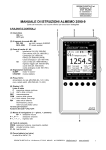

Download Ahlborn ALMEMO 2390-5 Operating instructions

Transcript