Download Samsung BQ1VQ6T012 Specifications

Transcript

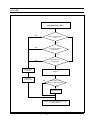

OVEN BASIC: BQ1Q4T090 MODEL: BQ1VQ6T012 MODEL CODE : BQ1VQ6T012/XEF SERVICE OVEN Manual CONTENTS 1. Precaution 2. Product Specification 3. Disassembly and Reassembly 4. Troubleshooting 5. Exploded Views and Parts List 6. PCB Diagrams 7. Wiring Diagrams 8. Schematic Diagrams Contents 1. Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-1 Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2 3 4 3. Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3-1 Tools for Removal and Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3-2 Replacement of Case upper & Cover back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3-3 Replacement the Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3-4 Replacement of Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3-5 Replacement of Door Glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3-6 Replacement of the rear oven Lamp Bulb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 3-7 Replacement of the side Halogen Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 3-8 Replacement of Assy Control Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3-9 Replacement of Tube Steam Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3-10 Replacement of Assy Steam Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3-11 Assembly for Main Assy Steam module part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3-12 Replacement of Assy generator sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 3-13 Replacement of Motor Fan Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3-14 Replacement of Duct Cover, Bracket & Spring Duct & Ceramic Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3-15 Replacement of Motor Convection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3-16 Replacement of Heater Convection twin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3-17 Replacement of Assy Partition S/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3-18 Replacement of Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 3-19 Replacement of Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 3-20 Replacement of Sensor Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 3-21 Replacement of Heater Grill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 3-22 Replacement of Heater Bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 3-23 Replacement of Assy PCB Parts (Main PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 3-24 Replacement of Assy-Door Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 4. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 4-1 Failure Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 5. Exploded Views and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Main Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Main Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 Door Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 Control Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 Standard Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 43 44 45 46 47 48 6. PCB Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 6-1 PCB Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 7. Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 7-1 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 8. Schematic Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 8-1 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 1. Precaution Follow these special safety precautions. 1-1 Safety precautions ( ) 10. Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead; always remove the instrument’s ground lead last. 1. All repairs should be done in accordance with the procedures described in this manual. This product complies with Federal Performance Standard 21 CFR Subchapter J(DHHS). 2. Check all grounds. 3. Do not power the OVEN from a “2 - prong” AC cord. Be sure that all of the built - in protective devices are replaced. Restore any missing protective shields. 4. When reinstalling the chassis and its assemblies, be sure to restore all protective devices including nonmetallic control knobs and compartment covers. 5. Make sure that there are no cabinet openings through which people --particularly children --might insert objects and contact dangerous voltages. 11. Components that are critical for safety are indicated in the circuit diagram by shading, or . 12. Use replacement components that have the same ratings, especially for flame resistance and dielectric strength specifications. A replacement part that does not have the same safety characteristics as the original might create shock, fire or other hazards. NOTE: Connect the oven to a 25 A. When connecting the oven to a 16 A, make sure that circuit breaker can operate. 6. Service technicians should remove their watches while repairing an OVEN. 7. Design Alteration Warning: Use exact replacement parts only, i.e., only those that are specified in the drawings and parts lists of this manual. Never alter or add to the mechanical or electrical design of the OVEN. Any design changes or additions will void the manufacturer’s warranty. Always unplug the unit’s AC power cord from the AC power source before attempting to remove or reinstall any component or assembly. 13. Never touch any circuit wiring with your hand nor with uninsulated tool during operation. 14. For your safety, wear gloves on your hands. 15. Remove the all water from water-tank and Steam generator, before repairing the oven set. 8. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the unit (or any of its assemblies) unless all solid-state heat sinks are correctly installed. 9. Some semiconductor (“solid state”) devices are easily damaged by static electricity. Such components are called Electrostatically Sensitive Devices (ESDs). Examples include integrated circuits and field-effect transistors. Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your body by touching a known earth ground. -1- 2. Specifications 2-1 Features BASIC MODEL Built In Oven NEW MODEL Built In Oven Model Name BQ1Q4T090 BQ1VQ6T012 Model Type Install Single Built-in Single Built-in GEO GEO Dual cook Dual cook Pyro Lytic Coating Pyro Lytic Coating STSS STSS Q Q Door Opening Drop Down Drop Down Interior Lamp 1(Halogen) 2(Halogen) Back/Side Back/Side Tact Button & Dial Tact & Touch & Dial Display 2 Layer LED 2 Layer LED Oven Steam & Self Steam & Self & Descaling Heater Drop Down Fixed - Single 40~300 °C 300 °C: Grill only 40~270 °C 270 °C: Grill only 170~250 °C 170~250 °C 1600W/1100W 1600W/1100W 1100W 1100W 1200W/1200W 1200W/1200W A/A/A A/A/A 11 15 1. Convection Yes Yes 2. Top heat + convection Yes Yes 3. Conventional Yes Yes 4. Large Grill Yes Yes 5. Small Grill Yes Yes 6. Bottom + convection Yes Yes 7. Steam cook - Yes 6. Steam assist cook - Yes Design Main sales point Oven Features Cavity Interior Oven Colors Oven Doors (D: double, T: triple, Q: quadruple) Interior Lights position Control Method(Oven) Cleaning Method Electric Features Oven Temp Ranges - Upper or Lower Grill Heater (In/Out) Bottom Heater Convection Heater (Upper/Lower) Energy Class Oven Function Number of Functions Single Mode -2- 2-1 Features BASIC MODEL Built In Oven NEW MODEL Built In Oven 1. Convection Yes Yes 2. Top heat + convection Yes Yes 3. Large grill Yes Yes 1. Convection Yes Yes 2. Bottom heat + convection Yes Yes 3. Steam cook - Yes 4. Steam assist cook - Yes Clock Yes Yes Child Safety Lock Yes Yes (Hidden) Yes (Hidden) Yes (Hidden) Count Timer Yes Yes Cook Time Yes Yes End Time Yes Yes Oven Temp Yes Yes Steam Cleaning Yes Yes Self Cleaning Yes Yes Language Option No No Light On/Off Yes Yes Smart buzzer Smart buzzer No No YES No Square Baking Tray 2 2 Square Wire Rack 1 2 UPPER Mode LOWER Mode Control Features Sound On/Off Sound Equipment Supplied Multi spit Barbecue spit 2-2 Specification Specifications BASIC NEWMODEL 230V 50Hz, AC 230V 50Hz, AC Outside 595 x 595 x 566mm 595 x 595 x 566mm Cavity 440 x 365 x 405mm 440 x 365 x 405mm Net 47Kg, Gross 52Kg Net 49Kg, Gross 55Kg Power source Dimension (W x H x D) Shipping weight -3- 2-3 Accessory The following accessories are provided with your oven. Description Code No. Q’ty Rack-wire DG59-00001A 1 RACK-WIRE ROAST DG59-00004A 1 tray-Baking a DG63-00012A 1 tray-Baking B DG63-00011A 1 Assy-partition DG97-00015A 1 DG01-00010A DG63-00246A DG63-00242A 1 Front Front STEAM-glass STEAM-tray sub STEAM-tray -4- 3. Disassembly and Reassembly 3-1 Tools for Removal and Reassembly Tool 1. Tool : Nut Driver 2. Type : 7mm 3. Remarks : Heater bracket Nut 1. Tool : Nut Driver 2. Type : 9mm 3. Remarks : Convection Fan Nut 1. Tool : Longnose 2. Remarks : Tube Clamp 3-2 Replacement of Case upper & Cover back * You must remove it before the repair -5- 3. Disassembly and Reassembly 3-3 Replacement the Tube The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Prepare long-nose to remove the Tube clamp. 2. Grab the Tube clamp with longnose. Tube 3. remove the Tube clamp. 4. remove the Tube. -6- 3. Disassembly and Reassembly 3-4 Replacement of Door Assembly The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Turn over the clips of both hinges. Door Assembly 2. With both hands, grasp the middle sides of the oven door. 3. Rotate the door by approx. 70degree until the hinges can be taken out completely from the hinges holes. -7- 3-5 Replacement of Door Glass The Assembly is reverse order of disjointing. WARNING Whenever the door is separated from the oven, the clips should always be turned over. When the door is mounted, if some of the parts (Door glass or other parts) are removed from the door, it can cause injury due to sheet. ATTENTION The glass may break if you use force especially on the edges of the front sheet. Parts Explaination Photo Explaination 1. Remove the two screws of the left and right sides of the door. Door Glass 2. Take off the door bracket. 3. Detach the inner glass #1 (number 1) from the door. *W hen assembly the inner glass#1, put printing to direction below. Glass #1 Printing -8- 3-5 Replacement of Door Glass (Continued) The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination Glass #2 4. Detach the inner glass #2 and springbrackets from the door. Door Glass Door Bracket Holder Glass Rubber Glass #1 Glass #2 Glass #3 Glass #4 -9- 3-6 Replacement of the rear oven Lamp Bulb The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination Lamp Bulb Glass cap Sheet ring Metal ring Lamp 1. Take off the cap by turning counterclockwise. 2. Remove the metal ring and the sheet ring and clean the glass cap. 3. If necessary, replace the bulb with a 25 watt, 230 V, 300 °C heat - resistant oven light bulb. 4. Fit the metal and the sheet ring to the glass cap. 5. Replace the glass cap. 3-7 Replacement of the side Halogen Lamp The Assembly is reverse order of disjointing. Parts Lamp Bulb Explaination Photo Explaination 1. To remove the glass cover, hold the lower end with one hand, insert a flat sharp implement such as a table knife between the glass and the frame and pop out the cover. 2. If necessary, replace the halogen bulb with a 25 ~ 40 watt, 230 V, 300 °C heat - resistant halogen oven light bulb. Tip Always use a cloth when handling a halogen bulb to avoid depositing oils from your fingers on to the surface of the bulb. 3. Replace the glass cover. - 10 - 3-8 Replacement of Assy Control Box The Assembly is reverse order of disjointing. Parts Explaination Photo Assy Knob Dial Assy Display Encoder Parts Buzzer Assy Knob Dial Select Parts Assy Inlet Door Lock Assy PCB Parts (Main PCB) Pump Motor Motor Fan Cooling Explaination Photo Explaination 1. Remove one connector from the main pcb. Assy Control Box 2. Remove two Tubes and one connector at assy inlet. 3. Remove 3 screws at both sides and top inside of assy control box, lift up assy control box and pull forward to separate. - 11 - 3-8 Replacement of Assy Control Box (Continued) Remove 2 screws. Remove 11 screws. Remove one connector. Remove 4 screws. - 12 - 3-9 Replacement of Tube Steam Module The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Remove the control-box. 2. Remove the 3 tubes. Tube Steam Module 3. Remove the 2 connectors and 4 hook. 4. Remove the 4 screws. - 13 - 3-9 Replacement of Tube Steam Module (Continued) The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 5. Remove the Pump Motor. Tube Steam Module 6. Remove 2 rubbers. - 14 - 3-10 Replacement of Assy Steam Module The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Seperate the wire-harness from the hook on assy steam module and separate the 1 tube from assy steam generator. 2. Remove 7 connectors and 2 TCO from the assy steam generator. * Lower Lamp is optional. Assy Steam Module 3. Seperate the 2 tubes. 4. Remove 5 screws. - 15 - 3-10 Replacement of Assy Steam Module (Continued) The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 5. Lift up assy steam module to seperate from oven. Seperate the cover upper steam. There are totally 4 hook that each has different direction. Assy Steam Module 6. Seperate right and up side hook first. 7. Seperate left and up side hook also. 8. Seperate last 2 hook. - 16 - 3-10 Replacement of Assy Steam Module (Continued) The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 9. Remove 5 tubes. 10. Seperate the right side hook by using a flat head screwdriver. And then remove the assy steam generator. Assy Steam Module 11. Seperate the right side hook by using a flat head screwdriver. And then remove the water valve. 12. Seperate the 4 hook by using a flat head screwdriver. And then remove the assy water tank. - 17 - 3-11 Assembly for Main Assy Steam module part Parts Explaination Photo Explaination Assy Water tank 1. Press the 4 point of assy water tank and check the right assembly with hook. 1. Insert left side of water valve into hook. Water valve 2. Press the right side of water valve. Assy Steam 1. Insert left side of assy steam generator into hook. generator - 18 - 3-11 Assembly for Main Assy Steam module part (Continued) Parts Explaination Photo Explaination Assy Steam 2. Press the right side of assy steam generator. generator Connectors and Assy steam module 1. Check the right position between assy steam module hole and connector. - 19 - 3-12 Replacement of Assy generator sub Parts Explaination Photo Explaination Assy generator sub 1. Remove 2 connectors. 2. Remove the 2 tubes and 2 screws. - 20 - 3-13 Replacement of Motor Fan Cooling The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Remove two screws and turn toward the clockwise to separate. Fan Cooling 3-14 Replacement of Duct Cover, Bracket & Spring Duct & Ceramic Filter Parts Explaination Photo Explaination 1. Remove 6 screws from ass’y cover cooling motor. Fan Cooling - 21 - 3-15 Replacement of Motor Convection The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Seperate the 1 tube from the adiabatic rear. * Be sure to connect tube again when assembly. 2. Remove 5 screws at the back inside cavity to separate the cover casing. 3. Turn flange nut to the left to release and separate spacer fan convection and fan convection. Motor Convection 4. Remove two connector from convection motor 5. Remove turn toward the counterclockwise to separate. Reference Convection fan is turn in the opposite direction each other for improvement cook performance. Upper fan is turn in counterclockwise direction, Lower fan is fan turn in clockwise direction therefor convection fan direction and netflange are opposited each other. Convection fan is indicated (U),(L) and netflange is different the head shape. Upper Upper Lower Main Blade Motor Convection E-ring Lower Cavity Nut-Hexagon cap Nut-Hexagon cap Fan-Convection - 22 - 3-16 Replacement of Heater Convection twin The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Remove the two connectors. 2. Remove two screws securing heater convection twin at the rear. Heater Convection Twin 3. Pull the securing bracket at the left forward, and pull it toward the left to separate heater convection twin. 3-17 Replacement of Assy Partition S/W Parts Explaination Photo Explaination Partition S/W 1. Remove a connector. 2. Remove two screws. - 23 - 3-18 Replacement of Thermostat The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination Thermostat 1. Unfold one point. 3-19 Replacement of Terminal Block Parts Explaination Photo Explaination Terminal Block 1. Remove two wires from terminal block.. 2. Remove three screws. 3-20 Replacement of Sensor Thermistor Parts Explaination Photo Explaination Sensor Thermistor 1. Remove one screws. - 24 - 3-21 Replacement of Heater Grill The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Remove the four connectors. 2. Remove each nut frange at right and left sides. Heater Grill 3. Turn the upper nut circular inside the cavity to the counterclockwise to release, pull heater girll forward to separate. 3-22 Replacement of Heater Bottom Parts Explaination Photo Explaination 1. Remove the two connectors. 2. Remove one screw and pull forward to separate it. Heater Bottom - 25 - 3-23 Replacement of Assy PCB Parts (Main PCB) The Assembly is reverse order of disjointing. Parts Explaination Photo Explaination 1. Remove a screw. Assy PCB Parts (Main PCB) 2. Seperate 3 hook. 3-24 Replacement of Assy-Door Lock Parts Explaination Photo Explaination Assy-Door Lock 1. Remove two screws. - 26 - 4. Troubleshooting 4-1 Failure Codes There are a kind of error code and two kinds of warning codes. Possible error codes during use can be checked before service. Press [Stand by Mode + Current time 0:00] and [Function + Time] at the same time and hold them for 5 seconds, error codes are displayed. Press [Function] button, the latest 5 error codes can be checked. But, if the oven turns off, the stored error codes are deleted. Press [Function + Time] button to return to ‘normal display mode’. 4-1-1 Temp Sensor Error Error Code Gerneral Function Solution Page Cavity upper sensor open Cavity lower sensor open Cooling motor sensor open Sensor Open Error It occurs due to a defective sensor, misplaced wires, a defective PCB. 29 Page Sensor Short Error It occurs due to a defective sensor, misplaced wires, a defective PCB. It may occur when the ambient temperature falls under -5°C. 30 Page Steam generator sensor open Cavity upper sensor short Cavity lower sensor short Cooling motor sensor short Steam generator sensor short 4-1-2 Safety Error Error Code Gerneral Function Overtime Temp Time ~ 100°C 16 hours 105°C ~ 240°C 8 hours 245°C ~ 4 hours Touch Button Short Solution Page This error occurs when the oven works during CUT-OFF TIME in the same mode and at the same temperature without any operation of an user. This error is to prevent a risk of fire and hazards in case an user forgets to turn off the oven after use or the oven automatically starts in an unusual way. The oven can be used after off. 32 Page This error occurs when a button is pressed and held for over 10 seconds. It may occur when water soaks through the inside of the control panel or dust particles are stuck to TOUCH PAD. In this case, remove DISPLAY PCB, clean TOUCH PAD PCB or replace it. 31 Page - 27 - 4-1-2 Safety Error (Continued) Error Code Gerneral Function Solution Page Divider Missing This error occurs when the divider sensing switch senses that the divider is used at the inappropriate mode. 33 Page Preheating Time Out This error occurs when the set preheating time, 30 minutes, is over. It may occur due to a heater’s open, defects of relay contact point and wiring defects. 35 Page Excess of cooking compart- - This error occurs when the temperature of cooking ment’s temperature compartment maintains over 320°C for more than 5 minutes. - This error occurs when a fire occurs inside cooking compartment or the temperature cannot be controlled because of sensor’s failure. 38 Page Excess of cooking compart- - This error occur immediately after the temperature ment’s temperature of cooking compartment reaches 350°C. - This error occurs when a fire occurs inside cooking compartment or the temperature cannot be controlled because of sensor’s failure. 38 Page Cooling motor lock sensed - This error occurs when the temperature sensor on the Main PCB senses abnormal temperature. - It occurs 30 ~ 60 minutes after the cooling motor does not operate. - It may occur when the cooling motor stops running by power off during operation of the oven, then it runs again. 34 Page Exess of steam generator temperature - This error occurs when the temperature sensor in the steam generator senses abnormal temperature. 36 Page Water valve open sensed - This error occurs when generator sensor can not sense the water even though water valve is opened for 30 sec. 28 Page - 28 - 4-1-3 E-27,E-29, E-2b, E-71 Sensor Open Error (E-27, E-29, E-2b, E-71) YES Connect the sensor. Is the sensor disconnected? : Check if the sensor housing is inserted into the connector of the main PCB. NO Connect the wire properly. NO Is the sensor wire connected properly? : Check if the sensor wire is damaged, if the housing is loose and if the sensor and the wire are properly connected. YES S/W Error Does the voltage change as the humidity, temperature and weight change? NO NO After Power -> On, does the symptom continue? The sensor is out of order. YES Replace the PCB. Replace the sensor. Perform the operation again and check if it is working properly. - 29 - : Check if the voltage of the GND and sensor changes using a digital multi-meter by forcefully changing the humidity, temperature and weight. 4-1-4 E-28, E-2A, E-2C, E-72 Sensor Short Error (E-28, E-2A, E-2C, E-72) Remove the shorted part YES of the temperature sensor. Is the sensor shorted? : Check if both terminals of the sensor are slightly shorted. NO Remove any foreign Substance from the shorted part. YES Is the sensor terminal part of the PCB shorted? : Check if the sensor and related parts such as the connector or soldering parts are slightly shorted. NO S/W Error YES Does the voltage change as the humidity, temperature and weight cha NO NO After Power > On, does the symptom continue? The sensor is out of order. YES Replace the PCB. Replace the sensor. Perform the operation again and check if it is working properly. - 30 - : Check if the voltage of the GND and sensor changes using a digital multi-meter by forcefully changing the humidity, temperature and weight. 4-1-5 -SE- Key Short Error (- SE -) YES Is the key not recognized at all? NO YES Is the key recognized intermittently? NO Is a specific key not recognized? YES NO The membrane is defective. Replace the Control Panel. S/W Error NO After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 31 - 4-1-6 S-01 Over Time Error (S-01) YES Is it temperature 100°C in oven? NO Has it worked for 6 hours continuously? Is it temperature 105°C~240°C in oven? NO Re-check the Cut-Off-Time for the corresponding internal temperature. YES Is it temperature 245°C in oven? NO Re-check the Cut-Off-Time for the corresponding internal temperature. NO Does same error arise? YES Has it worked for 8 hours continuously? NO YES YES Has it worked for 4 hours continuously? S/W Error YES NO After Power > On, does the symptom continue? YES Re-check the Cut-Off-Time for the corresponding internal temperature. Does same error arise? Replace the PCB. NO Turn the oven off and let it cool sufficiently. NO Does same error arise? NO YES S/W Error After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 32 - 4-1-7 dE Divider Missing Error (dE) NO NO NO Is it Upper, Lower Mode? YES YES Is divider inserted? YES Single Mode? YES Is the Divider detection S/W out of order? Is divider inserted? YES Is the Divider detection S/W connected properly? Remove the Divider. NO Connect correctly wire. YES Are the connections in the Main PCB normal? NO YES S/W Error NO Replace S/W NO YES NO Insert divider Is the Cooking Mode Twing? After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 33 - Connect correctly. 4-1-8 E-0b Cooling Motor Sensor Error (E-0b) Is the temperature sensor of the PCB open? YES An “E-2b” error occurred. NO Insert the temperature sensor. Was there a shortcircuit in the temperature sensor of the PCB? YES An “E-2C” error occurred. NO Repair the short circuit. Is the temperature of the PCB over 90°C? YES An “E-0b” error occurred. NO NO Is the Cooling Motor rotating? S/W Error YES Check the Motor drive part. The temperature sensor is out of order. NO Replace the temperature sensor. After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 34 - 4-1-9 E-08 Preheating Error (E-08) Check the heater related drive part. NO Does the heater work? : Check the voltages of both heater terminals. YES Replace the heater. YES Is the heater temperature very low? : After operating the heater for more then 10 minutes check if the heater temperature remains low. NO Reconnect the temperature sensor properly. NO Is the temperature sensor connected properly? YES Replace the heater. YES Is the resistance between the heater terminals more then a few MΩ? NO S/W Error NO After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 35 - : A normal heater’s resistance is a few Ω. A short circuit increases the resistance to a few MΩ. 4-1-10 E-73 Steam generator temp Error (E-73) Temp sensor malfunction. NO Does the steam generator temp sensor work? : Check the Resistance of temp sensor YES NO Is the PCB part shorted? : Check short circuit in the PCB part such as relay and sensor part. YES Replace the Assy steam generator. Replace the PCB. Perform the operation again and check if it is working properly. - 36 - 4-1-11 E-78 Water Over Supply Error (E-78) Connect steam generator water level connector. YES Is steam generator water level connector disconnected? NO NO Does Water Valve work? Replace the Water Valve : Check short circuit in the PCB part such as relay and sensor part. YES S/W Error NO After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly. - 37 - 4-1-12 E-0A, E-09 Internal Oven Temperature Abnormal “E-09, E-24, E-0A” 가 표시된다 Error (E-0A, E-09) An “E-09” error occurred. YES Is the oven internal temperature maintained over 320 degrees? NO An “E-24, E-0A” error occurred. YES Has the oven internal temperature reached over 350 degrees? NO Reconnect the temperature sensor properly. NO Is the temperature NO sensor connectivity normal? YES Off TurnOven을 the oven off하고 and let it 충분히 cool sufficiently. 식힌다. Check and repair 히터 the구동부를 heater 점검 수리한다 drive part if necessary. NO Is the Heater connectivity normal? YES S/W Error NO After Power > On, does the symptom continue? YES Replace the PCB. Perform the operation again and check if it is working properly - 38 - 4-1-13 Power Failure No Power - Check terminal block voltage, 230V. NO Reset The circuit braker or Check main power YES - TCO open Check (main TCO, Convection TCO) NO Replace TCO NO Repair Faulty wiring YES - Check the input voltage of PCB SMPS (input checkpoint : 230V ) YES Replace PCB or display PCB check - 39 - 4-1-14 TCO Open Note : When oven is operating , if main power off, power oven off, in temporary temperature rise, TCO is possible will can open. TCO Open Replace TCO Replace Motor - Motor Terminal Voltage check NO NO - Colling motor, Conveclion Motor check YES YES - PCB SMPS Input Voltage check (input check point: 5V, 230V) • Motor Connect wire Remove - Motor Resistor check (Cooling motor: 238Ω Convection Motor: 218Ω) YES NO Repair Faulty wiring NO Replace PCB YES Replace PCB YES - PCB SMPS output Voltage check (output check point: 5V, 12C) YES - PCB Relay contact short check NO Check wire short and operation of a sensor - 40 - NO 4-1-15 PCB Failure PCB Failure - TCO Open? NO - Check the input voltage of PCB SMPS (input checkpoint : 230V ) YES Replace TCO NO YES -C heck Terminal block voltage(230V). YES Repair Faulty wiring or PCB check NO Reset the circuit braker or check main power. - Check the output voltage of NO PCB SMPS (Output checkpoint : 5V/12V ) NO - Check fuse protecting SMPS Replace FUSE YES Replace PCB Replace PCB YES - Do all relays operate? YES NO - Check the operating base voltage(5V) which is appropriate for each relay. • After Lamp On - Safety Relay Contact point ON(12V)? YES YES NO - Check the operating Base voltage(0V) of Safety Relay. YES Replace Relay NO Replace PCB - 41 - Replace Safety Relay 4-1-16 Failure of heating elements Failure of heating elements - Check heater’s terminal voltage (230V) YES NO • After removing Heater Wire - Check Heater resistance (Large G :32.8Ω, Small G:48.6Ω, Bottom : 48.1Ω, Conv:44Ω) YES - Repair Faulty wiring (Possible termial contact failure) - TCO Open? YES Perform “TCO Open Check Process” NO - Check Relay Terminal Voltage (230V) YES - Repair Faulty wiring (Possible termial contact failure) NO Perform ‘PCB Check Process’ - 42 - NO Replace heater 5. Exploded Views and Parts List 5-1 Exploded Views B034 W002 H052 M258 M007 C003 M302 M260 H008 M261 C003 P284 H051 C195 B028 B048 M392 D120 H054 P186 H094 H050 M251 H106 P214 H125 M253 H107 M032 H111 M003 H111 M242 P329 M229 M017 M264 M300 M294 P282 M262 M236 M032 H451 M013 M370 M293 M015 M389 M250 M482 W006 G005 P282 M265 M277 H053 U013 M279 M248 M249 M224 H049 H048 T111 P280 H123 T112 H057 T030 U005 Z814 H048 H049 H058 U029 P229 H005 M241 P285 U028 P225 Z031 D205 - 43 - 5-2 Main Parts List (SNA : SERVICE NOT AVAILABLE) No. Code No. Description Specification Q’ty SA/ SNA Remark M260 DG61-00056A SUPPORT-MOTOR COOLING PA66+GF15%,BT63BSS 1 SA - - 44 - 5-2 Main Parts List No. Code No. Description Specification - 45 - Q’ty SA/ SNA Remark 5-3 Door Parts List D049 ASSY DOOR D151 D113 D110 D049 P420 D109 P421 D105 V002 D015 V002 D106 D147 D019 (SNA : SERVICE NOT AVAILABLE) No. Code No. Description Specification - 46 - Q’ty SA/SNA Remark 5-4 Control Parts List C082 ASSY CONTROL-BOX C082 C187 Y101 C185 C235 C188 C360 C009 C048 C154 C197 C236 C188 C190 C187 Y102 C352 C178 C001 C074 C360 (SNA : SERVICE NOT AVAILABLE) No. Code No. Description Specification - 47 - Q’ty SA/ SNA Remark 5-5 Standard Parts List (SNA : SERVICE NOT AVAILABLE) LEVEL Code No. Description Specification - 48 - Q’ty SA/ SNA Remark 6. PCB Diagram 6-1 PCB Diagram No. Parts Number No. Parts Number Part Name Function and Rule 1 CN101 Display connector-1 A Terminal for Connecting with display module. 12 RY104 Upper heater Relay A relay for Connecting with Upper heater 2 CN102 3 CN103 Display connector-2 A Terminal for Connecting with display module. 13 RY105 Lower heater Relay A relay for Connecting with Lower heater Temp sensor & divider switch connector A Terminal for Connecting with divider and temp sensor. 14 RY106 Latch open Relay Latch open control 4 CN104 Buzzer A Terminal for Connecting with speaker. 15 RY107 Latch close Relay Latch close control 5 CN105 Door Lock motor connector A Terminal for Connecting with Door Lock motor. 16 RY108 Uppwe lamp Relay Uppwe lamp control 6 CN106 Neutral , upper/lower lamp A Terminal for Connecting with Neutral,upper/lower lamp. 17 RY109 Lower lamp Relay Lower lamp control 7 CN107 Spit , Upper/lower fan , Cooling fan A Terminal for Connecting with Spit , Upper/lower fan , Cooling fan. 18 RY111 Spit Relay Spit Source 8 CN108 Door latch , Door sensing A Terminal for Connecting with Door latch , Door sensing 19 RY112 Source Relay Supply power for all relay 9 RY101 Large grill Relay A relay for Connecting with Large grill heater 20 SSR101 Upper fan SSR Upper fan control 10 RY102 Small grill Relay A relay for Connecting with Small grill heater 21 SSR102 Lower fan SSR Lower fan control 11 RY103 Bottom heater Relay A relay for Connecting with Bottom heater 22 SSR103 Cooling fan SSR Cooling fan control Part Name Function and Rule - 49 - 7. Wiring Diagram ( This Document can not be used without Samsung’s authorization. ) 7-1 Wiring Diagram - 50 - 8. Schematic Diagram 8-1 Schematic Diagram 3 8 D104 MBRF5100 R11 470K R105 8 Vcc 7 In 6 Thr 1 R04 100K INT +5V R106 20K D105 1N4007 R03 10K D02 EM518 R01 470K R104 47K Isw 2 Ire C02 1uF Out DIVIDER & TEMP SENSOR -TWIN & PYROLYTIC C03 10uF 2 +5V DV-SW AD_U 3 4 AD_L 5 6 C301 10uF C302 10uF +5V R803 2K R801 13K 3 2 R802 80.6K 1 STEAM-TEMP STEAM TEMP CN501 SMW250-04_WHT 2K R09 470 PC01 TLP-181 1 R501 13K R503 2K 2 R502 80.6K 5 TXD 8 SCL 7 SDA 6 WAKE-UP 9 TOGGLE 3 5 + 6 - R406 2K R408 4 5 2K R407 6 7 LATCH-1 LATCH-2 LIVE-2 RY203 DU12D1-1P DOOR-SW + D203 MM4148 RY204 DU12D1-1P 7 - 2 RY205 DU12D1-1P RY207 T9AS1D22-12 RY208 G5T-1A-ASI-12VDC 1 RY210 G5T-1A-ASI-12VDC 3 + 5 W-H OUT 2 WL - + W-L OUT 1 6 CN204 SMW250-03A_RED WH IC402 KIA358F VCC=+6V,GND=DGND - 7 RY211 G5T-1A-ASI-12VDC TR204 KRC246 TR205 KRC246 3 RY215 G5T-1A-ASI-12VDC 4 TR217 KRC246 TR209 KRC246 RY212 G5T-1A-ASI-12VDC 2 RXD1 3 TXD1 6 RESET CN701 SMW200-06P C701 100nF 200K R414 200K 200K 1 TR210 KRC246 TR211 KRC246 RY213 G5T-1A-ASI-12VDC TR212 KRC246 SL 1 3 WH 4 WM 5 WL 6 7 WATER LEVEL TR213 KRC246 SSR201 AQG22212 C202 10uF LATCH-CONTROL TR201 KRC246 5 TR218 KRC246 SSR202 AQG22212 M NEUTRAL SSR203 AQG22212 P TR220 KRC246 RXD1 X1 R702 330 +5V 36 EMU1 GRILL-SUB R601 2K Vcc 8 1 A0 95 96 9 10 89 14 63 67 68 41 19 22 62 18 11 33 34 39 40 L-BAND-2 2 A1 WP 7 3 A2 SCL 6 CLK 4 Vss SDA 5 DATA DATA CLK S-LEVEL IC601 24C04 W-H +5V W-M W-L R201 2K TR221 KRC246 +5V +5V +5V +5V R302 26.1K R301 26.1K R303 R306 470 VCC STAND-BY LATCH-CONTROL IC301 KIA75S393F 10K DV-SW LATCH-1 VEE R304 1.87K UPPER-LP C307 100nF LATCH-2 SIDE-RACK VCC R307 W-PUMP IC302 KIA75S358 10K C303 10nF R308 1K VEE R309 12.7K R311 2K C304 10nF R310 30.1K +5V R312 26.1K S-U TEMP SENSOR PYROLYTIC TWIN +6V R313 IC303 KIA75S358 10K C305 10nF R314 1K VEE R315 12.7K R317 2K C306 10nF R316 30.1K COOLING +5V 1 2 PROBE AD-IN-U AD-IN-L STEAM-TEMP TEST-1 TEST-2 SOURCE LOWER-FAN UPPER-FAN GRILL-MAIN GRILL-SUB BOT-HT UPPER-HT LOWER-HT STEAM-HT W-VALVE OPTION LATCH-OPEN LATCH-CLOSE UPPER-LP LOWER-LP W-PUMP COOLING SPIT U-BAND-2 U-BAND-1 R318 100K R319 3.01K AD_U 3 D303 MM4148 MM4148 L-BAND-1 L-BAND-2 R324 2K AD-IN-L 2K D301 MM4148 D302 MM4148 U-BAND-1 U-BAND-2 R320 2K R321 AD-IN-U 2K TEMP SENSOR N/P SINGLE R902 R901 5.1K Changed by MS_JEON - 51 - S-L PCB-TEMP D304 R325 AD_U 4 2K Engineer Date Changed 17 JAN, 2011 SAMSUNG ELECTRONICS MS_JEON PCB-TEMP 416, Maetan-3Dong, Yeongtong-Gu, Suwon-Si, Gyeonggi-Do, KOREA 443-742 Drawn by MS_JEON C901 1uF +5V M R322 100K AD_L S-L +5V +5V R323 3.01K N/P TWIN +5V VCC UPPER-FAN S-U TEMP SENSOR PYROLYTIC +6V LOWER-LP SPIT DOOR-SW R305 100K TR222 KRC246 AD_U LOWER-FAN 23 TXD1 24 RXD1 35 EMU0 TXD1 12pF C601 100nF SOURCE AD_L TR219 KRC246 SCL TOGGLE L-BAND-1 TR202 KRC246 LATCH-CLOSE P 7 SDA X2 12pF EEP ROM GRILL-MAIN TR216 KRA226 TR208 KRC246 LATCH-OPEN C201 10nF TXD EMU0 D202 MM4148 +5V 65 NMI 42 43 77 SDA0 78 SCL0 80 WAKE-UP XTL1 16.000MHz C117 RY202 DU12D1-1P STEAM-HT R114 2K RXD OPTION D201 MM4148 DVSS DVSS1 DVSS2 AVSS 28 X2 30 X1 X2 OSCILLATOR RY201 DU12D1-1P LOWER-HT 3 M IC105 7033P C116 29 64 86 4 97 90 98 91 99 100 92 1 8 7 2 88 69 87 84 83 82 81 79 6 76 75 70 21 72 71 74 73 20 25 12 13 17 16 15 52 60 59 47 48 49 50 51 46 44 45 53 54 55 56 57 61 58 94 93 37 38 OVP X1 W-VALVE TR215 KRC246 D212 MM4148 P CN202 SMW250-07A_RED EMU0 1 CN402 SMW250-07_WHT 2 R412 4 R413 R701 2K 200K +5V R411 +5V 5 +5V TR214 KRC246 DVCC DVCC1 DVCC2 VREFH AVCC AM0 AM1 32 RESET INT R113 2K C113 10uF D215 MM4148 UPPER-HT TR206 KRC246 TR207 KRC246 +5V 2 D213 MM4148 On board writing RESET R112 2K D214 MM4148 1 C115 100nF RESET RELAY CONTROL D211 MM4148 1 3 ZD101 UZ5.1B D210 MM4148 5 7 C111 470uF C110 470uF R111 1K C106 100nF 7 RY214 G5T-1A-ASI-12VDC TR203 KRC246 D209 MM4148 1 3 8 D205 MM4148 9 IC401 KIA358F VCC=+6V,GND=DGND S7 1 27 66 85 3 5 26 31 C112 100nF R110 220 PC102 TLP-181 D204 MM4148 RY209 G5T-1A-ASI-12VDC W-M OUT S8 S6 2 IC103 KIA78D05PI 6 +12V D208 MM4148 IC402 KIA358F VCC=+6V,GND=DGND 3 S5 R109 12K +12V SIDE-RACK LATCH MODULE WM 6 D207 MM4148 2K 8 B C107 2.2nF +5V +5V 2K 2K R405 3 S-LEVEL OUT R410 2K R409 2 IC401 KIA358F VCC=+6V,GND=DGND SL 2K 2K 1 LIVE CN201 SMW250-09A_RED RXD SMW250-08_WHT 4 CN401 CN102 SMW250-09(WHT) 2 R404 R403 1 5 6 OVP 3 +5V D E D206 MM4148 +12V +5V 4 IC102 TNY276P +6V 5 4 RY206 DU12D1-1P DISPLAY PCB C105 10uF R10 1K 4 1 STAND-BY C05 1nF R06 12K PROBE R402 5 TR102 KRC246 C 4 D102 UF4007 D101 1N4007 +5V KRA226 TR01 3 MEAT PROBE CN801 SMW250-03_WHT CN301 SMW250-06(WHT) R05 47 R12 10K R02 10K C01 4.7uF PC101 TLP-181 1 3 4 C114 1nF R401 2K RC R08 1K Gnd 2K +5V R07 470K CN203 SMW250-04_RED R103 47K C04 100nF IC01 LM331N R102 47K R101 47K IC02 78L05 OVP LIVE-2 D01 EM518 BOT-HT LIVE-2 INTERRUPT A C109 470uF 47K 9 NEUTRAL C108 470uF 47K 2 TR101 KRA226 R115 C104 1nF IC104 KIA7812API C CN302 SMW250-04_BLU 2 R108 150K A TH901 TTC05103K 1 C103 10uF C102 10uF 10 R116 1 +12V D103 MBRF5100 ST101 ST-ALCD ZNR101 560V TVR14561 R107 1.2M C101 100nF IC101 TMP91FW60FG +5V POWER SUPPLY BD101 DF06S 3 RESET L101 LF-2CTOP 4 PTC101 270M LIVE R&D CHK PCB TEMP Time Changed 09:00 AM DOC CTRL CHK MFG ENGR CHK QA CHK Size TITLE A2 24" OVEN_MD REV Drawing Number Sheet 1 of 1 GSPN (Global Service Partner Network) Contry Web Site North America service.samsungportal.com Latin America latin.samsungportal.com CIS cis.samsungportal.com Europe europe.samsungportal.com China china.samsungportal.com Asia asia.samsungportal.com Mideast & Africa mea.samsungportal.com This Service Manual is a property of Samsung Electronics Co.,Ltd. Any unauthorized use of Manual can be punished under applicable International and/or domestic law. © Samsung Electronics Co., Ltd. April 2011 Printed in Korea