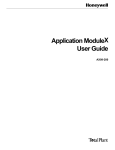

Download Modulex EXT 321- 1123 User Manual (GF-143)

Transcript