Download Gasoline Edger - Olympia Millennium

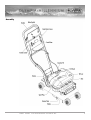

Transcript

Olympia Gasoline Edger W arra n ty Welcome to the Olympia Advantage The entire Olympia's Product line is designed and built to exacting standard to provide trouble free performance. Like all mechanical equipment however, trouble free performance requires a complete maintenance and proper operating procedures to be followed. Failure to follow a complete and on-going maintenance program will invalidate the Resurfice Corp. warranty on the Olympia Edger. Purchaser: ........................................................................................................................................................................ Address: ........................................................................................................................................................................ ........................................................................................................................................................................ ........................................................................................................................................................................ ........................................................................................................................................................................ Model: ........................................................................................................................................................................ Serial Number: ........................................................................................................................................................................ Date Delivered: ........................................................................................................................................................................ We have included a maintenance log form at the back of this manual to assist you in maintaining a permanent record of the maintenance carried out on the Olympia Edger. The illustrations and product information contained in this manual were current at the time of publication. In order to continue Resurfice Corp.'s development of its technology, Resurfice Corp. reserves the right to change designs, models and specifications without notice and without liability for such changes. Resurfice Corp. warrants the components of your Olympia Edger against defects in material and workmanship, for two full years from the date of delivery. The engine for your Olympia Edger is a 6 hp Briggs & Stratton. To validate it's warranty it must be placed on an ongoing maintenance program as outline in the engine manual included with the Olympia Edger. For the continued safe, economic operation and to validate the Resurfice Corp. warranty, the over all maintenance and operation of your Olympia Edger must strictly follow the guideline outlined in this manual. Resurfice Corp. or an authorized dealer must first authorize all warranty repairs. No warranty on this machine will be honored by Resurfice Corp. other than that stated above. WHAT EVERY ICE RESURFACER SHOULD BE i T able of C o n te n ts For Safe Operation The OLYMPIA™ Gasoline Edger is intended for use, only by people who have a basic knowledge of motorized equipment operation and maintenance. Resurfice Corp. cannot accept responsibility for any accidents that occur as a result of operation or maintenance of the machine . Operating conditions vary widely and Resurfice Corp. cannot predict these varying conditions, and it is therefore the user's responsibility to determine the appropriate settings in the operation of the OLYMPIA™ Gasoline Edger. Each OLYMPIA™ Gasoline Edger is shipped with a variety of built-in safety devices. To prevent the occurrence of such accidents, all operators and maintenance personnel that deal with the machine must carefully read the manuals supplied by Resurfice Corp. and Briggs & Stratton, before attempting to operate and maintain the OLYMPIA Gasoline Edger. Because there are many "things that cannot be done" and "things that must not be done" when using the OLYMPIA™ Gasoline Edger, it is impossible to cover it all in the OLYMPIA™ Gasoline Edger manual. Assume that something is impossible or unsuitable unless the manual specifically states that it can be done. The following manual is customized for the OLYMPIA™ Gasoline Edger. It provides detailed information regarding the following: 1 - DELIVERY PROCEDURE Assembly Procedure................................................................................................................................ 1 2 - OPERATING PROCEDURE Gasoline Edger Overview......................................................................................................................... 2 Blade Inspection and Replacement Procedures....................................................................................... 5 Maintenance Program............................................................................................................................. 5 Edger Operational Procedure.................................................................................................................. 7 3 - PARTS LIST..................................................................................................................................................... 8 Please make use of this material when operating and maintaining the OLYMPIA™ Gasoline Edger. Fundamental safety information is high lighted throughout the manual. All cautions on operation must be strictly observed when operating the machine, carrying out maintenance work, and storing the equipment. Failure to observe the fundamental safety information can cause accidents in which the operator or other personnel that deal with the OLYMPIA™ Gasoline Edger are seriously injured, or the machine is damaged. All personnel that deal with the machine must carefully read and thoroughly understand the information in the following pages before attempting to operate or maintain the OLYMPIA™ Gasoline Edger. ii O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D 1 A ssembly Assembly Instructions Olympia Gasoline Edger A B C Attach the Edger handle to the base using three 3/8" x 1" bolts and lock nuts as shown in fig. A Place the Depth Selection Lever in the top position. Attach the tie rod end to the lower adjusting bracket using the 3/8 x 1 1/4 bolt, washer and lock nut as shown in fig. B (Please note the adjusting rod is preset to the proper length) Check and add oil if necessary to engine. Fill the gasoline tank on the engine. Connect the electric leads as shown in fig. C WHAT EVERY ICE RESURFACER SHOULD BE 1 2 Gasoline fueled Olympia Edger Overview O perati n g P rocedure WARNING! All operators of the Olympia Edger must read and familiarize themselves with this parts and service manual. Particular attention must be paid to the Briggs and Stratton operating and maintenance manual supplied with the Olympia Edger. Maintenance log must be completed for safe operation and to retain warranty coverage the Olympia Edger must be properly maintained and in safe working order. If problems occur the edger is to be turned off immediately, and removed from service until the equipment has been properly repaired and tested. Prior to each edging operation you must 1. Remove the spark plug wire to prevent accidental starting of the engine. 2. Check that the carbide cutting blades are securely fastened and not damaged. 3. If the blades are damaged remove them and replace them with new blades as per the blade replacement procedure. (see page 3) 4. Replace the spark plug wire. Always make sure the arena ventilation system is on and operating properly prior to starting the Olympia edger. Always make sure the ice is clear of both members of the public and arena staff prior to operating the edger. Safety Glasses, (steel toed) safety boots with proper grips, and proper ear protection gear must be worn by all staff during edging operation. 2 O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Assembly WHAT EVERY ICE RESURFACER SHOULD BE 3 2 O perati n g P rocedure Safe Operation of Gasoline fueled Olympia Edger SAFETY WARNING: If the following instructions are not followed it can result in a fire or an explosion can occur causing personal injury Operating Safe Guards Olympia Edger 1. DO NOT start or operate the edger when an odor of gasoline is present or other explosive conditions exist. 2. Make sure the edger muffler is in place and operating properly. 3. Carry out periodic inspections of the muffler, clean away any debris or combustible material from the muffler area. Replace the muffler when necessary. A defective muffler can permit an increased exhaust noise level. 4. Never operate the edger if the air cleaner or cover directly over the carburetor air intake is removed. 5. DO NOT choke the carburetor to stop the engine. 6. NEVER tamper with the preset governor springs, governor links, nor make any adjustment to the factory engine speed presets. 7. DO NOT touch the mufflers, cylinders or fins as contact may cause burns. 8. Dirt or debris in the cooling fans or governor parts can adversely affect engine performance. Turn off engine, let cool and then clean with a non-flammable brush. 9. Prior to starting the edger, check to make sure the blade is properly in place. A loose blade or no blade can cause a sever kickback, making sure to remove the spark plug wire prior to checking. 10. Always keep hands and feet clear of moving parts. 11. If manual start is necessary always pull starter cord rapidly to avoid kickback. Refueling Olympia Edger 1. Always shut down the motor of the edger and allow the engine to cool for at least two minutes before adding any gasoline to the fuel tank. 2. In it situation where gasoline is spilled, move the edger away from the spill to a safe, vented area and do not create any source of ignition until the gasoline has evaporated and the fumes have been exhausted out of the area. 3. Do not attempt to fill the edger while the engine is running. 4. Allow the engine time to cool off before refueling. 5. Refuel the gasoline fueled Olympia Edger outdoors or in a well ventilated refueling area. 6. When transporting the edger or when not in use, make sure the fuel supply valve is fully closed to prevent the possibility of fuel leaking from the carburetor. 7. When servicing or checking the edger, first remove the wire from the spark plug or remove the spark plug. 8. DO NOT tilt the edger over at any time. This will prevent oil from draining into the carburetor or exhaust. 9. Never fill above 75% of the capacity of fuel tank. 4 NEVER RUN THE Olympia Gasoline FUELED EDGER IN AN ENCLOSED AREA. Gasoline engine exhaust contains carbon monoxide, an odorless and deadly poison. O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Maintenance Procedure To properly maintain the Olympia Edger follow the engine manufacturer’s maintenance instruction manual, which came with your Olympia Edger. Make sure you adhere to the oil specifications, grade and change intervals, air filter service and replacement schedule. When you replace the spark plug at the appropriate scheduled time, make sure you replace it with the same kind of spark plug that came with the engine and insure that the gap is set to 0.030 inches. SAFETY NOTE: Never attempt to adjust the carburetor system! Battery Maintenance The Olympia Edger comes equipped with a fully recyclable, non-hazardous material 12-volt electric battery. Please note the battery on the Olympia Edger should be fully charged prior to use. To prevent deterioration of the battery it should be stored at room temperature between 15 and 24 degrees Celsius (or 60 and 80 degrees Farenheit). It is important the battery be fully charged prior to storage. Fuel Storage Spare fuel for the Olympia Edger must be stored in a well-ventilated storage area, which is safe and secure and complies with all fire and safety regulations. SAFETY IS YOUR FIRST JOB: Always keep the edger away from all sources of ignition. Never allow operators to smoke around the edger or in the refueling and storage areas. Never inspect the underside of the edger while the engine is running or while the spark plug wire is attached. Blade Changing Procedure Before using the OLYMPIA™ Gasoline Edger you first must inspect the blades to ensure they are undamaged and secured tightly to the blade plate. SAFETY NOTE: Prior to inspecting the blade tips make sure you are wearing protective gloves. (1.6 mm) 1. With the assistance of a second person, lift the edger onto a workbench, making sure to lift with the legs not the back. 2. Always remove the spark plug wire first before servicing the edger. 3. Remove the Oil Drain Plug and drain the oil. 4. Re-install the Oil Drain Plug. WHAT EVERY ICE RESURFACER SHOULD BE 5 2 O perati n g P rocedure SAFETY NOTE: Failure to follow this procedure will result in oil leaking from the carburetor saturating the air filter, making it very hard to start the edger and requiring the air filter to be replaced. 5. Rotate the blade plate and visually inspect each of the blade tips to ensure they are undamaged, sharp and securely tighten to the blade plate. If the blade tip is damaged, the edger will vibrate and you will get an uneven finish on the ice. Even more important, a loose or damaged blade tip could seperate from the blade plate and cause serious injury or damage. SAFETY NOTE: Most blade damage is caused by hitting screws in the dasher boards or ice surface entrance threshholds. 6. When a blade needs replacement, first undo the four bolts holding the blade plate in place. 7. On a work surface loosen the two bolts holding the blade tip to the blade plate. Remove the damaged tip and replace it with a new blade tip, making sure to position it correctly on the plate before tightening the holding bolts to a maximum 11 ft. lbs of torque. 8. Using a straight edge along the opening in the cutting side of the edger, adjust the blade tips in or out along the slotted guides until they are 1/16 of an inch (1.6 mm) from the straight edge. Hand tighten and check clearance. Positioning the blade tip beyond the blade guard casing will cause damage to both the blade tip and the boards. To maintain the consistent edging, make sure the blade tips are the same distance from the outer edge of the blade guard casing. To double check, measure an existing undamaged blade for the proper measurement and adjust the new blade accordingly. 9. On the eight blade plate, we recommend every second blade be inset by moving it to the back of the slide groove. The alternate blade tips are positioned correctly by measuring from the outer edge of the blade guard casing to the tip of the blade. It should be 1/16" to 1/8" inside the edge. Positioning the blade tip beyond the blade guard casing will cause damage to both the blade tip and the boards. To maintain the consistent edging, make sure the blade tips are the same distance from the outer edge of the blade guard casing. To double check, measure an existing undamaged blade for the proper measurement and adjust the new blade accordingly. When the blades are inspected and replaced if necessary, re-attach the blade plate with the four bolts making sure to tighten to a maximum 11 ft. lbs. of torque on the grade 8 bolts. Safety Note: Make sure you do not over torque the blade attachment bolts. It can cause the blade to break and fly out from under the edger. Because of the high velocity of the spinning blade plate this can be extremely dangerous. 10. Refill the oil using 10W/30 oil 11. Reconnect the spark plug wire. 12. With the assistance of a second person lift the edger off the workbench and place it back onto the floor. 6 O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Ice Edging Proceedure Once the egder blades have been inspected and replaced if necessary, you are ready to edge the ice surface. The OLYMPIA™ Gasoline Edger is designed to remove ice build up along the boards and level the ice surface. Ice buildup extends from the board into the ice surface. To properly level the ice we recommend the following proceedure: 1. 2. 3. Check to ensure there is adequate fuel in tank. Check the oil level and top up if necessary. With the blades in the "Up" position, push the Olympia Hand Edger onto the ice surface. Safety first: Before entering the ice surface make sure you are wearing steel toed boots, safety googles or glasses, and studded slip on boot covers to provide proper traction on the ice. 4. Push the OLYMPIA™ Gasoline Edger onto the ice surface. Securely close the entrance door and ensure that all the other entrance doors are closed and secured. 5. Walk the entire circumference of the ice surface examining the board surfaces for protruding screws and materials embedded into the ice and / or boards. Remove any such debris. This will prevent damage to the edger, the boards and most importantly to the operator. 6. After completing the board inspection walk around the circumference of the rink a second time, examining the ice surface for high spots. Using a felt tip pen, mark the beginning of a high spot with a line and an arrow pointing forward along the high spot. At the end of the high spot mark another line and an arrow pointing backwards. This will clearly indicate where you have to spot edge the ice. 7. Move the remote choke lever forward to choke the engine prior to starting. 8. Compress the safety handle bar. 9. Turn the key on the handle to start the engine. 10. Once the engine has started, return the choke lever to the off position 11. With the blades in the fully up positon push the edger forward to the first marked high spot. It is very important to keep the edger moving thoughout the edging process. 12. When the edger is against the board and you reach the first arrow, lower the cutting blades by pushing the lock button on the blade height control lever to release it and lower the cutter asembly by pushing the lever downward. The blades will begin to cut into the high spot , removing the ice. As you reach the end of the high spot, push in the control button on top of the blade height lever and pull up to bring the blades off the ice surface. Repeat this until each high spot has been removed. 13. Once the high spots are removed do a second lap around the ice circumference. Move the edger against the boards with the blades spinning in the raised position. Now, moving forward, push the blade height control lever until the cutter assembly starts cutting a thin cut of the ice. Maintaining that cut level, edge the entire circumference of the ice surface. SAFETY NOTE: NEVER move the OLYMPIA™ Gasoline Edger backward when the blades are moving or try to cut backwards. 14. After completing the edging operation, pull the blade level lever back to the top position in order to fully raise the blades. (Damage to the cutting tips, blade arm and /or crankshaft may occur if the blade arm is not fully raised prior to starting and stopping the edger engine.) WHAT EVERY ICE RESURFACER SHOULD BE 7 3 PARTS LIST Edger Electric Start Ignition Switch 8 Ref# Part # 1 55-10165 2 55-10160 Descritption Electric Start Key Electric Start Switch OEM # 63-8360 46-5780 O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Electrical System Ref# 1 2 3 4 5 6 7 Part # 55-10165 55-4000 49-30120 55-10155 55-10150 49-33115 55-500 Descritption Electric Key Start Edger Handle Socket Cap Screw 10/24 x 3/4 Electric Start Battery Case Electric Start Battery Locknut-Nylon 10-24 6HP Intek Engine & Electric St. OEM # 63-8360 Model 5 Lawnboy 95-3017 Lawnboy 55-7520 10-24 Nylon Insert Locknut 121607-0227-E1 WHAT EVERY ICE RESURFACER SHOULD BE 9 3 Control Arm 10 PARTS LIST Ref# Part # 1 55-5120 2 10-120 C18291600318 3 55-5100 4 55-5110 5 50-51925 6 49-30550 1-1/4 7 25-51855 8 49-33600 9 49-37800 10 49-19035 11 49-33500 12 49-36300 13 55-3300 14 49-30050 15 55-3210 16 49-33555 17 49-33235 18 55-3100 19 5-3200 20 55-3150 O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Descritption Depth Selector Handle Knob Gear Shift Spring Depth Selector Rod Depth Selector Handle Stripper Bolt 1/2 x 1-1/4 Hex Hd Bolt 3/8 x 1-1/4 OEM # 3/8 - 16 x Rod End VCW6 Hex Hd Nut 3/8 - 24 Split Pin 1/4 x 1-1/2 Grease Fitting 1/4 - 28 Straight Locknut - Nylon 3/8 - 16 Flat Washer 1/2 SAE Depth Adjustment Rod Stripper Bolt 3/8 x 3/8 Engine Mount Connecting Bar Hex Jam Nut 3/8-16 Hex Jam Nut 5/16-18 Engine Mount Back Engine Mount Depth Adj. Front Engine Mount Depth Adj. Under Carriage Ref# 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Part # 55-500 55-3100 49-33555 55-1000 55-3000 49-30200 49-36170 50-51975 49-30150 49-36100 55-25355 50-51760 49-36250 49-30560 Descritption 6HP Intek Engine & Electric St. Engine Mount Hex Jam Nut 3/8 –16 Rubber Wheel 4" Edger Base Hex Hd Cap Screw 1/4 x 3/4 Lock Washer 1/4 Bottom Hub Hex Hd. Bolt 1/4 x 1/2 Flat Washer 1/4 hole Bottom Plate 12" - 8 Blade Edger Blade Flat Washer 3/8 Hex Hd Bolt 3/8 x 1 1/4 OEM # 121607-0227-E1 Model 5 100SRP Model 5 1/4 - 20 x 3/4 1/4 - 20 x 1/2 3/16 flat Washer – Zinc 3/8 – 24 x 1 1/4 WHAT EVERY ICE RESURFACER SHOULD BE 11 3 Gasoline Fuel System 12 PARTS LIST Ref# 1 2 3 4 5 6 7 8 9 Part # 55-4000 55-4500 55-2000 55-9010 49-30245 37-60120 49-33200 55-2050 55-500 O L Y M P I A M I L L E NN I U M – T H E N E W S T A N D A R D Descritption Edger Handle Safety Shut-off Bar Pivot Stop Throttle Cable Hex Hd Bolt 1/4 x 1 1/2 1/4" Tube Clamp Locknut Nylon 1/4 - 20 Brake Cable 6 HP Intek Engine & Electric St. OEM # 92-5412 93-4186 1/4 - 20 x 1 1/2 HCS GANGC2 766321 98-7147 121607-0227-E1 4 MAINTENANCE LOG Maintenance Log To assist you in maintaining a permanent record of your maintenance program for your new Olympia, keep track of all maintenance performed in the following log. Copy this form for additional pages as needed. Date Hours of Operation Maintenance Performed .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. .............................................................................................................................................................................. WHAT EVERY ICE RESURFACER SHOULD BE 13