SDI 10 12 #RESET 32 VDD A K BLVDD C1 4.7uF/50V STPS1L40M U1 8 1 7 3 9 SW Vo Vi NC EN GND FB PGND Rset STLD40DPMR BLGND 40 41 Z1 L1 R8 do not fit 36 37 38 39 11 4.7uH(1A) BL_Control R5 0 4K7 4K7 R4 LCD board connector to Mother board BLGND R2 R3 VDD 0 CN2 VSYNC HSYNC DotClk Enable The 34-pin connector to mother board for both serial & 16bit interface. Compatible with MB694 with Touch screen signals added on Pin 31-34. C2 2.2uF 10K Soldered for Serial interface only 3.2LCD_connector BLVDD R1 6 5 BLGND 44 43 6 42 45 1 VSYNC HSYNC DOTCLK ENABLE NC CS WR/SCL RD RS SDO SDI RESET VCC VCC LED_A LED_K VSS VSS VSS VSS IM1 IM3 IM0/ID YU YD XR XL D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13 D14 D15 D16 D17 8 9 7 5 4 3 2 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 RP1 YU YD XR XL PD0 PD1 PD2 PD3 PD4 PD5 PD6 PD7 PD8 PD9 PD10 PD11 PD12 PD13 PD14 PD15 PD16 PD17 PD16 PD14 PD12 PD10 10K RP2 PD8 PD6 PD4 PD2 10K RP3 PD9 PD0 RS RD 10K RP4 PD17 PD15 PD13 PD11 FF0245SS1 AM-240320D4TOQW-T00H(R) 4 2 R6 100K 10K RP5 R7 10 PD7 PD5 PD3 PD1 VDD RP6 BLGND HSYNC Enable VSYNC DotClk 10K C3 1uF/50V 10K Title: 47/52 3.2" LCD module with both SPI & 1 Number:MB785 Rev: A.1(PCB.SCH) Date: 3/27/2009 Schematics STMicroelectronics STM3210C-EVAL I/O assignment Appendix A STM3210C-EVAL I/O assignment Table 27. STM3210C-EVAL I/O assignment Pin No. 48/52 UM0600 Pin name STM3210C-EVAL I/O assignment 1 PE2 Trace_CK 2 PE3 Trace_D0 3 PE4 Trace_D1 4 PE5 Trace_D2 5 PE6 Trace_D3 6 VBAT Battery 7 PC13-ANTI_TAMP Anti-tamper button / IDD_CNT_EN 8 PC14-OSC32_IN 32K OSC 9 PC15-OSC32_OUT 32K OSC 10 VSS_5 GND 11 VDD_5 +3V3 12 OSC_IN 25MHz OSC 13 OSC_OUT 25MHz OSC 14 NRST RESET# 15 PC0 MC_ADC10 pin 26 (heatsinktemp) / SmartCard_3/5V 16 PC1 ETHER_MDC 17 PC2 ETHER_TXD2 18 PC3 ETHER_TX_CLK 19 VSSA GND 20 VREF- GND 21 VREF+ +3V3 22 VDDA +3V3 23 PA0-WKUP ETHER_CRS / IDD_WAKEUP / MC_TIM5_CH1 pin 23 (Dissip_brake) 24 PA1 ETHER_RX_CLK 25 PA2 ETHER_MDIO 26 PA3 ETHER_COL 27 VSS_4 GND 28 VDD_4 +3V3 29 PA4 MicroSD card CS / Audio_DAC 30 PA5 MC_ADC5 pin 14 (Bus voltage) 31 PA6 IDD_Measure 32 PA7 MC_ADC7 pin 15 (Current A)/BNC1 Doc ID 15082 Rev 4 UM0600 STM3210C-EVAL I/O assignment Table 27. STM3210C-EVAL I/O assignment (continued) Pin No. Pin name STM3210C-EVAL I/O assignment 33 PC4 Potentiometer 34 PC5 VBAT_measure 35 PB0 MC_ADC8 pin 17(Current B)/BNC2 36 PB1 MC_ADC9 pin 19 (Current C) 37 PB2 Boot1/ LCD CS 38 PE7 SmartCard_OFF 39 PE8 MC_TIM1_CH1N pin 5 (UL) 40 PE9 MC_TIM1_CH1 pin 3 (UH) 41 PE10 MC_TIM1_CH2N pin 9 (VL) / CS_Sdcard 42 PE11 MC_TIM1_CH2 pin 7 (VH) 43 PE12 MC_TIM1_CH3N pin 13 (WL) 44 PE13 MC_TIM1_CH3 pin 11 (WH) 45 PE14 SmartCard_CMDVCC 46 PE15 MC_TIM1_BKIN pin 1 (STOP) 47 PB10 ETHER_RX_ER 48 PB11 ETHER_TX_EN 49 VSS_1 GND 50 VDD_1 +3V3 51 PB12 ETHER_TXD0 / Audio_WS 52 PB13 ETHER_TXD1 / Audio_CK 53 PB14 IO_EXP_INT 54 PB15 Audio_SD 55 PD8 ETHER_RX_DV / SmartCard_IO 56 PD9 ETHER_RXD0 / SmartCard_Reset 57 PD10 ETHER_RXD1 / SmartCard_CK 58 PD11 ETHER_RXD2 59 PD12 ETHER_RXD3 60 PD13 LED2 61 PD14 MC_TIM3_CH2 pin 27(PFCsync1) 62 PD15 MC_TIM3_CH3 pin 29 (PFCpwm) 63 PC6 MC_TIM4_CH3 pin 31 (EnA) / Audio MCK 64 PC7 MC_TIM4_CH4 pin 33 (EnB) 65 PC8 MC_TIM5_CH4 pin 34 (Index) 66 PC9 OTG_PPWR 67 PA8 MCO Doc ID 15082 Rev 4 49/52 STM3210C-EVAL I/O assignment Table 27. STM3210C-EVAL I/O assignment (continued) Pin No. 50/52 UM0600 Pin name STM3210C-EVAL I/O assignment 68 PA9 OTG_VBUS 69 PA10 OTG_ID 70 PA11 OTG_DM 71 PA12 OTG_DP 72 PA13 Debug TMS 73 NC 74 VSS_2 GND 75 VDD_2 +3V3 76 PA14 Debug TCK 77 PA15 Debug TDI 78 PC10 SCL_Sdcard_LCD 79 PC11 MISO_Sdcard_LCD 80 PC12 MOSI_Sdcard_LCD 81 PD0 CAN1 RX 82 PD1 CAN1 TX 83 PD2 MC_IO pin21(NTC) 84 PD3 LED3 85 PD4 LED4 86 PD5 UART2 TX / IrDA TX 87 PD6 UART2 RX / IrDA RX 88 PD7 LED1 89 PB3 Debug TDO 90 PB4 Debug TRST 91 PB5 ETHER_PPS_OUT / CAN2_RX 92 PB6 E2P_SCL / Audio_SCL / IO_SCL / Mems_SCL / CAN2_TX 93 PB7 E2P_SDA / Audio_SDA / IO_SCL / Mems_SDA 94 BOOT0 BOOT0 95 PB8 ETHER_TXD3 96 PB9 User Button 97 PE0 MC_TIM3_ETR pin 27 (PFC SYNC2) / microsdCard_Detect 98 PE1 OTG_Overcurrent 99 VSS_3 GND 100 VDD_3 +3V3 Doc ID 15082 Rev 4 UM0600 Revision history Revision history Table 28. Document revision history Date Revision 26-Feb-2009 1 Initial release 19-Jun-2009 2 Update for PCB rev.B 16-Oct-2009 3 Update to make schematics searchable 4 Updated LCDs’ PCB. Correction to Figure 2. Replace TPS2041 by STMPS2141STR in Figure 20: Full speed USB-OTG. 10-Feb-2011 Changes Doc ID 15082 Rev 4 51/52 UM0600 Please Read Carefully: Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to ST’s terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein. UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK. Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST. ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners. © 2011 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com 52/52 Doc ID 15082 Rev 4