Download 1 Overview of the X77 Fusion Splicer

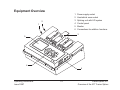

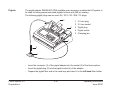

Transcript