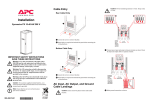

Download APC 10-40kW 208/480V Installation guide

Transcript