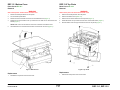

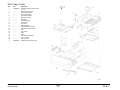

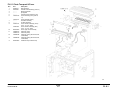

Download Xerox DocuPrint N2125 Network Laser Printer Service Manual

Transcript