Download Installation & Operating Instructions

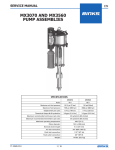

Transcript