Download TECHNICAL DATA & SERVICE MANUAL

Transcript

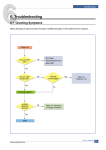

® TECHNICAL DATA & SERVICE MANUAL 0.8180.367.0 05/2004 Page 3 3 4 1. SPECIFICATIONS 1-1 Unit Specifications 1-2 Major Component Specifications 6 6 2. DIMENSIONAL DATA 2-1 Unit Dimensions 7 7 3. ELECTRICAL DATA 3-1 Electric Wiring Diagram 8 8 4. REFRIGERANT FLOW DATA 4-1 Refrigerant Flow Diagram 5. FUNCTION 5-1 Room Temperature Control 5-2 Heat Exchanger Frosting Prevention 5-3 Dry Operation (Dehumidification) 9 9 9 10 11 11 6. PERFORMANCE DATA 6-1 Performance Chart 7. TROUBLESHOOTING 7-1 The unit does not work 7-2 Electrical circuit interrupted after "ON" button is pressed 7-3 Electrical circuit interrupted 3 minutes after "ON" button is pressed 7-4 Fan motor does not work while "ON" button is pressed 7-5 Fan works at one speed only 7-6 Poor cooling 7-7 Fan motor works normally but the compressor does not operate 2 12 12 12 13 13 14 14 15 1. SPECIFICATIONS 1-1 Unit Specifications Power source 220 - 240 V ~ 50 Hz Voltage rating 230 V Performance Capacity (1) Efficiency (2) Air flow rate (evaporator) Air flow rate (condenser) Moisture removal Moisture removal Moisture removal Electrical ratings Available voltage range Power input Running amperes Power input Running amperes Power input Running amperes Compressor locked rotor (1) (2) Package dimensions Weight DEHUMIDIFICATION WITHOUT AIR EXHAUSTING TUBE 2100 2,75 310 / 260 290 / 240 1 - - W W/W m³/h m³/h l/h l/24h l/24h Hi/Lo Hi/Lo (3) (4) V W A W A W A A (3) (3) (4) (4) Features Controls/Temperature controls Control unit Timer Fan speed Air Filter Operation sound Lp (5) Hi/Lo Compressor Refrigerant / Amount charged at shipment Refrigerant control Water tank capacity Flexible exhaust tube I.D. extended length Hole in the window Electric cable with plug length Dimensions & Weight Unit dimensions COOLING WITH AIR EXHAUSTING TUBE dB(A) g liters mm m mm m 260 240 23 42 198 - 264 700 3,3 - 710 3,2 770 3,5 13 Microprocessor / I.C. Thermostat Switches on the unit 2 1 Washable 55 / 51 51 Rotary (hermetic) R410A / 470 Capillary tube ~ 3,3 115 1 138 2,9 Height mm Width mm Depth mm Height mm Width mm Depth mm Volume m³ Net kg Shipping kg Data subject to change without notice 870 476 390 1110 577 483 0,31 32 41 Rating conditions (1) Cooling indoor air temperature: 27 °C d.b. , 19 °C w.b (2) Cooling indoor air temperature: 35 °C d.b. , 24 °C w.b (3) Dehumidification indoor air temperature: 27 °C d.b. , 21 °C w.b , 60% u.r. (4) Dehumidification indoor air temperature: 30 °C d.b. , 27 °C w.b , 80% u.r. (5) Reference data: room size 100 m3 , reverberation time 0,5 s , distance 2 m Operating limits Indoor air temperature maximum Cooling 35 °C d.b. , 24 °C w.b Dehumidification 35 °C d.b. , 28 °C w.b 3 minimum 15 °C d.b. , 12 °C w.b 10 °C d.b. , 6,5 °C w.b 1-2 Major Component Specifications Controller PCB Controls (CE) setting differential °C °C Starting delay time Function selection and indicator lamp Trasformer capacity primary secondary coil resistance primary (20°C) coil resistance secondary (20°C) Thermistor (coil sensor) VA V V Ω Ω (TH1) °C °C open close Resistance Ω Thermistor (room sensor) (TH2) Resistance Ω Fan & Fan Motor Type Q'ty ……. Dia. and lenght No. Of poles Rpm Power input (230 V) (FM) mm Hi / Lo speed W (Hi / Lo) Coil resistance (25°C ) Ω type Safety devices operating temp. open close °C °C (C1) µF VAC Run capacitor Float microswitch Contact rating (MS) up down RY2 Electronic 15 ± 1,5 ÷ 31 ± 2 0,9 ± 0,2 3 min ± 10 s ON / OFF COOLING / FAN HIGH / LOW FAN ALARM LAMP 1,5 220 10,5 2754 ± 10% 17,1 ± 10% NTC 1±1 6±1 -20 °C: 5846 ± 5% ; 20 °C: 604 ± 5% -10 °C: 3159 ± 5% ; 30 °C: 368 ± 5% 0 °C: 1766 ± 5% ; 40 °C: 230 ± 5% 10 °C: 1018 ± 5% ; 50 °C: 147 ± 5% NTC 10 °C: 1018 ± 5% ; 30 °C: 368 ± 5% 15 °C: 781 ± 5% ; 35 °C: 290 ± 5% 20 °C: 604 ± 5% ; 40 °C: 230 ± 5% 25 °C: 470 ± 5% ; 50 °C: 147 ± 5% M01974 Centrifugal blower 1…. Ø 170 / L 156 4 1275 / 1058 with flexible exhaust tube retracted 109 / 80 GREY-WHITE: 87,3 ÷ 101 WHITE-VIOLET: 36,2 ÷ 41,6 VIOLET-YELLOW: 22,8 ÷ 26,3 YELLOW-PINK: 22,8 ÷ 26,3 GREY-BROWN: 51,9 ÷ 59,6 Thermostat 150 ± 10 Automatic 3 450 CROUZET F83161.3 16(4) A - 250 VAC open close Power relay (compressor) Contact rating Coil supply Coil resistance (20 °C) (PR) VDC Ω OMRON G4F 20 A - 250 V 12 158 ± 10% Compressor Model Nominal input (230 V) Compressor oil (CM) Rotary (hermetic) Coil resistance ( 20°C) C-R C-S W cc Ω Ω 5RS080EAA (R410A) 675 300 5,19 ± 7% 5,56 ± 7% Data subject to change without notice 4 Safety devices Type Operating temperature Operating amperes (25 °C) (OLR) open close open with Run capacitor (compressor) °C °C (C3) µF VAC Condensate pump Model Nominal input (230 V) Winding resistance (PC) Pump relay Contact rating Coil supply Coil resistance (20 °C) (RP) W Ω Heat exchanger coil Coils Rows Fin pitch Face area Heat exchanger coil Coils Rows Fin pitch Face area 20 450 291036 5 778 ± 8% VAC kΩ H62S 5 A - 220 V 230 17,2 ± 10% mm m² EVAPORATOR COIL Aluminium fin - 3/8" Copper tube 4 1,8 0,042 mm m² 5 EXTERNAL TYPE MRA99137 - 9201 145 ± 5 °C 69 ± 9 °C 14 A in 6 ÷ 16 s CONDENSER COIL Aluminium fin - 7mm Copper tube 5 1,3 0,084 Data subject to change without notice 2. DIMENSIONAL DATA 2-1 Unit Dimensions 6 3. ELECTRICAL DATA 3-1 Electric Wiring Diagram 4,9 COMPRESSOR CAPACITOR ELECTRIC HEATER FAN MOTOR OVERLOAD PROTECTOR ELECTRONIC CONTROL COMPRESSOR RELAY CONDENSATE PUMP PUMP RELAY DEHUMIDIFIER SWITCH FLOAT MICROSWITCH ELECTRIC HEATER RELAY SENSOR THERMOFUSE SAFETY THERMOSTAT PROGRAMMER CM/C Cx RE FMI/MV OLR/K CE PR/RC PC RP ID MS RR TH1/S TF TS P 32 Legend of colors BLACK BLUE BROWN GREEN/YELLOW ORANGE RED WHITE YELLOW GREEN PINK 7 BLK BLU BRN GRN/YEL ORG RED WHT YEL GRN PNK 4. REFRIGERANT FLOW DATA 4-1 Refrigerant flow diagram 8 5. FUNCTION 5-1 Room Temperature Control Room temperature control is obtained by cycling the compressor ON and OFF by means of room temperature sensor TH1 minimum 3 minutes ON/OFF SWITCH ON COMPRESSOR SWITCH ON COMPRESSOR ON ON SET TEMPERATURE +1°C SET TEMPERATURE SET SPEED FAN NOTES 1. If the compressor is turned off, the control circuit sets an automatic minimum 3 minutes delay to protect the compressor from stalling out when trying to start against the high side refrigerant pressure. 2. If the room temperature is 1°C above the set temperature, the compressor starts working if this has been OFF for at least 3 minutes. 3. If the room temperature is the same or under the set temperature the compressor stops working. 5-2 Heat Exchanger Frosting Prevention The electronic control stops automatically the compressor each time the coil sensor TH1 reaches a temperature of 1 °C for 8÷10 minutes long, the compressor starts again automatically when the temperature of heat exchanger reaches 8 °C. the fan goes "ON" working at the set speed. minimum minimum 10 minutes 3 minutes ON/OFF SWITCH ON COMPRESSOR SWITCH ON COMPRESSOR ON ON HEAT EXCHANGER TEMP. = 8°C HEAT EXCHANGER TEMP. = 1°C SET SPEED FAN 9 5-3 Dry Operation (Dehumidification) AMBIENT TEMPERATURE MAX. 35 °C - PUSH BUTTON COOL/DRY. - COMPRESSOR "ON". - LOW SPEED. - AMBIENT THERMOSTOR BY-PASSED. - COMPRESSOR OFF AFTER 10 MIN. WITH AMBIENT TEMPERATURE AT 10 °C. - UNIT WITHOUT AIR RXHAUSTING TUBE. MIN. 10 °C MIN. 3 MIN. MIN. 10 MIN. AMBIENT TEMPERATURE 10 °C ±1 °C DRY POSITION BUTTON COOL/DRY COMPRESSOR ON OFF LOW SPEED FAN ON LED YELLOW 10 ON OFF 6. PERFORMANCE DATA 6-1 Performance Chart 4,9 32 Operating characteristics with relative humidity around 50% Operating current (A) 5,00 4,50 4,00 3,50 3,00 2,50 18 20 22 24 26 28 30 Room temperature (°C) 11 32 34 36 7. TROUBLESHOOTING 7-1 The unit does not work Check the voltage. Are there 198 ÷ 264 volts ? YES NO Check the unit electrical cable Check if programmer contact is closed (black brown cables). (IF INSTALLED) YES NO Check if there is supplied voltage between 1-2 the electric control (CE) NO YES If it is impossible to close the contact, replace the programmer. Check if tank micro switch contacts are closed. (1 - 2 MT contacts) NO YES Replace the electronic control (CE) Check the electrical supply line Check if the pilot lamp is burnt. Eventually replace it NO Is the flickering alarm lamp on the control panel not visible ? 7-2 Electrical circuit interrupted after "ON" button is pressed Check the unit hardness Is it insulated ? YES NO Insulate the short circuit cable Check if the fan motor is working (FMI) YES NO Replace the fan motor (FMI) Check the electronic control (CE) YES NO Replace the electronic control (CE) Check the leds printed circuit. NO NO Replace the leds printed circuit. Check the motor YES Replace the programmer (P) programmer (P). Is it short circuited? (IF INSTALLED) 12 7-3 Electric circuit interrupted 3 minutes after "ON" button is pressed COOLING OPERATION Check if compressor relay NO Rebuild the connections. YES Replace the compressor relay connections are insulated. YES Check if compressor relay works. Is it in short circuit ? (PR) NO Check if compressor winding are short circuited. YES Replace the compressor(CM) 7-4 Fan motor does not work while "ON" button is pressed Disconnect the unit from line. Check if the fan motor is well fitted and if the blades can rotate YES NO NO Check hardness and various continuities YES Fit the fan motor properly or replace it Remove obstruction or replace fan motor assembly Check the capacitor capacity (C) YES NO Replace the capacitor INTERRUPTED Replace the fan motor assembly Check the fan motor windings (FMI). YES Replace the electronic control (CE) 13 7-5 Fan works at one speed only Check electrical conections. Is there continuity ? YES NO Fit electrical connec tions properly Check power supply between 1-7(high) or 1-8(low) electronic control contacts (CE) YES NO Replace the electronic control (CE) Is the unit cooling capacity suitable for the room thermal loads ? YES NO Suggest a more powerful unit Are both air filters and heat exchanger cleaned ? YES NO Clean filters and / or heat exchanger Check if Difference between room air temperature and outlet air delivered is up to 10 °C YES The unit works properly Check fan motor winding values (MV) YES Replace fan motor (MV) 7-6 Poor cooling NO Low gas charge Proceed with normal operations foreseen for the above points 14 NO 7-7 Fan motor works normally but the compressor does not operate Check hardness and continuity. Is the relay compressor coil (PR white cable) power supplied ? YES Replace the relay (PR) NO Check if relay contects are closed YES YES Replace klixon (ORL) YES NO Check compressor klixon contacts (ORL) Are they open ? Is room tempera ture over 15 °C ? NO Adjust thermostat position NO The unit cannot operate below 15 °C NO Replace the sensor (TH2) YES Check the capaci tor capacity (C) Check the sensor continuity (TH2) through 9-10 electronic control (CE) terminal blocks YES YES Replace the compressor NO YES NO Replace the capacitor (C) Is the thermostat in the right position ? Check the com pressor winding continuity Check electronic control (CE) 15 Via Varese, 90 - 21013 Gallarate - Va - Italy Tel. +39 0331 755111 - Fax +39 0331 776240 www.argoclima.it