Download VV600/VV602Plus Planning and Installation manual

Transcript

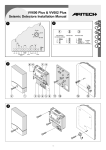

VV600/VV602Plus Vault Protection System Planning and Installation manual VV600Plus English version Revision 1A: September 2000 Aritech is a division of InterlogiX B.V. Copyright © InterlogiX B.V. 2000. All rights reserved. No part of this publication may be reproduced, transmitted, stored in a retrieval system, or transmitted in any form, or by any means – electronic, photocopying, recording, or otherwise – without the prior written permission of InterlogiX B.V.. InterlogiX B.V. reserve the right to change information without notice. CONTENTS 1. General information..................................................................................................................... 3 1.1. Application ........................................................................................................................... 3 1.2. Function............................................................................................................................... 4 1.3. Detecting and Testing.......................................................................................................... 4 1.3.1. The detection function.......................................................................................... 4 1.3.2. The testing system ............................................................................................... 5 1.4. Features of the System ....................................................................................................... 5 2. Basic Equipment of the VV600Plus System.............................................................................. 6 2.1. System components ............................................................................................................ 6 3. Functional description ................................................................................................................ 7 3.1. The VV600Plus standard seismic detector ......................................................................... 7 3.1.1. Sensor element .................................................................................................... 7 3.1.2. The integration channel........................................................................................ 7 3.1.3. The counting channel........................................................................................... 7 3.1.4. The explosion channel............................................................................................... 8 3.1.5. Power supply ............................................................................................................. 8 3.1.6. Sabotage protection .................................................................................................. 8 3.1.7. Alarm-output circuitry................................................................................................. 8 3.2. The VV602Plus ATM seismic detector................................................................................ 9 3.2.1. Sensor element .................................................................................................... 9 3.2.2. The low integrating channel ................................................................................. 9 3.2.3. The high integrating channel................................................................................ 9 3.2.4. The explosion channel ......................................................................................... 9 3.2.5. Power supply........................................................................................................ 9 3.2.6. Sabotage protection ............................................................................................. 9 3.2.7. Alarm output circuitry ........................................................................................... 9 4. Planning instructions ................................................................................................................ 10 4.1. Planning limitations............................................................................................................ 10 4.1.1. Electric motors, transformers, fans, air conditioners.......................................... 10 4.1.2. Water piping....................................................................................................... 10 4.1.3. Ultrasound detectors .......................................................................................... 10 4.1.4. Bells ................................................................................................................... 10 4.1.5. Human activity.................................................................................................... 10 4.2. Detection range of the VV600/602Plus ............................................................................. 10 4.2.1. The vault or safe sensitivity test ......................................................................... 11 4.3. Planning a vault protection ................................................................................................ 12 4.4. Planning safe, document cabinet and filing cabinet protection ...................................... 13 4.4.1. Detectors mounted inside the safe .................................................................... 13 4.4.2. Detectors mounted on the outside of the safe ................................................... 13 4.4.3. Filing cabinets .................................................................................................... 14 4.5. Planning the protection of an automatic teller machine (ATM) and a night deposit box 14 4.5.1. Automatic teller machine.................................................................................... 14 4.5.2. Night safe deposit box........................................................................................ 15 4.6. Planning guide-lines .......................................................................................................... 15 5. Installation.................................................................................................................................. 16 5.1. General instructions for system components .................................................................... 16 5.2. Mounting directly onto a steel surface ............................................................................... 16 5.3. Mounting on steel and concrete using a mounting plate ................................................ 17 5.4. The mounting plate VM600P ............................................................................................. 17 5.4.1. Mounting on concrete......................................................................................... 18 5.4.2. Mounting plate for welding VM604P .................................................................. 19 5.5. Mounting of accessories.................................................................................................... 20 Planning and Installation manual VV600/VV602Plus 1 5.5.1. 5.5.2. 5.5.3. 5.5.4. 5.5.5. 5.5.6. Recess mounting box VM602P and VM610P.................................................... 20 The VM603P weather protection box................................................................. 21 The movable mounting plate kit VM651P .......................................................... 22 The VM652P key-hole protection kit .................................................................. 23 The VM654P armoured cable kit ....................................................................... 23 The junction box VM655P .................................................................................. 24 6. Connecting the detector ........................................................................................................... 25 6.1. Cable requirements ........................................................................................................... 25 6.2. Wiring the detector into the system ................................................................................... 25 6.3. Control and function test.................................................................................................... 26 6.4. Trouble shooting................................................................................................................ 28 7. The Testsystem.......................................................................................................................... 29 7.1. VT705P.............................................................................................................................. 29 7.2. Wiring and commissioning ................................................................................................ 29 2 Planning and Installation manual VV600/VV602Plus 1. GENERAL INFORMATION 1.1. Application The Aritech VV600Plus Vault Protection System is a seismic system designed to detect attempts to break into vaults, safes, night deposit safes, automatic teller machines and other enforced physical areas. The detection technology used will react within seconds to all breaking and entering tools such as drill hammers, side grinders, acetylene cutters termic lances etc. At the same time it allows for free movement around the protected area without the risk of creating false alarms. The Aritech VV600Plus system has been field proven to be a very effective and reliable solution for safe, vault and atuomatic teller machines protection. It provides protection with the highest security level possible. A complete range of accessories makes it application efficient and easy to use. Of the many applications possible, we mention: • Banks and post offices: Vaults, safes, coin cabinets, automatic teller machines and night safe deposit boxes. • Military defence: Safes, filing cabinets, weapon stores, early warning systems on gates and other physical barriers. • Government buildings: Archives, safes, document safes and computer data storage areas. • Industry: Safes, filing cabinets and other storage areas. • Pharmacies and hospitals: Drug cabinets, vaults and safes and instrument stores. • Computer rooms: Tape and disk cabinets, safes. • Jewellers shops: Vaults, safes and show-cases. • Museums: Safes, vaults and store rooms. • Galleries: Show-cases. • Private homes: Safes. Planning and Installation manual VV600/VV602Plus 3 1.2. Function The detection principle is based on the structural vibrations generated in walls, floors, ceilings and doors upon an attempt to break through such physical barriers. The Aritech VV600Plus System features a high level of discrimination between real attacks and normal background noise generated by human activities, effectively reducing the level of unwanted alarms to almost zero. To achieve this, three important parameters are analysed before an alarm is triggered: • signal strength (amplitude) • signal frequency • signal duration These parameters are very different between real attacks and "normal" background vibrations. In general, one may describe the signal characteristics of a true break-in attempt as per below: Explosive means generate a signal with a very high amplitude and a short duration. Mechanical destruction generates signals with a moderate to high amplitude and a long signal duration. Rotating devices generate signals with a moderate to high amplitude and a long signal duration. Thermal devices generate signals with low amplitude and a long signal duration. In the "Functional description", therefore, you will find that different analysing channels deal with different types of signals in the Aritech VV600Plus System. The application of surface mount technology in the actual sensor device itself, has enabled the incorporation of complex circuits in a small housing, thus providing unobtrusive, aesthetically pleasing detectors without operational trade-offs. 1.3. Detecting and Testing The Aritech VV600Plus System consists of two main system functions which in close co-operation guarantee an extremely high security level: • the detecting function • the testing function 1.3.1. The detection function The core of the Aritech VV600Plus System is the vibration detectors VV600Plus and VV602Plus. Each VV600/602Plus seismic detector is a fully equipped vibration detector. This means that all necessary processing electronics is incorporated within each VV600/602Plus unit. Each such unit is ready to co-operate with almost any control panel presently available. No intermediate signal processing is necessary, no vulnerable slave microphones are used. The VV600Plus utilises the most advanced microelectronic processing circuits to reduce the risk of false alarms while maintaining the highest detection level. The unique counting channel that is featured on the VV600Plus allow higher sensitivity settings on safe and document cabinets without generating nuisance alarms from ambient noise. It will also detect attacks with hammers, sledgehammers, crowbars and hydraulic jacks at a very early stage.The VV602Plus model is used to protect night deposit safes and automatic teller machines (ATM’s). The counting channel has been omitted in 4 Planning and Installation manual VV600/VV602Plus the VV602Plus and replaced by two integrating channels, to cope with the knocking sound of the cassettes being deposited in the night deposit safe and the pay out procedure in ATM’s, which may otherwise generate nuisance alarms. This adapted signal processing does however not affect the detection efficiency. A full range of mounting accessories for different applications facilitates a wide range of mounting requirements. 1.3.2. The testing system In order to provide the highest level of security, a daily test of the function of all VV600Plus and VV602Plus detectors in a system is required. Therefore, the Aritech VV600Plus System features a full functional test system that may be operated in parallel with the detection system itself. When activated, the test system will test the following important functions the detection system: • Proper acoustical connection between VV600/602Plus seismic detectors and the protected surface. • Proper signal processing capability of circuits inside the VV600/602Plus seismic detectors. • Proper functioning of alarm-output circuitry of the VV600/602Plus seismic detectors. The actual tester is designated VT705P and is mounted inside the detector cover. The tester only consists of a signal generator. The electronics to generate the test signal is incorporated in the detector. This gives a very simple and cost efficient test transmitter that is very easy to install. 1.4. Features of the System • Will detect all known methods of attack against vaults, safes ATM’s etc. • Compact and unobtrusive design using advanced microelectronics. • Compatible with virtually all control units. • Each seismic detector has full processing capability. • Sensitivity adjustment available over a wide range. • Unique advanced signal processing differentiates between ambient noise and real attacks. • Unique test system using a self contained test transmitter in each detector. • Three analysing channels. • Counting circuit effectively suppress false alarms but maintaining best detection capability. • Full tamper protection. • Wide operating temperature range facilitates application in severe environments. • Approved by VdS and many other approval bodies • Calibrated and easily adjustable sensitivity setting to adapt to various applications. • The detectors intergration level can be measured with a Voltmeter on connection no. 4. • Full range of accessories enables a wide range of applications to suit any requirements. Planning and Installation manual VV600/VV602Plus 5 2. BASIC EQUIPMENT OF THE VV600PLUS SYSTEM 2.1. System components VV600Plus Safe and vault vibration detector VV602Plus Detector for protection of ATM’s and Night Safe Deposit Boxes VM610P Floor mounting box VM603P Damp resistant mounting box VM654P 8 conductor armed cable kit VM655P Tamper resistant metal junction box VM600P Mounting plate VM651P Moveable mounting kit VT705P Remote test transmitter VM604P Steel plate for tack welding VT610P Hand held test unit VM652P Keyhole protection kit VM602P Recess mounting box VT611P Safe application test sensor VM653P Spacer for keyhole kit 6 Planning and Installation manual VV600/VV602Plus 3. FUNCTIONAL DESCRIPTION 3.1. The VV600Plus standard seismic detector The VV600Plus is a fully equipped seismic detector, compatible with almost any commercially available security control panel, without the need of any additional processing circuitry. FUNCTIONAL DESCRIPTION OF THE VV600PLUS Test Internal VVT Test oscillator Integrating channel Accelero meter Counting channel Alarm output Sabotage protection Explosion channel Signalconditioning Sensitivity Power supply 11 Spare 10 Test 9 Sabotage 8 Sabotage 7 Spare 6 Alarmrelay 5 Alarmrelay 4 Testpoint 3 Alarm LED 2 - 1 9-15 VDC + 3.1.1. Sensor element The VV600Plus is sensing the structural vibrations caused by an attack against the protected surface. A piezo-electric sensor converts the seismic signal into an electric signal. This signal is then analysed in three independent signal processing channels. 3.1.2. The integration channel The integrating channel is designed to recognise low to medium amplitude signals with long duration, like those caused by electric power tools or termic tools like a burning bar or acetylene torch. The signal is first amplified in a preamplifier and filtered in a band pass filter only allowing relevant frequencies to pass. After processing, the signal is fed into an integrator which stores the incoming signals. When a pre-set level is reached, the level detector triggers the alarm. The sensitivity of this channel is set by adjusting the pre-amplification level. 3.1.3. The counting channel The counting channel is designed to detect attacks with mechanical means like hydraulic jack and hammer and chisel. It avoids having to set the integrating channel to high sensitivity and long integrator discharge times to cope with intermittent, short duration mechanical attacks. The incoming signal is amplified and pulse formed for a pre-set time to avoid counting multiple bounces. At the first incoming pulse, the counter counts 1 and starts the timer. If a second pulse is detected within 180 seconds the counter counts 2 and restarts the timer to look for a third pulse. If a second pulse is not detected within 180 seconds the counter will be reset. Five consecutive counts trigger the alarm. The sensitivity of this channel is pre-set and is not affected by the sensitivity setting of the integration channel. Planning and Installation manual VV600/VV602Plus 7 3.1.4. The explosion channel The explosion channel is set to detect very high amplitude and short duration signals as caused by explosives. An alarm will immediately be triggered by the level detector when the pre-set amplitude is detected. The sensitivity is pre-set and is not affected by the sensitivity setting of the integration channel. 3.1.5. Power supply The supply voltage is first filtered and regulated thus providing insensitivity to electrical interference. The internal voltage requirement is 6 V thus allowing the detector to operate in a broad voltage range. The power supply features extremely good protection against high energy electrical surges. The transient absorbers and the general design of the detector also give a very good protection against RFI, for example from GSM cellphones. 3.1.6. Sabotage protection Of course, the VV600Plus seismic detector is equipped with comprehensive antitamper provisions, a tamper alarm is given when an attempt is made to: • Pry the unit off the wall • Burn or weld the unit • Lower the supply voltage below 7,5 V • Open the unit The detector is equipped with a solid state relay and consequently no protection against outside magnetic fields is necessary. 3.1.7. Alarm-output circuitry The circuitry may be activated by all three detection channels. The alarm output provides two forms of alarm signals: • One potential free normally closed contact, opening in alarm. • One open collector transistor output, going out of conductive mode upon alarm condition. The transistor is being protected against short circuit with a series resistor. 8 Planning and Installation manual VV600/VV602Plus 3.2. The VV602Plus ATM seismic detector The Aritech VV602Plus detector is a seismic detector capable of detecting vibrations from an attack on an automatic teller machine (ATM) or night safe deposit box to which it is attached, but still disregarding the vibrations created by the normal operation of the protected object. FUNCTIONAL DESCRIPTION OF THE VV602PLUS Test Internal VVT Test oscillator Low level integrating channel Accelerometer High level integrating channel Alarm output Sabotage protection Explosion channel 11 S 10 Te 9 S 8 S 7 S 6 A 5 A 4 Te 3 A 2 - Signal conditioning Sensitivity Power supply 91 + 3.2.1. Sensor element As in VV600Plus. 3.2.2. The low integrating channel The low integrating channel looks at the low amplitude, long duration signals. This integrating channel is inhibited until the signal amplitude reaches a certain pre-set level. Upon reaching this amplitude level, the signal is further processed and integrated. At the same time a timer is started. As long as the signal is constantly available the timer will run, upon an interruption of the signal, the timer will reset the channel to inhibited state after a pre-set time. 3.2.3. The high integrating channel To prevent signals from the night-safe or the ATM from disturbing the VV602Plus, upon the first appearance of high amplitude signals, these signals are treated as if coming from the protected unit itself and are inhibited from reaching the integrator. At the same time a timer is started. After a short period of time the high integration channel timer runs out and if the signal still is present, the signal is released for integration. 3.2.4. The explosion channel As in VV600Plus. 3.2.5. Power supply As in VV600Plus. 3.2.6. Sabotage protection As in VV600Plus. 3.2.7. Alarm output circuitry As in VV600Plus. Planning and Installation manual VV600/VV602Plus 9 4. PLANNING INSTRUCTIONS 4.1. Planning limitations Although the Aritech seismic detectors are designed to provide a high level of immunity against nuisance alarm sources, some precautions have to be observed. Below we would like to mention some circumstances to preferably avoid: 4.1.1. Electric motors, transformers, fans, air conditioners. Do not apply the detectors in close proximity of electrical devices creating mechanical vibrations in the protected structure. If possible avoid mechanical contact between such devices and the protected surface, or reduce the vibrations by using suitable insulating materials. 4.1.2. Water piping The flow of water through piping, when in mechanical contact with the protected structure, emits a strong signal in the structure itself, which may cause nuisance alarms. 4.1.3. Ultrasound detectors May emit a signal that is within the frequency range of the detectors. It is advisable to avoid placing ultrasound detectors closer than two meters from the protected surface. It is useful to remember, in this respect, that it is not normally the detector itself picking up the ultrasound signals, but mainly metal objects attached to the protected surface (vault door, steel cabinets, etc.). 4.1.4. Bells May generate overtones in the frequency range of the detectors. A simple solution is to suppress the overtones through application of a piece of tape on the bell. 4.1.5. Human activity Normally, people in close proximity to the protected area are not a problem. It is impossible, however, to always predict their activities. It is therefore advisable to keep a look-out for: floors running over the vault’s ceiling, stair-ways adjacent to vaults and safes on concrete or marble floors. In most cases, carpeting or the application of insulation materials will solve any problems that may occur. 4.2. Detection range of the VV600/602Plus The range of each installation depends on: • The construction of the vault or safe. • The vibration characteristics of the construction. • The sensitivity required in each sensor. • The natural vibrations and ambient noise level in the premises. To determine these factors, it is best to perform a field test. The field test should include the following: • Visual inspection of the vault or safe. • A test to determine the existence of irregularities in the construction. • A noise test. • A plan to define the location of each sensor. As a guide-line we have made a table showing the range as a function of the methods of attack and type of material in the construction of the protected surface. 10 Planning and Installation manual VV600/VV602Plus DETECTION RANGE IN METERS OF THE VV600PLUS & VV602PLUS Material Sensitivity setting Concrete K-35 Steel Brick Concrete K-35 Steel Brick Concrete K-35 Steel Brick Concrete K-35 Steel Brick Concrete K-35 Steel Brick - Termic lance 1 / Gmax 2 / Gref. 3 / Gmin 4 5 4 8 3 3 4 1 2 2 1 1 - Method of attack Diamond Drilling disk 14 14 8 9 9 6 6 6 4 5 5 3 4 4 2 14 14 8 9 9 6 6 6 4 5 5 3 4 4 2 The exact detection range can only be determined by practical tests on site. This table is only to be regarded as a guide line and gives the detection radius in meters as a function of material, attack method and selected sensitivity. Please note that cracks and joints in the material may reduce the range. Corners in the structure will reduce the range by approx. 25%. The above mentioned detection ranges for concrete are applicable on vaults and strong rooms cast according to most national norms for such structures. 4.2.1. The vault or safe sensitivity test Where the surface of the vault or safe shows cracks, gaps, or has other irregularities, perform a test to determine if the protection range of each sensor will be affected. Additional detectors may be needed for full coverage. For concrete, block and brick construction, perform the following test, using an electric drill and a 6 mm carbide tipped drill bit. For test on steel the test equipment VT610P and VT611P should be used. 1. Locate any irregularity in the construction. The mortar between bricks and blocks should be considered as irregularities. 2. Install a detector at one side of the suspected irregularity. 3. Wire the detector to power and alarm circuit. 4. Set sensitivity to Gmax. 5. Drill into the wall at a point equal to the protection radius (R) depending on the construction type as described in visual inspection section. Check for an alarm. 6. If an alarm does not occur, assume that the irregularity limits the protection range of the detector. Drill again closer to the sensor until an alarm occurs and identify where it happens. 7. Take all irregularities into account when spacing detectors. Additional detectors may be required. - The separation between vault door and the frame will require an additional detector on the door to encounter a possible attenuation at this point. Planning and Installation manual VV600/VV602Plus 11 4.3. Planning a vault protection As a general rule it is recommended to have one detector on each wall, floor, and ceiling inside the vault and one detector on, or inside the vault door. The detectors should be recess mounted with VM602P or surface mounted with the VM600P on the walls. We recommend to mount them at least about 1,80m high to keep clear from safes, document cabinets, and customer deposit boxes. The range is reduced at joints between walls and floor and/or ceiling if the reinforcement bars are not connected. Joints, severe cracking or doors should be regarded as insulating and additional detectors shall be applied on both sides of this irregularity. As the vault door is regarded to be isolated from the walls by its hinges, it is recommended to have one detector on or preferably inside the vault door. New vault doors normally have cable channels inside the hinges to provide easy connection of the detector to the alarm system. The detector can also be mounted on the outside of the vault door. This gives a very efficient protection against torch-cutting and a thermic lance as the vault door acts like a membrane and picks up the signal even before the attack on the surface has started. The detector could be surface mounted either fixed directly on the surface or with the VM600P or VM604P mounting plates or it may be mounted on the movable plate VM651P. Be careful when you drill into the vault door, so that you don’t damage the mechanical protection of the door. If you are installing the detectors in an existing vault you can protect the walls on either side of the door with a detector mounted on the door frame. Layout plan It is recommended to prepare a plan to define the location of each sensor and other components of the system. A fold out plan will help in doing this. 12 Planning and Installation manual VV600/VV602Plus 4.4. Planning safe, document cabinet and filing cabinet protection Most of the attacks against safes are aimed at the door and the locking mechanism. It is, therefore, advisable to mount a detector on the door where the lock is situated. The hinges my attenuate the signal transmission from the body to the door. We therefore recommend to use one detector on the body of the safe as well. 4.4.1. Detectors mounted inside the safe Mount the first detector on a suitable space on the body of the safe, normally this is at the front top side of the safe. Mount the second detector on the inside of the door, close to the hinges. Use flexible cable kit VM654P together with the junction box VM655P. Also add a magnetic contact on the door. Cable outlet facilities are normally provided in new safes. If not, we recommend mounting the detectors on the outside. 4.4.2. Detectors mounted on the outside of the safe We recommend a two detector layout, with one detector on the side of the safe, close to the hinges. If you use the junction box VM655P and the steel cable kit VM654P you will have a safe and reliable installation. The second detector can be mounted on the door in three different ways as illustrated: • Mounted fixed, close to the hinge providing a short distance to the junction box with the cable kit VM654P. • Mounted on the key-hole protection plate VM652P close to the lock, see 5.5.4. • With the movable mounting kit VM651P, mount the detector in such way that the cable prevents opening the door when the detector is on the night position plate, see 5.5.3. Although the detectors are better protected when mounted on the inside, detectors mounted on the outside will have a deterring effect. The VM651P and VM652P have the advantage of forcing the staff to handle the alarm installation properly. It prevents the staff forgetting to remove keys or properly closing the safe doors. Planning and Installation manual VV600/VV602Plus 13 4.4.3. Filing cabinets Normally the lock is placed on one side of the upper drawer on the front. We therefore recommend to use one detector placed on the side of the cabinet close to the lock. If special high security on one drawer is required we recommend to use the movable mounting kit VM651P on that drawer. Mount the night position plate on the drawer and the day position plate on the side together with the junction box VM655P. Use cable kit VM654P. 4.5. Planning the protection of an automatic teller machine (ATM) and a night deposit box For both units we recommend the use of VV602Plus which is specially adapted to handle the noise created when the units are in operation. We recommend to have one unit on the safe body and one unit on the door. - If you want to mount a detector on a light weight safe we do recommend you to contact Aritech for further information. The VV602Plus can be mounted directly on the surface, with the movable mounting kit VM651P, or the key-hole protection kit VM652P. In any case we would recommend using the junction box VM655P and cable kit VM654P. 4.5.1. Automatic teller machine Normally the best points for detectors are the door and as close to the dispenser opening as possible, as these are the most likely points of attack. See illustration. detectors 14 Planning and Installation manual VV600/VV602Plus 4.5.2. Night safe deposit box Protection is planned exactly as a safe. Attenuate the chute and the landing place with rubber insulating material to reduce the noise created by the falling cash boxes when deposited. detectors rubber pad 4.6. Planning guide-lines Do’s: Do prepare a vault layout plan showing vault dimensions and locations of all equipment to be installed. Do check that vault is constructed of monolithic concrete or concrete with steel liner, or where constructed of concrete block or brick, masonry must be bonded with Portland cement. Do check that sensors are mounted directly to masonry or steel surface and that approved mounting hardware is used. Do install at least one sensor on each wall as well as on the floor and ceiling. Do protect vault door with sensor mounted as close as possible to side of door, embedding it in door frame. Do perform drill tests, whenever possible, on the outside of the vault. Do apply silicone sealant around all openings of sensor (cover, screw heads, and cable port) after surface-mounting sensor on floor. Dont’s: Don’t assume that covered concrete walls are free of cracks, loose mortar or other irregularities. Don’t install sensors permanently before determining sensitivity settings and ambient noise level. Don’t install sensor on cinder block or other unproved masonry surface without contacting Aritech. Don’t mount sensor on rough surfaces, sand all surfaces. Don’t allow test signal transmitter to make contact with mounting plate or sensor on mansonry installaiton. Planning and Installation manual VV600/VV602Plus 15 5. INSTALLATION 5.1. General instructions for system components The VV600Plus and VV602Plus seismic detectors have cast zinc housing, with the outside dimensions of 101 x 81 x 28 mm, and a weight of 380 g. By removing the screw holding the cover to the chassi gives access to: • Mounting holes • Terminal • Sensitivity setting • Mounting space for testtransmitter VT705P • Tamper switch 5.2. Mounting directly onto a steel surface In most cases it is advisable to mount the detector directly onto a steel surface using the bolts provided and threaded holes which you will have to make. For mounting the following tools are recommended: 16 • Mounting plate VM600P used as drill template. • Electric drill hammer. • Felt pen. • High speed steel drill, diam. 3.3 mm (for M4 tap). • High speed steel drill, diam. 4.2 mm (for M5 tap). • High speed steel drill, diam. 10 mm. • Tap M4 (to mount VV600Plus on steel surface). • Oil to cool drill and tap. Planning and Installation manual VV600/VV602Plus 1. Define the exact location of the VV600Plus.Using the felt pen, mark the location of the 3 threaded mounting holes. Use the mounting plate VM600P as a template and use a centre punch for exact location of the drill holes. 2. Drill three holes, using a 3.3 mm diam. drill, as deep as the steel surface will allow. 3. Thread the holes with a M4 tap. 4. Remove burrs with a 10 mm drill bit. 5. Mount the detector to the steel surface using the three M4 screws supplied. 6. If a VT705P test transmitter is used, it can be mounted in the detector’s righthand bottom corner, see illustration on previous page. 5.3. Mounting on steel and concrete using a mounting plate In the following cases you should use the VM600P or VM604P mounting plates: • Always use the VM600P mounting plate for surface mounting on concrete. • Use the VM604P welding mounting plate when drilling in the protected steel surface is impractical or impossible. • Use the VM600P mounting plate when replacing Securitas SSD70/SSD 2000/SSD 4000 or Cerberus GM 31/35/36/550/560 5.4. The mounting plate VM600P A B C D E F G = = = = = = = Mounting holes for VV600Plus & VV602Plus Mounting holes for Securitas SSD70. Mounting holes for Cerberus GM 31,35, 550, 560 Mounting hole for expansion plug or recess mounting box. Mounting holes for Securitas 2000. Mounting hole for expansion plug to the test transmitter, VT705P. Mounting holes for accessories Planning and Installation manual VV600/VV602Plus 17 5.4.1. Mounting on concrete In order to surface mount the VV600/602Plus on concrete, a VM600P mounting plate is always required. Please follow the instructions below carefully. 1. Define the exact location of the VV600Plus and hold the VM600P mounting plate to the wall. 2. Mark the location of the hole for the expansion plug on the wall. 3. Drill a hole using a 9 mm drill. The hole shall be at least 60 mm deep, but if the surface finish is thicker than 10 mm, drill deeper, making sure at least 50 mm of the expansion plug is in the concrete itself. You will need to use a longer bolt in this case. 4. Introduce the expansion plug into the hole you have just drilled and make sure that the top end of the plug does not stick out of the wall. Note that only the supplied metal expander should be used. If no test transmitter is used, go to no. 9. 5. Rotate the mounting plate 180o, drill a marker hole in the concrete through the hole F (6,5 mm), see ill. A, in the lower right hand corner. Rotate the mounting plate back 180o and tighten the bolt, see ill. B. 6. Drill a hole using a 9 mm drill on the spot you marked before. See point 2 above. 7. Introduce the expansion plug into the hole you have just drilled and make sure that the top end of the plug does not stick out of the wall. Fix the VT705P test transmitter with the bolt provided with the plug. 8. Tighten the VT705P bolt. Make sure that the VT705P does not touch the VM600P mounting plate. 9. 18 It is recommended that all bolts are tightened at the first service after installation, to compensate for inevitable material expansion in both wall and plug. After completion of the mounting of the VM600P, install the VV600Plus detector with the three supplied M4 screws. Planning and Installation manual VV600/VV602Plus 5.4.2. Mounting plate for welding VM604P 1. Remove paint or other surface finish from the area where the VM604P will be mounted. 2. Fix the mounting plate into position on the surface and ensure that it can’t move during the welding process. 3. Weld the VM604P mounting plate to the surface. First weld the points 1,2,3,4 then weld the seams 5 and 6 on the inside of the two slots, see illustration. 4. Mount the VV600/602Plus detector to the VM604P mounting plate, using the three M4 screws supplied. Planning and Installation manual VV600/VV602Plus 19 5.5. Mounting of accessories 5.5.1. Recess mounting box VM602P and VM610P For recess mounting of the VV600Plus in concrete, the VM602P/610P recess mounting boxes are available. Not only will this accessory give a nice and tidy installation but it also ensures a better coverage of the detector as it is anchored in the reinforcement bars of the concrete. For the best results, please follow the instructions below: 1. Select the exact location where the VV600Plus units shall be mounted and make arrangements with the construction company to be on the construction site when the concrete casting shutters are being put up. Do not forget floors and ceilings ! 2. On the pre-defined locations, drill two 7 mm holes in the panel and mount the VM602P recess mounting box to the panel using the two M5 threaded pins enclosed with the VM602P. 3. Fasten the bracket in the tapered hole on the back of the mounting box. 4. Weld the bracket to the reinforcement bars in the wall. 5. After completion of the mounting of the VM602P to the wooden concrete shutter, introduce the conduits into the holes on the sides of the mounting box. Seal the holes around the conduit, to prevent concrete from running into the mounting box. Attaching the conduit to the reinforcement rods will prevent them from falling out during the casting process. 6. Save the cover plate. 7. When the casting is completed mount the VV600Plus detector on the VM600P mounting plate supplied with the VM602P. 8. After completion of the installation and a successful test, mount the cover plate with the enclosed screws. 20 Planning and Installation manual VV600/VV602Plus The VM610P, floor mounting box is mounted in the same way as the VM602P. 5.5.2. The VM603P weather protection box To protect the sensor from vandalism or high humidity, use a VM603P protection box. In an environment with high humidity and large variations in temperature it is recommended to mount a heat resistor (a few Watt is sufficient, 12 VAC/ 100 Ohm/2 W gives approx. 1,5 W) in the mounting box and drill a small drain hole in the lowest point of the box. This will give a far better result then trying to seal the box with silicone, which will only result in condensation problems. Planning and Installation manual VV600/VV602Plus 21 5.5.3. The movable mounting plate kit VM651P The VM651P movable mounting kit is designed to enable movable (day/ night) mounting of VV600Plus and VV602Plus on vault and safe doors. 22 1. The night position plate shall be mounted close to the keyhole or the code wheel on the door (the night position plate has a little tap in the right-hand corner). The best way to connect the VM651P is in series with the alarm relay of the detector. This way the system can only be armed when the detector is in the night position. 2. Mark the three mounting holes. Drill/tap holes for the three M4 bolts as described in chapter 5.2. Make sure the holes you drill in the door does not damage the locking mechanism. 3. Mount the night position plate using M4 bolts. 4. Mount the junction box and day position plate together on the side of the safe or on the wall close to the detector in such a way that the cable prevents opening the door. 5. On metal surface mount exactly as the night position plate. On other surfaces than steel suitable screws and expanders have to be selected by the installer. 6. Mount the VV600/602Plus detector on the base plate of the VM651P kit with the three screws supplied. Planning and Installation manual VV600/VV602Plus 5.5.4. The VM652P key-hole protection kit The key hole protection mounting plate VM652P has a stainless steel lever which in night position will cover the key hole and thereby stop the intruder from inserting explosives in the key hole. At the same time the detector protects the safe or vault door from other kinds of attack. The lock/release button must always face up (1).VM652P can be mounted with the lever facing any direction (2). 1. Select a location for the VM652P on the vault/safe door. 2. Mounting holes A are used for the VM652P. 3. Drill/tap mounting holes as described in chapter 5.2. 4. Mount the VV600/602Plus detector on the VM652P cover plate and wire the detector according to the desired system configuration. 5. The micro-switch inside the VM652P should preferably be wired into the detector’s alarm loop to inhibit arming the alarm system if the keyhole protection lever is not in the protected position. 6. The location of the lever can be changed if necessary. To open the mounting plate and re-position the lever, the centre screw (B in the illustration) has to be removed. 5.5.5. The VM654P armoured cable kit The armoured cable kit is designed to be used as a protective transfer from the door of a safe or vault to the body or wall. Preferably it should be used together with the junction box VM655P. The VM654P includes the following items: • 8 core cable, white • Flexible stainless steel conduit • Protective ferrules • Cable straps • Plastic insert for double conduit The protective ferrules are used on the two ends of the steel conduit to protect the cable from the sharp edges. The cable straps are used to secure the conduit in the VV600Plus or VV602Plus. Planning and Installation manual VV600/VV602Plus 23 5.5.6. The junction box VM655P The VM655P is a well protected junction box. It has a steel insert in the lid to protect it from drilling and a tamper contact to protect it from being opened. The junction box has two terminal blocks with a total of 26 terminal, two of which are used for the tamper switch and one for the screen to the base. There is a plastic strap for strain relief for the cable and flexible conduit. 24 Planning and Installation manual VV600/VV602Plus 6. CONNECTING THE DETECTOR 6.1. Cable requirements The wiring of VV600Plus detectors requires the following cable layout: Number of Leads Features Power Alarm Tamper Test LED Test in System common 2 2 2 1 1 Per detector 1 6.2. Wiring the detector into the system Bring the cable(s) to the detector, feed them through the cable inlet, cut them, leaving approximately 10 cm of cable after the strain relief. Remove the wire insulation with about 1 cm. Wire the terminals according to wiring diagram below. (Illustration A: Form-A relay. and illustration B: Form-C relay) A Planning and Installation manual VV600/VV602Plus B 25 6.3. Control and function test • Check the proper mounting of the detector, the VT705P and the cabling around them • Check the proper wiring of the system, preferably against a wiring diagram. • Apply power to the detector. • Perform the following tests: 1. Press the front of the VT610P, hand tester against the protected surface at the fringe of the expected coverage area. Press the button. A buzzing sound will be heard. The generated frequency is similar to the frequency of a termic lance attack. The VV600Plus should give an alarm within 30 seconds and the VV602Plus within 45 seconds. 1 2 2. 26 Knock firmly with a hammer around the detector with two-second intervals between blows. After five blows, the VV600Plus shall alarm. To protect the surface from damage it is advised to use a small aluminium plate between hammer and surface. This test simulates the attack with hammer and chisel and is only valid for VV600Plus. Planning and Installation manual VV600/VV602Plus Give one powerful blow near the detector with a hammer. Both VV600Plus and VV602Plus should give an alarm immediately. This test simulates an attack with explosives. Check up the background signal level in the detector to prevent nuisance alarm. Connect a DC volt-meter, internal resistance 20 KOhm/V or more, to terminal 2 (negative) and terminal 4 (positive). Place the volt-meter in the range around 3 V. Put the sensitivity selector in the maximum sensitivity Gmax. Make sure that all possible causes for vibrations in the protected area are present and operating. Check the output voltage and take measures accordingly. For VV600Plus For VV602Plus Measure 0.7 V 0V None 1.4 V 2V Reduce range/remove source 2.5 V 3.5 V Alarm, reduce range/ remove source Preferably, you should try to remove the source of ambient noise instead of reducing the range. - Do not forget to set the detector’s sensibility at the right value. Close the lid of the detector and check for closed-loop condition of the tamper-loop. Perform a functional test of both alarm and tamper signals according to panel specifications. Planning and Installation manual VV600/VV602Plus 27 6.4. Trouble shooting 28 Planning and Installation manual VV600/VV602Plus 7. THE TESTSYSTEM 7.1. VT705P The VT705P is a testsystem consisting of a testgenerator inside the VV600/602Plus and a crystal unit which is mounted on the protected object, inside the detector housing. There are two possiblitities for testing: 1. Test disabled (ex-factory setting). 2. Internal test of the detector’s electronics = Position jumper between connection 1 and 2. 3. Function test of the detector and its physical contact with the protected object = Position connector from test transmitter VT705P between connection 2 and 3. 7.2. Wiring and commissioning The VT705P shall be mounted inside the detector, see illustration under 5.4.1. The VT705P is connected over a 2 Pole plug to the detector. Planning and Installation manual VV600/VV602Plus 29 4466-1A