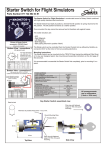

Download The TRC Multi Controller USER MANUAL for connecting

Transcript