Download PH4000Ri/E Service Manual

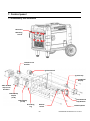

Transcript