Download WK 499 775

Transcript

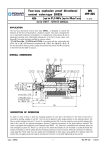

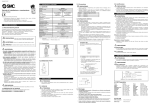

WK 499 775 Intrinsically safe directional control valve type IWE6 NS6 up to 31,5 MPa up to 20dm3/min DATA SHEET - OPERAT RATION MANUA MANUAL NUAL 02.2014 APPLICATION The 4-way directional control valves type IWE6… electrically operated are intended for change in direction of fluid flow in a hydraulic system. This valve is mainly used in hazardous areas especially in underground pit mines (group I) and in equipment working in vicinity of flammable substances like gas, vapour, fog (group II). It is certified with explosion proof attest - ATEX: ATEX I M1 Ex ia I Ma; II 2G Ex ia IIC T6/T5 Gb; Ma Gb GOST - R: PO Ex ia I Ma; Ma 1Ex ia IIC IIC T5/T6 Gb. Can work with outlet explosion proof circuit “ia” or “ib” with maximum parameters Ui = 15 V; V li = 1,6 A; Ci = 0; 0 Li = 0. Temperature classes T5 and T6 are dependent on ambient temeperature, according to data table on page 2. DESCRIPTION OF OPERATION The directional valve is switched by changing position of the spool (3) which moving along its axis separates or connects ports A , B , P , T in the housing (1). The move of the spool is secured by the putting voltage on coil (2) through the terminal strip (10) The return of the spool is realized by the spring (4). A n optional manual override button (6) permits movement of the spool without solenoid. The valve is equipped with explosion proof solenoid type EMSGI – 45. Solenoid is assembled with sleeve (5) and manual override button (6). There is a coil (2) on the sleeve (6). Outside of coil mounted is cable box (7). Inside the cable box (7) are diodes as well as safety device (9) preventing excessive current increase. Electrical connection for is realized by using terminal strip (10) and for type with light signaling applied diode LED (11). The diode is mounted inside cable box (7). Power lead must be sealed and immobilized using gland (12). Sealing rings (14) protect the coil against external impacts and prevent from turn of coil after tightening up the nut (13). 4IWE6E12/G12NDL 12 2 7 11 4 14 5 a b 6 13 A P B 9 T 3 1 10 8 Type IWE6 -1- WK 499 775 02.2014 DESCRIPTION OF OPERATION Directional valve type IWE6… IWE6 … can be equipped by throttle insert (15) mounting in port P - version …IWE6…B B …. 15 P TECHNICAL DATA Hydraulic fluid Required Required filtra tio tion Recommended filtration Nominal fluid viscosity Viscosity range Fluid temperature range Optimum fluid temperature range Relative humidity of air Protective coating Maximum Maxim um operating pressure Maximum Maxim um flo fl ow Weight Supply vol tage U n Supply current In Degree of protec tio ti on mineral oil up to16 to 16 µm up to10 µm 37 mm 2/s at temperature 55 oC 2,8 up to 328 mm 2/s -20 up to 60 o C o 40 up to 55 C to 95 % housing epoxy chemically resistant enamel hot galvanizing solenoid port P , A, B - 31,5 MPa port T - 21 MPa 20 dm 3 /min 1,6 kg 12 V DC 110 mA IP 6 5 COMPLIA PLIAN IANCE WITH STANDA ANDAR DARD SY S YS T E M Standard system Certifica Certi ficate fica te of o f examinati on type 1456 145 6 KO MAG MAG 06AT EX201X 201 X - 20 do 40 C II 2G 2 G Ex ia I IC T6 /T 5 Gb for class temperature T6 o - 20 do 40 C for class temperature T5 o - 20 do 60 C 1Ex ia I IC T5/T 6 Gb for class temperature T6 o - 20 do 40 C for class temperature T5 o - 20 do 60 C o Quality Quali ty assurance certi ficate fica te RU CC-PL.ГБ08.B.0025 PL. 08.B.00251 08.B.00251 PO Ex ia I Ma o - 20 do 40 C I M 1 Ex ia I M a Intrinsic tri nsic safe ty feat ure Ambient temperature Ta G O ST - R ATE ATEX (94/9/WE) 1026 102 6 FTZ FT ZU No N o. FTZ FT ZU 05 AT EX Q 01 3 ASSEMBLY AND OPERATION REQUIREMENTS 1. 2. 3. 4. 5. WK 499 775 Electric connection of the valve must be made according to electric scheme on page 5. 5. Conductors of valve must be meet requirements applied in the mining machinery. Only skilled workers can direct connect valve to an an electrical system. The plug must be supported by retains screw. During the period of operation must be kept the fluid viscosity and filtration according to requirements defined in Service Manual 02.2014 6. In order to ensure the failure free and safe operation must be check: • condition condition of the electrical connection • the verity proper working of the valve • cleanness of the hydraulic fluid 7. Any valve repair in the mine condition is forbidden. A damaged valve must be supplied to the producer in order to repair. The address of service is shown on the last page of this Data sheet – Service Manual 8. A person that operates the valve has to acquaint with Service Manual. -2- Type IWE6 OVERALL AND CONNECTION DIMENSIONS OO 61,5 23 42 b a 80 2 9,4 - 4 depth holes 5,3 - 4 holes 3 1 2 S6 45 4 8 164 31 32,5 T A B 0,75 P 40,5 73 5 81,5 17 7 164 236 1 - Solenoid a 2 - Solenoid b 3 - Sealing ring - o - ring 9,2 x 1,8 - 4 pcs/kit 4 - Manual override 5 - Diode LED - light signaling (only version IWE6…DLL…) 6 - Valve dimension: 3 - position directional valve with return springs spri ngs (solenoids a and b, spool symbols: E , H , J, L, M, U according to page 4) 2 - position directional valve without return springs (solenoids a and b spool symbols: A , C, D according to page 4) 7 - Valve dimension: 2 - position directional directional valve with return spring (solenoid a, spool symbols: A, C, D , EA , HA, LA,MA HA JA ,LA LA MA,UA MA UA according to page 4) 8 - Valve dimension: 2 - position directional valve with return spring (solenoid b, spool symbols: B , Y, EB, EB HB, HB JB, JB LB, LB MB,UB MB UB according to page 4) 9 - Porting pattern for directional spool valve configuration of connection holes in accordance with the following standards: • CETOP RP 121H - identified by CETOP 4.2-4-03 (nominal size CETOP 03) 03 • ISO 4401 - identified by ISO 4401-03-02-0-94 mounting bolts M5 x 50 - 10.9 in accordance with PN - EN ISO 4762 - 4 pcs/kit, tightening torque Md = 9 Nm 10 - Subplate surface required O M5 gł 10 - 4 holes 7,6 (max) - 4 holes (P,T,A,B) 9 T B 26,55 31,75 32,5 A P 10,3 19 27,8 40,5 min 73 r 0,75 5,95 16,25 min 45 6 min 17 0,01/100 mm 0,63 10 Type IWE6 -3- WK 499 775 02.2014 SCHEMES Grap Graph aphic sy s ymbo mbols for 2-po 2-p o sit sition directtional spo direc spoo l valves Grap Graph aphic sy s ymbo mbols for 3-po 3-p osit si tion directtional spo direc spoo l valves IWE6...1X/... IWE6..A...1X/... IWE6...B...1X/... A A B 0 b a a P a a b B A 0 0 b T P T B P b T Grap Graph aphic sy s ymbo mbols for spo spo ols working and indirect positions A a B 0 a b T P B A 0 P B A b a A 0 T a T P working and indirect positions A B working positions working and indirect positions working positions B P 0 P T P T B A b 0 0 working positions b T E EA EB H HA HB J JA JB L LA LB M MA MB U UA UB Grap Graph aphic sy s ymbo mbols for 2-po 2-p osit si tion directtional spo direc spool valves A B ...IWE6...1X/... a a ...IWE6..1X/O... a A b a P T B P A B a b B A b a b a b T T P b T P Grap Gr aph aphic sy symbo mbols for spo sp ools working and indirect positions working positions A B A B a b P a T working and indirect positions a b P B A P T B A a b T położenia robocze i pośrednie A B working positions P a b B A T B A a b P T położenia robocze b P T BX C D WK 499 775 02.2014 Y -4- Type IWE6 SCHEMES Electrical scheme of directional control valve version with cable box without LED IWE6…D D ... version with cable box and light signaling LED IWE6…DL DL… DL B1 - 0,25 A + B1 - 0,25 A - + (-) (+) 12 V D C - (-) (+) 12 V D C View of electrical electrical connections versions with cable box IWE6…D D …; IWE6…DL DL... DL + (-) Type IWE6 12V DC DC (+) -5- WK 499 775 02.2014 PERFOMANCE CURVES For fluid viscosity v = 41 mm2/s and temperature t = 50ºC Flow resistance flow direction: P → A; P → B; A → B; A → T 0,6 0,6 ∆p [MPa] 0,5 0,5 0,4 0,4 0,3 0,3 0,2 0,2 0,1 0,1 0 5 10 15 Q [dm 3/ min min] 20 25 Flow limits 35 30 1 p [MPa] 25 Spo Spool type schemes according to page 4 3 E, A, B A/ O H, M, C/ C /O, D/ D /O C, D, J, Y 20 2 15 10 L, U 5 0 5 10 15 3 Q [dm /mi / min min] 20 25 20 25 Perform Perf orma orm ance di d iagram agr am number 1 2 3 4 5 35 30 p [MPa ] 25 5 20 15 10 4 5 0 5 10 15 3 Q [dm /min min] NOTES: The flow limits refer to typical application of 4-way directional control valve i.e. with using 2 lines e.q. P to A and B to T at the same time. In case of using WK 499 775 02.2014 4-way directional valve with line e.q. P to A (B B plugged) or A to T (B B plugged) actual flow limits are considerably lower. -6- Type IWE6 HOW TO ORDER IWE Number of service ports 3-way - for spools A, B 4-way - for the other spools =3 =4 Nominal size (NS) NS6 =6 Spool type spool symbol 6 12 N - according to page 4 = 1X (10-19) - installation and connection dimensions unchanged = 12 Series number Spool centering/positioning spring centering without reverse spring = no designation =O Voltage for solenoids DC voltage 12V DC = G12 Manual override solenoids with manual override button =N Electrical connections (schemes according to page 5) cable box without LED =D cable box with LED = DL Throttle insert without throttle insert throttle insert Ø 0.8 mm throttle insert Ø 1.0 mm throttle insert Ø 1.2 mm = no designation = B 08 = B 10 = B 12 Sealing NBR (for fluids on mineral oil base) FKM (for fluids on phosphate ester base) = no designation =V NOTES: Orders coded in the way showed above should be forwarded to the manufacturer. Shorter terms of deli del ivery f or valves with ith par p arameters arameters in bo b old are po p ossib ssible. ible. Coding example: 4IWE6 E 12/G12 N D Type IWE6 -7- WK 499 775 02.2014 EXAMPLE OF APPLICATION IN HYDRAULIC SYSTEM A B 4IW 4I WE6 J... P T M SUBPLATES AND MOUNTING BOLTS Subplates must be ordered according to the data sheet WK 496 480. Subplates: G 34 3 41/01 - threaded connection G 1/ 1/4 G 34 3 /8 3 42/01 - threaded connection G 3/ G 34 3 41/02 - threaded connection M14 x1,5 1, 5 G 34 3 42/02 - threaded connection M16 x1,5 1,5 WK 499 775 02.2014 Subplates and bolts fixing directional valve M5 x 50 - 10,9 0,9 in accordance with PN - EN ISO 4762 - 4 pcs/kit must be ordered separately. -8- Type IWE6 Special execution type ...IWE6...SO495 APPLICATION, DESCRIPTION OF OPERATION, ASSEMBLY AND OPERATION REQUIREMENTS, PERFORMANCE CURVES, SCHEMES, CONNECTION DIMENSIONS, SUBPLATES, MOUNTING BOLTS, 16 4 as in basic execution of directional control valve according to pages pages 1 - 6 button of manual control in initial position (unlocked) DESCRIPTION OF OPERATION Directional control valves type …IWE6…SO495 are equipped with set of latch spring mounted on solenoids. Latch spring (16) centrally mounted forces valve presetting without necessity of manual pressing on button (4). The button is unlocked after latch spring release (16) and return the set to initial position. NO T E S : button of manual control locked Before st artart -up the t he po p ositi ition of latc l atch atch spring spri ngs ngs of man ma nual con co ntrol tro l to t o be chec c heck hec ked. TECHNICAL DATA Hydraulic fluid Required Required filtra tio ti on Recommended filtration Nominal fluid viscosity Viscosity range Fluid temperature range Optimum fluid temperature range Relative humidity of air Protective coating Maximum Maxim um operating pressure Maximum Maxim um flo flow Weight Supply vol tage U n Supply current In Degree of protec tio ti on mineral oil up to16 to 16 µm up to10 µm o 37 mm 2/s at temperature 55 C 2,8 up to 328 mm 2/s -20 up to 60 o C o 40 up to 55 C to 95 % housing epoxy chemically resistant enamel hot galvanizing solenoid port P , A, B - 31,5 MPa port T - 10 MPa 20 dm 3 /min 1,6 kg 12 V DC 110 mA IP 65 65 COMPLIA PL IAN IANCE WITH STANDA ANDAR DARD SY S Y ST E M Standard system Certifica Certi ficate fica te of o f examinati on type 1456 145 6 KOMA KO MAG MAG 06ATE 06AT EX201X 201 X - 20 do 40 C II 2G 2 G Ex ia I IC T6 /T 5 Gb for class temperature T6 o - 20 do 40 C for class temperature T5 o - 20 do 60 C 1Ex ia I IC T5/T 6 Gb for class temperature T6 o - 20 do 40 C for class temperature T5 o - 20 do 60 C o Quality Quali ty assurance certi ficate fica te Type IWE6 RU CC-PL.ГБ08.B.0025 PL. 08.B.00251 08.B.00251 PO Ex ia I Ma o - 20 do 40 C I M 1 Ex ia I M a Intrinsic tri nsic safe ty feat ure Ambient temperature Ta GOST - R ATE ATEX (94/9/WE) 1026 No o. FTZ FT ZU 05 AT EX Q 01 3 102 6 FTZ FT ZU N -9- WK 499 775 02.2014 Special execution type ...IWE6...SO495 OVERALL AND CONNECTION DIMENSIONS OO 42 61,5 b 23 a 80 9,4 - 4 depth holes 5,3 - 4 holes 3 1 S6 2 8 bolts 5 45 4 9 197 31 32,5 T A B 0,75 P 115 40,5 73 6 17 8 197 7 303 View of connection and required conditions of connecting surface acc. to page 3. WK 499 775 02.2014 1 - Solenoid a 2 - Solenoid b 3 - Sealing ring - o - ring 9,2 x 1,8 - 4 pcs/kit 4 - Press button of manual control 5 - Lock spring 6 - Diode LED - light signal (only type IWE6…DLL…) 7 - Valve dimension with 2 solenoids - a, b: b •3 3 -position po sition directional valve centered with springs (spool symbols: E, H , J, L, M, U according to page 4) •2 2 - position without reverse springs (spool symbols: A, C , D - according to page 4) 8 - Valve dimension with 1 solenoid - a •2 2 -position pos ition set with spring (spool symbols: A , C , D, EA, EA HA , JA,LA JA LA,MA LA MA,UA MA UA according to page 4) 9 - Valve dimension with 1 solenoid - b •2 2 -position set with spring (spool symbols: B , Y, EB, EB HB, HB JB, JB LB, LB MB,UB MB UB according to page 4) - 10 - Type IWE6 HOW TO ORDER IWE Number of service ports 3-way - for spo ols A, B 4-way - for the other spools =3 =4 Nominal size (NS) NS6 =6 Spool type spool symbol 6 12 N - according to page 4 = 1X Series number (10-19) - installation and connection dimensions unchanged = 12 Spool centering/positio ning spring centering without reverse spring = no designation =O Voltage for solenoids DC voltage 12V DC = G12 Manual override solenoids with manual override button =N Electrical connections (schemes according to page 5) cable bo x without LED =D cable box with LED = DL Throttle insert without throttle insert throttle insert Ø 0.8 mm throttle insert Ø 1.0 mm throttle insert Ø 1.2 mm = no designation = B 08 = B 10 = B 12 Sealing NBR (for fluids on mineral oil base) FKM (for fluids on phosphate ester base) = no designation =V Special type solenoids with latch spring of button manual control = SO495 NOTES: Orders coded in the way showed above should be forwarded to the manufacturer. Shorter terms of delivery for valves with parameters in bold are possible. Coding example: 4 IWE6 E12/G12 N D SO495 Type IWE6 - 11 - WK 499 775 02.2014 PONAR Wadowice S.A. ul. Wojska Polskiego 29 34-100 Wadowice tel. +48 33 488 29 00 fax.+48 33 488 21 03 www.ponar-wadowice.pl WK 499 775 02.2014 - 12 - Type IWE6