Download 111348

Transcript

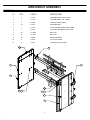

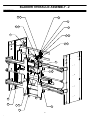

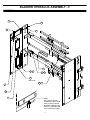

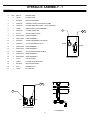

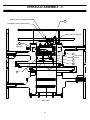

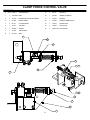

SERVICE MANUAL / PARTS LIST CONTENTS: APPLIANCE CLAMP SOFT TOUCH MODEL #111348 PATENTS PENDING PAGE 1 Lift Truck Requirements General Installation Procedures General Inspection 2-3 Clamp Assembly 4 Arm Group Assembly 5-7 Bladder Hydraulic Assembly 8-10 Hydraulic Assembly 11 Clamp Cylinder Assembly 12 Clamp Adjustments 13 Control Valve 14 Clamp Force Control Valve 15 Arm Slide & Shim Replacement 16 Trouble Shooting 425 Hazel St. Kelso WA 98626 (800) 248-6079 Fax (360) 578-9934 LIFT TRUCK REQUIREMENTS CAPACITY CLAMP HYDRAULICS Capacity shown on the Clamp name plate is for the Clamp only. The combined truck and Clamp capacity is provided by the lift truck manufacturer. Recommended Truck Pressure: 2300 to 2500 PSI (159 to 170 bar) Hydraulic fluid: petroleum based hydraulic fluid only Hydraulic supply group: includes hoses and take-up - one set for each function Auxiliary valve: 2 Function (Side Shift & Clamp) = a double auxiliary valve Oil Volume Settings: Side Shift = 3 GPM Clamp Open/Close = 7 GPM GENERAL INSTALLATION PROCEDURES 1. Make sure that the attachment centering lug is completely seated in truck carriage center notch. 2. Clearance between the lower retainers that hold the attachment to the truck lower carriage bar should be as shown below. .13" (3.2mm) MAXIMUM TRUCK LOWER CARRIAGE BAR LOWER RETAINER 3. Attach truck supply group (take-up) to clamp valve on attachment base. 4. Standing clear of the Clamp attachment cycle the attachment in and out several times. Use caution because partially filled hydraulic lines may cause erratic movement. GENERAL INSPECTION AND MAINTENANCE 1. Check all hydraulic fittings, hoses, cylinders and valves for leakages - repair or replace as required 2. Check bladder/water pressure. If out of operating range adjust as required using Loron Hand Pump #112909. Check clamp force and adjust. (See page 12.) 3. Time Schedule: Check pressure and clamp forces every 3 weeks. Water pressure = 4-6 psi Clamp Force = 1600lbs 4. All bolts should be checked and tightened as required. 5. Check lower retainer clearance - see item 2 in General Installation Procedures above. 1 CLAMP ASSEMBLY - 1 DRAWING REFERENCE 111420 # QTY PART # DESCRIPTION 12 2 111380 CYLINDER ROD WASHER 1 1 111421 FRAME 13 2 107870 LOWER RETAINER 2 2 111714.1 CYLINDER ASSEMBLY 14 1 111423 LOWER LOAD BACKREST 3 1 111439.1 LOAD BACKREST 15 2 11G.1028 BOLT LSP 4 4 111622.1 SLIDE - FLAT 16 12 111619 SLIDE BUTTON 5 8 111621.1 SLIDE - ANGLE 17 1 111222 CYLINDER GUARD 6 12 109212.4 SHIM 18 4 25G.0608 BOLT LSP 7 8 25G.0832 BOLT LSP 19 4 2F.06 WASHER LSP 8 8 4E.08 LOCKWASHER LSP 20 2 4E.10 LOCKWASHER LSP 9 4 111631 BEARING SPHERICAL 21 2 11G.08136 BOLT LSP 10 4 100029.301 ROD CENTERING SEAL 22 2 17D.08 NUT ESNA LSP 11 4 100574.86 COTTER PIN LSP 16 6 4 5 13 21 22 2 CLAMP ASSEMBLY - 2 DRAWING REFERENCE 111420 11 12 3 9 10 7 8 11 1 9 10 19 17 2 14 20 15 3 18 ARM GROUP ASSEMBLY DRAWING REFERENCE 111164.2 # QTY 1 PART # DESCRIPTION 1 111722 ARM WELDMENT RIGHT HAND 2 1 111724 ARM WELDMENT LEFT HAND 3 2 111209 CONTACT PAD (LOWER) 4 20 111031 RETAINING NUT 5 1 111216 TIP PLATE WELDMENT RIGHT HAND 6 1 111218 TIP PLATE WELDMENT LEFT HAND 7 20 1C.0820 BOLT LSP 8 10 1C.0812 BOLT LSP 9 30 108088 SPRING WASHER 10 2 112057 TIP PLATE UPPER 11 2 111210 CONTACT PACT (UPPER) 11 1 2 3 5 10 9 7 9 6 4 6 4 BLADDER HYDRAULIC ASSEMBLY - 1 DRAWING REFERENCE 111440.1 # QTY PART# DESCRIPTION 16 2 111290.0094 HOSE 1 3 111350 AIR TANK VALVE 17 2 111290.0166 HOSE 2 9 111295 HOSE CLAMP 18 2 111290.0114 HOSE 3 1 111290.0025 HOSE 19 24 9G.0412 BOLT 4 1 111296 PRESSURE GAUGE 20 12 111471 CLAMP BAR 5 1 111543.01 21 8 109256 HOSE CLAMP 6 1 111292 BRANCH TEE 22 8 25G.0508 BOLT 7 1 111290.0220 HOSE 23 2 113026.0360 COVER HOSE 8 1 111293 RUN TEE 24 4 111128 HOSE GUIDE 9 1 111290.0180 HOSE 25 12 25G.0512 BOLT 10 1 111290.0082 HOSE 26 1 111085 CLAMP FORCE CONTROL VALVE -REF- 11 1 111290.1170 HOSE 27 1 111289 PIPE ELBOW 12 1 111290.1115 HOSE 28 2 111510 SPRING 13 1 111299 HOSE CLIP 29 24 111878 19 GA. STAINLESS STEEL WIRE TIE 14 1 25G.0516 BOLT 30 2 112391 MODIFIED BLADDER 15 4 111030 BLADDER 0.06 5 BLADDER HYDRAULIC ASSEMBLY - 2 DRAWING REFERENCE 111440.1 2 6 1 2 27 26 3 9 4 13 14 7 8 2 28 11 2 8 12 10 6 5 BLADDER HYDRAULIC ASSEMBLY - 3 DRAWING REFERENCE 111440.1 2 1 30 16 23 19 20 21 22 29 SEE NOTE 25 24 17 15 18 NOTE: USE TWO 19 GAUGE STAINLESS STEEL WIRE TIES (111878) AT EACH BLADDER CONNECTION TWIST TO TIGHTEN AND CLIP TO REDUCE ENDS 7 HYDRAULIC ASSEMBLY - 1 DRAWING REFERENCE 111441 # QTY PART # DESCRIPTION 1 1 111193 CLAMP VALVE 2 2 25G.0524 BUTTON HEAD BOLT 3 7 100676.06 STRAIGHT THREAT ADAPTER FITTING 4 2 111518.06 FITTING ADAPTER 04 PIPE - 06 JIC STRAIGHT 5 1 111085 DIRECTIONAL VALVE ASSEMBLY 6 1 100227.05 FITTING UNION TEE 7 1 111123 IN-LINE CHECK VALVE 8 1 103441.0352 HOSE ASSEMBLY 9 1 100674.0290 HOSE ASSEMBLY 10 1 100678.05 O-RING TEE BRANCH FITTING #6 11 2 100440.05 12 1 100674.0340 HOSE ASSEMBLY 13 1 100674.0275 HOSE ASSEMBLY 14 4 100095.05 15 1 100674.0410 HOSE ASSEMBLY 16 1 100674.0200 HOSE ASSEMBLY 17 1 111514 VALVE GUARD 18 1 100222 19 1 25G.0520 BUTTON HEAD BOLT 20 1 4F.05 WASHER FLAT 21 1 17D.05 NUT NYLOCK 3 3 OPEN CLOSE RIGHT END VIEW 11 3 FLOW 14 SS1 SS2 LEFT END VIEW FLOW DETAIL 8 11 HYDRAULIC ASSEMBLY - 2 DRAWING REFERENCE 111441 17 19 20 21 SIDE SHIFT FORCE CONTROL 18 2 15 CLAMP OPEN / CLOSE SIDE SHIFT 8 3 14 12 13 10 FRONT VIEW 16 9 HYDRAULIC ASSEMBLY - 3 DRAWING REFERENCE 111441 CLAMP FORCE ADJUSTMENTS 5 MAXIMUM CLAMP FORCE RELIEF OPEN FORCE CONTROL 11 SEE LEFT END VIEW 4 7 4 6 9 BACK VIEW 10 SEE FLOW DETAIL CYLINDER ASSEMBLY DRAWING REFERENCE 111714.1 PART # 111714.1 R E S NET STROKE 35.08 66.16 31.08 31.08 # QTY PART # DESCRIPTION 1 1 111715.1 2 1 3 1 9 1 100028.2 BACK-UP RING LSP TUBE WELDMENT 10 1 100029.201 "O" RING LSP 111717.1 ROD 11 1 27D.10 NUT SELF LOCKING LSP 111482 SEAL KITS (NOT SHOWN) 12 1 100027.7 LOCKWIRE LSP 4 1 100032.6 POLY-PAK "B" LSP 13 1 111374 PISTON 5 1 102099.1 WEAR RING LSP 14 1 111373 GLAND 6 1 100031.7 POLY-PAK LSP 7 1 102098.5 ROD WIPER LSP 8 1 100029.2 "O" RING LSP REF. 15 1 111380 CYLINDER WASHER R = RETRACTED E = EXTENDED S =STROKE 15 CLEARANCE NOTE: .03/.06 EACH CYLINDER END ADJUST SLOTTED NUT TO ALLOW FOR CLEARANCE AS SHOWN. INSERT COTTER PIN AFTER ADJUSTMENT. 6 2 1 11 7 14 8 9 10 12 13 5 4 CYLINDER SERVICE Prior to assembly lubricate seals, cylinder bore and rod with STP. Inspect all parts for scratches, nicks and gouges- -replace all damaged components. Inspect cylinder bore and rod for scoring- -replace if scored Avoid damage to seal grooves- -use a dull screwdriver for seal removal Torque piston nut to 110 FT/LBS. (15.3 kg-m) 11 CLAMP ADJUSTMENTS CLAMP FORCE CHECK/ADJUSTMENT OPEN FORCE CHECK/ADJUSTMENT 1) Check water pressure. If out of operating range fill with Loron hand pump #112909. Note: when operating in below freezing temperatures us RV antifreeze in place of water. Open the arms against a force fixture and adjust for desired maximum force. 2) Check the clamp force centered on lower pad 1) Clamp on the heaviest load that will be handled 2) Adjust the side shift force down until the arms stop 3) Turn the adjusting screw one turn in. SIDE SHIFT FORCE ADJUSTMENT CLAMP FORCE CONTROL VALVE AIR BLEED FILL VALVE WATER PRESSURE GAUGE SIDE SHIFT FORCE CONTROL OPEN FORCE CONTROL AIR BLEED 12 CONTROL VALVE 111627 REDUCE/REL. VALVE TORQUE 15-20 FT/LBS SEAL KIT 112065 103813 FLOW DIVIDER TORQUE 10-12 FT/LBS 104711 SEAL KIT ORIFICE A I B D C F 111244 CHECK VALVE TORQUE 30-35 FT/LBS SEAL KIT 112059 E G H 112406.1 & 112406.2(G) RELIEF TORQUE 20-25 FT/LBS SEAL KIT 112064 HYDRAULIC SCHEMATIC C1 C3 C2 #6 #6 C4 #6 #6 #6 SS2 G D NOTE: 1. Lubricate threads & seals prior to assembly. C E #6 F I ORIF. QTY PART # DESCRIPTION 1 111627 PRESSURE REDUCE / RELIEF VALVE 1 103813 FLOW DIVIDER 1 112406.2 BI-DIRECTIONAL RELIEF VALVE 2 112406.1 RELIEF VALVE 3 111244 P.O. CHECK CARTRIDGES 850 PSI B H 1700 PSI A #6 CLOSE 13 #6 OPEN MM-12335 SS1 CLAMP FORCE CONTROL VALVE DRAWING REFERENCE 111085 # QTY PART # DESCRIPTION 9 1 1D.10 HEX NUT 1 1 11G.0844 BOLT 10 1 111328 WHEEL HOUSING 2 1 111573 MOUNTING PLATE WELDMENT 11 1 111097 SPRING 3 1 111094 DIRECTIONAL 12 1 111098 SPRING TENSION CAP 4 2 4E.04 LOCKWASHER 13 1 111572 SPRING CAP 5 1 7D.08 JAM NUT 14 1 111655 CLEVIS PIN 6 1 110906 WHEEL 15 1 100574.28 COTTER PIN 7 1 111091 AIR SPRING 8 2 1C.0424 BOLT 6 10 13 7 14 15 12 9 4 1 5 2 3 14 8 ARM SLIDE & SHIM REPLACEMENT 1. To replace the slides extend the arms to the fully open position. Release system pressure prior to removing the arms by turning the truck off and working the side shift and clamp function controls several times. 2. Support the arm with an overhead crane or lift truck. Be sure to secure the chain or sling in a manner that prevents the arm from falling out of the chain or sling when hanging free of the clamp frame. 3. Remove the cotter pin, slotted nut and spherical bearing from the end of the clamp cylinder rod. Keeping hands and feet clear, carefully slide the clamp arm off of the clamp frame. 4. Install the arm on the clamp frame ensuring that the arm moves freely without excessive binding. If the arm is too loose or too tight add or remove shims as required. Once the clearance is satisfactory insert the cylinder rod into the cylinder anchor on the arm. Install the spherical bearing, nut and cotter pin onto the cylinder rod end. Be sure to leave .03" - .06" (.7mm to 1.5mm) clearance to allow the cylinder to "float" on it's mountings (see page 11).Remove the cotter pin, slotted nut and spherical bearing from the end of the clamp cylinder rod. Keeping hands and feet clear, carefully slide the clamp arm off of the clamp frame. BLOCK: FOR L20 CLAMP MODELS 2" X 2" X 3" LONG (50.8mm X 50.8 mm X 76mm) FOR L35 CLAMP MODELS 2.25" X 2.25" X 3" LONG (57.2mm X 57.2mm X 76mm) ARM CLAMP FRAME ARM BAR 5. Inspect slides and slide buttons for wear. Slides may be rotated end-for-end and re-used if excessively worn on the outer end only. Extra shims may be used to tighten operating clearance on slightly worn slides. Replace any slides worn to less than .06" (1.5mm) thick or any slide that is deeply scored or broken. 6. To aid in replacing the slides a block may be fashioned of wood or another convenient material to the dimensions shown above. The block is inserted in the end of the arm to hold the slides, shims and buttons in position while the arm is inserted over the arm bars on the clamp frame. The block is expelled out the opposite end of the arm as the arm is pushed onto the frame. 7. Prior to installing the arm the block may be used to determine the number of shims to place under the slides. Adjust the clearance between the slides and the block to provide approximately .06" (1.5mm) running clearance between the slides and arm when installed. 15 TROUBLE SHOOTING GUIDE LOADS SLIPPING OR DROPPING POSSIBLE CAUSES SOLUTIONS 1. Clamp force set too low 1. Adjust clamp force page 12 2. Internal leakage in cylinder. 2. Replace cylinder seals. If tube, piston or rod is scored replace with new parts. 3. Load too heavy for the clamp capacity 3. Consult factory. 4. Load my not by stacked correctly or may need to be unitized 4. Restack or unitize load (shrink wrap) 5. Bent arms or contact pads 5. Consult factory. 6. Damaged / leaking hydraulic hose 6. Replace damaged hose CRUSHING LOADS POSSIBLE CAUSES SOLUTIONS 1. Clamp force set too high 1. Adjusting clamp force, page 12 2. Bent arms or contact pads 2. Consult factory 3. Leak in bladder system 3. Check for leaks and repair. ARM CHATTERING OR ERRATIC MOVEMENT POSSIBLE CAUSES SOLUTIONS 1. Bent clamp arms 1. Consult factory 2. Nylon slides sticking Note: Sticking slides can cause inconsistent clamp force measurements 2. Clean slides if necessary, the slides are self lubricating. 3. Nylon slides worn, broken or missing. 3. Replace damaged slides, shims and retaining buttons. 16