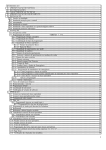

Download Getting Started with NMRA DCC

Transcript