Download Craftsman 139.653000 Specifications

Transcript

S_

_kL_

i

]

_!iii_

__i!_i_iiii_

i!i_:_ii_

_:_!_

_:_'::_s:_'_i

SECTgOHAL

DOORS

ONE PIECEDOORS

Before You Start.,.

identify your door •follow specific index for assemblyand installation

Sectional D DOt

With Curved Track

One Piece Door. Jamb Hardware_

Horizontal Track°

One Piece Door, No Track. Jamb

Hardware,,

One Piece Door. No Track, Pivot

Hardware,

.f

UX

gx

,,/_,

/

,,

/il

//

//

DOOR

\

DOOR

\

\

\

TRACK

/

//

TRACK

!

//

//

DOOR

9

iNSTRUCTiON

Assembly

INDEX

.........

installation

......

COMMON

INDEX

:

JAMB

HARDWARE

iNSTRUCTION

INDEX

INSTRUCTION

Pg_ 6

Assembly

.........

pg.

Pg,

installation

.......

Pg., 14

8

6

Warranty

............

Maintenance

.........

Assembly

2

3

iNDEX

INSTRUCTION

...........

Installation

PIVOT

pg,

..........

Safety Rules

Radio Controls

6

Assembly

Pg. 14

...........

........

Installation

3

17

INDEX

..............

P_

............

Wiring Diagram

.......

Parts Lists .............

CartonCheck List-SEARS Has packaged your Garage Door Opener in 2 cartons with handles,,_

THE LARGE CARTON

CONTAINS:

"_J_!Ji_i!#_

1 Box of Radio Controls

I

Box of chain

1

1

1

1

1

1

1

1

Curved door arm

_,_ '

Straight door arm

Bag of installation hardware

Handy hints labeF

Operator assembly (in foam end caps)

Plastic light lens

Box of rail assembly hardware

Owners manual

THE SMALL CARTON CONTAINS:

I Three-section Tee rai!

2 Sections of hanging strap

Sears Garage Door Opener Warranty

FULL

When

the Garage Door

a period

of

90 DAY

Opener

will,

for

90 days

the

Garage Door Opener,

WARRANTY

is installed,

from

at no

the

adjusted

day of

the

91st

day

until

one

year

adjusted

and operated

in accordance

defective

parts

Garage Door

Warranty

service

the United

which

in the

vary

is available

from

This

warranty

from

state

to

state.

OPENER

in accordance

repair

any defect

with

our instructions,

in material

Sears

or workmanship

in

with

gives

WARRANTY

the day

of purchase,

our instructions,

Opener,

by simply

States.,

and operated

purchase,

DOOR

charge,.

LIMITED

From

ON GARAGE

free of

contacting

you

specific

the

Sears will

charge.

the

when

You

nearest

furnish

pay

Door

Opener

replacement

is instatled,

parts

fm

any

labor,

Sears store

tegal rights,

Sears Roebuck

Garage

and you

or service

may

center

also

& Co., BSC 41-3, Sears Tower,

throughout

have other

Chicago,

6

Pg 14

rights

_L60684

20

21

Preparation

MAiNTAiN THE VALUEOF YOURGARAGEDOOROPENER

MAINTENANCEAGREEMENT

Here

\

is a comparative

Maintenance

chart

Agreement

indicating

coverage

the warranty

for

and

a Sears Maintenance

Agreement

....

.................. Coverage

AGREEMENT

,'

l

1

\

1) Defective

2) Service

Sears Garage

tested

for

Opener

Door

Openers

years of dependable

however,

may require

Sears warranty

plus

vides

from

coverage

use and

from

are designed,

The only

operation

service

unexpected

Agreement

bills

from

the maximum

to the

Agreement

acts of abuse, fire,

and parts

necessary

for proper

operation

not covered

coverage

are repairs

flood,

wind,

provided

by the Sears'

necessary

lightning

because

4) Preventive

of

check

and freezing.

YOUR SEARS SALESPERSON

AGREEMENT TODAY!

To obtain

the

best service

"Save-A-Call"

MA

MA

MA

MA

MA

MAiMA

by the

maintenance

at customer's

request

W = Warranty

CONTACT

TENANCE

MA

warranty

exceptions

Maintenance

MA

(technical

pro m

purchase,,

MA

MA

and non-technical)

use possible

MA

90 Days

Warranty

parts

The

normal

MA

W

to replace

3) Service,

4

MA

Parts

defective

Door

time to time,

repair

of obtaining

and

Any Garage

from

the Sears Maintenance

assures you

your

manufactured

Years of Ownership

2

3

from

your

OR LOCAL

Garage

Door

MA = Maintenance Agreement

SEARS SERVICE CENTER

Opener

and to avoid

MA

AND PURCHASE

needless inconvenience

ASEARS

or service expense,

MAIN-

please use

on Page 23 of this manual

RulesFor Safe Operation

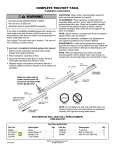

WARNING-DOOR

SPRINGS CAN CAUSE FATAL INJURIES°

DO NOT ATTEMPT ADJUSTMENTS UNLESS YOU ARE

PROFESSIONALLY

TRAINED.

t,

Installation

2, Keep door

continuing

4, Your

with

must conform

hinges

rollers well

quiet

3,, The only

solvent

and wiring

part

door

new

inoperative°

6, Remove

7,, Before

must

opener

Fasten

opener

rag, then

that

balance

provide

all ropes connected

making

Handy

repairs,

Hints

lubrication

with

for proper

is the rail on which

operation

wilf insure

wood

to opener!

unless garage door is in sight.

(Sectional

screw or other

to the garage door.

the trolley

safety

door

for your

a stout

power

of the opener

have a serviceman

locking

label near walt button,,

months

in hardware

are weal{,

adequate

electric

codes.,

used every three

rail grease included

open with

disconnect

transmitter

A lubrication

If the door springs

Pin the door latch

and electrical

minimum

maintenance

and

the tracks,

requires

re-lubricate

impetus°

will

lubricated,

Do not lubricate

be in good

manual

8,, Do not operate

g,

of your

and a clean

normal

5o Your

and

operation.

to local building

rides., Clean the rail once a year with

package.,

system.

replace

track-type

disabling

It should

travel

up and down

freely

them_

device°

door),

Existing

locks

should

be made

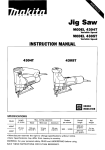

You'll Need Toels

During assembly and installation

of your opener, the instructions will call for use of various hand tools_

Have a stepladder handy, and those tools illustrated below: Hammer, electric drill (also 3/16" and 5/16"

drill bits), screwdriver', adjustable end wrench or socket wrench kit, wire cutters, pliers and hacksaw..

Adjustable

End

Wrench

Pliers

Stepladder

Wire

Socket

Cutters

Wrench

Accessories

Sears stocks many useful accessories for your garage door' opener. They are illustrated below with Sears

stock numbers and descriptions:

6545

Extra transmitter

for use with the following

Sears stock nos, 6550, 65.30,

6551 and 6531., Black with wood grain trim° ORDER BY CODE LETTER°

6528

j_,....

f4,_

J (_-.3)

.....

..

Outdoor Key Switch., Included with best models 6550 and 6551.. Just a turn

of the key opens the door automatically

from outside when transmitter' is

not handy..

6571

Quick-Release Key Lock. In case of power failure on garages without

entrances° Wood or metal doors only.

service

6785

Quick Turn Brackets for Garage Door Opener installations with low headroom

clearance, Reduces headroom requirement to 2 inches.

6538

Sectionalized T-Rail extension kit. ALlows opener to handle garage doors up

to 8 feet high,. Consists of replacement T-Rail section, chain and master link.,

For use on sectionalized rail models only.

.......

J

Hardware

Open the hardware containers

and check contents

before startingF

Rail Assembly

Hardware

Box

Chain

Retainer

Bracket

Trolley

Master

Rait

Link

Grease

12)

@

Items in this box

bly

of

the

nuts, bolts,

are actual

2 Lock

are for assem-

T.rail

IHustrated

screws

and washers

Washers

4 Carriage

1!4'°-20x

2 Nuts

3f8"

3/8--16

Bolts

1/2'"

2 Screws

3/8"'-16x7/8"

4 Lock Nuts

1/4--20

size

2 Washered

Screws

t Lock

Washer

5!16-

2 Nuts

5/t6--18

bolts,

screws,

5116"'-18x9tt6""

Items in this bag are for

washers are actual size

instalhng

the opener

Illustrated

nuts.

pins and

INSTALLATION

HARDWARE

) _I_IiIi_w!_I_1_iiii]]]_

BAG

Insulated

Staples

2 Lock

Washers

5/16"

2 Nuts

51t6"

O

l

2 Clevis Pins

318"xl

-1/t6"

4 Screws

3/8"-t6x7/8"

2 Ftat Washers

..5__

4 Nuts

3/8--

t6

4 Lag Screws

5/t6"xl-7!8"

Clevis

318'x3"

"-

4 Lack Washers

3!8"'

3 Cotter Pins

3132"x3/4-

Handle

'_'

Lead Wire

-5-

Rope

Header

Door

Bracket

Bracket

Pin

Assembly

Reverse

Step

Switch

Cover

1

Open Rail Assembly Hardware Box

REMOVE SPROCKET COVER FROM OPERATOR: Place operator on packing material to prevent scratching chassis cover.

Remove sprocket cover from top of chassis by unfastening

screw as illustrated. DO NOT REMOVE REVERSE SWITCH

COVER,

Screw

Sprocket

ASSEMBLE

numbers

RAIL:

as illustrated.

seated

in square holes

surface

during

Assemble

Square

the

in sections

assembly,. THIS

3 Tee rail

necks

sections

on carriage

bolts

by the

must be

t and 3. Place Tee rail on flat

TEE RAIL SECTION

N£1

IS IMPORTANT!

TEE RAIL SECTION

N_-2

1/4

LOCK

Cover

NUT

(KEPS)

SQUARE

CARRIAGE BOLT

HOLES

TEE RAIL SECTION

N£3

I/4 X I/2 CARRIAGE

BOLT

Bolt section 1 to section 2, Use 1/4 inch by 1/2 inch carriage

bolts, and !/4 inch loci( nuts.

Join bolted sections 1 and 2 to section 3, Use 1/4 inch by 1/2

inch carriage bolts, and 1/4 inch lock nuts,

CAUTION:

DO NOT tighten lock nuts until

seated in square holes,,

Step

7/8

inch

screws,

3/8

inch

lock

Connect

the sprocket

Tee rail Use 3/8 inch by

washers

and nuts as itlust[ated,

nuts and screws securely..

CAUTION:

R_:LEASE

LEVER

:

necks are

3

ATTACH

SPROCKET

BRACKET:

bracket

assembly to the assembFed

Tighten

bolt

Make

certain

sprocket

with

Tee rait,

straight

bracket

assembly

is aligned

_SSEMBL_D

TROLLEY

Step

4

INSTALL TROLLEY ASSEMBLY:

onto the Tee rait as illustrated,

-6-

Slide the assembled trolley

Assembty

5

'i6x_t6 LG

BOLT

ATTACH

ASSEMBLED

operator

two

on packing

holes

chassis

in

motor

an illustrated,

TEE

material

RAIL

to

end of

avoid

Tee rail

For convenience,

TO

OPERATOR:

scratching

with

holes

place

in operator

a support

sprocket bracket

Fasten Tee rail to operator

with

screws 5/16 inch by 9/16 inch Tighten securely,

ASSEMBLED TEE RAIL

WITH

TROLLEY

Place

cover,, Align

two

under

washered

5/I6

NUT

SCREWDRIV

SPROCKET

BRACKET

OPERATOR

CHASSIS

\TROLLEY

BRACKET

TROLLEY STUD

FLAT END

MASTER

LINK

INSTALL

CHAIN:

Tee rai!

Slide

Thread

located

trolley

Insert

about

back

or nail

in the hole

of the sprocket

in

bracket,,

SMALL

SPROCKET

to this point

one of the 5/16

one end of

a screwdriver

6 inches

the chain

inch

master link from

hardware

box,

the

CAUTION:

the chain

Keep

nuts onto

the trolley

stud

to the fiat end of the t_'olley

coin

envelope

taut

included

white

Fasten

stud using

a

LARGE

SPROCKET

in the assembly

unwinding

it to prevent

kinking

Extend

back

to the

the

around

chain

the

trolley

around

small

Make

the idler

sprocket

certain

sprocket

bracket,

on the operator,

that

teeth

from

then

each

Proceed

forward

sprocket

engage the chain

CAUTION:

Tile

chain

illustrated

MASTER

LINK

RETAINER BRACKET

DC_WASHER _6

DLER

SPROCKET

CHiN

STUb

TROLLEY

J

Connect the chain to the chain retainer bracket using the second

master tink in the coin envelope Slide the chain retainer bracket

onto the chain stud as illustrated

Secure it to the stud with

the second 5/16 inch nut and lock washer,,

retainer

position

bracket

during

should

assembiy_

be kept

in the

Installation

Step 7

TIGHTEN

two 5/16

THE

CHAIN:

Tighten

the chain

by

inch nuts on chain stud de_ignated"inner"

adjusting

the

and "outer"

as illustrated,,

Chain is propmty

tightened

when it is approximately

1/2 inch above the base of the Tee rait at its midpoint

between

idler

CAUTION:

sprocket

Chain

and the operator

/

Keep the chain from twisting

as nuts are turned

Remove screwdriver

or nait from Tee rail

Base of Tee Rail

REPLACE SPROCKET COVER REMOVED

IN STEP 1,

Assembly

of the garage door

statlation

now

begins+

Refer

operator

to

is complete

Pages t4-17

in-

for in-

stallation

on one-piece

doors,

With Step 8 below,

begin installation

on sectional doors with curved track,

Step

POSITION AND INSTALL HEADER BRACKET. Opener" hardware in plastic bag will be needed in the following steps,, Determine vertical center" line of garage door+ Extend this onto

garage header wall above door+ Position header bracket centeron-center with this line at height approximately 2 inches above

the high arc point (this is high point of travel of top edge of

door as illustratedL Mark either' pair of bracket holes - vertical

or horizontal on header" watlo Drill 3/16 inch pilot holes and

instatl bracket with 5/16 inch by 1-7/8 inch lag screws,.

GARAGE

HEADER

" +._

HEADER

BRACKET

Step

8

_"_

LAG SCREWS

NOTES: t, When headroom is not sufficient for 2 inch clearance, the bottom edge of bracket may be placed at

high arc height. Bracket can also be attached to

the ceiling+

2,, The header bracket must be rigidly fastened to the

header' walt or ceiling. Reinforce the wall or ceiling

with a 2 x 4 if necessary.

& If it is necessary to fasten the header bracket to the

ceiling, use the horizontal (left and right) bracket

holes°

9

PIN

ATTACH RAIL TO HEADER BRACKET: Place operator on

packing material° Raise Tee rail until sprocket bracket joins

header bracket, Align the bracket holes, Attach with 3/8 inch

by 3 inch clevis pin, Secure with cotter pin+

PIECE

OF'

Installation

POSITION

THE

OPERATOR:

Raise operator

onto

a stepladder,

Open the garage door,, Place a 2x4 on edge along top section

door, Rest the Tee rail on the 2x4 as illustrated

NOTE:

A 2x4 is convenient

for establishing

an ideal door-torail distance,

It is not a necessity where headroom

is

insufficient,,

weight

SECURE

tration)

THE

OPERATOR:

between

operator

Measure

and joist,

distance

or other

("L"

angles,. Fasten

3/8 inch by 7/8

hanging

3/t6

inch

pilot

with

5/16

inch

lag screws.,

Lubricate

ceeding,

to operator

precautions

and doors

with

against

damaging

sup_J

chassis with

holes

bottom

Use tube

in roof

surface

supports,

of

Tee

Fasten

rail

of rail grease included

brackets

before

pro-

in the hard-

BEND

AS

ware package

CUT

Step

FASTEN

Flat

Washer

center

Reinforcing

Board

12

DOOR

with

below),

Carriage

Bolt

light

windows,

inch screws, and 3/8 inch nuts and lock washers.,

Drill

NOTE:

brackets

Take

doors,

in illus-

garage roof

port

Cut both pieces of hanging bracket just beyond selected

holes

Notch bracket ends with hack saw.. Bend ends to form

desired

of

Align

either

top

Drill

5/16

BRACKET:

inside

vertical

bracket

and bottom,

inch

diameter

ears

Place

door

bracket

center

line

of door

with

top

rollers

or left and right

holes

in door

bracket

center-on-

(also see note

of

door

Mark

holes on door,

(or center

stile}

where

door bracket

holes were marked_ Bolt bracket

in place with

two 5/16 inch by 2_t/2 inch carriage bolts, and two 5/16 inch

loci< washers and nuts,,

Door

Bracket

NOTE : Use center stile on aluminum or light steel doors,

Where this is impractical; use the heavy flat washers

between bolt head and door, In such case also, REINFORCE THE INSIDE OF THE DOOR WITH A

BOARD 1 INCH THICK, 6 INCHES WIDE AND

ABOUT 12 INCHES LONG,

-9-

installation

Step

1:3

-x

/

Cotter

Pin

--

DETERMINE

cord

DOOR

through

end through

Remove

ARM

red handle

hole

plastic

LENGTH:

Thread

and secure with

in release arm of trolley,

carrying

strap

from

arm to

door

bracket

with

3/8

Straight

one end of nylon

knot,_ Thread

Secure

straight

with

door

other

a knot

inch clevis

ti

a_m,. Place

one end of straight

door arm in slot in trolley and fasten with

3/8 inch clevis pin and cotter pin,. Fasten short end of curved

door

Release Arm

_-%---- Clevis

Pin

Door Arm

Door

/

pin and cotter

pin

Curved Door

Arm

o Push the garage door to "closed tight"

o Bring the two door arm sections together If holes (in each

section) line up, join the sections with two 3/8 inch by 7/8

inch bolts, lock washers and nuts. PUT BOLT HEADS ON

STRAIGHT

DOOR ARM SIDE Select bolt holes as far

apart as possible to increase door arm rigidity,, DO NOT

USE MORE THAN ONE SLOTTED HOLE,

318"" Nut

31a- \@_

Lockwasher

318"' x 7/8-' Bolt

If door arm holes do not line up when the two sections are

brought together, cross the door- arms in scissors fashion (see

illustration)

until a pair of holes (one in each section) line up,

insert a 3/8 inch by 7/8 inch bolto Secure "finger tight" with

lock washer and nut,

-- Straight Door

Arm

•

Pull the emergency

•

Bring the door

both bolts,.

NOTE:

release cord to disengage

arm sections

Sears Keylock

together

Release accessory

an outside

emergency

service entrance door',

access

trolley,,

and bolt securely

No., 64-6571

for

ga[ages

with

provides

without

a

-10-

_

Door Arm

instaJlation

COD_

o

LABEL

CAUTION:

SIGNAL

CODE LABEL

RECEIVER

OR

ADDITIONAL

MUST

BE MOUNTED

SMALL

CHILDREN.

OUT

PUSH

OF THE

BUTTON

REACH

OF

INSTALL

RADIO

RECEIVER:

There are installation

flanges

at both ends of the receiver, Attach the receiver to an interior

OPENER TERMINAL BLOCK

ooi

garage

cation

wall with the wood screw, s provided.

A convenient

lois alongside

the service door When installing more than

one receiver

prevent

in a garage,

interference

door

operator

The

receiver

place

them

as far apart

(also keep wires

from

as possible

receivers

to

to garage

far apart)°

BELL WIRE

terminal

attachment

receiver

SH

flange

and

operator..

wire ends.. Connect

BUTTON

ir

, k.... t

Extend

the

receiver

using

tf

after

itself,

the

belt wire

connecting

1/2

staples,

inch

of

on back

the

bottom

bag to connect

insulation

from

end of operaton.

and down

the

wall to the

staples provided°

operate

face

just above

in hardware

to terminals

electric

not

(under

wire

across the ceiling

insulated

front

is located

Remove

wires

wires

or does

lower

strip

Use bell

of

power,

from

the

door

the

unit,

opens

receiver

check

or closes

push

for

button

a short

by

on

in the

for example).,

RECEIVER TERMINAL BLOCK

t4K]UNTING

FLANGE

The garage door opener

can be activated

or

push

from

the

receiver

override

those from

NOTE:

A special

button°

a transmitter

security

as a safety

switch

locking

plug

ELECTRICAL

devices

the

on door

attached

POWER:

First,

have been removed

3-pronged

electric

make

certain

or disabled.

cord

into

a

I,

wiring

is necessary

the door

by external

be opened

from

all

Then,

3-wire

Remove

electrical

chassis°

2, Remove

vided

CAUTION;

local

codes, proceed

o

operator

3,, Make

to meet

attached

the

connection

3-pronged

permanent

cover

plate

from

back

of

cord,

connection

through

the

hole

pro-

in the top of the operator.

IT IS EXTREMELY

UN IT BE GROUNDED

LEAD

MENT..

PROVIDED

Install

IN THE

a shut-off

GR£EN

LEAD

IMPORTANT

USING THE

WIRING

switch

THAT

THE

GROUNDING

COMPART-

in the line.

-tl-

on

is in the

can not

signal,

signals

will

feature,

is provided

receptacle,

If permanent

as follows:

button

the receiver,. When the switch

The opener can be activated

receiver push button,

CONNECT

by a transmitter

Push

the

LOCK

side of

position,

radio

signals°

a key switch

or the

justment

Step

16

ADJUST

OPENER

ptete up and clown

door

if

LtMITS:

Run the opener through

a comcycle. Adjustments

are not needed when

opens and closes

door

does

not

completely.

close

completely,

lengthen

door

arm

as

required,

A,. Run

door

in UP direction.

nut adjustments

CAUTION:

Disconnect

Bo Remove

4 cover

ward

from

C. Adjustments

or' down

tion),,

power

screws

Do

before

limit

as follows:

cover is removed,.

as illustrated

are made

limit

by turning

shaft just

and

slide

not

run

large plastic

behind

nut retaining

in place must be loosened

CAUTION:

Proceed

cover

for-

chassis.

a threaded

The

If it does not open enough,

are necessary.

bracket

before

opener

limit

the motor

which

nuts up

SCREW_-20

(see illustra-

/

holds the nuts

nuts can be turned.

before

limit

nut

bracket

_/TO

is

REMOVE

COVER

secured in original positiom

1.

2.

3.

4.

The top nut controls closing limits_

The bottom nut controls opening limits..

One turn of the limit nut equals 3 inches of trolley travel.

All adjustments require complete turns.

D,. TO MAKE ADJUSTMENTS:

Slide bracket to the left

Loosen limit nut bracket screw..

1. To increase UP limits-turn

bottom nut upward.

2. To decrease UP limits-turn

bottom nut downward

3. To increase DOWN limits-turn

top nut downward°

4_ To decrease DOWN limits-turn top nut upward..

5. These procedures may require repetition before adjustment is complete..

TURN

NUT ONE COMPLETE

REVOLUTION

FOR 3 _ OF

TROLLEY

TRAVEL

E. When adjustments are complete, slide bracket to its original

position and TIGHTEN SCREW SECURELY before applying power'.

LIMIT

NUT

F.. Replace cover and 4 cover screws. Reconnect power_

CAUTION:

After an adjustment,

power is turned on.

the motor

will

_

PLASTIC

RETAINER

NUT

SHAFT

run when

\

If door reverses at end of downward travel, the door arm is

too long. Shorten it one set of holes _ a time until reversing

ceases.

\

\

!

[

_1_\

DOWN

LIMIT

During limit nut adjustment procedure, if door reverses before

completing travel cycle in either direction, also check:

1.. Excessive binding of door (check manually and correct)..

2. Force adjustments are too light_ Refer to Step 17..

-:;--

CAUTION:

If the

door opener

is installed

on a door

with a height greater than 6 feet, the "UP'"

limit

-12-

must be adjusted.

ustment

ADJUST

DOOR

FORCE:

Determine

that

door

force

is not ex-

cessive in down direction.. Grasp the door handle or the bottom

of the door as it is about halfway

through

downward

travel.

/

Normally

the door

should

reverse

by this

action.

If it is hard to hold, or doesn't

reverse, loosen the clown

screw one turn at a time until the door reverses normally.

CLOSE

means

FORCE

ADJUSTMENT

SCREW

it will

not

reverse when

A. Adjustment

door)°

labels

\

door

next

opens

B Tighten

climatic

CAUTION:

at the end of

"Close"

"Open"

to

force

force

screws.

and

screw

screw

Turn

closes

adjustment

a travel

cycle,

and will

obstructed.

screws are near center

as illustrated.

ing

reverse

moderately

force

This

is on

left

clockwise

without

screws

of upper

chassis

is on the right

by

side.

half

flanges

sicle (facRefer

turns

to

until

reversing

an added

half

turn

to allow

for

changes.

Door force

hardware.

is not to compensate for faulty door

\

OPEN

FORCE

ADJUSTMENT

SCREW

Step 18

INSTALL

Light

off

LIGHT

turns

automatically

available,

"Rough

*Use 100 watt

60 watt

LENS:

AND

LENS:

on automatically

Gently

about

Install

when

90 seconds

Service"

bulbs

a light

opener

after

should

turn

stops,

if

be used.

in Model

t39 653000

bulbs

in Model

139.653100

lens and insert

in socket.

It will

the opener

bulbs

squeeze

bulb*

starts.

USE

IOOWATT BULB

60 WATT BULB

tabs in slots in chassis.

Release pressure and lens will snap

remove lens, reverse this procedure

into

_--'_-_

place., To

-13

-

_'_""_

MODEL

139 65300

13965310

LENS

One Piece Door Installations

One Piece Door° Jamb Hardware°

Step 1

H orizonta| Track.

Highest Point

ofir_ave

_

,,,_. . ....... INSTALL

bag will

_

DOO\\_\

5/16"

LOCK

WASHER

///

TRACK

DOOR BRACKET:

(Hardware

in plastic

be needed in the following

steps). Determine vertical

center line of garage door, Position

door bracket center-on-center

with this line at leading edge of top of door (see illustration),

holes.

Drill

5/16

inch holes through

Mark outer

door top,

Fasten bracket with

washers and nuts,,

bolts,

5/16

inch

carriage

LEADING

TOP OF DOOR

\

lock

5/t6'

One Piece Door° No ]rack.

Jamb

Hardwares,

Highest Point of

of Travel

INSTALL

HEADER

center

of door

door. Reinforce

bracket support,

//

DOOR

/i/

4

BRACKET:

onto

garage

Extend

header

vertical

wall

above

header wall if necessary for header

A 2x4 or 2x6 will suffice,. Posi-

tion the header bracket according

to door type and

its arc of travel (see illustrations

at left edge of page)°

A_

//

line

One-Piece

Door Without

Track:

Open door

to highest point

of travel, Measure distance

from top of door to floor,, Subtract

actual

height of door (top to bottom),

Remainder

is door rise (see column 1 of adjoining

chart),

Refer to chart for' setting height of header

bracket

above door, Place bracket

at referenced height and center-on-center

with

extended

vertical

center

line of door,

Mark

bracket

holes, Drill

3/16 inch pilot holes,

Fasten

bracket

with

5/16

by 1-7/8

inch

B_ One-Piece Door With Track: Position

header

bracket center-on-center

with extended vertical center line of door and approximately

2

inches above

the horizontal

tracks,

Mark

One Piece Boor,, No Track. Pivot

bracket

holes on wall

Drill 3/!6

inch pilot

holes.. Fasten bracket with 5/16 by 1-7/8 inch

lag screws,

Hardware,

Highest Point

of Travel

/

//

Step

3

DOOR

\,

ATTACH RAIL TO HEADER BRACKET: Place

operator on packing material.. Raise Tee rail until

sprocket bracket joins header b_acket. Align holes..

Attach with 3/8 inch by 3 inch clevis pin. Secure

with cotter pin..

//

PIVOT

-14-

I

h

_

H_'AD_R

LAG

SCREWS

_

BRACKET

Door'

Rise

In Inches

Iag

screws.

JAMB

HARDWARE

CARRIAGE

BOLT

Up to 4

4

to 8

8 to 12"

Location

Bracket

of Header

Above Door'

in I riches

10

15

20

*if door rise is greater than 12 inches, or

if low ceiling clearance doesn't allow

positioning header bracket as shown in

column 2 above, use the remote installation procedures on Page 17.

One Piece Door InstaHiations

POSITION

A

THE

OPERATOR:

One-Piece

Door Without

Track:

Raise motor

end

of opener

to a height

equal to door bracket

with door open. Support opener with stepladder.

For maximum

efficiency,

do not secure the

operator

more than 2 inches higher than this,.

B One-Piece

Door

With

Track:

Raise motor

end of

opener

to height

above and paraflel

to

zontal tracks.. Support it with stepladder.

\\-\\,

_

HEADER

hori-

BRACKET

SECURE

THE

OPERATOR:

Measure

distance

("L"

in iIfustration)

between

operator

and joist, or other

garage roof support., Cut both pieces of hanging brackTRACK

et just beyond selected holes,. Notch bracket ends with

hack saw. Bend ends to form desired angles. Fasten

hanging brackets

to operator

chassis with 3/8 inch by

7/8 inch screws, and 3/8 inch Iock washers and nuts

Drill 3/16 inch pilot holes in roof supports

Fasten

brackets wlth 5/16 inch lag screws.

NOTE:

Lubricate

bottom

proceeding.

in hardware

STR UCTURAL-_

MEMBER

surface

Use tube

box,

of Tee rail before

of rail grease included

P

!;l

HANGING

INSTALL

RADIO

RECEIVER:

Refer

to

Step

14

Page 11,

\

Step

CONNECT

Page 11.,

BEND

AS

NECESSARY

-15-

?

ELECTRICAL

POWER:

Refer to Step 15,

One Piece Door Installations

Step

8

SET OPENER

LIMITS:

(1) Using the radio controls,

run trolley

back to the "up" limit near motor end of

unit,

Disconnect

electric

power,

Remove

4 cover

screws

and slide

cover

forward

from

chassis

as

illustrated_

(2) Adjustments

are made by turning

large plastic

limit nuts up or down a threaded shaft just behind the

motor (see illustration),

The limit nut retaining

bracket which holds the nuts in place must be loosened before nuts can be turned°

CAUTION:

Do not run opener before limit nut

et is secured in original

position_

•

The top

nut

•

The bottom

=

One turn

travel,

•

All

controls

nut

of

closing

controls

limit

adjustments

nut

equals

require

limit

nut

complete

Loosen

bracket

_TO'REMOVE

COVER

limits.

3 inches of trolley

(3) Reset top nut (down

limit)

(counterclockwise)..

Reset bottom

nut (up limit)

(clockwise),

Slide

brack-

limits,

opening

TO MAKE ADJUSTMENTS:

screw, Slide bracket to left,.

SCREW _-20

to

turns,,

limit

nut bracket

6 turns

3 turns

right

and

to

to

TURN

NUT ONE COMPLETE

REVOLUTION

FOR 3'* OF

TROLLEY

TRAVEL

right

left

tighten

LIMIT

screw,,

SCREW/

Replace chassis cover,,

Reconnect

power.

CAUTION:After

when

an adjustment,

power is turned

NUT

RETAINER

BRACKET

the motor

on,.

wilt

O

run

PLASTIC

NUT

SHAFT

0

OOWN

L_MIT

Step

9

CAUTION:

CONNECT

DOOR

ARM:

Thread

one end of nylon

cord through red handle and secure with knot. Thread

other end through

hole in release arm of trolley.

Secure with

knot,, Remove

plastic carrying

strap from

straight door arm.,

Using 3/8 inch clevis

pin, connect

one end of

straight door arm and door bracket.

Secure with cotter pin, Use other 3/8 inch clevis pin to connect short

end of curved door arm to tro!ley,, Secure with cotter

pin..

5/16"

LOCK

WASHER

5t16"

NUT

,318""NUT

WASHER

Close the door tight, Bring the two door' arm sections together,. Bolt the sections if the holes line up,.

Use 3/8 inch by 7/8 inch bolts, and 3/8 inch lock

washers and nuts, Select bolt holes as far apart as possible to increase door arm rigidity,

DO NOT USE

MORE THAN ONE SLOTTED

HOLE

If the door arm holes do not line up to permit

bolting, follow the instructions in Step 13, Page 10.

If the door opener is installed on a door

with a height greater than 6 feet, the "UP"

limit must be adjusted.

_//_

/

/

5tl 6"

CARRIAGE

BOLT

-16 -

/

3/8" BOLT

One Piece

oor Instal

Otis

ADJUSTMENTS:

If, after installation

not open or close satisfactorily,

follow

and 17 on Pages 12 and 13,,

of opener, door does

adjustment

steps 16

P

INSTALL

REMOTE

INSTALLATION

LIGHT

CE I LING

Refer

to Step

T8, Page 13,

INSTALLATION

PROCEDURES:

(1)

Fasten

header bracket

to a suitable

support

on ceiling

(a 2x4 or

2x6 reinforcing

plank nailed to joists,

for example),

Tile

support

location

should be the most convenient

in line with

SUPPORT

HEADER

LENS:

PROCEDURES

REMOTE

IdIGH

POINT

or- TRAVEL

AND

BRACKET

the door bracket

and further

inside

the garage than tile

highest point of door travel.

(2) Follow

procedures

of Steps 3,4,5,6,

and 7 by which

[_<

garage door opener is fastened to header bracket and ceiling

Increased

distance

between

trolley

and door

bracket

is

joined

by 1 inch thin

walled

electrical

metallic

tubing

(EMT)

conduit

available at most electrical

supply or hardware stores,

(3) Run trolley

to "Down"

limit,, Close door, Measure

!

I

t

DIAMETER

THIN

WALLEO

EMT

m

distance

bracket

LJ

'\o o o o o o__...2jo

_cuT

between

holes for door arm clevis

and trolley

Subtract

24 inches,,

pins

in door

Remainder

is desired

length

of EMT,, Cut EMT

length. Insert long end of curved door arm, and one

straight

door arm into ends of conduit

at least 4

Flatten

EMT at each end where bolt hole is needed

o o o

AsREQ'D--J

taching to door arms, Drill 3/8 inch

inch by 7/8 inch screws, and 3/8 inch

to this

end of

inches,,

for at-

holes, Fasten with 3/8

lock washers and nuts,,

Radio Controls

1

The radio

control

=' A portable

automobile

has two

basic components:

transmitter

which

sends a coded

signal from

an

TRANSMITTER

RECEIVER

= A receiver which is attached to a garage wall. It receives the coded

signal, and activates the garage door opener..

FOR

SERVICE

-

DO

CONTROLS,

If service

page 23 of manual,

NOT

ATTEMPT

becomes

REPAIR

OF RADIO

necessary, see instructions

on

CovBr

2 THE TRANSMITTER

=

The transmitter,

including

contained

in an attractive,

is provided

transmitters

a battery

and push button

switch, is

high4mpact

plastic case, A metal clip

for attaching

the

can be installed

"_

I

,'_

".L .....

Battery

unit to an auto sun visor, Separate

in each of the vehicles using the

garage

3 THE

The

BATTERY

battery

should

weather

conditions°

weather

failure

mercury

batteries

Clip

operate

To

for

avoid

a time

unexpected

equal

to

battery

its normal

shelf

failure,

replace

fife (approximately

it at least once

one year),

a year.

This

There

may

be shortened

is Iess possibility

of

o

TO CHANGE

new battery

if a new battery

is installed

assure the most reliable

BATTERY-Remove

to connector.

Replace

cover

in autumn,

In regionswhere

temperature

extremes

are below 0

by

cold

O

F, and above 90

F,

operation.

as indicated

in accompanying

cover,

-17-

illustration

Disconnect

battery

from

connector.

CEip

Radio Controls

SEARS DiG|TAL

The coded

signal

in Sears Digital

is a flat blade screwdriver

switch

block.,

ranged

into

Changing

5t2

Radio

Controls

RADIO CONTROL

can be changed

Choose your own code by changing

the ON-OFF

position

of only

easily

position

one switch

without

the aid of a serviceman,,

of ON-OFF

makes

PAT

A PUEOFOR

switches

an entirely

numbered

different

code

The only

1 through

tool

needed

9 on the code

The 9 switches

can be ar-

code combinations,

OPENING THE RADIO CONTROLS

FIGURE 1

RECEIVER

STEP 1

Remove receiver cover by gripping top

lip of cover with ends of fingers and

pulling

outward

(Figure

1) Do not

move printed circuit

board compo nents

STEP 2

Disconnect

connector

FIGURE

the two wire,

24 volt,

AC

from the receiver (Figure 2)

2

FIGURE

4

TRANSMITTER

STEP 3

Remove visor clip from back of transmitter by prying it away from the case.,

Remove the screw (Figure 3),

STEP 4

Carefully

turn transmitter

case over

(with pushbutton

up} Remove top of

transmitter

case (Figure 4), Be careful,

Do not move circuit board components

FIGURE

3

HOW TO CHANGE THE CODE SWITCHES

FIGURE

5

STEP 5

Place the receiver cover with

_@_:

_:;,::_i_

,

its printed

circuit

board alongside that of the

transmitter

(Figure 5),. Code switch

blocks should be at the bottom (right

side up for reading).,

STEP 6

Use a pencil

or smewdriver

to change

switch positions (Figure 6). To change

a code, press one or more switches

either ON orOFF, Changing at! switches

to OFF wil! constitute a code

FIGURE 6

IMPORTANT

tional

into

NOTE:

transmitters

The

piace,_ The lock switch

mitter,.

new code setting

used to operate

Please keep this

the door,

on some

instruction

receivers

must

be exactly

Reconnect

(built

sheet for future

the

the same in both

AC connector

into side of case) must

reference,,

-18-

the receiver

and transmitter,

to the receiver

be unlocked

also, in any addi-

and snap the receiver

(Down

position),.

cover

Reassemble

back

trans-

TRANSMITTER

RECEIVER

r

CODE

I

LABEL

SIGNAL

CODE LABEL

OPENER TERMINAL

BELL

PUSH

BLOCK

ooI

WIRE i

BUTTON

RECEIVER

TERMINAL

BLOCK

FLANGE

Parts List

KEY

NO,

PART

NO,

[JESCRIPTION

RECEIVER

1

2

IB1436

IA1385S

Receiver

Receiver

case assy.

circuit board

IAI385Y

IA1492

with cover (Specify S

Receiver cover

J3

TRANSMITTER

4

5

6

7

-19-

IA1489

IAI138S

lAII38Y

2B126

57-6423

Case assembly

Printed circuit board

(specify S or Y)

Clip,visor

Battery, 9 volt

or

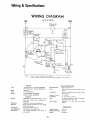

Wiring & Specifications

WIRING

DIAGRAM

117 V AC

LINE

60Hz

NEUT.

CONVENIENCE

OUTLET(X)

WHt

_,,C_r

I

I BUTTON

,'¢7

LAMP DELAY

SWITCH

YEL

CRK.

PSC

MOTOR

fiRK,

..=J

RELAY

iMPULSE

W/THERMAL

OVERLOAD

j

DOWN

LIMIT

OBSTRUC

0

SWITCH

I

REVERSE

DISABLE

CLASS

I

I

BLK

q

LSW_TCH j

t

I

I

UF

24vAC

270 .rz

YEL L

NOTE

:

I

PARTS(X)AND(Y)ffOT

2

SOME

USED _N ALL

VERSIONS

OF MANUAL

RESET

MODELS

SUTTON

HAVE

TERMINALS

MOTOR

Type

.....

Speed

Volts

t/3

.....

Cur_nt

run

.......

Speed Reduction

Belt and pulley

1/4 HP capacitor run (Model

t,0OO rpm

t t7 VAC 50/60 Hz

139653100)

Drive

Roller chain

Tee rail

Lubrication

Motor

4 5 emps

(Model

139653000)

26

(Model

139653100)

amps

Pushbutton

Electrical

........

reverse in down

Limit

Device

Limit

Adjustment

StertCireuit

Independent

.........

Motor'

.......

reversal

Length

....

overload

Traveling

Low

radio

protector

nuts on sprocket

voltage

cent! el

direction

Auto-

directions

pushbutton,

of Travel

Trave!

Rate

Lamp

,,

, ,

Linkage

adjustment

and low

,

8

6 -

8 inches

when

per

door

key

Length

switch

or

- 20-

(overall)

Headroom

Required,

Weight

......

Adjustable

release

10½

trolley

Drive

on steel

shaft

bronze

off

approxio

cord

trolley

second

starts

in travel

90 seconds after

"'L"

DIMENSIONS

shaft

piece

feet

voltage

nuts

two

lubricated

0 On

8, 1 : 1

and

bearings

mate]y

on

Door

up and down

self

oifite

both

pushbutton

wiring

Circuit

actuated by limit

.........

MECHANISM

139.653000)

matic

door

obstruction

Mechanical

REVERSED

(Model

SAFETY

Personal

2&3

DRIVE

HP capacitor

-J

BLK

feet

2 inches

60 pounds

arm

stop

pull

pair Parts

Rail AssembBy

2O

10

11_

12_

_6

4

\

I

8

7

11> ji PartsList

/

KEY

NO.

I

2

3

4

5

6

7

8

9

iO

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

- 21 -

PART

NO.

146A19

12A129

146A30

133A29

216A26

IA452

171A88

171AZ4

183B35

IA955

146A21

91A7

26A39

I09AII

IA1428

IB1435

133A87

2B123

171A191

183B36

171A184

133A28

216A25

12A197

178B22

178B23

12B198

DESCR IPT ION

Pin,cotter

Bracket,header

Pin,clevis,3/Sx3

Nut,3/8-16

Lockv,asher,3i8

Sprocket bracket assy.

Screw,hex,5i16xl-7/8

Screw,hex,3/8-16xl

Tee rail,header end

Trolley,outer

assy.

Pin,clevis,3!Sxl-I/16

Handle,pull

release

Rope,braided

Master link,chain

Roller,chain assy°

Trolley,inner

assy.

Locknut, I/4-20

Tee rail,center brace

Carriage bolt, I/4-20

Tee rail,motor end

Screw,Sems,5/16-18xl/2

Nut,5/16-18

Lockwasher,5/16

Bracket,cha in retainer

Strap,door arm,straight

Strap,door arm,curved

Bracket,door

Repair Parts

ChassisAssemblyParts List

KEY

f'lO.

3-L L_

.__=___r5_

2

_.__]5=._

- ,8

58

....1455 ............

'_-"-_II _<_ ,\',Ltt

. t, -_z

53 ,

50 _:,#"

"'

"'I

c.,14 E

. <

1_. _ ,51,11. =.,.41

........... \

r

_

'

11

'

I_/'1

_

--I

>......

/1_

i

..........

i

....._-_,.

1

.:,_ _>7,

"

/,\

I

;;"=i ..............r.........

+'-1]

]

............

.fill

<.-"_:

t7

I

"

18

9

,,

. { :-42

t

r16\

,.,I

i 17

<--'f:

:,

LI._

I

2

3

4

5

6

7

8

9

I0

II

12

13

14

15

16

17

18

19

20

21

22

23

,_2.4

25

26

27

28

PART

IlO,

171A183

31B129

31B127

171A74

IA950

216A95

158A30

BIA9

IB948

I 77A73

133AI06

216A I00

IIAI3

171A182

37D61

133A109

IA989

204B77

133A I05

IAI081

17tAI84

lIAl2

216A96

158A31

IAI481

12C 196

12A201

123D17

DESCRI PT _Of'i

Screw,BFx3/8

Cover,reverse

Swi'!'Ct_

Cover,sprocket

Screw,hex,BBx3/8

Shaft

and

Washer,shim,

"E"

sprocket

I/2"

ring_Ii2"

assy

I .D

shaft

i diet

Sprocke'l,

Lever,actuator

_v¢itch

Spring,switch

adjustment

I4ut,square,5i16-18

;'lasher,shim,3/4"I

D. xi"O.O.x

i_

,_._

22-_'26

.......

4 F:';

Y

:._

;

123D16

Screw,5i16-18x2-1i2

Chas_is,componeni

T inne rman,

mounting

I/ 4-20

Light

socket

Transformer

assy

Nut_sgeciel

limit

Switch,limit

_ssy.

Screw,washered,5/16-18x9i16

Bear

ing,3/B"i

D,

Washer,sh

Push

im,3/8"

on

Pulley

I, O,

ring,318"

a_sy+8

shaft

65

Bracket,shaft

pitch

Bracket,nut

retainer

Motor

for

assy

Motor

i_<I

-_°,

.................

::9:

...............

_9'<"

"><

3_

171A58

144B6

20A3

31DI06

171A175

108C6

IA35

171A51

2A150

133A49

12A194

30A205

assy.

Model

for

Model

6

139,653100,

amps;llTVAC;60

Pulley,drive

Belt,Vee,3L-31

Cover,chassis

Screw,hex,ii4-2Qxli2

Lens,tamp

cover

Light

delay

Screw_hex_6Tx3i8

Terminal

assy.

board

assy

T innerman,type

8U

tot

Bracket,capaci

mounti

ng

stari'

Capacitor,motor

for

Model

653000,Rating;50-60MFD;250VAC

Capacitor,motor

t39

34

139,653000,

amps;II7VAC;50/6OHz

Screw,set,5!16-1B

139

30A218

eLemeter

re'raining

Rating:Ii4hp;2

29

30

31

32

33

34

35

36

37

38

39

40

010

Bearing,to_,Ii2"l,O,

Rating:Ii3hp;,l,5

f7 7: 4o

assy

653100

,II

216AI0

Lockwesher,

42

IA1375

Wiring

,13

12A218

Bracket,reset

for

star#

Model

box

,Rat ing:36-42MFD;250VAC

internal

tooth

,No,6

assy

for

button

Model

139.653000

44

45

46

47

48

49

f80B48

171A189

160B27

12B208

171A15

iBOB50

Reset

button

for

I,_del

139,653000

Screw,BBxl

Relay_impulse

Bracket,relay

mountin

Screw,sems,8-32x3i16

Reset

button

9

for

Model

139,653100

50

12B225

INSET

Bracket,reset

Model

51

133A43

button

Tinnerman

nut

for

139,653100

52

53

54

55

56

57

58

-22 -

31FI03

203A68

IAI070

30A219

IA942

28A60

26A42

Wiring

box cover

Terminal

board

Resistor,2?O

Capacitor,,22

ohms,2

watt_

MFD;2OOVDC

S_iteh,reverse

assy,

Cable,clamp

Cable,line

_er

139653100

cord,4

ft.

Model

Hz

SAVE-A-CALL BY CHECKINGTHESE BASIC POINTS.

INSTALLATION GUARANTEED BY THE INSTALLER.IF IT iS A

SELF-INSTALLATION, CORRECTIONSWILL BE MADE ON A

CHARGE BASIS.

O

WHEN DOOR OPENS

t

Check pushbuttons

ding

pushbutton(s}

staples, etc,

WHEN

DOOR

WILL

NOT OPEN WITH TRANSMITTER(S).

NOR WALL

OR RECEIVER

PUSHBUTTONS:

1. Check to be certain

that NO LOCKS

OR BOLTS

are preventing the door from opening,

2 Check for tripped

circuit

breaker or blown fuse..

3 Check to be certain any waff switch used to supply power to

the opener is in "ON"

position.

4

Check wire from wall receiver

broken where wire terminates)

if the unit has been operated

5

to opener

for break

numerous

times

2.

(generally

WHEN

DOOR

DOES

PLETELY:

t

Check to be certain

STOPS

preventing

WITHTRANSMITTER,WORKS

OR SECOND

TRANSMITTER:

pletely.

2., Opener

1. Check

battery,

If two transmitters

are used, check by exchanging with "working"

transmitter.,

2. if wall receiver is equipped

with LOCK SWITCH,

check to see

that the switch

is "in the "OFF"

position

(away from

lock

labett.

WHEN

DOOR

REVERSES

FOR

NO APPARENT

Increase

tension

opener

chassis.

ment instructions

of FORCE

Check

SCREW(S)

label

and

WHEN

ATOR

REASON:

located

Owner's

at side(s)

Manual

limit

Controls.

set your own

in the Owners Manual

NOT

t.

setting

WHEN

FROM

1

2

3

of

LIGHT

DOES

tS ENERGIZED:

Check

light

QUITE

OPEN

OR

there are NO PHYSICAL

the door

from

opening

needs

NEW

INSTALLATIONS

your Owners Manual,

1. Check for DOOR BALANCE';OR

BINDING

Disconnect

door

from opener

by pu!_;,_g RED HANDLE.

Open and close door

manually,

Door ,should

operate

smoothly

and reasonably

easy. If door is binding,

check for physical

binding

at jamb,

track,

etc, If service is needed, call a garage DOOR

service

company.

2

Check to determine

if a SEARS

garage door opener in the

neighborhood

uses the same radio code. If same IDENTICAL

codes exist, bring

BOTH

the receiver

AND

transmitter

to

SEARS service to obtain a different

code., if your unit features

the Sears Digital

Radio

agcording

to instructions

in succession,

a thermal

overload

switch

in the motor

may have tripped

Allow several minutes for cooling before operation

is repeated.,

6,, Check reset button

on back of operator

chassis

WHEN DOOR WILLNOTOPEN

OK, FROM PUSHBUTTONS,

AND/OR

CLOSES BY ITSELF:

and wiring

(receiver

to opener}

by prodand wiggling

wire,

especially

under

adjustment,

See

NOT

GO

code

COM-

UNINTENDED

or closing com-

ESPECIALLY

ON

instruction

WHENEVER

THE

in

OPER-

bulb(s}

THERE

WITHIN

IS INSUFFICIENT

THE CAR:

TRANSMITTER

Check battery,

Change transmitter

location

in car.

Check antenna

to be certain

connection

for adjust-

CLOSE

easy-to-follow

ON

pew

proper,THERE

IS NO ANTENNA

with

RANGE

or installation

Digital

Radio

is

Controls.

CAUTION:

• OPERATE DOOR ONLY WHEN FULLY VISIBLE, PROPERLY ADJUSTED,

e DO NOT PERMIT CHILDREN TO PLAY IN AREA OF DOOR,.

e READ THE INSTRUCTION

MANUAL,.

THINGS

TO REMEMBER

DOOR

nected

(ie

DISCONNECT

from

power

failures)

trolley

It will

reactivated

Your

when

_farage door

manual

down

when

LUBRICATION

every

is

3

-

months

Oil

LUBRICATION

surfaces

door

Use

_

rollers,

silicone

Clean

ot" tee rail once

bearings

lubricant,

and

a year

reg_;ase

or

top

and

light

and

IN

CASE

SERVICE

OF

RADIO

RECEIVER

CONTROL

COVER

ONLY

PROBLEMS.

WITH

REMOVE

ATTACHED

-

Make certain

held fast(ie

(see Things

Check

door

replace

If one

BALANCE

-

best when

the

by

connect)

A door

opening

travel

while

ments

are needed,

RECEIVER

PRINTED

CENTER.

_23 -

is not locked

down.

Disconnect

door from

Raise

manually

is broken,

The opener's

door

door

have

a garage door

auLomatic

is in good

and closing

is balanced

being supported

COVER

CIRCUIT

dool

ice)

it

works

manually

snow,

1o Rernember)

springs

DOOR

Use rail grease sup-

plied

BRING

opener

tied to the

the opener

SPRINGS

or oiherwise

is necessary

on the red handle

automatically

DOOR

can be discon-

operation

company

hinges

oil

bottorn

Pull

reconr'ect

DOOR

OPENER

,, ,

-

the opener

AND FREE OF OBSTRUCTIONS,

the

tt

system

is tested

(see Doo_

il stays

solely

by itsspiings

Dis.

in any pointof

If adjust-

company

BY UNLATCHING

AND

(toot

when

call a gmage door

BOARD

safety

balance

TRANSMIT

AND

UNPLUGGING

I E:R TO A SEARS

HOW TO ORDER

REPAIR

PARTS

The Model Number' will be found on the label attached to the back of the

opener.. Always mention the Model Number when requesting service or repair

parts for your SEARS ELECTRONIC

GARAGE DOOR OPENER°

All parts listed herein may be ordered through SEARS, ROEBUCK AND CO.

When ordering parts by mail, selling prices will be furnished on request, or

parts will be shipped at prevailing prices and you will be billed accordingly.

WHEN ORDERING

REPAIR PARTS, ALWAYS

INFORMATION

AS SHOWN tN THIS LIST:

1. The PART NUMBER

2. The MODEL NUMBER

GIVE

THE

FOLLOWING

3o The PART DESCRIPTION

4, The NAME of the ITEM

Your Sears merchandise takes on added value when you realize that Sears has

over 2,000 Service units throughout

the country, Each is staffed by Searstrained, professional technicians using Sears approved parts and methods.

IMPORTANT

NOTE: Include Radio Control code Wh_a ordering radio control parts. If you suspect radio malfunction, take radio controi: to the nearest

SEARS Service Center for test and/or low cost exchange.

FEATURES

OF YOUR OPENER

Opener light-will

convenience,,

2

Automatic

either

3

Reverse

on and off

reverse-door

up or down

Emergency

reverses

automatically

automatically

for your

when

safety

and

obstructed

in

direction,.

disable-automatic

inches of down

etc,

4,

turn

reverse

t, avel to prevent

disconnect-pull

feature

nuisance

is disabled

in

last

few

reversals due to ice, snow,

cord disconnect

permits

manual

door

operation.

5,. Automatic

ation

6,

Digital

reconnect-trolley

when opener

Radio Controls-Coded

SEARS, ROEBUCK

Part No,, 114A351D

is energized

halves

reconnect

after emergency

for

automatic

oper-

disconnect,_

signal can be changed easily

by owner.

AND CO.. BSC 41-3 SEARS TOWER

CHICAGO,

ILLINOIS

60684