Download PowerMaster - Gates N Fences

Transcript

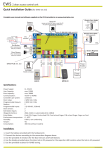

PowerMaster Installation Manual SWING GATE OPERATOR UL 325 AND UL 991 LISTED UL R MODEL “CSWC” & ”CSWI” TABLE OF CONTENTS COMMERCIAL & /INDUSTRIAL SWING GATE OPERATOR Important Safety Information……………..…………….......3 UL Installation and Safety Considerations……..…....………4 System Designer Safety Instructions……...…….……..........6 Installer Safety Instructions ………...……....………….............8 End User Safety Warnings …….…………………………..12 Installation & Setup Procedure Before Installing Operator……..…...……..……...………15 Installation of Cement Pad………......………..…………...17 Installation of Operator………………..……….…….....19 Manual Operation………………….…..……...….…..........21 Electrical Connections………………..………………….22 Left Hand/Right Hand Conversion …………….……........24 Connection of a 3 Button……….………..…….……….…26 Master/Slave Installation ……………………….…….…...28 Limit Adjustment ……..…….…...………….…………….30 Emergency Control Station ……………………….……....32 Timer To Close……….…………………….…….….……33 Audible Pre-Move Warning…....……….…………...…….34 Auxiliary Circuit …….………………...……………….35 Accessory Connections Connection of a Radio………….…………………..……..37 Loop Detector Systems…..…………………….…….…….38 Loop Installation (Standard Layout Chart)....…………..….39 Cutting The Required Groove……..........……....................40 Loop Connections………………..…...……..….…………..........41 Safety Device Connections Inherent Obstruction Sensing Device…………………….……....42 Clutch Adjustment………...……………………………………44 Secondary Obstruction Sensing Devices Contact - Sensing Edge ………………...........45 Non-Contact – Photo Eyes …………..….…...47 2004 LED & Dipswitch Information/Wiring…...…….…….50 Maintenance Log/Notes/Warranty……………….…............52 2 IMPORTANT! FOR SWING GATE OPERATING SYSTEMS SAFETY IS EVERYONE’S BUSINESS Automatic gate operators provide convenience and security to users. However, because these machines can produce high levels of force, it is important that all gate operator system designers, installers, and end users be aware of the potential hazards associated with improperly designed, installed, or maintained systems. Keep in mind that the gate operator is a component part of a total gate operating system. The following information contains various safety precautions and warnings for the system designer, installer and end user. These instructions provide an overview of the importance of safe design, installation, and use. Warnings are identified with the ▲ symbol. This symbol will identify some of the conditions that can result in serious injury or death. Take time to carefully read and follow these precautions and other important information provided to help ensure safe system design, installation and use. ▲ WARNING: Gate operators are only one part of a TOTAL GATE OPERATING SYSTEM. It is the responsibility of purchaser, designer, and installer to ensure that the total system is safe for its intended use. All secondary entrapment safety devices must be RECOGNIZED by U/L to ensure the safety of the complete operating system. 3 U/L INSTALLATION AND SAFETY CONSIDERATIONS INSTALLATION CLASSES CLASS I – RESIDENTIALVEHICULAR GATE OPERATOR CLASS III- INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR A vehicular gate operator (or system) intended for use in an industrial location or building such as a factory or loading dock area or other locations not intended to service the general public. A vehicular gate operator (or system) intended for use in a home of one to four single-family dwellings, or a garage or parking area associated therewith. CLASS II–COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR CLASS IV- RESTRICTED ACCESS VEHICULAR GATE OPERATOR A vehicular gate operator (or system) intended for use in a commercial location or building such as a multifamily housing unit (five or more single family units), hotel, garages, retail store or other building servicing the general public. A vehicular gate operator (or system) intended for use in a guarded industrial location or building such as an airport area or other restricted access locations not servicing the general public, in which unauthorized access is prevented via supervision by security personnel. 4 5 SYSTEM DESIGNER SAFETY INSTRUCTIONS ▲ 1. Familiarize yourself with the precautions and warnings for the installer. Users are relying on your design to provide a safe installation. ▲ 2. The operator is supplied with a primary obstruction sensing entrapment protection system. The installation must also have a secondary entrapment protection system installed, such as photoelectric sensors or an electric edge system. The illustrations and descriptive captions found on the following pages provide precautions to help eliminate injuries or fatalities. Familiarize yourself with them when designing the total system. ▲ 5. Design the gate system so a person cannot reach over, under, around, or through the gate to operate any controls. Never place controls on the gate operator itself. ▲ 3. When designing a system that will be entered from a highway or main thoroughfare be sure the system is placed far enough away from the road to eliminate traffic backup. Distance from the road, size of the gate, usage levels, and gate cycle/speed must be considered to eliminate potential traffic hazards. ▲ 4. Swing gates have two potential entrapment zones you must avoid. Electric Edge, On Vertical Out Side Edge Of Gate. Wired To Reverse While Closing. 1 ENTRAPMENT ZONE 2 ENTRAPMENT ZONE Horizontal Electric Edge, On Inside Bottom Of Gate. Wired To Reverse While Opening. Horizontal Electric Edge, On Bottom Outside Edge Of Gate. Wired To Reverse While Closing. ∇ Pedestrians should keep clear of path of gate, particularly in the area before fully closed. ∇ The area of the gate arm and linkage must be avoided as it can create an entrapment. 6 7 INSTALLER SAFETY INSTRUCTIONS BEFORE INSTALLATION ▲ 1. Check to see that the operator is proper for this type and size of gate and its frequency of use. If you are not sure, consult factory. ▲2. Check to see that there are no structures adjacent to the area, which may pose a risk of entrapment when gate is opening or closing. ▲3. You must ensure that the gate has been properly installed and works freely in both directions. Replace or service any worn or damaged gate hardware prior to installation. A freely moving gate will require less force to operate and enhance the performance of the operator as well as the safety devices used within the system. ▲7. You must install a pushbutton control or key switch to allow for normal operation of the gate if the automatic controls do not work. Locate the push button or key switch and small warning placard within sight of the gate in a secured area at least 10 feet or more from any moving parts of the gate or operator. ▲8. Outdoor or easily accessed gate controls should be of the security type to prohibit unauthorized use. Please consult your local distributor concerning the types and specifications of available controls. ▲4. Install the gate operator on the inside of the property and/or fence line. DO NOT install an operator on the public side of the gate. ▲5. Severe injury or death can result from entrapment by a gate. The operator is supplied with an obstruction sensing primary entrapment protection system. Additional safety equipment such as electric edges or photocell sensors must be installed to provide the required secondary entrapment protection system. For assistance in selecting the correct type of safety equipment, consult the factory. ▲6. Review the operation of the unit and become familiar with the manual operation procedure and safety features of the system. 8 9 DURING INSTALLATION ▲ 1. Be aware of all moving parts and avoid close proximity to any pinch points. ▲ 2. Disconnect power at the control panel before making any electric service connections. Connection location for controls and safety equipment can be found on the wiring diagram, and in this manual. ▲ 3. Know the procedure for disengaging and manually operating the unit. ▲ 4. Adjust the open and close force adjustment on the control board, in each direction, to the minimum force required to operate the gate smoothly. DO NOT increase the force adjustment setting to make up for rough spots in gate travel - FIX THE GATE INSTEAD! ▲6. Attach large warning signs provided to each side of the gate or fence in the most conspicuous place. Mount control station and smaller warning placard together within sight of the gate opening. WARNING Moving Gate Can Cause Serious Injury or Death. KEEP CLEAR! Gate May Move at Any Time. Children Should Not Operate Gate. Operate Gate Only When Area is in Sight and Free of People and Obstructions. ▲ 5. Locate the controls at least 10 feet from the moving gate so that the user can observe the gate operation, but is not able to come in contact with the gate while operating the controls. AFTER INSTALLATION ▲ You are responsible for ensuring that the end user understands the basic operations and safety systems of the unit, INCLUDING THE MANUAL OPERATION PROCEDURE. ▲ Point out that the safety instructions in brochure are the responsibility of the end user, and then LEAVE THIS MANUAL WITH THE END USER 10 11 END-USER SAFETY WARNINGS ▲ 3. DO NOT allow children to play near your gate, or to operate the gate. The manufacturer of the gate operator does not know what type of gate you have, or what type of automatic system is installed on your gate. Be sure you’ve been fully instructed on the sequence of operation for your specific gate system(s). Keep the gate properly maintained and have a qualified service person make repairs. ▲ 1. Be sure the following safety instructions are distributed to all persons authorized to use your gate. ▲ 2. KEEP GATEWAY CLEAR (Front and Back) AT ALL TIMES. Your automatic gate is not for pedestrian use. No one should ever cross the path of the moving gate. ▲ 4. DO NOT operate your gate system unless you can see it when the gate moves. ▲ 5. Be sure a pushbutton or key switch has been installed for manual electric operation in the event your radio or card key does not work. Any mounted control station should be located a minimum of 10 feet from the moving parts of the gate and operator so these moving parts cannot be touched by or come in contact with the person operating the control. ▲ 6. DO NOT operate any controls without watching the movement of the gate. ▲ 7. Your gate system is required to have a primary and a secondary entrapment safety system installed and maintained. 12 13 ▲ 8. If your gate closes automatically, loop detectors should be installed to detect the presence of a vehicle. INSTALLATION INSTRUCTIONS ▲ WARNING: DO NOT APPLY POWER UNTIL TOLD TO DO SO! RISK OF ELECTRICAL SHOCK OR INJURY MAY RESULT! ▲ 9. DO NOT increase force adjustment to compensate for a damaged gate. The gate should always be maintained to operate manually as easily as possible to provide maximum protection. BEFORE INSTALLING OPERATOR IMPORTANT: Operator should always be mounted inside the gate. Determine whether the installation is Left hand or Right hand by the direction the gate moves in order to open, when viewed from inside the fence. ▲10. Check all safety systems at least once per month for the correct force, speed and sensitivity. Gate must reverse when hitting a rigid object, or when a non-contact sensor is activated. If these functions are observed to operate improperly, discontinue use and have it serviced immediately! ▲11. You are responsible for ensuring that warning signs are installed and maintained on both sides of your gate. ▲12. To ensure safe operation of this equipment, you must read this safety manual and keep it for reference. 1. Gate must swing freely to fully opened and fully closed position. RIGHT HAND INSTALLATION LEFT HAND INSTALLATION Fence Hinge Gate Gate Hinge Fence OPERATOR Operator 2. The operator will be located as shown above, for left and right hand installation. 4' MINIMUM 14 15 CEMENT PAD LAYOUT: 1. Lay out per drawing below depending on if you have a CSWC or a CSWI. PUBLIC AREA OR STREET 2. Locate electrical conduit and mounting bolts. Note: Bolt pattern must be parallel to fence line as shown. 3. Pour cement, insuring top surface is level and allow 2 days cure time before installing operator. RIGHT HAND CSWC PAD LAYOUT CEMENT PAD 22" 10" ELECTRICAL CONDUIT 10" 36" PUBLIC AREA OR STREET 10" 20" 5-5/8" 15" 7" 2" TO 4" 30" 1-1/8" 1/2" MOUNTING HARDWARE BY OTHERS 2" MIN. GROUND LINE LEFT HAND 1" MIN. DEPTH AS REQUIRED BY LOCAL CODE OR BELOW FROST LINE 16 30" CEMENT PAD 17 ELECTRICAL CONDUIT CSWI PAD LAYOUT OPERATOR INSTALLATION CEMENT PAD 22" 10" ELECTRICAL CONDUIT 10" 36" 10-1/4" 20-1/2" 1. Mount operator on cement pad, locating electrical conduit under access hole, and secure position with 1/2 inch hardware. 2. Set control arm on output shaft of operator without drive key, and install control arm extension using hand knobs to secure position. The diagram below shows the correct holes to start with. 30" 15" 5-1/4" 7" 2" TO 4" HAND KNOB BOLTS FOR MANUAL DISCONNECT 2" 30" 1/2" MOUNTING HARDWARE BY OTHERS 2" MIN. NOTE: TO DISCONNECT OPERATOR FOR MANUAL OPERATION; REMOVE HAND KNOB BOLTS AND SEPARATE CONTROL ARM EXTENSION FROM CONTROL ARM. CONTROL ARM 3/8" DRIVE KEY 5/16" SQUARE HEAD SET SCREW CONTROL ARM EXTENSION 5/16" SET SCREW RUBBER SEAL DRIVE SHAFT USE CENTER HOLES AS STARTING POSITION GROUND LINE RAIN PLATE OPERATOR 1" MIN. DEPTH AS REQUIRED BY LOCAL CODE OR BELOW FROST LINE CEMENT PAD ELECTRICAL CONDUIT 3. Install end fittings on connecting rod and attach assembly to end of control arm extension with stop bracket, as shown below. 4. Install gate bracket on end of connecting rod. Flat Washer Bolt Set Screws Spacer Bushing Stop Bracket Gate Arm End Fitting Flat Washer Gate Bracket Nut Lockwasher Bolt Flat Washer Spacer Bushing End Fitting Stop Bracket Gate Arm Tube Spacer Lockwasher U-Bracket 18 19 Nut 5. Locate gate bracket in position on gate, as shown below, and clamp in position. 6. Move control arm to its maximum close position. Arm assembly should be in locked position against stop bracket. 36" Gate Hinge 7. Move control arm to its open position. Note: Open position of gate may be adjusted slightly with limit switch adjustment, but when finished, open position of control arm assembly should be as close as possible to that shown below. If mechanical adjustments are made to achieve desired open position of gate, repeat steps 6 & 7, since this will affect the closed position. CL Of Gate Connecting Rod Assembly Gate Bracket Gate Angle (By Others) Control Arm Gate Bracket Pivot Bolt Control Arm Pivot Pin Electrical Access Operator Operator Stop Bracket Gate Note: Adjustment can be made in (4) locations to get desired closed position, as described below. Always start with option “a”. a) Move the gate bracket to left or right of the 36 inch starting position. b) Change length assembly. c) Relocate control arm extension on control arm to a different hole pattern then start position. See figure #4. d) of connecting rod Move connecting rod bolt in gate bracket to a different hole. See figure #6. 20 Control Arm Assembly Connecting Rod Assembly 8. When the desired open and closed gate position have been achieved, place gate in the fully closed position and remove control arm extension from control arm. 9. Remove control arm from operator drive shaft and insert drive key. 10. Replace control arm on operator drive shaft with drive key and secure with (2) 5/16 set screws. 11. Replace control arm extension on control arm and secure with hand knobs. 21 MANUAL OPERATION Disconnect operator control linkage in order to manually operate the gate as follows: 1. Unscrew and remove (2) hand knob bolts connecting control arm extension to control arm. 2. Lift control arm extension with linkage off of control arm. 3. Fold control arm and linkage against gate. 4. Manually open and close gate as required. NOTE: TO DISCONNECT OPERATOR FOR MANUAL OPERATION; REMOVE HAND KNOB BOLTS AND SEPARATE CONTROL ARM EXTENSION FROM CONTROL ARM. CONNECTION OF INCOMING POWER WARNING: DO NOT APPLY POWER UNTIL TOLD TO DO SO! RISK OF SHOCK OR INJURY MAY RESULT. NOTE: Before connecting the operator to an incoming power supply, use a voltmeter to determine that the electrical service is the same as that on the operator label. If the operator is connected to an incorrect power supply, damage will result, which is NOT covered by warranty. ▲ 1. Be sure the power switches at source, the operator are OFF. HAND KNOB BOLTS FOR MANUAL DISCONNECT CONTROL ARM EXTENSION ELECTRICAL SET-UP AND CONNECTIONS CONTROL ARM and at ▲ 2. In the diagram below find the supply power that matches your installation and connect as shown. OPERATOR L1 L2 Ground Hot Neutral Ground L1 L2 L1 L2 L3 Ground Hot Hot Incoming Power Incoming Power Incoming Power 115V - 1Ø 220V - 1Ø ALL - 3Ø NOTE: Wiring to operator must use watertight materials in accordance with local electric code. See the following wire gauge/distance charts for proper sizing. Master/Slave installations should have SEPARATE power supply wiring or 22 23 length of wire runs should be figured at half that shown on the chart. This unit must be grounded in accordance with N.E.C. and local codes. LOW VOLTAGE WIRE GAUGE/DISTANCE CHART 24 AWG: 20 AWG: 18 AWG: Up to 150' 150' - 200' 250' - 1,500' INSTALLATION OPTIONS LEFT/RIGHT HAND CONVERSION: Determine the hand of the operator required for this installation by checking the direction the gate moves in order to open, when viewed from inside the fence. Swings RIGHT to open is a right hand installation, swings Left to open is a left hand installation. Control wiring should be run as twisted pairs. DO NOT run control wires in the same conduit as power wires. telephone wires, or loop detector leads. 24 25 NOTE: This unit is factory setup for RIGHT HAND operation. To convert operator to left hand operation move dipswitch #2 to on position. CONNECTION OF A THREE-BUTTON STATION: NOTE: All control contacts must be NORMALLY OPEN unless dipswitch #3 is placed to the “ON” position, which will change the circuitry to accept a NORMALLY CLOSED STOP BUTTON. P3 P4 P4 P3 LD1 LD1 POWER LD18 MAX LD13 FORCE ADJUSTMENT TB1 ON SHADOW LOOP COM COM COM OPN EDG CLO EDG MST OPN MST CLO REV SHW OPN PHO CLO PHO COM COM COM STO CLO ON 1 2 3 4 5 OFF OFF LD1 POWER LD18 LD10 LD19 LD2 U2 LD11 OPEN LD3 LD12 LD4 ALT STOP CLOSE U1 OPEN STO CLO OPN FRE CRO ALT RDO OPN COM 24V AC 24V AC FORCE ADJUSTMENT Open Close Stop Common 27 LH OPN LIM IT MOTOR OPEN MOTOR C LOSE LD7 SH ADOW LOOP COM C OM C OM R EV SH W C OM LD13 OPN PH O CLO PH O ALT C LO OPN 24V AC 24V AC C RO FR E R DO OPN C OM U4 TB1 MAX TB2 LD17 COM CLOSE PHOTO LD9 OFF 1 2 3 4 5 F ORCE ADJUSTMENT CLOSE LD16 STOP PUSH OPEN PHOTO AUTO RECL OSE TIMER LD13 C OM CLOSE PUSH LD8 U4 LD17 TB1 Right Hand Operation C LO EDGE LD6 R H CLO OPEN LD16 OPN EDG C LO ED G MST OPN MST C LO LD14 OPN EDGE LH C LO LIM IT STOP PUSH OPE N PHOTO MID L IMIT R EV LOOP LD5 R H OPN C OM C LOSE PUSH CLOSE LD15 COM OFF RAD IO OPE N STO RAD IO OPN / CLO CLOSE PHOTO 26 MOTOR CLOSE LD7 ON 1 2 3 4 5 for Normally Open Stop Button 1 2 3 4 5 FREE EXT Left Hand Operation OPN FRE MOTOR CLOSE OPE N PUSH OFF MOTOR OPEN TB2 P4 1 2 3 4 5 LH OPN LIMIT MOTOR OPEN SHADOW LOOP OPN EDG CLO EDG MST OPN MST CLO REV SHW OPN PHO CLO PHO COM COM COM OPN FRE CRO CLO ON LD9 MAX 1 2 3 4 5 P3 Place Dipswitch #2 In "ON" Position For Left Hand Operation And "OFF" Position For Right Hand Operation. LD8 AUTO RECLOSE TIMER OFF TB2 RDO OPN COM ALT FORCE ADJUSTMENT LH OPN LIMIT CLO EDGE LD7 1 2 3 4 5 TB1 COM LD9 OFF LD13 24V AC 24V AC CLOSE PHOTO LD17 COM OPEN PHOTO LD8 AUTO RECLOSE TIMER U1 LD17 ALT U1 U4 CLOSE U4 COM CLOSE COM OPEN LD16 STOP PUSH CLOSE PHOTO OPN EDGE LD6 RH CLO OPEN LD16 OPEN PHOTO REV LOOP LH CLO LIMIT STOP LD14 STOP PUSH MID LIMIT LD5 RH OPN LD15 CLOSE PUSH CLO EDGE LD6 RH CLO COM LD14 CLOSE PUSH LD4 CLOSE RADIO OPEN LH CLO LIMIT STOP COM RADIO OPEN OPN EDGE LD5 RH OPN LD15 LD12 CRO LD4 CLOSE RADIO OPN/ CLO COM LD12 STO RADIO OPN/ CLO LD3 RDO OPN LD3 LD11 OPEN ALT LD11 OPEN ALT REV LOOP C OM FREE EXT LD2 U2 COM LD2 U2 LD10 FREE EXT COM LD10 LD19 OPEN PUSH MID LIMIT 24V AC 24V AC LD19 COM POWER LD18 OPEN PUSH for Normally Closed Stop Button 1. Connect a wire from the common connection of the control station to any “COM” terminal on the control board. MASTER/SLAVE INSTALLATION NOTE: A single unit is considered a Master. In a Master/Slave installation, one unit must be converted to LEFT HAND operation. 2. Connect a second wire from the “OPEN” button of the control station to the “OPN” terminal on the control board. 1. Place dipswitch #5 on the MASTER operator’s control board in the “OFF” position. 3. Connect a third wire from the “CLOSE” button of the control station to the “CLO” terminal on the control board. 2. Place dipswitch #5 on the SLAVE operator’s control board in the “ON” position. MASTER OPERATOR CONTROL BOARD SLAVE OPERATOR CONTROL BOARD P4 P4 P3 P3 LD1 LD1 LD11 OPEN ALT RADIO OPN/ CLO LD12 CLOSE LD15 RADIO OPEN STOP LD14 CLOSE PUSH OPEN LD16 STOP PUSH LD17 OFF LD9 OFF MAX CLO EDGE MOTO R OPEN MOTO R CLO SE SHADOW LO OP COM TB 2 COM COM LH OPN LIMIT LD7 1 2 3 4 5 FORCE ADJUSTM ENT ON 1 2 3 4 5 LD8 AUTO RECLOSE TIME R LD1 3 COM COM COM OPN EDG CLO EDG MST OPN MST CLO REV SHW OPN PHO CLO PHO U1 U4 TB 1 COM COM COM STO CLO ON CLOSE LD1 7 COM CLO SE PHOT O OPE N LD1 6 OPN EDG CLO EDG MST OPN MST CLO SHADOW LO OP OPN EDGE LD6 RH CLO REV OPEN PHOT O REV LO OP LH CLO LIMIT STOP SHW STO P PUSH MOTO R CLO SE LD1 4 MID LIMIT LD5 RH OPN CLO PHO CLO SE PUSH MOTO R OPEN TB 2 OPN COM RADIO OPEN RH CLO LH OPN LIMIT LD7 1 2 3 4 5 FORCE ADJUSTM ENT LH CLO LIMIT CLOS E LD1 5 OPN PHO RADIO OPN/ CLO COM CLO EDGE COM MAX LD4 STO LD1 3 COM LD9 OFF LD3 LD1 2 CLO LD8 AUTO RECLOSE TIME R LD1 1 OPE N OPN U1 U4 TB 1 NOTE: If Dipswitch #3 is in the “ON” position for use with a NORMALLY CLOSED “STOP” BUTTON, then the board mounted “STOP” button must be held depressed in order to use the open and close buttons. Releasing the stop button will then stop the operator. CLOSE LD1 7 LD2 U2 ALT COM OPE N LD1 6 FRE CLO SE PHOT O LD6 CRO OPEN PHOT O STOP RDO OPN STO P PUSH LD1 4 OPN EDGE LD5 RH OPN LD1 5 ALT CLO SE PUSH CLOS E FREE EXT FRE LD4 24V AC 24V AC RADIO OPN/ CLO LD1 0 REV LO OP ALT LD1 2 ALT LD19 OPEN PUSH CRO LD3 RADIO OPEN If Dipswitch #3 is in the “OFF” position, the board mounted three button station will function normally. U2 LD1 1 OPE N POW ER LD1 8 MID LIMIT COM LD1 0 COM BOARD MOUNTED CONTROL STATION FREE EXT LD2 RDO OPN LD19 24V AC 24V AC POW ER LD1 8 OPEN PUSH COM 4. Connect a fourth wire from the “STOP” button of the control station to the “STO” terminal on the control board. 1 2 3 4 5 OFF Master Slave P3 P4 LD1 POWER LD1 8 LD19 OPEN PUSH FREE EXT LD1 0 LD2 U2 LD1 1 OPEN LD3 LD1 2 LD4 ALT ON 1 2 3 4 5 CLO EDGE OFF OFF LD6 RH CLO CLOSE U1 LD8 U4 AUTO RECLOSE TIMER LD1 7 LD9 OFF LD1 3 MAX COM COM OPN EDG CLO EDG MST OPN MST CLO REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO MOTOR OPEN MOTOR CLOSE SHADOW LOOP TB 2 RDO OPN ALT FORCE ADJUSTMENT TB 1 LH OPN LIMIT LD7 1 2 3 4 5 COM OPEN LD1 6 24V AC 24V AC CLOSE PHOTO ON 1 2 3 4 5 LH CLO LIMIT STOP LD1 4 COM OPEN PHOTO COM STOP PUSH OPN EDGE LD5 RH OPN LD1 5 RADIO OPEN CLOSE PUSH CLOSE COM RADIO OPN/ CLO MID LIMIT REV LOOP For Normally Open Stop Button 28 For Normally Closed Stop Button 3. Connect a wire from the “MST OPN” terminal on the Master operators control board, to the “OPN” terminal on the Slave operators control board. 4. Connect a second wire from the “MST CLO” terminal on the Master operators control board, to the “CLO” terminal on the slave operators control board. 29 5. Connect a third wire from any “COM” terminal on the Master operators control board, to any “COM” terminal on the Slave operators control board. MASTER OPERATOR CONTROL BOARD SLAVE OPERATOR CONTROL BOARD P4 P4 LD1 AUTO RECLOSE TIMER LD9 OFF LD13 MAX 1 2 3 4 5 FORCE ADJUSTMENT COM COM COM COM COM COM OPN EDG CLO EDG MST OPN MST CLO REV SHW OPEN LIMIT SWITCH ADJUSTMENT: FORCE ADJUSTMENT TB1 OPN PHO CLO PHO COM LD13 COM CLOSE PHOTO STO SHADOW LOOP LD7 U4 LD17 CLO OPEN PHOTO OPN MOTOR CLOSE NOTE: For master slave installation, travel time for the master operator must be set longer than the slave operator. CLOSE LD16 FRE STOP PUSH CRO MOTOR OPEN RDO OPN MAX MOTOR CLOSE TB2 24V AC 24V AC OFF 1 2 3 4 5 NOTE: Operator should be completely installed, mechanically and electrically, before attempting to set limit switch cams. MOTOR OPEN SHADOW LOOP OPEN LD9 LH OPN LIMIT LD7 COM COM COM REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE LD8 U4 LD17 TB1 AUTO RECLOSE TIMER CLO EDGE ALT CLOSE PHOTO TB2 CRO ALT SHADOW LOOP LD16 COM 1 2 3 4 5 FORCE ADJUSTMENT U1 OPN EDG CLO EDG MST OPN MST CLO OPEN PHOTO CLOSE REV STOP PUSH MOTOR CLOSE OPEN SHW MOTOR OPEN LD7 OPN EDGE LD6 RH CLO OPN PHO CLO PHO MAX REV LOOP LH CLO LIMIT ST OP COM LD9 OFF LD14 MID LIMIT LD5 RH OPN LD15 COM CLOSE PUSH LD4 COM AUTO RECLOSE TIMER LD13 COM LH OPN LIMIT LD3 CLOSE STO LD8 U4 LD17 COM RADIO OPEN LD2 U2 LD12 CLO U1 LD16 TB1 LH CLO LIMIT LD19 LD11 OPEN ALT CLOSE LD10 COM OPEN RDO OPN CLOSE PHOTO RADIO OPN/ CLO LD6 RH CL O 24V AC 24V AC OPEN PHOTO ALT CLO EDGE COM CLOSE PUSH STOP PUSH FREE EXT OPN EDGE OPN ST OP OPN EDG CLO EDG MST OPN MST CLO LD14 OPEN PUSH REV LOOP LD5 RH OPN LD15 RADIO OPEN MID LIMIT FRE LD4 CLOSE CRO LD3 LD12 COM RADIO OPN/ CLO RDO OPN LD2 U2 LD11 OPEN ALT COM LD10 FREE EXT 24V AC 24V AC OPEN PUSH PO WER LD18 COM LD19 ▲ WARNING: READ ENTIRE PROCEDURE BEFORE STARTING. TURN OFF MAIN POWER BEFORE MAKING ANY ADJUSTMENTS! ▲ WARNING: STAY CLEAR OF ALL MOVING PARTS AND ELECTRICAL COMPONENTS OF THE OPERATOR WHILE TESTING! P3 P3 LD1 PO WER LD18 LIMIT ADJUSTMENT PROCEDURE SLAVE MASTER 1. Turn on power. Press open button on control station, gate should stop before full open position is reached. If gate does not stop when open position is reached, PRESS STOP BUTTON! 2. To adjust gate for more open travel, loosen open limit cam set screw and rotate limit cam, in the opposite direction drive shaft rotates to open gate. Re-tighten set screw after adjustment (See next page). 3. If it was necessary to stop gate, adjust open limit switch cam for less open travel, by rotating the cam in the same direction that the drive shaft rotates to open the gate. 4. Press close button and stop gate in mid travel with stop button. 5. Repeat procedure until desired open setting is obtained. 30 31 CLOSE LIMIT SWITCH ADJUSTMENT: EMERGENCY CONTROL STATION OPTION 1. Press close button on control station, gate should stop before full close position is reached. If gate does not stop when close position is reached, PRESS STOP BUTTON! 2. To adjust gate for more close travel, loosen close limit cam set screw and rotate limit cam, in the opposite direction drive shaft rotates to close gate (See Figure below). NOTE: When this emergency mode of operation is activated, the control station functions as a constant pressure control. P3 3. If it is necessary to stop gate, adjust close limit switch cam for less close travel by rotating the cam in the same direction that the drive shaft rotates to close the gate. Provision has been made to change the control station operational mode to one that would only be activated when the entrapment sensing system is in stop mode; with the warning horn activated. This would give a person access to control the gate in an emergency situation, but it would be inoperative under normal circumstances. To activate this option, move dipswitch #1 to the “ON” position. P4 LD1 LD10 LD2 LD3 OPEN ALT CLOSE OPEN PHOTO LD6 RH CLO OPEN CLOSE U1 CLOSE LIMIT SWITCH LD8 U4 AUTO RECLOSE TIMER LD17 SHW REV OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO ALT LH OPN LIMIT MOTOR OPEN MOTOR CLOSE LD7 SHADOW LOOP TB2 RDO OPN COM 24V AC 24V AC FORCE ADJUSTMENT TB1 COM OPEN LIMIT CAM MAX 1 2 3 4 5 CLOSE PHOTO LIMIT CAM LD9 OFF LD13 COM OPEN LIMIT SWITCH CLO EDGE LH CLO LIMIT STOP LD16 LIMIT SWITCH OPN EDGE COM LD14 CLOSE PUSH COM RADIO OPEN MID LIMIT REV LOOP LD5 RH OPN LD15 COM RADIO OPN/ CLO LD4 LD12 STOP PUSH DRIVE SHAFT LD19 U2 FREE EXT LD11 NOTE: After both “Open” and “Close” limit adjustments are complete, check that both limit cam set screws are tight. POWER LD18 OPEN PUSH OPN EDG CLO EDG MST OPN MST CLO 4. Press open button and stop gate in mid travel with stop button. Repeat procedure until desired close setting is obtained. CLOSE LIMIT CAM ACTUATING SCREW ADJUSTMENT SET SCREW Emergency Control Option ON 1 2 3 4 5 ON 1 2 3 4 5 OFF OFF ON OFF 32 33 TIMER TO CLOSE OPTION AUDIBLE PRE - MOVE WARNING By moving Dipswitch #4 to the “ON” position the option of a 3 second Audible Warning, before gate movement, may be selected. P3 P4 The operator is equipped with a timer to close option for use with OPEN ONLY control devices such as a radio control, or card key control. The AUTO RECLOSE TIMER adjustment screw is located on the printed circuit board. The operator is shipped from the factory with this timer preset to the off position; fully counter clockwise. As the timer adjustment screw is rotated clockwise, the closing of the gate can be delayed from 2 seconds to 60 seconds. The timer to close will be activated whenever the gate is stopped, except in the closed position. LD1 LD 18 LD 10 LD 11 LD3 OPEN AL T LD4 LD 12 CLOSE P3 P4 RA DIO OPEN LD19 OPEN PUSH LD10 LD3 OPEN ALT CLOSE OPEN CLOSE U1 LD16 LD8 U4 AUTO RECLOSE TIMER LD17 LD9 OFF LD13 MAX LD8 AUTO RECLOSE TIMER LD 17 LD9 OFF LD 13 MAX FORCE ADJUS TMENT MOTOR OPEN MOTOR CL OSE LD7 1 2 3 4 5 CL OSE PHO TO LH OPN LIM IT SHA DO W LOO P TB2 REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO ALT ON MOTOR CLOSE SHADOW LOOP Location Of Auto Close Timer Adjustment. Audible Pre-move Warning Option 1 2 3 4 5 OFF OFF MAX OFF 34 COM COM COM SHW REV OPN EDG CLO EDG MST OPN MST CLO ON 1 2 3 4 5 OFF OFF AUTO RECLOSE TIMER MAX. OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO ALT RDO OPN 24V AC 24V AC COM COM MOTOR OPEN TB2 RDO OPN 24V AC 24V AC COM TB1 COM FORCE ADJUSTMENT LH OPN LIMIT LD7 1 2 3 4 5 CLOSE PHOTO COM U1 U4 COM OPEN PHOTO CLOSE CLO EDGE LD6 RH CLO CLOSE PUSH STOP PUSH OPEN TB1 LH CLO LIMIT STOP COM LD14 COM RADIO OPEN OPN EDGE OPEN PHO TO CL O EDG E LD5 RH OPN LD15 OPN EDG CLO EDG MST OPN MST CLO RADIO OPN/ CLO LD4 LD12 REV LOOP OPN EDG E LD6 RH C LO STOP PUSH COM LD11 LD2 U2 FREE EXT REV LOO P LH CL O LIMIT STOP LD 16 MID LIMIT MID LIMIT LD5 RH OPN LD 15 LD 14 POWER LD2 U2 FR EE EXT CL OSE PUSH LD18 LD19 OPEN PUSH RA DIO OPN / CL O LD1 POWER 35 ON AUXILIARY CIRCUIT FOR USE WITH GATE LOCKS, WARNING LIGHTS, ETC An auxiliary 24 VAC power circuit, for use with a 24V control relay, has been provided. This circuit will be activated just prior to gate movement and will continue to be active until the gate stops. It may be used to control a gate lock, activate warning lights and solenoid controlled devices or any other system required during this time interval. Two control options are available. OPTION #2 – POWER SUPPLIED DURING GATE MOVEMENT The following diagram shows the connection of a device, such as a solenoid operated gate lock, requiring power during gate movement. Power In To Aux. Device Neutral Power leg Relay With 24 VAC Coil To Gate Locks, Warning Lights, Ect. N.C. N.O. WH OPTION #1 – POWER REMOVED DURING GATE MOVEMENT From Transformer Y 24 VAC WH BR GND (Common) P3 Below is a diagram showing the connection of a device, such as a magnetic gate lock, requiring the removal of power during the gate movement. WH R Y GY BK WH R P4 LD1 POWER LD18 LD19 OPEN PUSH LD10 STOP CLOSE STOP PUSH FORCE ADJUSTMENT LD3 OPEN ALT LD4 LD12 CLOSE STOP LD6 RH CLO CLOSE U1 LD8 U4 AUTO RECLOSE TIMER LD17 LD9 OFF LD13 MAX 36 REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO ALT MOTOR OPEN MOTOR CLOSE SHADOW LOOP TB2 RDO OPN COM COM 24V AC 24V AC FORCE ADJUSTMENT TB1 LH OPN LIMIT LD7 1 2 3 4 5 CLOSE PHOTO COM OPEN PHOTO OPEN LD16 COM CLOSE PUSH STOP PUSH CLO EDGE LH CLO LIMIT COM LD14 OPN EDGE LD5 RH OPN LD15 RADIO OPEN OPN EDG CLO EDG MST OPN MST CLO RADIO OPN/ CLO COM Aux. Circuit Using Normally Closed Control Relay MID LIMIT REV LOOP 37 MOTOR OPEN MOTOR CLOSE SHADOW LOOP COM COM SHW REV OPN PHO CLO PHO COM COM COM CLO OPN COM COM LD11 LD2 U2 LH OPN LIMIT LD7 TB2 P4 LD10 FREE EXT MAX 1 2 3 4 5 P3 LD19 OPEN PUSH LD9 OFF LD13 LD1 POWER LD8 AUTO RECLOSE TIMER LD17 TB1 LD18 U1 U4 COM OPEN LD16 CLOSE PHOTO CLO EDGE LD6 RH CLO CLOSE PUSH OPEN PHOTO OPN EDGE LH CLO LIMIT OPN EDG CLO EDG MST OPN MST CLO LD14 MID LIMIT REV LOOP LD5 RH OPN LD15 RADIO OPEN FRE 24 VAC GND (Common) WH BR LD4 CLOSE ALT From Transformer Y WH R Y GY BK WH R RADIO OPN/ CLO STO Aux. Circuit Using Normally Open Control Relay N.O. WH LD3 OPEN CRO N.C. LD12 RDO OPN Power leg LD11 ALT To Gate Locks, Warning Lights, Ect. 24V AC 24V AC Neutral COM Power In To Aux. Device Relay With 24 VAC Coil LD2 U2 FREE EXT ACCESSORY CONNECTIONS RADIO CONTROL INSTALLATION A Three or Four wire radio control receiver can be installed on this operator. This radio control receiver can only be used to open the gate, therefore the “TIMER TO CLOSE” option must be activated for closing. NOTE: If your radio’s connecting wires are not color coded as shown, see the radio’s installation manual to determine which wires are for the normally open contacts and which require the 24 VAC Power Supply. N.O. CONTACT 4 WIRE RADIO LOOP DETECTOR SYSTEMS AND INSTALLATION The diagram below depicts the typical loop options for a Slide Gate installation. 1. The Exit Loop provides a signal to open the gate when a vehicle enters the loop zone. 2. The Reversing Loop protects a vehicle in the loop zone from being contacted with the gate by overriding any close signal while the gate is open, and by reversing the gate if closing. 3. The Shadow loop protects a vehicle in the loop zone from being contacted with the gate by overriding any close signal while the gate is in full pen position. R1 GY R2 GY R3 BK USE THESE 3 TERMINALS FOR 3-WIRE RADIO CONTROL 4' 4' 4' 24 VAC R4 R 4' Approx. 10' 4' 4' RADIO CONTROL TERMINAL 3/16" To 1/4" Saw Slot 4' Road Surface Min 1" Sealant Loop wires 38 39 LOOP INSTALLATION 1. Layout the desired loop locations per the diagram. The standard size chart below will give an approximate length of wire required for various loop dimensions and number of turns required. The length of the lead in wires should be added to this amount to get the total amount of wire required for the installation. CAUTION: The Loop wires and Lead-in wires must be a continuous piece of wire without splices. Only use wire intended for this type of application. (Type XHHW insulation 16AWG) 2. Cut the required groove as shown in the diagram below at the locations laid out in Step #1. Loop Wire (See Chart) Lead In Wire (Twisted At 6 Turns Per Foot) 1/2" Conduit NOTE: Buried steel from drains or other systems may affect functioning of the loop system. Check with the factory for advice on any special installations. (1-800-243-4476). STANDARD LOOP LAYOUTS FOR APPROX 36” HEIGHT DETECTION LOOP SIZE # OF TURNS 4’X4’ 4’ X 6’ 4’ X 8’ 4’ X 10’ 4’ X 12’ 4’ X 14’ 4’ X 16’ 4’ X 18’ 4’ X 20’ 4’ X 22’ 4’ X 24’ 4’ X 26’ 4’ X 28’ 4’ X 30’ 4’ X 32’ 4’ X 34’ 4’ X 36’ 4’ X 38’ 4’ X 40’ 4 4 3 3 3 3 3 3 3 3 3 3 3 2 2 2 2 2 2 40 LOOP WIRE LENGTH (FT) 64’ 80’ 72’ 84’ 96’ 108’ 120’ 132’ 144’ 156’ 168’ 180’ 192’ 136’ 144’ 152’ 160’ 168’ 176’ Conduit Cut 3/16" To 1/4" 1" To 2" 1" To 2" 3. Leaving enough wire for the LEAD IN, insert the specified number of turns of wire in the cut grooves. (See chart). CAUTION: Be careful not to damage the wire insulation during installation. 4. After completing the required number of loop turns, twist the ends together at the rate of 6 turns per foot to form the LEAD-IN. 5. Seal the LEAD-IN wire in the conduit to prevent moisture seepage into the conduit. 41 LD13 8. Connect loop detector to the control board as shown in the following diagrams. BK OPN EDG REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE RDO OPN CRO Y V OR R P Not Used BL BR GY GR LD16 U4 STOP PUSH TO DRIVEWAY LOOP NOTE: TWIST LEADS APPOX. 6 TURNS PER FOOT. LD17 LD13 WH BK V OR R P COM STO CLO OPN FRE CRO ALT COM COM COM RDO OPN FORCE ADJUSTMENT TB1 24V AC 24V AC CLOSE PHOTO TB2 WH EXIT LOOP CONNECTION OPEN PHOTO ALT FORCE ADJUSTMENT TB1 24V AC 24V AC CLOSE PHOTO LD17 COM OPEN PHOTO COM 7. Mount the loop detector in the operator and connect the wire loop. SHADOW LOOP CONNECTION COM 6. Fill over the loop wires in the groove with a recommended loop sealant. Contact your distributor for available sealants. Not Used SAFETY DEVICE CONNECTIONS INHERENT OBSTRUCTION SENSING DEVICE: BL Y BR TO DRIVEWAY GY LOOP GR NOTE: TWIST LEADS APPOX. 6 TURNS PER FOOT. REVERSING LOOP CONNECTION LD13 BK Y V OR R P OPN EDG REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO ALT TB2 RDO OPN 24V AC 24V AC COM FORCE ADJUSTMENT TB1 COM CLOSE PHOTO LD17 COM OPEN PHOTO Not Used BL WH GR BR GY TO DRIVEWAY LOOP NOTE: TWIST LEADS APPOX. 6 TURNS PER FOOT. 42 NOTE: The gate MUST move smoothly and easily in manual operation before attempting this adjustment. WARNING: TURN OFF POWER TO OPERATOR WHEN MAKING ANY ADJUSTMENTS. This unit is supplied with a speed sensing system, which will stop the gate when it encounters an obstruction and then backs the gate off approximately 2 inches. If the gate is started again and a second encounter occurs before hitting a limit switch, the gate will stop and sound a warning signal. A constant pressure control will then be needed to start the gate. This sensing system has sensitivity adjustments located on the printed circuit board. These adjustments are set at the factory to handle the requirements of most installations. The force required to activate the system may be adjusted in both OPEN and CLOSE directions separately. 43 For heavy gates increase the force setting until it is just over what is required to move the gate smoothly without any nuisance tripping. NOTE: Most required sensitivity settings may be accomplished by adjusting the clutch. See the clutch adjustment before settings on control board. WARNING: NEVER INCREASE FORCE SETTING TO MAKE UP FOR A GATE THAT IS NOT MAINTAINED PROPERLY. THIS WILL DESENSITIZE THE OPERATION OF THE SAFETY SYSTEM. CLUTCH ADJUSTMENT NOTE: The clutch comes pre-adjusted from the factory and will function properly for the majority of installations. NEVER INCREASE FORCE SETTING OF CLUTCH TO MAKE UP FOR A GATE THAT IS NOT MAINTAINED PROPERLY. THIS WILL DESENSITIZE THE OPERATION OF THE SAFETY SYSTEM. NOTE: If more sensitivity is desired on a light gate: V-Belt Pulley P3 1. Turn off power on electric plate. Locking Set Screw P4 LD1 POWER LD18 LD19 OPEN P US H LD10 LD11 LD2 U2 FRE E E XT LD3 OPEN ALT CLOSE LD5 LD15 STOP LD6 OPEN P HO TO LD8 U4 AUTO RECLOSE TIMER LD17 MAX REV SHW OPN PHO CLO PHO COM COM COM STO CLO OPN FRE CRO OPN E DG E CLO E DG E RH OP N LH CLO LIMIT RH CLO LH OPN LIMIT 2. Loosen locking set screw in adjustment nut. Adjustment Nut M OTOR OPEN M OTOR CLOSE S HADO W LOO P TB2 RDO OPN ALT COM 24V AC 24V AC FORCE ADJUSTMENT REV LOO P LD7 1 2 3 4 5 COM COM LD9 OFF LD13 TB1 CLOSE U1 LD16 CLOSE P HO TO OPEN CLOSE COM S TOP P US H OPEN COM LD14 CLOSE P US H COM RADIO OPEN Location Of Drive Force Adjustment LD4 OPN EDG CLO EDG MST OPN MST CLO RADIO OPN/ CLO LD12 MID LIMIT 3. Loosen adjustment nut counter-clockwise ¼ of a turn. 4. Turn on power. To check sensitivity, stop gate in mid travel by manually obstructing gate. MAX. 5. Re-start gate. MIN. MIN. MAX. FORCE ADJUSTMENT NOTE: If operator goes into safety obstructionsensing mode when gate is started from mid travel position, the clutch is too loose. 6. Retighten adjustment nut, until the desired sensitivity is obtained. Lock adjustment with the locking set screw. If more driving force is required on an extra heavy gate: 7. Turn off power on electric plate. 44 45 8. Loosen locking set screw in adjustment nut. 1. Install electric edge sensors in locations shown below. 9. Tighten adjustment nut clockwise ¼ of a turn. 10. Turn on power and run gate to check the adjustment. NOTE: A separate pedestrian gate must be installed if there is no other entry access but the vehicular gate. 11. If gate is stopped in mid travel and then restarted without the operator going into the safety obstruction sensing mode, the clutch is tight enough. NOTE: If the clutch is too tight, the belt or drive chain may jump and a banging sound may be heard when the gate is obstructed in mid travel. 12. Loosen adjustment nut, until the desired drive force is obtained, then lock adjustment with the locking set screw. Electric E dge Mounted On Outside Bottom Of Gate SECONDARY OBSTRUCTION SENSING DEVICES 2. Connect contact sensor edges to the control board as shown in the illustration below. NOTE: 24 VAC power is available at marked terminals for devices that may require it (i.e., photo eyes, loop detectors, radio controls, etc. ) OFF MAX LD7 1 2 3 4 5 SHADOW LOOP COM COM REV Outside Edge COM NOTE: All safety device contacts must be NORMALLY OPEN. Electric E dge Mounted On Vertical Outside Edge Of Gate OPN EDG CLO EDG MST OPN MST CLO Another sensing device (Either a contact or a non-contact system) must be installed and connected to this unit to increase protection against entrapment per U/L requirements. Electric E dge M ounted On Inside Bottom Of Gate CONTACT SENSOR INSTALLATION: NOTE: Wireless sensors must be installed so there is no signal interference. NOTE: All hard wiring to safety edges must be installed so there is no threat of mechanical damage to wiring between components, when the gate is moving. 46 Inside Edge Vertical Edge 47 NOTE: The outside edge and vertical edge are connected to “CLO EDG” and “COM” terminals. 3. After sensors are mounted and electrically connected, turn on the power. 4. Test the close obstruction sensing system for proper operation, by depressing the outside edge sensing strip while the operator is running closed. 2. Photocells should be installed across the gate opening and behind the gate (as shown below) at least 10 inches above ground. NOTE: A separate pedestrian gate must be installed if there is no other entry access but the vehicular gate. NOTE: The operator should stop and reverse a short distance and then stop. 5. Run the operator to the open limit and repeat step #4 for the vertical edge. Photo Electric Cell ( For Open Direction) 6. Run the operator to the close limit. 7. Test the open obstruction sensing system by depressing the inside edge sensor while the gate is opening. NOTE: The operator should repeat the STOP AND REVERSE procedure. NOTE: If an edge is activated twice or a second edge is activated before a limit is hit (full open or close) operator will stop and sound a warning horn. To reactivate system turn operator power switch off then on. Photo Electric Reflector (Mount Past Gates Full Close Position ) 3. Connect NON-CONTACT sensors to the control board as shown below. NON CONTACT SENSOR CONNECTION 10 11 12 13 14 NON-CONTACT SENSOR INSTALLATION Reflector Close Photocell Sensor 1. Install photoelectric cell as close to FULL OPEN and FULL CLOSED position of gate as possible. 48 Photo Electric Reflector (Mount Past Gates Full Close Position ) Photo Electric Cell (For Close Direction) 49 Align With Reflector Align With Reflector Reflector Open Photocell Sensor NOTE: Close photocell is connected to “CLO PHO” and “COM” terminal. Open photocell is connected to “OPN PHO” and “COM” terminal. AFTER SENSORS ARE CONNECTED: LED & DIPSWITCH INFORMATION FOR 2004 UMCB-01 CONTROL BOARD 1. Turn on power. 2. Make sure the photo-beams are properly aligned per the manufacturer’s specifications. 3 . Test the CLOSE obstruction sensing system for proper operation, by blocking the beam across the gate opening while the gate is running closed. NOTE: The gate should stop and reverse a short distance and then stop. 4. Run operator to close limit. 5. Test the OPEN obstruction sensing system by blocking the beam mounted at the back area of the gate while the gate is running open. NOTE: The operator should repeat the stop and reverse procedure. 50 51 MAINTENANCE SUGGESTIONS The Reducer is completely sealed and should not require lubrication. Periodically check drive belt and all hardware (nuts, bolts, screws, etc) for tightness. Maintenance Log/Notes ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ 52 53 PowerMaster Limited 5 Year Warranty PowerMaster warrants all gate operators to be free of defects in materials and workmanship for a period of Five (5) years from date of purchase. If any part is found to be defective during this period, new parts will be furnished free of charge. Failure of this product due to misuse, improper installation, alterations, vandalism, or lack of maintenance is not covered under this warranty, and voids any other implied warranties herein. PowerMaster is not responsible for any labor charges incurred in connection with the installation of warranted parts. In order to activate this warranty, the registration form on opposite page MUST be completed and sent within THIRTY CALENDER DAYS FROM DATE OF PURCHASE VIA fax (631-951-3934) or via email to [email protected] If registration is not activated, a one year warranty will apply. Model RSW CSWC/CSWI Date Installed____________ Serial # ________________ The end user should retain this information for their records and to obtain warranty service. Installer’s Information Company Name _____________________ Company Address ___________________ Company Address ___________________ Company Address ___________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ Company Telephone # ________________ Company Contact ____________________ 54 55 Model CSWC/CSWI Date Installed____________ Serial # ________________ Location Installed: Address _______________ Address _______________ Address _______________ Installer’s Information Company Name _____________________________ Company Address ___________________________ Company Address ___________________________ Company Address ___________________________ Company Telephone # ________________________ Company Contact ____________________________ 56