Download fetatrack DD250 desk doppler

Transcript

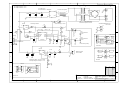

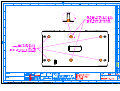

Ultrasound Technologies Ltd ® fetatrack DD250 desk doppler Service Manual Issue 1 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Contents ABOUT THIS MANUAL ..................................................................................................................... 1 SAFETY IN USE................................................................................................................................ 2 Special Precautions........................................................................................................................... 2 Electrical Shock Hazard .................................................................................................................... 2 Explosion Hazard .............................................................................................................................. 2 Handling the Delicate Transducers ................................................................................................... 3 Symbols Used ................................................................................................................................... 3 PARTS AND THEIR FUNCTIONS .................................................................................................... 4 Unit Controls ...................................................................................................................................... 4 RS232 Output ................................................................................................................................ 5 Probe Connection .......................................................................................................................... 5 TROUBLESHOOTING ...................................................................................................................... 9 No Display Information on LCD......................................................................................................... 9 Unit Does Not Respond..................................................................................................................... 9 No Sound From Loudspeakers ......................................................................................................... 9 No FHR Information on Display......................................................................................................... 9 No Chart Printed................................................................................................................................ 9 MAINTENANCE .............................................................................................................................. 10 General ............................................................................................................................................ 10 System Cabinet............................................................................................................................ 10 Transducers ................................................................................................................................. 10 ENVIRONMENTAL.......................................................................................................................... 11 Electrommagnetic Compatibility ...................................................................................................... 12 WEEE and RoHS ............................................................................................................................ 13 Dismantling Procedure .................................................................................................................... 14 Circuit Description ........................................................................................................................... 15 Power supply Circuit........................................................................................................................ 15 Battery Low Indicator....................................................................................................................... 16 Ultrasound Transducer .................................................................................................................... 16 Oscillator and Transmitter Amplifier ................................................................................................ 16 Receiver and Detector..................................................................................................................... 17 Audio Amplifier................................................................................................................................. 17 Digital Signal Processing................................................................................................................. 17 Performance .................................................................................................................................... 18 Introduction .................................................................................................................................. 18 Performance Checks ................................................................................................................... 18 Drawings.......................................................................................................................................... 19 Parts Lists .................................................................................................................................... 19 Circuit Data .................................................................................................................................. 19 Assembly Drawings ..................................................................................................................... 19 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd About This Manual This booklet explains the operation and service of the FETATRACK DD250 Desk doppler. Care has been taken during the design and manufacture of this product so that it satisfies all of the current safety standards set down by BS EN60601-1-2006. To achieve the best from this product read the following sections several times and if you have any problems in the operation of a particular part of the product then contact your dealer immediately or contact : Ultrasound Technologies Ltd Lodge Way Portskewett Caldicot, NP26 5PS South Wales UK Tel +44 (0) 1291 425425 Fax +44 (0) 1291 427093 EMAIL [email protected] This service manual contains circuit descriptions, diagrams, parts and spares lists for the FETATRACK DD250 To maintain the FETATRACK DD250’s performance it is recommended that it be included in a periodic maintenance program. The user preventative maintenance program is covered in this manual. Maintenance outside the scope of the user should be undertaken on an annual basis by trained service personnel; full details are available from your supplier, service centre or from Ultrasound Technologies Ltd. The FETATRACK DD250 is supplied complete with the following: Choice of 2, 3, 5, 8MHz doppler probes Ultrasound Coupling Gel 0.25ltr AC line cord User Instructions FetatrackDD250 Service Manual Issue1 1 1 1 Page 1 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Safety Special Precautions Your FETATRACK DD250 has been designed for electrical safety. All the safety and operating instructions should be read before operating the FETATRACK DD250. Failure to do so could result in injury to the user, patient, or damage to the system and accessories. Electrical Shock Hazard Do not defeat the grounding integrity of this system. Protection against electrical shock, in the event of failure of basic insulation, is provided by the connection of the chassis to the safety ground. Safety grounding occurs only when the 3-wire cable and plug provided with the system are connected to a properly grounded receptacle. Do not remove the system cover. The system should be serviced by trained and qualified personnel only. Contacting the hazardous voltages within the system could cause serious injury. Do not use the system if the power cord has any cuts or openings. Do not use the transducer if the cable has any cuts or openings. Do not use the transducer if the transducer face is cracked or chipped. Do not immerse the transducer cable connectors in any liquids. Should the electrical safety fuses have to be replaced, use only fuses of the same type and rating. Explosion Hazard Do not operate or use this system in the presence of flammable anesthetics, gases or oxygen rich environments as it could lead to explosion. FetatrackDD250 Service Manual Issue Page 2 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Safety Handling the Delicate Transducers The transducers are delicate parts of the ultrasound system and should be treated with care. The delicate crystals in the transducer may crack and render the transducer unusable if the transducer is subject to shock. Room temperature liquids should be used for cleaning. NEVER use alcohol or mineral oil as an acoustic coupling agent as transducer face and cable damage will occur. ONLY use approved ultrasound coupling gels. Symbols Used The following symbols are used on the FETATRACK DD250 and are in accordance with BS EN60601-1-2006. Where they are associated with the connection of external equipment, that equipment must meet the relevant safety standards in all cases. Type B equipment Consult accompanying documents Alternating Mains Current DO NOT disposed of with your normal waste Unit On / Off Battery Charge / Discharge state FetatrackDD250 Service Manual Issue1 Page 3 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd System Operation FETATRACK DD250 Front Panel Controls The front panel control area contains 1 button and one rotary volume contol, these controls are combinded. (F) (C) (A) (B) (D) (E) (A) IEC 3pin mains cord inlet (B) Illuminated Mains on/ off switch. The mains switch is illuminated green when AC mains power is connected and the switch is on, a green mains on indicator (C) is also situated on the units front panel. (D) Serial RS232 connection. (E) Headset connection. (F) Volume Control / unit on push switch FetatrackDD250 Service Manual Issue1 Page 4 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd System Operation RS232 Output This output is for the connection of an external computer for data transfer. The maximum voltage that can be applied to this output is 15VDC. WARNING: Any external equipment connected to this output must meet the equivalent MEDICAL safety standard to this product. Connection must only be made by a qualified technician. An isolation connection may be necessary when connection is to be made to a personal computer. Transducer Input. Transducers are connected via the pug on the retractile cable. This is for the connection of Fetatrack DD250 transducers ONLY. The maximum voltage that can be applied to this output is 15VDC. FetatrackDD250 Service Manual Issue1 Page 5 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd System Operation Operating the FETATRACK DD250 In this section, information is supplied which will help you use the FETATRACK DD250 for the fist time. General The DD250 is a mains or rechargeable battery operated desk Doppler designed to suit the needs of the General Practitioner and clinic where multiple disciplines require interchangeable transducers. The DD250 can take a choice of 4 transducers, 2 for fetal heart rate detection (2 and 3 MHz) and 2 for vascular flow detection (5 and 8MHz). The DD250 provides for the audio presentation of the fetal or vascular signal as well as digital fetal heart rate detection with the fetal heart rate displayed on an LCD display. RS232 data port is included for the transfer of data to a PC to review the fetal heart rate traces (A) (B) (C) FetatrackDD250 Service Manual Issue1 Page 6 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd System Operation The DD250 includes a storage area from 2 transducers (A). These are held in place using magnetic retention. There is a choice of up to 4 transducers that can be used with the DD250, 2 for fetal use and 2 for vascular use. These are connected to the DD250 using a retractile cable with a latching connector. The selected transducer (B) is connected to the unit by the connector (C) , to disconnect pull back on the outer cover of the connector, DO NOT TWIST. To connect a transducer align the red dots and lightly push the connector into the transducer socket. The transducers are colour coded at the socket to indicate frequency. Transducer colour coding Connector ring colour 2MHz 3MHz 5MHz 8MHz Red Orange Green Grey Obstetrics The DD250 can be used to detect the beating fetal heart from approximately the 10th week of gestation, though this will vary between patients. Apply a liberal amount of coupling gel to the area just above the symphysis pubis and position the transducer face flat against the abdomen. Tilt the transducer slowly until the fetal heart is heard in the loudspeaker or headset (in early pregnancy the headset helps to eliminate ambient noise making it easier to detect the weaker signals). Later on in pregnancy the best signals are generally found higher up the abdomen. Avoid sliding the transducer over the abdomen as this results in an increase in the background noise and makes it more difficult to detect the fetal heart sounds. The DD250 may be used to locate the position of the placenta, thus aiding in the early diagnosis of placenta praevia or eliminating placental site where amniocentesis is to be performed. The sound from the placenta is an indistinct swishing, caused by bloodflow in many vessels. There is no distinct beat pattern to the sound. The vessels of the umbilical cord give rise to a higher pitched sound than the normal fetal heart, with pulsations at the fetal rate. FetatrackDD250 Service Manual Issue1 Page 7 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd System Operation Vascular The DD250 can be used to detect both surface vessels, deeper arteries and veins using either the 5MHz or 8MHz transducers. To obtain the best signal, apply a liberal amount of coupling gel to the area of the vein or artery under investigation. Tilt the transducer at approximately 45 degrees to the vessel. Arteries give a high pitched pulsatile sound, with veins giving a sound like a roaring wind. The optional headset helps to eliminate ambient noise, making it easier to detect the weaker signals. It is also usual for the DD250 to be used in association with a pressure cuff and sphygmomanometer to indicate the location and extent of arterial occlusion in the form of ankle/brachial pressure index and segmental pressures. Due to the variation of leg blood pressure over a wide range with the systemic pressure, the actual values are less useful than the pressure index, which relates the ankle pressure to the pressure obtained at the brachial artery. Using the DD250 to measure both pressures will ensure compatibility. In cases where patients have peripheral arterial disease using the DD250 , due to its high sensitivity, can be the only technique suitable for the measurement of leg blood pressure. Pressure Index = Ankle systolic pressure Brachial systolic pressure Normal - ankle systolic pressure > brachial pressure. Normal pressure index >1 Abnormal pressure index <1 FetatrackDD250 Service Manual Issue1 Page 8 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Troubleshooting The information in this section will help you to check and correct common operation and system problems. Refer to the troubleshooting hints which deal with your problem. Perform the suggested steps. If the problem is not solved, check once again to make sure that you have used all of the suggested steps to resolve the problem. Electronic failures and service procedures are not included in this manual, as all servicing of the system must be performed by a qualified service technician. Valuable time however can be saved by documenting the problem . In general, when you have a problem, check your control settings to be sure that they are in proper operating position. Consult the appropriate section in this manual for specific information on particular controls or operating modes. WARNING: Disconnect system from the power source before checking fuses and connections. Check all connections and fuses. Replace fuses with same type and rating as indicated on the rear panel of the unit. No display information on LCD Verify the system is on and that the fuses are intact.: · Keyboard does not respond · · Reset system by turning off then back on. Verify the system is on and that the fuses are intact. No sound from loudspeaker. · · · · Verify the system is on and that the fuses are intact. Check volume control is set high. Check that a transducer has been connected. If possible change the transducer. No FHR information on display or FH trace printed on recorder. · · · Check that a transducer has been connected. Check connection of the transducer. Check for audio FH complex and reposition transducer until clearly heard. Unit will not operate from batteries. · · · Verify the system is on and that the fuses are intact. Leave the unit for 5 Hours to charge with mains connected Check on off button is pressed FetatrackDD250 Service Manual Issue1 Page 9 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Maintenance The following are the user preventative maintenance tasks. It is recommended that these be performed on a regular basis at a frequency determined by the usage of the equipment, but not less than once every month. WARNING: Before undertaking any of these tasks disconnect the unit from the mains. General Check all cables, connectors and transducers for damage and repair or replace where necessary. The repair may involve your local service centre, supplier or Ultrasound Technologies Ltd. For advise on any damaged part contact them immediately. Cleaning - Enclosure Clean the exterior of the system with a soft dry cloth. In the event of stubborn spots, disconnect the system from the power source. Use a soft cloth that has been dampened - not soaked - in a mild detergent solution. Be sure to keep excess moisture from entering the cabinet via any openings that may be present. Cleaning - Transducers Use a cloth dampened in a mild detergent solution to clean the transducer and cable. Remove all traces of the detergent by wiping with a cloth dampened in clear water. Never soak the transducer cable or connector. WARNING: Transducers must never be exposed to gas or heat sterilization or be left immersed in any liquid for more that a few seconds. FetatrackDD250 Service Manual Issue1 Page 10 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Specification ULTRASOUND Type: Transducer: Operating Frequency Power Output Continuous Doppler 2 crystal narrow beam option of 2, 3, 5, 8 MHz +/- 10% <5mW/cm² SATA (2, 3 MHz fetal probe) <15mW/cm² SATA (5 and 8MHz vascular probe) Response 300Hz—1KHz ( 2, 3 MHz fetal) 300Hz—4KHz ( 5, 8 MHz vascular) 500mW Software AUTOCORRELATOR 50 to 210 bpm Audio: Audio output Signal Processing Range: CONTROLS Keys: Controls: Indicators: 1 key for unit on / off (Push Volume control) Rotary Volume LCD Display with icon for battery low and pulse, battery charge LED, mains on LED. POWER SUPPLY Voltage: Power: Battery Charge Life: Battery Charge Time: 100-130 VAC or 200-260 VAC 46/64 Hz 20VA >30 hours of use (battery's will self discharge when not used) <5 Hours ENCLOSURE Material Size: Weight: Plastic PCABS 32 x 19 x 6 cm 1.9kg ENVIRONMENTAL Working temperature +10°C to +40°C Relative humidity 30% to 75% Storage/Transport temperature -10°C to +70°C COMPUTER INTERFACE Transfer Data Rate Data Standard Data Format 3 wire RS232 9600 baud 8 bits no parity 1 stop bit UltraTec Comms Standard SAFETY Classification: Complies with EN60101-1:2006 Class 1 Type B The following Consumables are available for use with the FETATRACK DD250 Power Cord Coupling gel (0.25ltr) (12 per box) This Equipment complies with the essential requirements of the European Council Directive. 93/42/EEC 0120 FetatrackDD250 Service Manual Issue1 Page 11 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Electromagnetic Compatibility Guidelines for Identifying and resolving adverse EMC conditions Emissions Care has been taken through the design and manufacturing processes to minimise the EM emissions that may be produced by this equipment. However, in the unlikely event that the unit causes an EM disturbance to adjacent equipment, we suggest that the procedure is carried out 'out of range' of the affected equipment. Immunity If the user has any doubt regarding the unit's EM immunity during routine operation, we suggest that the source of EM disturbance is identified and its emissions reduced. If the user has any doubt regarding the identification and resolution of adverse EM conditions, they may contact Ultrasound Technologies Ltd to seek advice EMC Testing During conformity testing the Fetatrack DD250 was subjected to International Standard EMC tests. During the majority of these tests no non conformances were observed. During EN60601-1-1:2001 testing the FetaTrack DD250 was shown to be susceptible to the following tests. Effect was a displayed rate of 115 to 125 bpm at each harmonic and sub Conductive Test applied a 3Vrms RF magnetic harmonic of the transducer frequency. disturbance induced field to transducer cables with a 2Hz No disturbance was detected at other by applied RF field modulation. frequencies Radiated RF Effect was a disturbance to the UA transducer causing a static UA Test applied: 3V/m 80Mz to 2.5GHz reading of up to 9 units Applied test signal is very high for high sensitivity electronics and non applied transducers. With correctly applied transducers interference from in band RF signals is unlikely. Normal operation is unaffected and the static reading can be cancelled by pressing the toco zero button Normal mains power is unlikely to cause such a transient / burst. Displayed rate is Electrical fast Test applied: +/-2KV AC power, +/- Effect was a FHR reading of 198 BPM unlikely to occur when transducers are transients and bursts 1KV Signal Cables . connected to a patient. Electro Static Discharge Test applied: +/-2KV, +/-4Kv, +/8KV Air Discharge, +/-2KV, +/4KV, +/-6KV Contact Discharge. Repetition Rate 1second Effect was a FHR reading of 58 BPM Unit should be used in a low static environment. Displayed rate is unlikely to occur when transducers are . connected to a patient. Surge Test applied: +/-0.5KV, +/-1KV, +/2KV AC power line to ground, +/0.5KV, +/-1KV, +/-6KV AC power line to line Effect was a FHR reading of 58 BPM Normal mains power is unlikely to cause such a surge. Displayed rate is unlikely to occur when transducers are . connected to a patient. FetatrackDD250 Service Manual Issue1 Page 12 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd WEEE and RoHS Waste Electrical and Electronic Equipment (WEEE) Directive (2002/96/EC) There is an increasing interest in the proper disposal of used electronic equipment. The European Union (EU) has developed the WEEE (Waste Electrical and Electronic Equipment) Directive to ensure that systems for collection, treatment and recycling of electronic waste will be in place throughout the European Union. 1 Ultrasound Technologies Position with regard to the WEEE Directive Product recycling is nothing new and Ultrasound Technologies have implemented processes in each member state where the company has a presence. Ultrasound Technologies will comply with the provisions of the WEEE Directive and national implementing legislation. 2 Instructions for Disposal of Waste Equipment by Users in Private Households This symbol on the product or on its packaging indicates that this product must not be disposed of with your other household waste. Instead, it is your responsibility to dispose of your waste equipment by handing it over to a designated collection point for the recycling of waste electrical and electronic equipment. The separate collection and recycling of your waste equipment at the time of disposal will help to conserve natural resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where you can drop off your waste equipment for recycling, please contact your local waste disposal authority, your household waste disposal service or the supplier where you purchased the product. As a producer of electronic devices, Ultrasound Technologies will provide for the financing of the treatment and recycling of waste returned through these designated collection points in accordance with local requirements. 3 Instructions for Disposal of Waste Equipment by Commercial Users For users of Ultrasound Technologies equipment, other than private households, Ultrasound Technologies will provide free recycling of equivalent medical electronic equipment once a customer has returned the equipment to Ultrasound Technologies, with all transport and importation costs paid, and where a replacement product is being supplied by Ultrasound Technologies. Where a replacement product is not being supplied, recycling services may be provided on request at additional cost. RoHS The RoHS (Restriction of Hazardous Substances) directive (2002/95/EC), compliments the WEEE Directive by banning the presence of specific hazardous substances in the products at the point of manufacture. Ultrasound Technologies is a manufacturer of Medical Devices and is currently exempt from this directive. However at Ultrasound Technologies we take our responsibilities to the environment very seriously and currently 100% of our entire manufacturing process and parts meet the RoHS directive and we are therefore fully compliant.. FetatrackDD250 Service Manual Issue1 Page 13 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Disassembly Dismantling Procedure 12 WARNING:- ELECTROCUTION RISK Mains voltages are present at these points and adjustment MUST NOT be untertaken with the mains lead connected. NO electrical TEST, SERVICE or INSPECTION of the board should be undertaken without the board being fitted to the base of the DD250. Note: Before disassembling the unit, unplug the transducers, accessories cable (if present), and the power cord from the instrument. To remove the Top Cover, remove the four screws around the edge on the bottom of the unit and carefully lift the lid upwards. The Top Cover can now be removed taking care to disconnect the connections between the lid and the base.. Internal Layout The mains and charge board are connected to the base and the audio and compute board to the lid. FetatrackDD250 Service Manual Issue1 Page 14 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Circuit Description Technical Descriptions The following sections provides a technical explanation of each of the sections within the Fetatrack DD250 and its accompanying transducers.: 11 4 Unit Power Supply The unit operates from either a mains connection or the internal rechargeable battery packs B1 and B2. Mains voltage is supplied to the unit via an IEC 3pin mains inlet (J5) where it is routed to spade jumpers J14, J15, J16, J17, J18 this allows the unit to be set to 110V or 220V input voltages. 13 WARNING:- ELECTROCUTION RISK Mains voltages are present at these points and adjustment MUST NOT be untertaken with the mains lead connected. NO electrical TEST, SERVICE or INSPECTION of the board should be undertaken without the board being fitted to the base of the DD250. The selected mains voltage is converted into the unit’s operating voltage of 14 – 16VDC by passing via an encapsulated toroidal transformer T1, L1 to remove any common mode signals and D3 a diode bridge rectifier. The resultant DC voltage is smoothed by C5 and C6. When mains is connected and turned on the mains inlet on/off switch is illuminated green, this is also mirrored by the DC supply illuminating D7 via R2. The Doppler circuits are powered from the mains derived DC after it has been regulated to 10V by U3 and passes through D5 where D6 blocks current being drawn from the batteries. With the mains connected and switched on, the batteries will be placed into a charge mode. The state of this mode is indicated by the rate of flashing of D8. The charge controller U2 varies the rate of charge dependent on the state of battery packs B1 and B2 and allows a current source of 500mA (U1) to be connected or disconnected from the batteries until a set charge state is reached. R9 and D4 allow a trickle charge to be present at all charge states. Temperature state of the batteries is monitored by R14 and U2. When there is no mains connected current is supplied to the Doppler system from the battery packs B1 and B2 via diode D6. Fuse F1 protects the batteries and circuits from any short circuits. The Doppler circuits are connected to the power supply at J2. FetatrackDD250 Service Manual Issue1 Page 15 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Circuit Description (the following descriptions and circuit references refer to the PD1 plus s3 circuits) The Doppler detection circuits are turned on by the pressing the volume control which activates an integral push – push switch, which is mounted on the front of the unit. Closing the switch, grounds the CLK input of U2 pin 11, the output on pin 12 switches on Q2 allowing current to flow into the various circuits. The unit will remain switched on for approximately 3 minutes from the last detected signal (monitored by U6) after which it turns off automatically, U6 activates Q1 which pulls the clock signal at U2 pin 11 low, unless the user forces the unit off by pressing the ON/OFF switch again. 5 Battery Low Indicator U6 also monitors the input voltage via R9 and R10. When the voltage on pin 26 drops below the threshold set by R9 and R10 (7.3V), U6 enables the battery ICON on the LCD display. (the following descriptions and circuit references refer to the PD1 doppler transducer circuits) 6 Ultrasound Transducer The ultrasound transducer operates on the continuous wave Doppler principle. There are a number of transducer frequencies suitable for different applications, however the basic operating principles are identical. Each transducer consists of a pair of piezo ceramic crystals, each crystal pair is arranged as a transmitter and receiver, the ultrasonic output beam is focused through a lens or faceplate. With all the transducers, the electronics are housed in the probe. The oscillator and detector are built up of four discrete sections. These are the master oscillator, transmitter amplifier, receiver amplifier and detector. These operate to produce a continuous wave ultrasound signal that is passed to the transmitting crystal in the transducer. The signal is then reflected from moving interfaces within the body to the receiver crystal in the transducer, amplified and then detected so the audio Doppler shift of that moving interface can be heard audibly and / or converted into a velocity signal. 7 Oscillator and Transmitter Amplifier Field effect transistor Q2, with L1, C16, C17 and associated components form a Colpitts oscillator. This oscillator runs at a nominal frequency of 2, 3, 5 or 8MHz producing a sinewave of amplitude of approximately 5V Pk. The signal is then fed to output transistor Q3 that drives the transmitter crystal in the transducer. The signal is fed to the transducer via a tuned transformer L2 (C20), the output impedance of which is set correctly to match the transducer crystal impedance. The output drive signal is nominally 1.5V Pk. FetatrackDD250 Service Manual Issue1 Page 16 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Circuit Description 8 Receiver and Detector The reflected Doppler signal is fed via a resonant transformer L4 (C25) to the gate of Q5, the drain of this FET connects to the source of Q4 to form a cascode amplifier the drain of which contains the resonant circuit L3,(C21). From the drain of Q4 the amplitude complex of the received signal is detected by passing the signal through synchronous detector Q6 with the high frequency signals being filtered by R12 and C15. The raw low frequency complex is then amplified and filtered by U1 where its associated components form a band pass filter amplifier with a bandwidth of 150Hz to 1KHz for the obstetrics or 300Hz to 4KHz in the vascular transducer. This signal is passed to the main unit via the retractile cable. (the following descriptions and circuit references refer to the PD1 plus s3 circuits) 9 Audio Amplifier The audio signal is routed via the retractile cable to J4 pin 4 on the audio circuit board. The signal passes through the potentiometer VR1 to the audio amplifier U3, where it is amplified and output to the loudspeaker connected to J3. 10 Digital Signal Processing The audio signal is fed from the band pass amplifier, U4d through the AGC circuit formed around U4c and U7. The microprocessor controls in input gain to maximise the signal between the limits of 1V and 4.5V at the A/D converter. The signal then passed via the average value circuit (U4b and U4a) and into the A/D converter U6 pin 25. The digitally converted signal is correlated to find the input rate which is displayed on the LCD display driven by the display interface circuit (U5). RS232 data output of the rate information is provided at connector SK2 as a digital RS232 stream from U8 of +/- 5Vdc. FetatrackDD250 Service Manual Issue1 Page 17 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Performance Checks Introduction The following sections details tests to ensure that the FETATRACK DD250 is operating within specification. These tests may be performed in whole or part, however, if any repairs are carried out to the power supply circuits then it is recommended that the whole test/calibration procedure is undertaken. The test procedures may be performed without removal of the circuit board from the unit. Performance Checks The following procedure is intended to provide a means of determining the functional status of the unit. It should be included as part of a preventive maintenance plan and should be performed on a regular basis. 1) Plug the monitor line cord into a grounded receptacle of suitable line voltage and frequency as indicated on the rear panel of the FETATRACK DD250 2) Turn monitor on. The green front panel LED will illuminate. 3) The display will first show the system selftest followed by the software revision, this indicates the instrument is switched on and awaiting inputs. Ultrasound 4) Connect an ultrasound probe to the retractile cable, and increase volume. 5) Place transducer in palm of hand and gently stroke the back of the hand at a constant rate of about 2 times a second. 6) Check audio volume is present, digital display will display the simulated rate (approx 120 ). FetatrackDD250 Service Manual Issue1 Page 18 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk Ultrasound Technologies Ltd Drawings The following pages contain drawing data to assist in the service of the product. Parts lists (Bills of material) Fetatrack DD250 Mains Battery Circuit Fetatrack DD250 PD1 Plus Circuit Fetatrack DD250 Pocket Doppler Transducer 2MHz Fetatrack DD250 Pocket Doppler Transducer 5MHz Fetatrack DD250 Pocket Doppler Transducer 8MHz Circuit Data Fetatrack DD250 Mains Battery Circuit Fetatrack DD250 PD1 Plus s3 Audio Circuit Fetatrack DD250 PD1 Plus s3 Digital Signal Processor Fetatrack DD250 Pocket Doppler Fetal Transducer 2MHz Assembly Drawings Fetatrack DD250 Assembly Base Fetatrack DD250 Assembly Top Fetatrack DD250 Assembly Main PCB Fetatrack DD250 Assembly PD1 Plus PCB Fetatrack DD250 Assembly Main FetatrackDD250 Service Manual Issue1 Page 19 ©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom. T +44 (0) 1291 425425 F: +44 (0) 1291 427093 E: [email protected] W: www.doppler.co.uk 3 4 2 1 3 7 1 C10 + 100nF C8 100uF C12 100uF C16 680pF 3 C20 220pF B R2 2K2 C7 + 100nF 6 3 1 D 3 G 0841 L1 TxSig A L2 0876 3 3 6 C 1 B 2 E (VR1) S 10nF C18 2 4 C23 1nF 2 1 1 D1 BZX84C6V2 2 C17 330pF C5 100uF 8 R14 27K 100R R13 C3 + 100nF MMBF4416 Q2 A Vrf E C Q1 BC848B 5 BC848B Q3 2 R7 22R 1 R15 1K5 C14 10nF R17 10R C24 100nF R11 2K2 R20 180K 1 B J1 2 B Vrf 3 4 1 C19 220pF 6 R5 100K 2 2 3 MMBF4416 Q6 C15 1nF R18 100K R12 100K D 1 3 G S 2 C26 100nF R19 100K R6 100K D 1K0 R3 1K0 R8 C4 1uF 1 3 G S C9 1nF R1 2K2 C2 100nF C Q5 MMBF4416 4 I- I- L3 0842 Q4 MMBF4416 TL072 100K R10 TL072 S 1 5 10nF C13 7 I+ 3 4 U1 10nF C6 C1 100nF I+ 1 8 8 U1 C21 470pF 3G R9 100K D R4 100K Transducer Connector C22 100nF 2 1 C25 220pF 4 3 6 R16 10R RxSig C11 1uF Issue 1 2 3 4 5 D 3 4 5 Date March 98 15/05/98 18/01/99 18/05/00 12/05 158 181 Drawn: nas - utl Drg No: PD1D110-ASSY Lodge Way Portskewett, Caldicot Date: 18/05/2000 South Wales. NP26 5PS. UK Name: FETALTDR_R5 Sheet 1 of 1 Copyright ultratec 2003 2 ECN Pocket Doppler Fetal Transducer 2MHz Ultrasound Technologies Ltd 1 C L4 0838 6 7 8 D D E F T1 Mains Transformer 11 DC Voltage at 230VAC = 15.5V DC Voltage at 200VAC = 13.4V DC voltage 15.5V DC current 900mA C2 100nF C5 2,200uF DC+ AC1 3 3 DC- 2 AC2 2 2 4 4 100R R9 Fast charge is 500mA 2 4 14 10BQ040 1 2 D1 2 Charge 4 4 10BQ040 1 J1 3 1 2 VsenOP TrefH F/TOP Tsen Gnd TrefL R12 10K 8 7 I = 72.7uA with Vbat = 9.6 6 5 R8 27K MC33340 R13 22K Mains On LED Indicators R50 3 S 100K G1 5 U3 LM317S Vout TAB C3 10uF 2 2 4 + C7 100nF Adj 1 + C1 100nF BATTPACK4V8 4.8V + 1 J6 B2 3 10K NTH4G 4 RS232_Rx 5 RS232_Tx J11 1 1 2 2 5 1 1 2 10BQ040 C8 10uF J7 J2 DD250 DC Output 1 AC power on 12VDC, 200mA J8 1 3 3 4 4 2 10K LOG R6 1K5 1 2 1 2 1 J9 1 J10 6 LED PCB R7 220R 1 J12 SK2 Socket PCB Battery State 7 2 4 3 1 4 RS232 6 LED out SK1 Parts in close proximity R5 200R Min dropout voltage = 2V (input / output) Min output voltage for min input = 11.4V Audio Socket 2 4 3 1 2 BATTPACK4V8 4.8V D5 12.13V Vin D B1 22K R51 2 3 + R14 C9 100nF R10 4K7 J4 1 1 F1 Vcc 3 4 3 3 R11 100K v sense = 1.6V VsenIP C4 100nF 2 2 Vertical Mounting Blades 0.25" RS 534-834 J3 1 SPD8P06SM Q3 100R R3 1 N L 1 Isen = 10nA R2 6K8 4 Nuvotem 70052K RS223-9339 Transformer Output 12VAC 15VA 10BQ040 U2 R1 6K8 AC4 1 0.75A TAB AC1 3 D2 2 Adj AC3 SW1 POLYFUSE0A75 Vout 4 AC2 At 80% full charge I = 43mA 2R2 R4 Vin 3 13 1 D4 3 5 L1 1000uH 2 U1 LM317S 12 1 D3 1 PE C6 2,200uF 2 J5 6 Common mode rejection DBLS203G 1 H D7 1 G IEC Mains input / fuse and On/Off Switch D8 C LGN971 B LYN971 A J13 Issue ECN Date 1 2 3 3 4 7 Mar 09 May 10 Jan 11 5 S1 LED in Volume and on/off switch Volume PCB Copyright ultratec 2011 A Mains / Battery circuit for DD250 Drawn: Nas Drg No: D250C100-103 Lodge Way Date: Portskewett, Caldicot of 1 South Wales. NP26 5PS. UK Name: DD250POWER_3 Sheet 1 Ultrasound Technologies Ltd 8 B C D E F G H 8 4 Q2 FDN352AP C11 100uF R11 2K2 R9 12K Battery Input U2 8 SET 11 CLK 9 D 10 RESET 1 J2 E C22 100uF VSewardprobe A C19 100uF 2 3 BatteryCondition {02} + 13 Q 12 Q D2 BZX84C6V2 R10 4K7 R5 1M CD4013 C3 100nF C12 100uF 1 R1 1M Unit On / Off control C21 + 100nF 3 C18 + 100nF 2 3 + C7 100nF 8 Q3 BC848B 1 R4 1M 10BQ040 G1 2 A 7 B 1 2 2 6 C 1 S D1 J1 5 3 3 VddSw {02} 2 D 1 + C6 1u0F probe_switch 3 B UnitShutDown {02} VddSw {02} 1 Q 2 Q CD4013 5 6 C8 220uF + + 100nF C20 C9 220uF + C15 10uF C14 10nF VSewardprobe U1 C1 100nF + VO- V1+ CAP+ 100uF C2 GND CAP- SK1 2 4 3 1 8 2 3 C4 10uF + C5 100nF C 8 R8 22K U3 5 P LM386M M R7 10R VR1 100K 3 2 100nF C17 Volume Control 7 4 5 C10 100uF R3 100R + TP1 J3 4 1 2 SI7661 J4 3 4 1 C 2 probe_switch 6 U2 6 SET 3 CLK 5 D 4 RESET Transducer Power Connector 1 AudioComplex {02} 47R R6 G 1 VddSw {02} S 2 VddSw {02} BSS138 Q1 B 10K R2 D C16 10uF C13 100nF + Loudspeaker Issue 1 2 3 4 5 6 7 8 D ECN Date June 98 Sept 99 Nov 99 Jun 00 Aug 02 Jan 05 Aug 05 Aug 07 176 178 182 210 228 230 PD1 Plus s3 Audio Circuit Drawn: NAS Drg No: Lodge Way 100-0002-00 Date: Portskewett, Caldicot Sheet 1 of 2 South Wales. NP26 5PS. UK Name: PD1PLUS3 Ultrasound Technologies Ltd Copyright ultratec 2007 1 2 3 4 5 6 7 8 D 1 2 3 4 5 6 7 8 LCD Interface Disp1[1:7] 1 bp A S3 3 DispSym1 1 26 R 2 25 bp 3 24 Disp1[3] Disp1[6] 4 23 Disp1[4] Disp1[7] 5 22 Disp1[5] Disp2[2] 6 21 Disp2[3] Disp2[1] 7 20 Disp2[4] EZPQ Disp2[6] 8 19 Disp2[5] EZPCK 9 18 Disp2[7] Disp3[1] 10 17 Disp3[3] Disp3[6] 11 16 Disp3[4] 12 15 Disp3[5] 13 14 Disp3[7] DispSym2 6 STR Disp1[2] Disp1[1] Disp3[2] S4 4 5 7 8 C25 100nF 9 10 11 12 13 FR 14 15 16 17 18 J5 19 20 21 Disp3[1:7] B 22 23 24 25 26 1 S2 S1 2 S5 R S6 STR S7 D0 S8 Vlcd S9 VDD S10 VSS1 S11 DI S12 CLK S13 FR S14 S40 S15 S39 S16 S38 S17 S37 S18 S36 S19 S35 S20 S34 S21 S33 S22 S32 S23 S31 S24 S30 S25 S29 S26 S28 C37 100nF U8 U5 Disp2[1:7] S27 C33 100nF 52 Disp1[1] 51 Disp1[2] 3 50 Disp1[3] 4 49 Disp1[4] C34 100nF 48 Disp1[5] R19 10K 47 Disp1[6] R21 10K R22 10K Disp2[1] FR 44 Disp2[2] R 43 Disp2[3] 42 Disp2[4] 41 Disp2[5] 40 Disp2[6] 39 Disp2[7] 22 23 18 STR 19 Agc1 Agc2 Agc3 Disp3[1] 37 Disp3[2] 36 Disp3[3] 35 Disp3[4] 34 Disp3[5] 33 Disp3[6] 32 Disp3[7] Agc4 40 41 42 43 56 57 UnitShutDown {01} EZPD EZPQ DispSym1 30 C1- V- 2 6 C38 100nF C2+ C2- TP5 EZPCK DispSym2 58 12 13 14 15 29 PTC0 UCTS0 PTC1 URTS0 PTC2 URXD0 PTC3 UTXD0 UCTS1 PTA0 URTS1 PTA1 URXD1 PTA2 UTXD1 PNQ1 JTAG_EN PNQ4 TCLK PNQ7 TDI TDO SPI_DIN TMS SPI_DOUT 26 BatteryCondition {01} 27 V6108 28 36 35 34 33 TRST 30 6 12 Rx_Data 9 61 2 T1out T2in T2out R1out R1in R2out R2in Tx_Data RS232 14 7 13 8 MAX3232E 63 TP12 62 17 44 50 51 49 1 EZPD 54 RCON 16 SCL AN2 SDA AN3 ALLPST AN4 AN5 TEST AN6 RSTI AN7 VRH EXTAL VRL XTAL Vstby B 3 EZPCS 4 24 5 R32 1K0 AN0 AN1 J6 2 EZPQ EZPCK SPI_CS RSTO 31 10 TP10 5 SPI_CLK CLKMOD0 25 fetal_signal_complex 7 T1in PTA3 28 27 11 4 A SK2 2 4 3 1 RS232_Tx U6 45 31 V+ RS232_Rx 5 46 Disp1[7] 38 C1+ 6 8 7 Unit Programming Interface Vcc is 3.3V 9 55 3 R33 10K TP13 59 reset 60 47 device power on reset EXTAL 46 C31 22pF 37 R31 1M C40 1uF X1 11.05920MHz C23 1nF R13 68K LowPass Filter (5Hz) I+ 8 6 LM324M Precision Rectifier R25 100K VddSw {01} VddSw {01} I- 5 I- 9 4 U4 LM324M I+ 14 10 I- I+ 11 13 3 C42 100nF ZSR330G C30 10nF 12 11 R24 10K R26 10K R27 10K R29 10K U7 2 C28 47nF R23 10K YA CONTA XA 3 D YB CONTB XB 9 YC CONTC YD CONTD XC 10 XD Note: Power Rail +3.3 - 0V 1 IN C41 100nF AudioComplex {01} LM324M 11 R20 330K D3 BZX84C2V7 4 C39 10uF 1 3 fetal_signal_complex 7 4 U4 C35 100nF OUT R30 100K Fetal Complex BAS16 D4 U4 C U9 1 C36 + 100nF 330K R28 11 1uF C26 C32 22pF C29 1nF 3 TP2 C27 100nF I+ Low Pass filter fo = 220Hz R18 10K LM324M 3 100K R12 I- R16 22K 1 2 R15 68K U4 10K R17 VddSw {01} TP3 4 TP4 1 100nF C24 VddSw {01} R14 47K MCF5212CAE66 C VddSw {01} XTAL 2 3 4 5 74HC4066 13 Agc1 1 5 Agc2 4 6 Agc3 8 12 Agc4 11 Issue ECN 1 2 3 4 5 6 7 8 176 178 182 210 228 230 PD1 Plus s3 Digital Signal Processor Drg No: 100-0002-00 Drawn: NAS Lodge Way Portskewett, Caldicot Date: South Wales. NP26 5PS. UK Name: PD1PLUS3 Sheet 2 of 2 Ultrasound Technologies Ltd FHR Agc 6 Copyright ultratec 2007 Date June 98 Sept 99 Nov 99 June 00 Aug 02 Jan 05 Aug 05 Aug 07 7 8 D