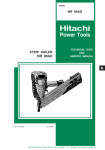

Download Hitachi - NR90GC

Transcript