Download WinPV User Guide - Power Commander

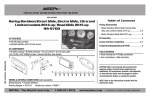

Transcript