Download Owner`s Manual Split Shaft and Gear Box

Transcript

Bulletin HY25-1202-M1/US

Owner’s Manual

Split Shaft and

Gear Box

Effective:

January 2005

Supersedes: HY25-1202-M1/US

April 2003

700 Series

712 Series

721 Series

732 Series

741 Series

901 Series

912 Series

931 Series

941 Series

2230 Series

2442 Series

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors

provide product and/or system options for further investigation by users having technical expertise. It is important

that you analyze all aspects of your application and review the information concerning the product or system in the

current product catalog. Due to the variety of operating conditions and applications for these products or systems,

the user, through its own analysis and testing, is solely responsible for making the final selection of the products and

systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and

pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

Offer of Sale

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or

its authorized distributors. This offer and its acceptance are governed by the provisions stated in the "Offer of Sale".

Patent Information

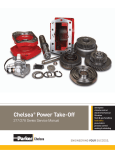

The Chelsea® Power Take-Off or its components shipped with this owner’s manual may be manufactured under

one or more of the following U.S. patents:

4610175

5228355

4597301

5645363

6151975

6142274

6260682

Other patents pending.

© Copyright 2005, Parker Hannifin Corporation, All Rights Reserved

II

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Contents

Owner’s Manual

Split Shafts and Gear Box

General Information

Safety Information ..................................................................................................... 1-3

Direct Mount Pump Support Recommendations ..................................................... 4

Shifting Procedures ................................................................................................... 5

Foreword ................................................................................................................... 6

Split Shaft and Gear Box Specifications .................................................................. 8

Horsepower-Torque-R.P.M. Conversion Chart .......................................................... 9

Installation of a Split Shaft

Application Data ........................................................................................................ 10-11

Lubrication Information ............................................................................................. 12

Installation Instructions ............................................................................................. 13

Model 901 Installation Drawings ............................................................................... 14

Model 901 Dimensional Drawings ............................................................................ 15

Model 912 Installation Drawing ................................................................................ 16

Model 912 Dimensional Drawing .............................................................................. 17

Model 931 Installation Drawings ............................................................................... 18

Model 931 Dimensional Drawings ............................................................................ 19

Model 941 Installation Drawing ................................................................................ 20

Model 941 Dimensional Drawing .............................................................................. 21

Installation of a Gear Box

Installation Instructions ............................................................................................. 22

Models 700, 712, 721, 732, 741, 2230 and 2442

Breather Hose Installation .............................................................................................. 23

Installation of a P.T.O. to a Split Shaft

Application Questions ............................................................................................... 24

Mounting Instructions—6 or 8 Bolt Applications ........................................................ 25-26

880/912 Split Shaft Installation ................................................................................. 27

Checking Backlash ........................................................................................................ 28

Wire Shift P.T.O.’s and Gear Boxes

Cable Control Installation Instructions ....................................................................... 29-32

Air Shift Installation Sketch

2442 Gear Box .......................................................................................................... 33

901, 912, and 941 Split Shafts ................................................................................. 34

Air Shift Circuit 2230 Series ..................................................................................... 35

Dash Drilling Templates

2442 Gear Box Air Shift Control .............................................................................. 36

901, 912, and 941 Split Shafts Air Shift Control ...................................................... 37

Wire and Lever Controls .......................................................................................... 38

Indicator Light Installation ......................................................................................... 39

Continuity Check ........................................................................................................... 40

Troubleshooting ............................................................................................................ 41-42

Power Take-Off Maintenance ....................................................................................... 43

Offer of Sale .................................................................................................................... 44

III

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Safety Information

These instructions are for your safety and the safety of the end user. Read them carefully

until you understand them.

General Safety Information

To prevent injury to yourself and/or damage to the equipment:

■

Read carefully all owner’s manuals, service manuals, and/or other instructions.

■

Always follow proper procedures, and use proper tools and safety equipment.

■

Be sure to receive proper training.

■

Never work alone while under a vehicle or while repairing or maintaining equipment.

■

Always use proper components in applications for which they are approved.

■

Be sure to assemble components properly.

■

Never use wornout or damaged components.

■

Always block any raised or moving device that may injure a person working on or under

a vehicle.

■

Never operate the controls of the Power Take-Off or other driven equipment from any

position that could result in getting caught in the moving machinery.

Proper Matching of P.T.O.

WARNING: A Power Take-Off must be properly matched to the vehicle transmission

and to the auxiliary equipment being powered. An improperly matched Power Take-Off

could cause severe damage to the vehicle transmission, the auxiliary driveshaft, and/or to

the auxiliary equipment being powered. Damaged components or equipment could

malfunction causing serious personal injury to the vehicle operator or to others

nearby.

To avoid personal injury and/or equipment damage:

■

Always refer to Chelsea catalogs, literature, and owner’s manuals and follow Chelsea

recommendations when selecting, installing, repairing, or operating a Power Take-Off.

■

Never attempt to use a Power Take-Off not specifically recommended by Chelsea for

the vehicle transmission.

■

Always match the Power Take-Off’s specified output capabilities to the requirements of

the equipment to be powered.

■

Never use a Power Take-Off whose range of speed could exceed the maximum safe

speed of the equipment to be powered.

This symbol warns of possible personal injury.

1

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Safety Information (Continued)

Cold Weather Operation of Powershift P.T.O.s

WARNING: During extreme cold weather operation [32°F (0°C) and lower], a

disengaged Powershift Power Take-Off can momentarily transmit high torque that will

cause unexpected output shaft rotation. This is caused by the high viscosity of the

transmission oil when it is extremely cold. As slippage occurs between the Power Take-Off

clutch plates, the oil will rapidly heat up and the viscous drag will quickly decrease.

The Power Take-Off output shaft rotation could cause unexpected movement of the driven

equipment resulting in serious personal injury, death, or equipment damage.

To avoid personal injury or equipment damage:

■

Driven equipment must have separate controls.

■

The driven equipment must be left in the disengaged position when not in operation.

■

Do not operate the driven equipment until the vehicle is allowed to warm up.

Rotating Auxiliary Driveshafts

WARNING:

■

Rotating auxiliary driveshafts are dangerous. You can snag clothes, skin, hair, hands,

etc. This can cause serious injury or death.

■

Do not go under the vehicle when the engine is running.

■

Do not work on or near an exposed shaft when the engine is running.

■

Shut off the engine before working on the Power Take-Off or driven equipment.

■

Exposed rotating driveshafts must be guarded.

Guarding Auxiliary Driveshafts

WARNING: We strongly recommend that a Power Take-Off and a directly mounted

pump be used to eliminate the auxiliary driveshaft whenever possible. If an auxiliary driveshaft is used and remains exposed after installation, it is the responsibility of the vehicle

designer and P.T.O. installer to install a guard.

This symbol warns of possible personal injury.

2

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Safety Information (Continued)

Using Set Screws

WARNING: Auxiliary driveshafts may be installed with either recessed or protruding

set screws. If you choose a square head set screw, you should be aware that it will

protrude above the hub of the yoke and may be a point where clothes, skin, hair, hands,

etc. could be snagged. A socket head set screw, which may not protrude above the hub of

the yoke, does not permit the same amount of torquing as does a square head set screw.

Also, a square head set screw, if used with a lock wire, will prevent loosening of the screw

caused by vibration. Regardless of the choice made with respect to a set screw, an

exposed rotating auxiliary driveshaft must be guarded.

IMPORTANT: Safety Information and Owner’s Manual

Chelsea Power Take-Offs are packaged with safety information decals, instructions, and an

owner’s manual. These items are located in the envelope with the P.T.O. mounting gaskets.

Also, safety information and installation instructions are packaged with some individual

parts and kits. Be sure to read the owner’s manual before installing or operating the

P. T. O. Always install the safety information decals according to the instructions provided.

Place the owner’s manual in the vehicle glove compartment.

WARNING: Operating the P.T.O. with the Vehicle in Motion

Some Power Take-Offs may be operated when the vehicle is in motion. To do so, the P.T.O.

must have been properly selected to operate at highway speeds and correctly matched to

the vehicle transmission and the requirements of the driven equipment.

If in doubt about the P.T.O.s specifications and capabilities, avoid operating the P.T.O. when

the vehicle is in motion. Improper application and/or operation can cause serious personal

injury or premature failure of the vehicle, the driven equipment, and/or the P.T.O.

Always remember to disengage the P.T.O. when the driven equipment is not in operation.

Pump Installation Precautions (see next page)

Use a bracket to support the pump to the transmission if:

■ The pump weighs 40 pounds [18.14 kg] or more.

■ The combined length of the P.T.O. and pump is 18 inches [45.72 cm] or more from the

P.T.O. centerline to the end of the pump.

This symbol warns of possible personal injury.

3

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Direct Mount Pump Support Recommendations

Note: For Proper Bracketing Attach At 2 or

more Transmission Bolt Locations

and 2 or More Pump Locations.

Use caution to ensure that bracket does not pre-load pump/

P.T.O. mounting

Chelsea strongly recommends the use of pump supports (Support Brackets) in all applications.

P.T.O. warranty will be void if a pump bracket is not used when:

1) The combined weight of pump, fittings and hose exceed 40 pounds [18.14 kg].

2) The combined length of the P.T.O. and pump is 18 inches [45.72 cm] or more from

the P.T.O. centerline to the end of the pump.

ALSO:

Remember to pack the female pilot of the P.T.O. pump shaft with grease before

installing the pump on the P.T.O. (reference Chelsea grease pack 379688)

This symbol warns of possible personal injury.

4

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Shifting Procedures

Gear Box Operation

P.T.O. mode to road mode:

Vehicle Stationary

Before shifting the gear box into or out of

gear, make sure the gears in the unit and

input shaft have stopped rotating.

1. Disengage the clutch.

2. Shift the split shaft to road mode.

3. Disengage the parking brakes.

4. Resume normal driving procedures.

Split Shaft Operation

Manual Transmission—Vehicle Stationary

Automatic Transmission

Road mode to P.T.O. mode:

Road mode to P.T.O. mode:

1. Disengage the clutch and stop the

vehicle.

1. Stop the vehicle.

2. Engage the parking brakes.

2. Engage the parking brakes.

3. Shift the transmission into Neutral “N.”

3. Shift the split shaft to P.T.O. mode.

4. Shift the split shaft to P.T.O. mode.

4. Select the desired transmission gear as

required.

5. Shift the transmission into the desired

drive range position.

5. Engage the clutch.

6. Apply throttle as required.

6. Apply throttle as required.

P.T.O. mode to road mode:

1. Shift the transmission into Neutral “N.”

2. Shift the split shaft to road mode.

3. Release the parking brake.

4. Resume normal driving procedures.

CAUTION: Inadvertent shift may cause

vehicle movement or unexpected

engagement of P.T.O.

5

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

Foreword

Since it is our major objective to show you how to get additional and more profitable

miles from truck, tractor, and trailer components, we want to provide you with information

on the installation of Chelsea Power Take-Offs.

We all realize that an inadequate Split Shaft will overwork any Power Take-Off in a very

short period of time. In addition, a mismatched Split Shaft/P.T.O. combination can result

in unsatisfactory performance of the equipment right from the start.

Before you order new trucks, be sure that you’re getting the right Gear Box, Split Shaft or

P.T.O. combination. This is vital for efficient performance and adequate power. To help you

select the proper type, size, and design of P.T.O., discuss your specific requirements with

a Chelsea P.T.O. specialist. They know their products and have easy access to equipment, transmission, and Power Take-Off manufacturers. They can tell you everything you

need to know about power, at the right time, before you specify components.

Chelsea P.T.O. Safety Label Instructions

1. The two black and orange on white 5" x 7" pressure sensitive vinyl labels, part number

379274; must be placed on the vehicle frame rails (one (1) on each side), in a position

that would be HIGHLY visible to anyone that would go under the truck near the P.T.O.

rotating shaft. If the vehicle is to be painted after these labels are installed, cover them

with two-(2) blank masking covers. Remove the masking covers after painting.

2. Place the one (1) black and orange on white 3.5" x 5" pressure sensitive vinyl label, part

number 379275, on the visor nearest the operator of the vehicle, this must be placed

near the P.T.O. visor label.

3. Place the one (1) red and white with black lettering 3.5" x 7.5" sensitive vinyl label, part

number 379915, on the opposite side of the visor from the above label # 379275.

4. Place the one (1) white and black heavy duty card, part number 379276, in the vehicle

glove box. Again in a position highly visible to the operator, for example: try to place this

card on top of whatever may be in the glove box.

If you require additional labels, please order part number 328946X at no charge from your

local Chelsea Warehouse or send request direct to:

Parker Hannifin Corporation

Chelsea Products Division

8225 Hacks Cross Road

Olive Branch, MS 38654

Customer Service: (662) 895-1011

6

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

General Information

Owner’s Manual

Split Shafts and Gear Box

7

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

General Information

Split Shaft and Gear Box Specifications

Model No.

700

Single Speed

712 Two

Speed Shaft

721

732

741

2230U

2442F

2442L

2442Q

2442R

2442S

2442U

2442W

2442X

Intermittent

Torque

Horsepower at

Rating

Approximate Lube

500 R.P.M. 1000 R.P.M. P.T.O. Shaft

Weight

Capacity Liters

11.9

10

23.5

20

125 ft. lbs.

110 ft. lbs.

39 lbs.

39 lbs.

1.5 pt.

1.5 pt.

.7

.7

11.9

13.2

13.2

13.2

21.4

23.5

23.5

21.4

21.4

19

18.6

16.7

13.2

23.5

26.5

26.5

26.5

42.8

47

47

42.8

42.8

38

37.2

33.4

26.5

125 ft. lbs.

140 ft. lbs.

140 ft. lbs.

140 ft. lbs.

225 ft. lbs.

250 ft. lbs.

250 ft. lbs.

225 ft. lbs.

225 ft. lbs.

200 ft. lbs.

195 ft. lbs.

175 ft. lbs.

140 ft. lbs.

39 lbs.

49 lbs.

49 lbs.

49 lbs.

88 lbs.

69 lbs.

69 lbs.

69 lbs.

69 lbs.

69 lbs.

69 lbs.

69 lbs.

69 lbs.

901•

500 ft. lbs.

185 lbs.

912•

*

130 lbs.

931•

941•

250 ft. lbs.

**

102 lbs.

60 lbs.

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

1.5 pt.

.7

2.5 qt.

vertical

2.4

3.0 qt.

horizontal

2.8

2.5 qt. less

P.T.O.

2.4

2.25 qt.

2.175

2.25 pt.

• For allowable split shaft input torque, please consult the chart on page 11.

* The 912 has 3 eight bolt P.T.O. openings on it. For correct P.T.O. applications please

consult your HY25-3000/US catalog.

**The 941 has 2 six bolt P.T.O. openings on it. For correct P.T.O. applications please

consult your HY25-3000/US catalog.

8

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

General Information

Horsepower-Torque-R.P.M. Conversion Chart

To find the Torque. Given: 100 HP at 1750 R.P.M.

Then: with a straight edge on HP scale at 100 (Left Side) and on R.P.M. scale at 1750.

Find Answer on T scale = 300 foot pounds torque (Middle).

Formula: HP x 5252 = T Foot Pounds Torque

R.P.M.

To find the HP. Given: 3 pounds feet torque at 1750 R.P.M.

Then: with a straight edge on the T scale at 3 (Middle) and on the R.P.M. scale at 1750.

Find Answer on the HP scale = 1 Horsepower (Left Side)

Formula: T x R.P.M. = HP Horsepower

R.P.M.

1000

10

9

8

7

6

500

5

400

4

300

3

250

2.5

200

2

150

1.5

100

1

.9

.8

.7

.6

70

50

.5

40

35

30

.4

.35

25

.25

20

.2

2000

30

100,000

1000

40

50,000

40,000

30,000

500

400

300

20,000

200

10,000

100

50

.1

HP

Horsepower

Scale

60

70

80

90

100

150

5000

4000

3000

50

40

30

2000

20

1000

10

500

400

300

5

4

3

200

2

100

1

50

40

30

.5

.4

.3

20

.2

.3

15

10

200,000

200

300

400

500

600

700

800

900

1000

1500

T

Torque

Foot Pounds Scale

9

2000

3000

R.P.M.

Revolutions

Per Minute Scale

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation of a Split Shaft

Application Data for Installation of a Split Shaft

Split Shaft Through Torque Ratings

The torque capacity of the Chelsea Split Shaft units is limited by either the engine capacity

or the vehicle wheel skid conditions. To correctly choose a split shaft model for a given

application, the maximum torque from the engine, and the maximum torque due to wheel

conditions, should be calculated. The limiting value obtained by these calculations should

then be compared with the charted split shaft torque capacity.

Formula

Maximum Through Torque From the Engine

1.

Maximum Torque From the Engine = Maximum Net Engine Torque X Manual Transmission Low Gear Ratio X 85% Efficiency

2.

For an automatic transmission, the maximum torque from the engine should be taken

from the engine-transmission performance curve stall torque valve. This information is

generally available from the manufacturer of the automatic transmission.

Maximum Torque Due to Wheel Skid Conditions

3.

Maximum ft. lbs. of Torque = GVW x f x RAD

12 x AR

Where:

GVW

f

RAD

AR

=

=

=

=

maximum gross vehicle weight on the rear wheels only

coefficient of friction

tire loaded rolling radius (inches)

axle ratio

Based on past experience, the coefficients of friction used have been:

f

f

= 0.8 for on-highway service (dry pavement)

= 0.5 for off-highway service

These are generally used values but if information is available for a specific application,

the appropriate coefficient of friction can be used.

10

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation of a Split Shaft

Application Data for Installation of a Split Shaft

Split Shaft Through Torque Capacity

Maximum Nominal Torque Rating (ft. lbs.)

Diesel Engine

Gas Engine

Split

Shaft

Model

901

Shaft

Outside

Diameter

1 3/4"

Automatic

Transmission

3,300

912

2 3/4"

13,000

2,000

16,000

15,000

931

1 3/8"

1,700

1,600

2,200

2,200

941

1 1/2"

3,100

2,900

4,200

3,900

Manual

Automatic

Manual

Transmission Transmission Transmission

3,100

4,200

3,900

SERVICE FACTOR CHART

Duty

Vehicle Description

Service Factor

Extra Light

Light Vehicle on Highway

1.0

Light

Light Vehicle off Highway

1.1

Heavy

Heavy Vehicle on Highway

1.2

Extra Heavy

Heavy Vehicle off Highway

1.3

The allowable split shaft torque can be calculated using the above charted values and

the following equation:

Allowable Split Shaft Torque = Maximum Nominal Torque Rating

Application Service Factor

11

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation of a Split Shaft

Lubrication Information

To insure proper lubrication and operating temperatures in these units, it is most important

that the proper lubricants be used and that correct oil levels be maintained.

Recommended Lubricants

The following lubricants are recommended, in order of preference, for use in all Chelsea

Split Shafts and Gear Boxes.

Models 700, 712, 721, 732, 741, 901, 912, 931, 941, 2230, and 2442

Temperature

Above 0°F

Below 0°F

Above 0°F

Below 0°F

Grade

S.A.E. 30, 40, or 50

S.A.E. 30

S.A.E. 90

S.A.E. 80

Type

Heavy Duty Engine Oil Meeting Spec

MIL-L-2104B or MIL-L-45199 Series 3

Straight Mineral Gear Oil

Do Not Use Extreme Pressure Additives, such as found in multi-purpose or rear axle

type lubricants. These additives are not required in our split shafts and gear boxes, and

they may in some cases create transmission problems. Multi-purpose oils, as a group,

have relatively poor oxidation stability, a high rate of sludge formation and a greater

tendency to react on or corrode the steel and bronze parts.

Oil Changes

We recommend an initial oil change and flush after the split shaft is placed in actual service.

This change should be made any time following 1,000 miles, but never to exceed 4,000

miles, of over-the-road service. In off-highway use, the change should be made after 24 and

before 100 hours of service have elapsed. There are many factors that influence the

following oil change periods, and we have not specified a definite mileage interval.

In general, it is suggested that a drain and flush period be scheduled every 20,000 miles for

normal over-the-highway operations. Off-the-highway usually requires an oil change every

30 days. The oil level in the split shaft should be checked every 2,000 miles on-highway, or

every 24 hours in off-highway operation. When it is necessary to add oil, we recommend

that types or brands of oil not be mixed. The correct oil level in all Chelsea Split Shafts is

established by the filler plug opening.

Refill—First, remove all dirt around the filler plug. Then refill with new oil of a grade recommended for the existing season and prevailing service.

Overfilling

Do not overfill the gear box or split shaft. Overfilling usually results in oil breakdown due to

excessive heat and aeration from the churning action of the gears. Early breakdown of the

oil will result in heavy varnish and sludge deposits that plug up oil ports and buildup on

splines and bearings. Overflow of oil usually escapes onto clutch or parking brakes,

causing additional trouble.

12

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Installation of a Split Shaft

Owner’s Manual

Split Shafts and Gear Box

Installation Instructions—Split Shaft

Split shaft Power Take-Offs are installed into the vehicle driveline. This requires cutting and

reworking driveshafts. No attempt will be made here to list driveline fabrication or rework procedures. For answers to specific questions, contact the Drivetrain Service Division. Listed are

the necessities for a good Power Take-Off installation that will run quietly and without

vibration. The unit itself should be suspended from a rubber isolated crossmember and will

replace the center bearing for the driveline. Grade 8 bolts should be used for all fastenings.

1.

Front—a short coupled joint connecting the transmission to the split shaft should be

installed so as to permit equal joint angles of less than 3°.

Rear—A two joint assembly connecting the split shaft to the rear axle should be

installed so as to permit equal joint angles of less than 5° to insure the best

performance. The joint angles should be kept within a minimum of 1° to 3°.

Front & Rear—the two joint assembly at the front and rear should be installed so as to

permit equal joint angles of less than 5°.

2.

Determine a suitable location for crossmembers for mounting the split shaft. Raise or

lower or move the split shaft front or rear as required to reduce the joint angles to a

minimum but not less than 1°.

3.

Align the split shaft with the transmission and rear axle.

A. For the best installation and optimum performance, the input and output shafts of

the split shaft should be parallel respectively within 1° to the main shaft of the

transmission and the pinion shaft of the axle.

B. With the shafts parallel, the joint angles should be in one plane only. Make sure the

offset in the horizontal or vertical planes will provide for equal joint angles of less

than 3° with a short coupled joint or less than 5° with a two joint assembly.

4.

Excessive angles result in a loss of speed and power. The figures shown below are

approximate and any angle less than those shown will provide a better installation.

Speed

True Joint Operating Angle

5,000 R.P.M.

3° 15'

4,000 R.P.M.

4° 15'

3,000 R.P.M.

5° 50'

Slight angles of 1° in each joint are necessary for the circulation of the needles.

5.

The front and rear shafts should be assembled, straightened, and balanced before

installation.

13

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

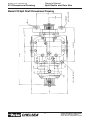

901 Installation Drawings

Owner’s Manual

Split Shafts and Gear Box

Model 901 Split Shaft Installation Drawings

Vertical Mounting

SPICER 1500 SERIES

RECTANGULAR FLANGE

34"

1511/32"

103/4"

33/8"

DRAIN AND OIL

LEVEL HOLES

/4"-10NC

SPICER 1410 SERIES

RECTANGULAR FLANGE

9

DRIVE SHAFT ANGLE TO

COINCIDE WITH ANGLE

GIVEN IN BODY BUILDERS

LAYOUT BOOK

3

/16"-12NC

SPICER 1500

SERIES FLANGE

BRAKE

BRAKE

ENGAGED DISENGAGED

Horizontal Mounting

BEARING CAP MUST BE

ROTATED UNTIL THE

BREATHER IS IN THE

UP POSITION

SHIFTER COVER MAY BE

ROTATED IN INCREMENTS

OF 90 DEGREES FOR

POSITION DESIRED

3

/4"- 10NC

51/2"

OPTIONAL

MOUNTING

HOLES

Horizontal Mounting

TOTAL

SHIFT 21/16"

14

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

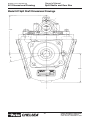

901 Dimensional Drawing

Owner’s Manual

Split Shafts and Gear Box

Model 901 Split Shaft Dimensional Drawings

10.500"

7.500"

4.594"

17.250"

15.281"

15

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

912 Dimensional Drawing

Owner’s Manual

Split Shafts and Gear Box

Model 912 Split Shaft Installation Drawing

4.060

15°

15°

J

C

A

B

4.060

When filling the 912 series split shaft unit with oil it is always important not to over fill the

Power Take-Off unit. This is very important when installing two 885 series P.T.O.s.

A change was made to the 912 housing (1-P-484) lowering the fill plug located on the lower

right rear of the housing (see drawing, Note A). To verify that you have a 912 housing that

has the proper plug location for checking the oil level with two 885 Power Take-Offs, check

for the “Revision” level of the housing. This revision level is in the form of a letter located on

the driveline output side of the housing and located to the right of the casting number (see

drawing, Note B). If the Revision letter is “J” or higher then the plug in the housing has

been changed for the correct oil level for two 885 series Power Take-Off.

On all other applications or with one 885 series P.T.O. use the oil level plug located on the

left side of the housing to check for proper oil levels (see drawing, Note C).

16

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

912 Dimensional Drawing

Owner’s Manual

Split Shafts and Gear Box

.625- 11 UNC- 2B TH’D

10.708

1.375

2.750

2.250

2.250

5.125

20.352

11.598 REF.

6.500

.656

3.625

TRUNNION

7.250

Model 912 Split Shaft Dimensional Drawing

NO. 328799- 3X REF.

Bulletin HY25-1202-M1/US

17

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

931 Installation Drawing

Owner’s Manual

Split Shafts and Gear Box

Model 931 Split Shaft Installation Drawings

With Cover and Crossmember Support - Below

MOUNTING KIT

328417X

T

N

RA

SM

ISS

ION

A-4

With Cover and Crossmember Support - Above

FR

AM

34"

EW

IDT

H

A-4

TR

S

AN

MIS

SIO

N

MOUNTING KIT

328417X

NOTE: When installing the Split Shaft, the Vent Assembly must be in an upright position.

18

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

931 Dimensional Drawing

Owner’s Manual

Split Shafts and Gear Box

Model 931 Split Shaft Dimensional Drawings

12.875"

12.750"

8.500"

11.500"

8.375"

17.875"

19

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

941 Installation Drawing

Model 941 Split Shaft Installation Drawings

12.8820"

9.212"

5.386"

2.756"

2.756"

8.086"

2.424"

2.756"

3.826"

5.761"

2.756"

3.000"

P. T. O.

OPENING

12.882"

20

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

941 Dimensional Drawing

Owner’s Manual

Split Shafts and Gear Box

Model 941 Split Shaft Dimensional Drawings

6.068"

15°

4.515"

21

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Installation of a Gear Box

Owner’s Manual

Split Shafts and Gear Box

Installation Instructions – Gear Boxes Models 700, 712, 721, 732,741,

2230, and 2442

Gear boxes are installed very similarly to split shaft Power Take-Offs. The differences are

that the gear box is driven from a Power Take-Off rather than the transmission main shaft,

and the gear box drives a piece of equipment rather than the rear axle. Installation of a

gear box requires fabrication of new shafts rather than cutting into the existing driveline.

Listed are the necessities for a good gear box installation which are basically the same as

those required for a good split shaft Power Take-Off installation. The unit itself is mounted

on a plate which must be mounted to a sturdy support on the vehicle. Rubber isolation of

the unit is important to prevent transmitting vibrations throughout the vehicle. Then follow

the steps below:

1.

Front—The short coupled joint connecting the Power Take-Off to the gear box should

be installed so as to permit equal joint angles of less than 3°.

Rear—The two joint assembly connecting the gear box to the driven equipment should

be installed so as to permit equal joint angles of less than 5°. To insure the best

performance, the joint angles should be kept within a minimum of 1° to 3°.

Front & Rear—The two joint assemblies at the front and rear should be installed so as

to permit equal joint angles of less than 5°.

2.

Determine a suitable location for mounting the gear box. Raise or lower or move the

gear box front or rear as required to reduce the joint angles to a minimum, but not less

than 1°.

3.

Align the gear box with the Power Take-Off and driven equipment.

A. For the best installation and optimum performance, the input and output shafts of

the gear box should be parallel respectively with 1° to the output shaft of the Power

Take-Off and the input shaft of the driven equipment.

B. With the shafts parallel, the joint angles should be in one plane only. Make sure the

offset in the horizontal or vertical planes will provide for equal joint angles of less

than 3° with a short coupled joint or less than 5° with a two joint assembly.

4.

Excessive angles result in a loss of speed and power. The figures shown below are

approximate and any angles less than those shown will provide a better installation.

Speed

5,000 R.P.M.

4,000 R.P.M.

3,000 R.P.M.

True Joint Operating Angle

3° 15'

4° 15'

5° 50'

Slight angles of 1° in each joint are necessary to permit circulation of the needles.

5.

If at all possible, the shafts front and rear should be assembled, straightened, and

balanced. The various models of gear boxes offer three (or several) types of shifters.

Wire shift is installed identically to a six bolt Power Take-Off installation. Linkage for

lever controls must be designed and fabricated by the installer. Air shift plumbing is

shown in the typical sketch on pages 33-35 for a single acting air shift.

22

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Breather Hose Installation

Owner’s Manual

Split Shafts and Gear Box

Breather Hose Installation

When installing a breather hose assembly on a gear box or split shaft, the top of the vent

assembly must be at least 12 inches above the unit as shown in figure 1. Figure 2 shows an

incorrect installation. When installing any vent assembly, make sure it is in the upright

position.

304.8

(12.00) MIN.

Fig. 1

Fig. 2

23

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation–P.T.O. to a Split Shaft

Application Questions for Installation of a P.T.O. to a Split Shaft

Specifying and mounting a P.T.O. to the 912

& 914 Split Shaft is accomplished the same

as on a transmission. There are certain

application questions and installation

procedures that you should follow. The next

four pages will take you through these steps.

1.

What is the make and model of your

transmission?

2.

Which P.T.O. opening will be used?

3.

What accessory is to be driven?

4.

How much horsepower is required to

drive the accessory?

5.

What is the required rotation of the

P. T. O. ?

6.

What is the required P.T.O. output shaft

speed as a percent of engine speed?

7.

S.A.E. 6 Bolt

S.A.E. 8 Bolt

What is the required method of shifting Standard SAE Power Take-Off Apertures

the P.T.O. – cable, lever or air?

Once all the answers to these questions

have been determined, a transmission

mounted P.T.O. can be selected to meet the

horsepower, speed, and rotation that you

require.

DRIVE GEAR TO FRONT

Having made the selection of a P.T.O., you

are ready to start the installation.

P. T. O.

Driver Gear

on right

side of

transmission

P.T.O. Drive Gear Location

The standard location for the P.T.O. drive gear

in the transmission is 1/2" to the front or 1/2"

to the rear of the vertical center line.

24

P. T. O.

Driver Gear

on left

side of

transmission

DRIVE GEAR TO REAR

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation–P.T.O. to a Split Shaft

Mounting P.T.O. to Split Shaft for 6 or 8 Bolt Applications

1.

Drain the oil from the transmission, and

remove the P.T.O. aperture cover plate.

(See Fig. 1.)

Fig. 1

2.

Discard the cover plate and cover plate

gasket. Clean the aperture pad using a

putty knife or wire brush. (See Fig. 2.)

NOTE: Stuff a rag in the aperture

opening to prevent dirt from entering the

transmission while you are cleaning it.

3.

Using your hand, rock the P.T.O. drive

gear in the transmission (See Fig. 3.) and

the driven gear in the P.T.O. assembly

(See Fig. 4.). Rocking the gears provides

two important factors.

Fig. 2

A. It shows you the amount of backlash

that has been designed into each unit.

B. It is helpful in establishing the proper

backlash when installing the P.T.O.

4.

Install the proper studs in the P.T.O. aperture pad using a stud driver. (See Fig. 5.)

5.

Where holes are tapped through the

transmission case, use Permatex or an

equivalent to prevent leaks.

Fig. 3

Fig. 4

NOTE: Avoid contact of Permatex with

automatic transmission fluid in

automatics. Always check to be sure the

studs do not interfere with transmission.

Fig. 5

25

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Installation–P.T.O. to a Split Shaft

Mounting P.T.O. to Split Shaft (Continued)

6.

Tighten the studs securely, and torque

them to 10 - 15 ft. lbs. (1.38 - 2.07 kg.

meters) for the 6 bolt and 15 - 20 ft. lbs.

(2.07 - 2.77 kg. meters) for the 8 bolt.

(See Fig. 6.)

7.

Place the correct number of gaskets

over the studs. (See Fig. 7.) Do not use

Permatex between gaskets because you

may want to add or subtract gaskets to

obtain the proper backlash.

Fig. 6

• When mounting a P.T.O., use gaskets

between all mounting surfaces.

• Do not stack more than 3 gaskets

together.

• Usually one thick gasket .020"

(.50 mm) will be required.

• Remember the lubricant in the

transmission also lubricates the P.T.O.

Therefore, at least one gasket must

always be used on either side of filler

blocks, adapter assemblies, or

adapter plates. More gaskets may be

required when establishing proper

backlash.

8.

9.

Fig. 7

Secure P.T.O. to the transmission. The

220 Series must always have a copper

washer under its one capscrew head

which goes through the inside of the

housing. (See Fig. 8.)

Fig. 8

Fasten the P.T.O. to the transmission.

Torque the 6 bolt to 30 - 35 ft. lbs.

(4.14 - 4.84 kg. meters) and the 8 bolt to

45 - 50 ft. lbs. (6.22 -6.91 kg. meters).

(See Fig. 9.)

Fig. 9

26

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Installation–P.T.O. to a Split Shaft

Owner’s Manual

Split Shafts and Gear Box

Installation Instructions for 880 Series with “L*” Output, Top Mounted

to 912 Series Split Shaft - Requiring Self-Lube Option

1. Drain split shaft oil at drain plug (A). Filter or screen oil & reuse if desired.

2. Remove top split shaft aperture cover plate at (B) or air shift Assembly (C) & reassemble

to either side of split shaft in place of shipping cover. Install P.T.O. on split shaft & set

backlash at .006" to .012". (See page 28 for checking proper backlash)

3. Install copper gasket (D), screened strain plug (E) & 90° elbow (F) in place of drain plug

at (A). Also install pressure lube hose (G) between elbow (F) and pump (H). (Use pipe

sealant on all pipe threads)

4. Fill split shaft with filtered, screened or new oil at fill plug (J), until oil reaches plug level,

then reinstall plug.

5. Finish P.T.O. & split shaft installation per owner’s manual. Also install shaft and/or pump to

be driven by P.T.O.

6. After brief P.T.O. operation, remove fill plug (J), add oil until it reaches plug level, then

reinstall plug.

IMPORTANT: Lube pump (H) must rotate clockwise (engine rotation) as view from front

of vehicle.

H

B

C

J

G

D

A

F

27

E

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Checking Backlash

Checking Backlash

To check for proper backlash on P.T.O.

with shift cover:

1.

Remove the P.T.O. shift housing and/or

inspection plate.

2.

Mount the dial indicator so that it registers

movement in the input gear (driven

gear) of the P.T.O. (See Fig. 10.)

NOTE: See Figure 11 for the proper

Fig. 10

location of the dial indicator’s contact point.

(Two common types of dial indicators are

shown.)

3.

4.

.006

.012 POINTER

INDICATES

SIDE MOVEMENT

Hold the P.T.O. driver gear in the

transmission with a screwdriver or bar, and

rock the P.T.O. input gear (driven gear) back

and forth with your hand. Note the total

movement on the dial indicator.

ALTERNATE

INDICATORS

.006

.012

BACKLASH

Establish backlash at .006" - .012" (.15

mm - .30 mm) by adding or subtracting

gaskets.

.006

.012

P.T.O. INPUT

GEAR

HOLD

TRANS.

P.T.O. DRIVE

GEAR

TRANSMISSION

NOTE: For any additional information on

hooking up the shifter or installation of

the P.T.O., please consult the Owner’s

Manual included with the unit.

.006

.012 PLUNGER

TYPE

POINTER

INDICATES

DEPTH

GASKET PACK

AS REQ’D.

P.T.O. CASE

Fig. 11

General rule—A Chelsea .010" gasket will

change backlash approximately .006." A

.020" gasket changes backlash approximately

.012."

28

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Wire Shift P.T.O.s and Gear Boxes Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Cable Control Installation Instructions*

1.

Find a suitable area on the dash to install the cable control (328346-10X) and the

control plate (68-P-18) indicator light.

Optional Location: As an option the control cable and knob can be located through floor.

Using this option the control plate and indicator light should still be located on dash, in

close proximity.

NOTE: The location of the cable control and the control plate should be as close to

each other as possible and easily accessible by the driver or operator, but should not be

an obstacle to driver movement nor interfere with other controls, instruments, or

equipment.

2.

CAUTION: Before drilling any holes, make sure there is adequate room on both sides

through dash wall, drill a 1/2" (.5") diameter hole for the control cable. [1]

3.

Install the control cable on the dash using the hex nuts supplied with the cable. The

knob can then be screwed into place [2]. The length of cable can then run through the

firewall and back to the P.T.O. —making sure it is kept away from the exhaust, moving

parts, etc.

NOTE: Do not kink the cable. In order for the cable to operate properly, there can be

no bends smaller than 6 inch radius. Total bends in the cable should not exceed 360°

(example - four 90° bends in cable).

4.

Using the template found on page 38

(SK-168) drill the necessary holes for the

control plate-indicator light.

5.

Install the control plate (68-P-18) stick on

decal and indicator light on the dash using

the hardware supplied in the 328751-1X

installation kit (Fig. 25).

Fig. 25

* All six bolt wire shifts with the exception of the reversible, dual shift units, and some

gear boxes.

29

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Wire Shift P.T.O.s and Gear Boxes Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Cable Control Installation Instructions (Continued)

6.

Determine from which direction the cable must come in order for the unit to be

disengaged when the knob is all the way in.

NOTE: The shifter must always be installed in the following manner:

* CABLE IN: P.T.O. DISENGAGED(6A): OUT OF GEAR POSITION

CABLE OUT: P.T.O. ENGAGED(6B): IN GEAR POSITION

* The wire shift cable should be installed so that when the cable (knob) is pushed all

the way in, the P.T.O. has also moved the full travel of the P.T.O. shifter, to the

disengaged mode.

7.

Install the wire control bracket found in either the 328380X or 328380-1X wire control

parts bag. [7]

8.

Line the cable up with the wire control bracket and shifter lever (disengaged position)

on the P.T.O. cover assembly [8]

NOTE: It may be necessary to change the position of the shifter lever on the P.T.O. To

do this, remove the shifter cover from the unit. This will prevent the possible loss of the

poppet and/or spring into the transmission if the shifter post assembly should be

pushed through the cover when reinstalling the lever.

9.

Shift the P.T.O. to the engaged position to see how much of the cable casing must be

cut to allow the lever enough travel to shift in and out completely. The casing need only

go just beyond the bracket, whereas, the wire must be long enough to go through the

swivel pin in the shifter lever. [9]

NOTE: In some instances the cable control may not be long enough. Chelsea has

available four longer lengths than the standard ten-foot cable. These come in five foot

increments (i.e., 328346-15X = 15-foot cable).

10. When the length of the casing has been determined, pull the wire back through until the

case can be cut without cutting the wire. Use a hacksaw or heavy pair of side cutters to

cut the casing.

NOTE: The cable can be held by a bench vise as long as the jaws are not tightened to

the point where the case mushrooms. If a vise is not accessible, a pair of vise grips will

do the job.

30

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Wire Shift P.T.O.s and Gear Boxes Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Cable Control Installation Instructions* (Continued)

11. Push the wire back through and install the cable using the hardware from the

previously mentioned wire control parts bag (328380X).

12. Cut the excess wire after the cable casing and wire have been installed and tightened.

* All six bolt wire shifts with the exception of the reversible, dual shift units, and some

gear boxes.

31

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Wire Shift P.T.O.s and Gear Boxes Split Shafts and Gear Box

Bulletin HY25-1135-M1/US

Cable Control Installation Instructions* (Continued)

Indicator Light Installation

Sketch (SK-286 Rev G)

CAUTION: Indicator switches are capable of 0.5 amps maximum.

NOTE: All wires and cables must be clear of heat source and moving parts.

13. Shift the P.T.O. to insure enough casing has been removed to allow full gear

engagement.

14. Install the wiring for the indicator light using the schematic above (SK-286 Rev G).

NOTE: Check both the cable and indicator light wires to be certain that they are not

near the exhaust system or any moving parts. Carefully fasten to stationary parts of

the vehicle if necessary.

15. Shift the P.T.O. The following should be adhered to:

15A. CABLE IN: P.T.O. DISENGAGED: LIGHT OUT

15B. CABLE OUT: P.T.O. ENGAGED: LIGHT ON

NOTE: The P.T.O. should be checked for continuity as per the instructions in this manual.

NOTE: Cable must be rigidly mounted-possibly to the transmission within 12-24" of the

P. T. O.

* All six bolt wire shifts with the exception of the reversible, dual shift units, and some

gear boxes.

32

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

33

Caution: When installing nylon tubing avoid sharp angles, exhaust and manifold systems.

Important: When this installation is used on vehicles with automatic transmissions, the P. T.O. drive gear must be stopped

before shifting.

NOTE: Tube nut is reusable as long as nylon tubing is not removed from the tube nut.

• The template for the control plate is on page 36.

Air Shift Installation Sketch

Warning: Connect directly to the air supply. Do not use tubing between the air supply and the pressure protection valve.

Bulletin HY25-1202-M1/US

Owner’s Manual

Split Shafts and Gear Box

Air Shift Installation Sketch for the 2442 Series Gear Box (SK-231 Rev D)

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Air Shift Installation Sketch

Owner’s Manual

Split Shafts and Gear Box

Air Shift Installation Sketch for 901, 912, and 941 Split Shafts

(SK-276 Rev G)

328388-61X Installation Kit

Warning: Connect directly to the air supply. Do not use tubing

between the air supply and the pressure protection valve.

Caution: When installing nylon tubing avoid sharp angles, exhaust and manifold

systems.

Important: When this installation is used on vehicles with automatic transmissions,

the P.T.O. drive gear must be stopped before shifting.

NOTE: Tube nut is reusable as long as nylon tubing is not removed from the tube nut.

NOTE: The template for the control plate is on page 37.

34

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Air Shift Installation Sketch

Owner’s Manual

Split Shafts and Gear Box

35

Warning: Connect directly to air supply. Do not use tubing between air supply and pressure protection valve.

To 230, 231, 236 Series

P. T. O. Inlet Port

Air Shift Circuit 2230 Series (SK-246 Rev E)

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Dash Drilling Template

Dash Drilling Template for 2442 Series Gear Box Air Shift Control

(SK-204 Rev C)

3.688"

1.312"

2.500"

1.250"

.219"

2.000"

1.250"

.625"

.750"

1.750"

36

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Dash Drilling Template

Dash Drilling Template for 901, 912, and 941 Split Shafts Air

Shift Controls (SK-204 Rev C)

3.688"

1.312"

1.750"

.875"

.219

2.688"

2.000"

.625"

1.344"

.750"

1.750"

37

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Dash Drilling Template

Dash Drilling Template for Wire and Lever Controls (SK-168)

3.468

.203 DIA.

2 PLACES

1.734

.906

1.812

.750 DIA.

1.500

3.000

38

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Dash Drilling Template

Owner’s Manual

Split Shafts and Gear Box

Indicator Light Installation (SK-286 Rev G)

For wire and lever shift option on the 700, 712, 721, 732, 741, 901, 912, 931, 941 and 2442

gear boxes.

Caution: Indicator switches are capable of 0.5 amps maximum.

NOTE: All wires and cables must be clear of heat source and moving parts.

39

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Owner’s Manual

Split Shafts and Gear Box

Bulletin HY25-1202-M1/US

Continuity Check

Continuity Check

379639 and 379652 Indicator Switches

In order to insure that the switch is

functioning properly, the following procedure

can be used with the unit on a bench, or

installed.

1. Use a continuity checker, battery type,

either meter or light. Attach one (1) probe

to the screw on the 379639 or 379652

Indicator Switch.

Note: Make sure 379639 and 379652

Indicator Switches in the P.T.O. shifter or

housing are torqued to 10-15 ft. lbs.

(1.38-2.07 kg meters).

Fig. 23

2. With the other probe, make contact with

the shifter cover or housing (Fig. 23).

3. Actuate shifting device and the meter or

light* should be actuated when P.T.O.

gear is engaged (Fig. 24).

4. Shift unit out of gear and the meter or

light* should return to normal as shown.

Fig. 24

This test procedure can be used to check

Chelsea wire, lever, and air shifter covers,

although an air source would be necessary

for the latter.

* If a meter is not available the light in the

328751-1X can be used. A six volt battery is

all that is necessary for a power source.

CAUTION: Indicator switches are capable of 0.5 amps maximum.

40

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Troubleshooting

Owner’s Manual

Split Shafts and Gear Box

Troubleshooting

Driver Training: One of the major causes of bearing and gear failures in the auxiliary unit

is poor driving habits. Drivers should be taught to always use the Lo Speed or reductions

available in the auxiliary unit and keep the front box in the higher ratios not vice versa.

Worn and pitted gears, as well as worn and pitted bearings are usually caused by excessive

use of the auxiliary overdrive gears with the mainbox in lower gear ratios.

Broken teeth in the auxiliary unit are usually caused by drivers trying to start their vehicles

with the auxiliary unit in the high ratio while the big reduction is made in the front box.

Frogging or quick release of clutch gives a jump start which is also noted for breaking teeth.

Noisy Operation: Noise is usually very elusive and generally not the fault of the auxiliary;

therefore, mechanics should road test to determine if the driver’s complaint of noise is

actually in the auxiliary. Remember that auxiliary units act as sounding boxes and in

numerous instances, drivers have insisted that the noise was in the auxiliary. However,

investigations revealed the noise to be caused by one of the following conditions:

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

M.

N.

O.

P.

Fan out of balance or bent blades.

Defective vibration dampers.

Crankshafts out of balance.

Flywheels out of balance.

Flywheels mounting bolts loose.

Engine rough at idle producing rattle in gear train.

Clutch assembly out of balance.

Engine mounts loose or broken.

P.T.O. gear not fully engaged or housing not properly shimmed.

Universal joints wornout.

Propeller shafts out of balance.

Universal joint angles out of plane or at an excessive angle.

Center bearings in driveline dry, not mounted properly, etc.

Wheels out of balance.

Tire treads humming or vibrating at certain speeds.

Air leaks on suction side of induction system—especially with turbo-chargers.

Mechanics should try to locate and eliminate noise by means other than auxiliary removal,

or overhaul. However, if the noise appears to be in the auxiliary, try to break it down into the

following classifications. If possible, determine what position the gear shift lever is in when

the noise occurs. If the noise is evident in only one gear position, the cause of the noise is

generally traceable to the gears in operation.

A.

Growling and humming or, more serious, a grinding noise. These noises are

caused by worn, chipped, rough, or cracked gears. As gears continue to wear, the

grinding noise will be noticeable, particularly in the gear position that throws the

greatest load on the worn gear.

41

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Troubleshooting

Owner’s Manual

Split Shafts and Gear Box

Troubleshooting

B.

Hissing or, more serious, a thumping or bumping type noise. Hissing noises can

be caused by bad bearings. As bearings wear and retainers start to break up, etc.,

the noise could change to a thumping or bumping.

C.

Metallic rattles within the auxiliary usually result from a variety of conditions.

Engine torsional vibrations are transmitted to the transmission through the clutch,

which may be amplified and transmitted to the auxiliary through the connecting

propeller shaft. In heavy duty equipment, clutch discs with vibration dampers are

not used, so a rattle, particularly in neutral, is common with diesel equipment. In

general, engine speeds should be 600 R.P.M. or above to eliminate objectionable

rattles and vibration during the idle. Always leave the main box in neutral and the

auxiliary unit in gear when idling. A defective or faulty injector would cause a

rough or lower idle speed and a rattle in the auxiliary. Rattle could also be caused

by excessive backlash in P.T.O. unit mounting.

D.

Improper lubricants or lack of lubricant can produce noises. Auxiliaries with low

oil levels sometimes run hotter than normal, as there is insufficient lubricant to

cool and cover the gears.

E.

Squealing, particularly when the auxiliary is operating at higher speeds, could be

caused by one of the free running gears seizing on the thrust face or fluted

diameter temporarily and then letting go. In general, a mild seizure will clear itself

up and the auxiliary will continue to operate satisfactorily without this defect being

known. See “G.”

F.

Gear seizure at High Speed, usually accompanied with a loud squealing noise,

is readily apparent to the driver, since the truck will suddenly slow down as if the

brakes were being applied. If the truck continues to move ahead, even though

the gear shift lever is placed in neutral, it would indicate the floating gear on the

main shaft had seized. Depressing the clutch should interrupt the driving torque.

The seized gear could be checked quite readily by depressing the clutch and

checking the action with the gear shift lever progressively in all shift positions. If

releasing the clutch tends to kill the engine, then this gear position has not

seized. In other words, the auxiliary would be in two gears at the same time. By a

process of elimination, the gear at fault can be readily identified. See “G.”

G.

Vibration. Gear seizures on thrust faces or fluted diameters are usually caused

by vibrations in the power train. This could be engine, propeller shafts, joint

angles, rear axles, differentials, etc.

42

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Bulletin HY25-1202-M1/US

Power Take-Off Maintenance

Owner’s Manual

Split Shafts and Gear Box

Power Take-Off Maintenance

Due to the normal and sometime severe torsional vibrations that Power Take-Off units

experience, operators should follow a set maintenance schedule for inspections. Failure to

service loose bolts or Power Take Off leaks could result in potential auxiliary Power Take-Off

or transmission damage.

Periodic P.T.O. MAINTENANCE is required by the owner/operator to ensure proper, safe and

trouble free operation.

Daily:

Check all air, hydraulic and working mechanisms before operating

P.T.O. Perform maintenance as required.

Monthly:

Inspect for possible leaks and tighten all air, hydraulic and

mounting hardware, if necessary. Torque all bolts, nuts, etc.

to Chelsea specifications. Insure that splines are properly

lubricated, if applicable. Perform maintenance as required.

With regards to the direct mounted pump splines, the P.T.O. requires the application of a

specially formulated anti-fretting, high pressure, high temperature grease. The addition of

the grease has been proven to reduce the effects of the torsional vibrations, which result in

fretting corrosion on the P.T.O. internal splines as well as the pump external splines. Fretting

corrosion appears as a “rusting and wearing” of the pump shaft splines. Severe duty

applications, which require long P.T.O. running times and high torque may require more

frequent regreasing. Applications such as Utility Trucks that run continuously and are lightly

loaded also require frequent regreasing due to the sheer hours of running time. It is

important to note that service intervals will vary for each and every application and is the

responsibility of the end user of the product. Chelsea also recommends that you consult

your pump owners manuals and technical services for their maintenance guidelines.

Fretting corrosion is caused by many factors and without proper maintenance; the anti-fretting

grease can only reduce its effects on components.

Chelsea offers the grease to our customers in two packages. The first is a 5/8 fluid ounce

tube (379688), which is included with every applicable P.T.O., and the second is a 14-ounce

grease cartridge (379831). Chelsea also offers greaseable shafts for most all output

designators.

Warranty:

Failure to comply entirely with the provisions set forth in the appropriate

Owner’s Manual will result in voiding of ALL Warranty consideration.

43

Parker Hannifin Corporation

Chelsea Products Division

Olive Branch, MS 38654 USA

Offer of Sale

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and

its authorized distributors are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its

authorized distributors. This offer and its acceptance by any customer ("Buyer") shall be governed by all of the following Terms and

Conditions. Buyer’s order for any such items, when communicated to Parker Hannifin Corporation, its subsidiary or an authorized

distributor ("Seller") verbally or in writing, shall constitute acceptance of this offer.

1. Terms and Conditions of Sale: All descriptions, quotations,

proposals, offers, acknowledgments, acceptances and sales of

Seller’s products are subject to and shall be governed exclusively

by the terms and conditions stated herein. Buyer’s acceptance of

any offer to sell is limited to these terms and conditions. Any terms

or conditions in addition to, or inconsistent with those stated herein,

proposed by Buyer in any acceptance of an offer by Seller, are

hereby objected to. No such additional, different or inconsistent

terms and conditions shall become part of the contract between

Buyer and Seller unless expressly accepted in writing by Seller.

Seller’s acceptance of any offer to purchase by Buyer is expressly

conditional upon Buyer’s assent to all the terms and conditions

stated herein, including any terms in addition to, or inconsistent

with those contained in Buyer’s offer, Acceptance of Seller’s

products shall in all events constitute such assent.

2. Payment: Payment shall be made by Buyer net 30 days from the

date of delivery of the items purchased hereunder. Amounts not

timely paid shall bear interest at the maximum rate permitted by law

for each month or portion thereof that the Buyer is late in making

payment. Any claims by Buyer for omissions or shortages in a

shipment shall be waived unless Seller receives notice thereof

within 30 days after Buyer’s receipt of the shipment.

3. Delivery: Unless otherwise provided on the face hereof, delivery shall be made F.O.B. Seller’s plant. Regardless of the method

of delivery, however, risk of loss shall pass to Buyer upon Seller’s

delivery to a carrier. Any delivery dates shown are approximate

only and Seller shall have no liability for any delays in delivery.

4. Warranty: Seller warrants that the items sold hereunder shall

be free from defects in material or workmanship for a period of:

(A) All Power Take-Off units one (1) year from date of installation.

(B) Except 267, 277, 278, 242, 244, 245, 250, 251 and 859 series

two (2) years from date of installation.

THIS WARRANTY COMPRISES THE SOLE AND ENTIRE WARRANTY PERTAINING TO ITEMS PROVIDED HEREUNDER.

SELLER MAKES NO OTHER WARRANTY, GUARANTEE, OR

REPRESENTATION OF ANY KIND WHATSOEVER. ALL OTHER

WARRANTIES, INCLUDING BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS FOR PURPOSE, WHETHER

EXPRESS, IMPLIED, OR ARISING BY OPERATION OF LAW,

TRADE USAGE, OR COURSE OF DEALING ARE HEREBY

DISCLAIMED. NOTWITHSTANDING THE FOREGOING, THERE

ARE NO WARRANTIES WHATSOEVER ON ITEMS BUILT OR

ACQUIRED WHOLLY OR PARTIALLY, TO BUYER’S DESIGNS

OR SPECIFICATIONS.

5. Limitation Of Remedy: SELLER’S LIABILITY ARISING FROM

OR IN ANY WAY CONNECTED WITH THE ITEMS SOLD OR

THIS CONTRACT SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT OF THE ITEMS SOLD OR REFUND

OF THE PURCHASE PRICE PAID BY BUYER, AT SELLER’S

SOLE OPTION. IN NO EVENT SHALL SELLER BE LIABLE FOR

ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES

OF ANY KIND OR NATURE WHATSOEVER, INCLUDING BUT

NOT LIMITED TO LOST PROFITS ARISING FROM OR IN ANY

WAY CONNECTED WITH THIS AGREEMENT OR ITEMS SOLD

HEREUNDER, WHETHER ALLEGED TO ARISE FROM BREACH

OF CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN

TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE,

FAILURE TO WARN OR STRICT LIABILITY.

6. Changes, Reschedules and Cancellations: Buyer may request to modify the designs or specifications for the items sold

hereunder as well as the quantities and delivery dates thereof, or

may request to cancel all or part of this order, however, no such

requested modification or cancellation shall become part of the

contract between Buyer and Seller unless accepted by Seller in a

written amendment to this Agreement. Acceptance of any such

requested modification or cancellation shall be at Seller’s discretion, and shall be upon such terms and conditions as Seller may

require.

7. Special Tooling: A tooling charge may be imposed for any

special tooling, including without limitation, dies, fixtures, molds

and patterns, acquired to manufacture items sold pursuant to this

contract. Such special tooling shall be and remain Seller’s property

notwithstanding payment of any charges by Buyer. In no event will

Buyer acquire any interest in apparatus belonging to Seller which

is utilized in the manufacture of the items sold hereunder, even if

such apparatus has been specially converted or adapted for such

manufacture and notwithstanding any charges paid by Buyer.

Unless otherwise agreed, Seller shall have the right to alter, discard

or otherwise dispose of any special tooling or other property in its

sole discretion at any time.

8. Buyer’s Property: Any designs, tools, patterns, materials,

drawings, confidential information or equipment furnished by Buyer

or any other items which become Buyer’s property, may be considered obsolete and may be destroyed by Seller after two (2)

consecutive years have elapsed without Buyer placing an order for

the items which are manufactured using such property, Seller shall

not be responsible for any loss or damage to such property while

it is in Seller’s possession or control.

9. Taxes: Unless otherwise indicated on the face hereof, all prices

and charges are exclusive of excise, sales, use, property, occupational or like taxes which may be imposed by any taxing authority

upon the manufacture, sale or delivery of the items sold hereunder.

If any such taxes must be paid by Seller or if Seller is liable for the