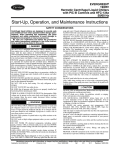

Download Carrier 19XR Operating instructions

Transcript